Tractel tirak X 1030 P Assembly And Operating Instruction

Electrically powered endless hoist for materials handling and man-riding in elevator installations

Hide thumbs

Also See for tirak X 1030 P:

- Original assembly and operating instructions manual (208 pages) ,

- Original operation and installation manual (172 pages) ,

- Original operating instructions (36 pages)

Table of Contents

Advertisement

Quick Links

Electrically powered endless hoist

for materials handling and man-riding

DIN EN ISO 14001

Zertifikat: 01 104 021411

DIN EN ISO 9001:2000

Zertifikat: 01 100 020037

OHSAS 18001

Zertifikat: 01 113 040078

Assembly and

Operating Instruction

tirak ™

L 503 P,

X 1030 P, X 1031 P,

X 1032 P, X 1033 P

This instruction manual must be available

for the user at all times.

Additional copies may be obtained on request.

tirak™

in elevator installations

1

Advertisement

Table of Contents

Summary of Contents for Tractel tirak X 1030 P

- Page 1 tirak™ Electrically powered endless hoist for materials handling and man-riding in elevator installations DIN EN ISO 14001 Zertifikat: 01 104 021411 DIN EN ISO 9001:2000 Zertifikat: 01 100 020037 OHSAS 18001 Zertifikat: 01 113 040078 Assembly and Operating Instruction tirak ™ L 503 P, X 1030 P, X 1031 P, X 1032 P, X 1033 P...

-

Page 2: Table Of Contents

4.7.1 Preparing the rope 4.7.2 Rope installation 19-20 4.7.3 Removing installed rope Information for this manual Date of edition Address of the manufacturer: TRACTEL Greifzug GmbH October 2015 Scheidtbachstraße 19-21 D-51469 Bergisch Gladbach Copyright Telefon: +49(0) 22 02 / 10 04-0... -

Page 3: Explanation Of Symbols Used

Explanation of symbols used Safety advice Symbol Code word Meaning Possible consequences of noncompliance IMMEDIATE or DANGER possibly imminent Fatal or serious injuries! danger: IMMEDIATE or DANGER possibly imminent danger through Fatal or serious injuries! dangerous voltage: Possibly CAUTION dangerous Injuries to persons situation: or damage to property. -

Page 4: Safety Advice

DANGER! Repairs must only be carried out by TRACTEL Greifzug GmbH resp. with written agreement of Using a tirak ™ hoist for man-riding on or the manufacturer and by persons, who have been inside an elevator cabin is only allowed, trained by him. -

Page 5: Machine Description

3. Machine description 3.1 Purpose tirak ™ hoists of the series L 500 P and X 1030 P are portable, electric driven hoists Lifting and Lowering of “Suspended access equipment (SAE)” by means of a tirak ™ wire rope prescribed by the manufacturer. -

Page 6: Main Components And Operating Controls

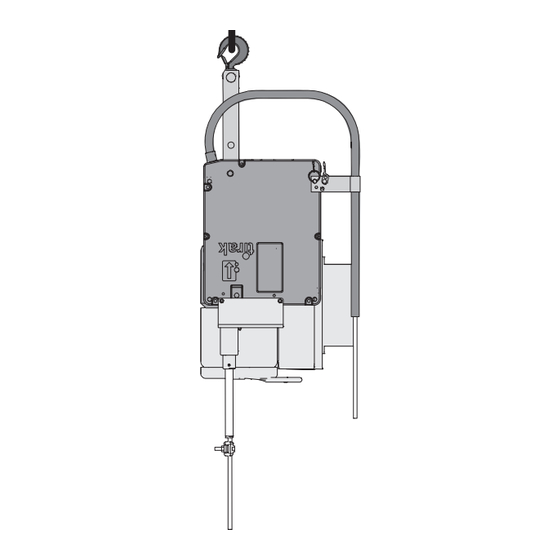

3.4 Main components and operating controls Basic package A tirak™ with Fig. 1 (Principle sketches) Suspension rope Motor Control box Remote control Rope drive B Adapter with safety hook C Rope defl ector (rope guide spring) D Safety rope Limit switch UP Rope limit switch (limit switch DOWN) (not shown) G Rope limit switch (limit switch DOWN) (not... -

Page 7: Noise Emission

3.5 Noise emission tirak™ series (Distance 1 m ) L 500 P ......max. 72 dB(A) X 1030 P ......max. 70 dB(A) 3.6 Technical Data Design according to DIN 15 020, transmission group 1 B or 1 C 3.6.1 tirak™ Hoist Technical modifi... -

