Summary of Contents for Oliver 705-N

- Page 1 Walker, Michigan, U.S.A. 49534-7564 USER’S OPERATING AND INSTRUCTION MANUAL MODEL 705-N DUAL BLADE BUN SLICER 705S20000-CV...

- Page 2 Cleaning ..................0705S20016-1/2 Lubrication..…................0705S20016-2/2 CHANGING THE BLADES ................ 0705S20017 TROUBLE SHOOTING ................0705S20018 PARTS LIST....................0705S20019 ASSEMBLY DRAWING MODEL 705-N SLICERS ……......0705S20020 WIRING DIAGRAMS ................0705S20021 WARRANTY..................... GEN 040225 WARRANTY PROCEDURE..............GEN 040226 RETURNED PARTS POLICY..............GEN 040227 REV.

-

Page 3: Specifications

MODEL 705-N DUAL BLADE BUN SLICER SPECIFICATIONS DESCRIPTION These bun slicers have welded steel frames and stainless steel chutes. They are compact, durable slicers for counter top use in slicing a variety of large buns with speed and economy. SPECIFICATIONS •... -

Page 4: Product Capacities

MODEL 705-N DUAL BLADE BUN SLICER SPECIFICATIONS (Continued) PRODUCT CAPACITIES • Maximum Product Size: 8-3/4 inches Wide and 4-1/8 inches High • Blade Height (adjustable to cut bottom slice): 5/8 inch to 1-1/2 inches 0705S20012-... -

Page 5: Safety Instructions

MODEL 705-N DUAL BLADE BUN SLICER SAFETY INSTRUCTIONS Every effort has been made by Oliver Products Company to provide you with a safe machine. It is essential, however, that machine operators and maintenance personnel observe the following safety precautions. 1. Before attempting to operate your slicer read this manual. Never allow an untrained person to operate this machine. - Page 6 GENERAL DEFINITIONS The use of the words WARNING, CAUTION, and NOTE in this manual should be guided by the following. WARNING AN OPERATING PROCEDURE, TECHNIQUE, ETC., WHICH MAY RESULT IN PERSONAL INJURY IF NOT CAREFULLY FOLLOWED. CAUTION AN OPERATING PROCEDURE, TECHNIQUE, ETC., WHICH MAY RESULT IN DAMAGE TO EQUIPMENT IF NOT CAREFULLY FOLLOWED.

- Page 7 MODEL 705-N DUAL BLADE BUN SLICER ADJUSTMENTS WARNING NEVER ATTEMPT TO ADJUST OR SERVICE THIS MACHINE UNTIL YOU ARE SURE THE BLADES ARE STOPPED. INSIDE SIDE GUIDES Normally when the machine is used to slice round product these guides can be set to the maximum opening size and do not need to be readjusted to fit each different product.

- Page 8 MODEL 705-N DUAL BLADE BUN SLICER OVERHEAD HOLD DOWN ADJUSTMENT On some buns, especially buns with sunken or rounded tops and bottoms, it may be beneficial to use the Overhead Hold Down. Buns with a flat side normally will not require the use of the hold down, especially if the flat side can be placed against the top of the table.

- Page 9 MODEL 705-N DUAL BLADE BUN SLICER OPERATING INSTRUCTIONS After making any required adjustments, (see adjustment section), you are ready to begin slicing your product. Start the motors by pushing the "ON" button of the switch, then place the product on the chute as close to the middle as possible and allow it to slide into the blades, (do not throw the product into the machine).

-

Page 10: Maintenance

MODEL 705-N DUAL BLADE BUN SLICER MAINTENANCE/CLEANING/LUBRICATION WARNING NEVER ATTEMPT TO CLEAN OR SERVICE THIS MACHINE UNTIL IT HAS BEEN DISCONNECTED FROM THE POWER SUPPLY AND YOU ARE SURE THE BLADES HAVE STOPPED. ALSO REMEMBER TO USE CARE WHENEVER YOU ARE WORKING NEAR THE BLADES. - Page 11 MODEL 705-N DUAL BLADE BUN SLICER CLEANING (continued) The BLADES should be cleaned at least daily and may be cleaned in place, the maintenance person should wear cut resistant gloves to prevent injury. More frequent cleaning of the BLADES is required when cutting fruity or sticky breads.

