Summary of Contents for Westermo 3635-0910

- Page 1 User Guide 6641-22531 REV. C Viper 20A Series 20 port Ethernet M12 switches Цены и срок поставки уточняйте на сайте www.2test.ru, по телефону: + 7 495 215-57-17 info@2test.ru или...

-

Page 2: Table Of Contents

Table of Contents 1. General Information ................ 3 1.1. Legal Information ..............3 1.2. About This Guide ..............3 1.3. Software Tools ..............3 1.4. License and Copyright for Included Free/Libre Open Source Software ..................3 1.5. WeOS Management Guide ............3 2. -

Page 3: General Information

Westermo reserves the right to revise this document or withdraw it at any time without prior notice. Under no circumstances shall Westermo be responsible for any loss of data or income or any special, incidental, and consequential or indirect damages howsoever caused. -

Page 4: Safety And Regulations

2. Safety and Regulations 2.1. Warning Levels Warning signs are provided to prevent personal injuries and/or damages to the product. The following levels are used: Level of warning Description Consequence Consequence personal injury material damage Indicates a potentially Possible death or major Major damage to the hazardous situation injury... -

Page 5: Safety Information

2.2. Safety Information Before installation: Read this manual completely and gather all information available on the unit. Make sure it is fully understood. Check that your application does not exceed the safe operating specifications for this unit. This unit should only be installed by qualified personnel. This unit should be built-in to an apparatus cabinet or similar, where access is restricted to service personnel only. -

Page 6: Care Recommendations

• Do not cover or bring mechanical force to the ventilation membrane on the back of the unit. If the unit is not working properly, contact the place of purchase, nearest Westermo distributor office or Westermo Tech support. 2.4. Maintenance No maintenance is required, as long as the unit is used as intended within the specified conditions. -

Page 7: Compliance Information

2.6. Compliance Information 2.6.1. Agency Approvals and Standards Compliance Type Approval/Compliance Climate • EN 50155/IEC 60571 class TX, Railway applications - Electronic equipment used on rolling stock • IEEE 1478 class 1, condition E4 (incl Salt Mist), Environmental conditions for transit rail car electronic equipment •... -

Page 8: Declaration Of Conformity

2.6.3. Declaration of Conformity Declaration of Conformity The manufacturer Westermo Teleindustri AB SE-640 40 Stora Sundby, Sweden Type of product Model 20-port managed Ethernet M12 Switch Viper-x20A 20-port managed Ethernet M12 Switch with 4Gbps ports Viper-x20A-T4G is in conformity with the following EU directive(s). -

Page 9: Product Description

Thorough type testing at independent ISO/IEC 17025 and ILAC MRA certified labs, accredited to a wide range of standards, show that the Viper series fulfilles EN 50155 and other requirements. The state-of-the-art Westermo production facility ensures the quality of each individual unit, e.g. through temperature cycling burn-in testing. -

Page 10: Hardware Overview

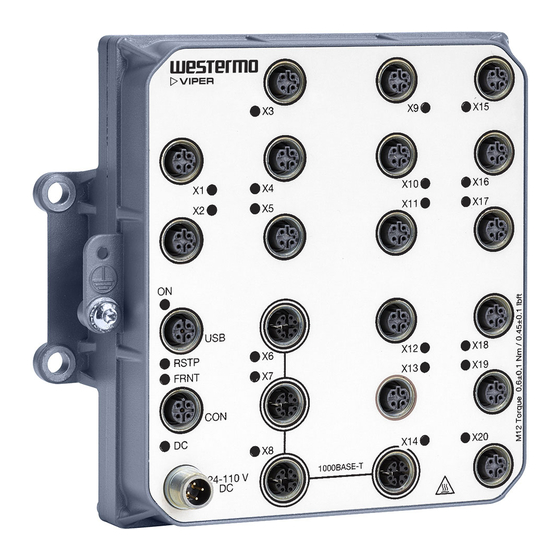

3.3. Hardware Overview RSTP FRNT 1000BASE-T 24-110 V Description Description LED indicator 100 Mbps port Gbps port DC port Console port USB port Protective earth connection Figure 1. Location of interface ports and LED indicators Viper 20A Series... -