Page 8: Fall Arrest Device

Fig. 2b Dimensions of X 1030 P series 3.6.2 Fall arrest device DANGER! Using a tirak ™ hoist for man-riding on or inside an elevator cabin is only allowed, if the FALL ARREST DEVICE OF THE CABIN is functioning. -

Page 9: Typical Applications

3.7 Typical application Fig. 3b Typical application on an elevator Fig. 3a Typical application on an elevator cabin with double capacity of the cabin with single capacity of tirak ™ tirak ™ hoist (Principle sketch) hoist (Principle sketch) DANGER! DANGER! NO MAN-RIDING NO MAN-RIDING WITHOUT FUNCTIONING... - Page 10 Fig. 3c Application on an elevator cabin with double capacity of the tirak ™ hoist (Principle sketch) DANGER! NO MAN-RIDING WITHOUT FUNCTIONING FALL ARREST DEVICE! Suspension device Diverter pulley Special tirak™ rope tirak™ Elevator rail Slack rope end Elevator cabin Elevator fall arrest device...

-

Page 11: Safety Devices

Safety devices Fig. 4 3.8.1 Primary brake Electromagnetic brake which closes automatically – if the UP/DOWN-button is released (Fig. 4), EMERG. – when pushing the EMERGENCY-STOP button, STOP – in case of power supply failure. DOWN 3.8.2 EMERGENCY STOP Pushing the red EMERGENCY STOP button in case of Hetronic Teleradio emergency completely switches off the hoist control. -

Page 12: Manual Operation

3.8.7 Manual Operation Fig. 7 3.8.7.1 Emergency Descent In case of power failure you can manually open the brake with lever (1) (Fig. 7). 3.8.7.2 Manual lifting With the brake opened the suspended ac- cess equipment can be lifted with the hand wheel (2). -

Page 13: Setting Up

4. Setting up 4.3 Anchoring the hoist General tirak ™ The manufacturer of the suspended access equipment important! is responsible for ensuring that the device, including If not described hereafter, follow the instructions the suspension construction, conforms to the applicable of the „Schindler-Installation Manual”... - Page 14 4.3.1 Verifi cation of the carrying capacity (Continued) Required statical certifi cation: A) tirak™ L 503 P Load x Safety factor 4! Fig. 9a Loads at the anchor points 500 kg 1000 500 kg 1) 500 kg capacity + 60 kg max. weight of the hoist...

- Page 15 4.3.1 Verifi cation of the carrying capacity (Continued) Required statical certifi cation: B) tirak™ X 1032 P Load x Safety factor 4! Fig. 9b Loads at the anchor points 1080 1000 kg 1080 2000 1000 kg 1) 1000 kg capacity + 80 kg max. weight of the hoist...

-

Page 16: Verifi Cation Of Carrying Capacity 13 To

4.3.2 Anchoring the hoist 4.3.1 Verifi cation of the carrying capacity (Continued) The hoist is equipped with a mounted adapter for an- choring by hook (Fig. 10). C) Safety rope Fig. 10 (Principle sketch) Load Fig. 9c on the anchor point in the arrest case max. -

Page 17: Electric Connections

4.4 Electrical Connections Max. tirak ™ tirak ™ tirak ™ rope 3 phase 1 ph. 3 phase 1 ph. speed The manufacturer of the suspended access equip- Series 400V 230V 230V~ 400V 230V 230V~ m/min ment is responsible for the connection of the tirak™ hoists taking into consideration the wiring diagrams L 500 P provided. -

Page 18: Pendant Control

4.6 Pendant control Fig. 13b Buttons for UP and DOWN. For hoists with 2 speeds: EMERG. STOP half depressed low speed fully depressed high speed EMERGENCY-STOP-button: DOWN push the button mains supply interrupted Pendant control for Pendant control for Important: If the hoist doesn’t start, two two speeds one speed phases of the power supply may be reversed... -

Page 19: Rope Installation

4.7.2 Rope installation Fig. 17 DANGER! For the wire rope installation, the cabin has to be at its lowest pos- sible position, to make sure, that the wire rope is sufficiently long. 4.7.2.1 Installation for direct pull a) Feed the wire rope as far as possible into the wire rope guide spring (A) (Fig. -

Page 20: Removing Installed Rope

“Highest allowable position” means: Fig. 20 Minimum 2 m distance between the cabin roof and an obstacle in the shaft or 5 m between cabin roof and tirak ™, e. g. the podest/catwalk, which is used for anchoring/servicing the hoist. “Lowest allowable position”... -

Page 21: Operation

5. Operation DANGER! Fig. 21 For man-riding with the elevator Antenna cabin: Before starting and afterwards daily: Function Check the proper function of the fall EMERG: control STOP arrest device of the cabin! lamp DOWN Checks before the fi rst use A qualifi... -

