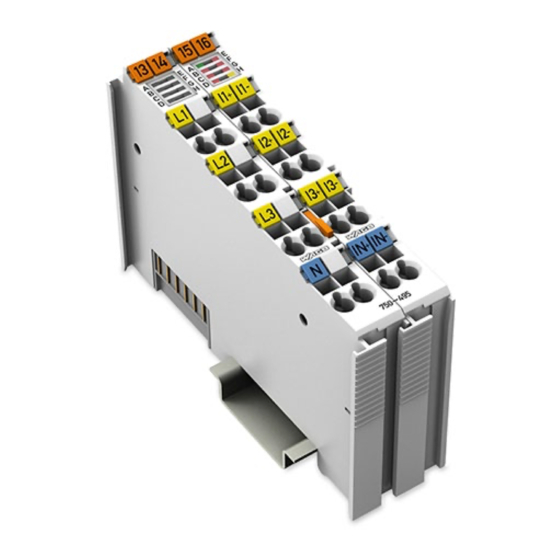

WAGO I/O System 750 Manual

3-phase power measurement module

Hide thumbs

Also See for I/O System 750:

- Manual (468 pages) ,

- Quickstart reference (54 pages) ,

- Product manual (28 pages)

Need help?

Do you have a question about the I/O System 750 and is the answer not in the manual?

Questions and answers