Page 11: Connector Pinout

3.4. Connector Pinout Signal Illustration +DC1 +DC2 -COM -COM Viper-x20A supports redundant power connection. The positive inputs are +DC1 and +DC2. The negative input for both supplies is -COM Table 3. Power connector Pin no. Signal Illustration No Connect. Do not connect. Table 4. - Page 12 Signal Illustration MDI, MDI-X and auto MDI/MDI-X modes are supported. The table shows signals in MDI mode. Table 6. 100 Mbps Ethernet connector Pin no. Signal Illustration Table 7. Gbps connector Viper 20A Series...

-

Page 13: Led Indicators

3.5. LED Indicators Status Description Unit has no power GREEN All OK, no alarm condition Alarm condition, or until unit has started up. (Alarm conditions are configurable, see WeOS Management Guide) BLINK Location indicator ("Here I am!"). Activated when connected to WeConfig tool, or upon request from web or/and CLI. - Page 14 164 ±0,5 Grounding point screw M5x10 Figure 2. Dimensional drawing Viper 20A Series...

-

Page 15: Installation

4. Installation 4.1. Wall Mounting The unit can be wall mounted vertically or horizontally. There are four pieces of 7 mm bores for this. Use four M5, M6 or 1/4" screws with 12 mm washers on a flat and stable surface. -

Page 16: Cooling

NOTICE - UNUSED CONNECTORS Unused connectors must be covered by a protective cap (delivered with the unit), tightened to the specified torque in order to fulfill the specified ingress protection code. 4.3. Cooling This unit relies on convection cooling. Make sure that it is installed so that the ambient temperature is within the specified temperature range, e.g. -

Page 17: Specifications

Reverse polarity protected Redundant power input Isolation to 2250 VDC to all other ports Connector 4-pin, male, M12, A-coded, recommended Westermo cables: 3146-1106 for 1.5 m 3146-1107 for 5 m Cable size M12, recommended cable area 0.5 mm² (minimum 0.25 mm²) - Page 18 Up to 150 m with CAT5e cable or better Isolation to 2250 VDC to all other ports Connector 4-pin, female, M12, D-coded, auto MDI/MDI-X, recommended Westermo cables: 3146-1100 M12-M12 - 1 m 3146-1101 M12-M12 - 5 m 3146-1103 RJ45-M12 - 1 m...

- Page 19 500 mA Circuit type SELV Isolation to Ethernet and DC ports: 2250 VDC No isolation to CON or chassis Connector 5-pin, female, M12, A-coded, recommended Westermo USB plug 3641-0190 Console port Electrical specification RS-232 Data rate 115.2 kbit/s Data format...

-

Page 20: Type Tests And Environmental Conditions

5.2. Type Tests and Environmental Conditions Environmental Basic Description Test levels phenomena standard EN 61000-4-2 Enclosure Contact: ±6 kV Air: ±8 kV Fast transients EN 61000-4-4 Power port ± 2 kV Signal ports Earth port L-E: ± 2 kV, 42 Ω, 0.5 µF, 1.2/50 µs Surge EN 61000-4-5 Power port... - Page 21 Environmental Basic Description Test levels phenomena standard Temperatures EN 60068-2-1 Operating -40 to +70°C (-40 to +158°F) EN 60068-2-2 Storage and -55 to +85°C (-67 to +185°F) transport Humidity EN 60068-2-30 Operating 5-95% relative humidity Storage and transport Altitude Operating 2000 m/70 kPa Service life Operating...

-

Page 22: Revision Notes

6. Revision Notes Revision Date Change description Rev. A 2017-05 First issue of user guide Rev. B 2017-07 New chapter (2.1 Warning levels chapter), Shock and NFPA 130 updated (2.6.1 Agency approvals updated), text updated (3.1 Product description), inrush current updated (5.1 Interface specifications), service life, shock and operating temperature updated (5.2 Type Tests and environmental conditions).

Need help?

Do you have a question about the 3635-0910 and is the answer not in the manual?

Questions and answers