Page 22: Operation

Attention! Fig. 23 Keep the wire rope lightly lubricated. This Antenna prolongs its life to a maximum. Check all power supply and control cables and if Function necessary replace. EMERG: control STOP lamp Operation DOWN 5.4.1 Stop / Emergency Stop (Fig. 23) a) To STOP movement release UP or DOWN button –... -

Page 23: Measures Of Precaution In The Highest Operation Area

Measures of precaution in the Fig. 25 highest operation area A safety rope c/w energy absorber (d1) arrests the tirak ™ hoist in case of its anchoring failing (Fig. 25) – the cabin itself is secured against fall by its own fall arrest device. - Page 24 6. Troubleshooting WARNING! AVOID INJURIES: 2. Repairs must only be carried out by TRACTEL 1. Checks of the electrical equipment of the Greifzug GmbH resp. with written agreement of tirak ™ must only be carried out by qualifi ed the manufacturer and by persons, who have been electricians! Repairs only after agreement by trained by him.

- Page 25 Breakdown Cause Remedy The hoist B4 Wrong connection, Compare connection with wiring diagram. doesn’t move at all. e. g. no neutral conductor If necessary conversion by the manu- facturer. B5 Protective switching off due to overheating: a) One phase is missing Check/repair fuses, leads and connections.

- Page 26 Install faultless hoist with a new energy absorber. f) By means of the hoist, lift the cabin to open the fall arrest device and continue working. Should these steps not explain the cause and provide a remedy please contact TRACTEL Greifzug GmbH.

-

Page 27: Out Of Operation

7. Out of operation Pause End of the job a) Anchoring the cabin: a) Safely put the cabin on the ground. – Lower the cabin to the ground with slightly b) Remove wire rope (see chapter 4.6.3), clean it, tensiond ropes and check it according to chapter 8.2, whilst coil- ing it on the hasp. -

Page 28: Maintenance

(qualifi ed person) tirak ™ Annually, at the latest however hoist UVV „Winden” BGV D8 after 200 operating hours EN 1808 (see above) (TRACTEL Greifzug GmbH) Annually: Energy absorber EN 355 (qualifi ed person) and snap-hook EN 362 8.1.3 Radio control 8.1 Maintenance... -

Page 29: Checks

Checks Fig. 27 8.2.1 Essential checks a) General “Pig-tail” Prior to every operation curl in wire rope during operation make sure, that – the tirak™ hoist, – the fall arrest device of the cabin – and all other used equipment (anchoring de- vices, pulleys etc.) are properly installed Kinked wire rope... -

Page 30: Safety Inspection

8.3 Repair Repair of tirak ™ hoists must only be carried out by Fig. 30 the TRACTEL Greifzug GmbH resp. with written agreement of it and by persons trained by it. Synthetic oil And only original spare parts shall be used. -

Page 31: Nameplates And Labels

9. Nameplates and labels Make sure that all nameplates and labels are in place and not obscured (see fi gs. 29 and 31). Replace missing labels and those which are not leg- ible! Spares are available from the manufacturer. Fig. 31 Ø... - Page 32 10. Radio control 10.1 General 10.1.1 Intended use and Warranty a) The radio control serves for controlling the tirak ™ hoist. b) Any modifi cation not authorized by the manufac- turer leads to the loss of any warranty. 10.2 Technical data See the documentation for the remote control.

- Page 33 AVOID INJURIES: 2. Setting and/or repairs of the radio control must 1. Checks of the electrical equipment of the ti- only be carried out by TRACTEL Greifzug GmbH must only be carried out by qualifi ed ™ resp. with written agreement of the manufacturer electricians! Repairs only after agreement by and by persons, who have been trained by him.

-

Page 34: Radio Control 32 To

AVOID INJURIES: 2. Setting and/or repairs of the radio control must 1. Checks of the electrical equipment of the ti- only be carried out by TRACTEL Greifzug GmbH must only be carried out by qualifi ed ™ resp. with written agreement of the manufacturer electricians! Repairs only after agreement by and by persons, who have been trained by him. - Page 36 Post address Residential address Phone & Fax Internet P.O.Box 20 04 40 Scheidtbachstr. 19-21 Tel.: +49(0) 22 02/10 04-0 www.tractel.com D-51434 Bergisch Gladbach D-51469 Bergisch Gladbach Fax: +49(0) 22 02/10 04-70 G834-2_BA_Schindler_08_GB.indd © TRACTEL Greifzug GmbH 10/2015...

Need help?

Do you have a question about the tirak X 1030 P and is the answer not in the manual?

Questions and answers