-

Page 12: Changing The Blades

MODEL 705-N DUAL BLADE BUN SLICER CHANGING THE BLADES WARNING NEVER ATTEMPT TO CLEAN OR SERVICE THIS MACHINE UNTIL IT HAS BEEN DISCONNECTED FROM THE POWER SUPPLY AND YOU ARE SURE THE BLADES HAVE STOPPED. ALSO REMEMBER TO USE CARE WHENEVER YOU ARE WORKING NEAR THE BLADES. - Page 13 MODEL 705-N DUAL BLADE BUN SLICER CHANGING THE BLADES (Continued) • Each BLADE can then be replaced by reversing the above procedure. • When reinstalling the BLADES, make sure that the points on the teeth are pointed in opposite directions as shown on the previous page.

-

Page 14: Troubleshooting

MODEL 705-N DUAL BLADE BUN SLICER TROUBLE SHOOTING WARNING NEVER ATTEMPT TO CLEAN OR SERVICE THIS MACHINE UNTIL IT HAS BEEN DISCONNECTED FROM THE POWER SUPPLY AND YOU ARE SURE THE BLADES HAVE STOPPED. THE SLICER MOTOR OR MOTORS WILL NOT START OR WERE RUNNING BUT SUDDENLY STOPPED. - Page 15 Screw-Hex HD 1/4-20 x 1/2 STST 5843-1001 Washer-Lock 1/4” STST 5851-9357 Holddown-Overhead 0705-0005 Bearing-Bronze Flange 5254-3110 Washer-1/2” Flat 18-8 STST 5851-9308 Knob-4 Prong 1/2-13 5911-7103 Spring-Comp 7015-4104 Door-Slow Down 0705-0007 To obtain Replacement Parts call Oliver Products Company at 1-800-253-3893 Rev. 12/02/02 0705S20019-...

-

Page 16: Part Description

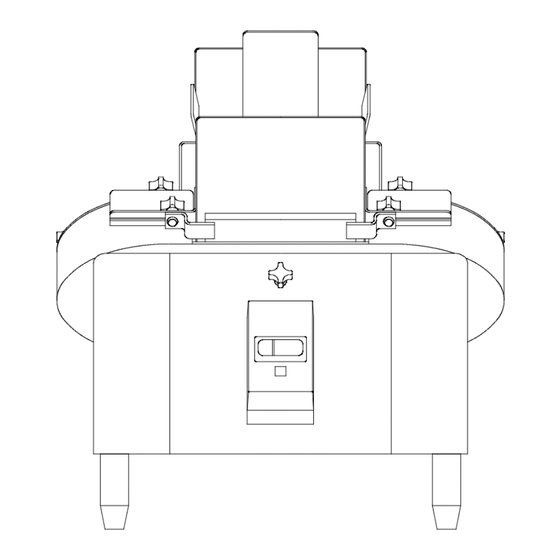

Screw- Rd Hd #10-24 x 3/8 STST 5843-5237 Washer-#10 STST Lock 5851-9394 Jumper-7” 0705-0010 Joint-Wire 5768-1239 Cap-Plug (1/60/230 VAC mach’s.) 5765-2030 * 419 Splice-Closed End 5768-1240 To obtain Replacement Parts call Oliver Products Company at 1-800-253-3893 * Rev. 12/02/02 0705S20019-... - Page 17 MODEL 705-N DUAL BLADE BUN SLICER ASSEMBLY DRAWING MODEL 705-N Rev. 12/4/02 Rev. 10-14-97 0705S20020...

-

Page 18: Wiring Diagrams

MODEL 705-N DUAL BLADE BUN SLICER WIRING DIAGRAMS Wiring Diagram (2/3 HP, 1Ph, 50/60 Hz, 115/110 VAC) Diagram No. 0705C12000 Wiring Diagram (2/3 HP, 1Ph, 50/60 Hz, 230/220 VAC) Diagram No. 0705C12001 REV. 2-21-06 0705S20021... - Page 19 THIS PAGE WAS INTENTIONALLY LEFT BLANK. GEN020319...

-

Page 20: Warranty

WARRANTY PARTS Oliver Packaging & Equipment Company warrants that if any part of the equipment (other than a part not manufactured by Oliver Packaging & Equipment ) proves to be defective (as defined below) within one year after shipment, and if Buyer returns the defective part to Oliver Packaging & Equipment within one year, Freight Prepaid to Oliver Packaging &... - Page 21 THIS PAGE WAS INTENTIONALLY LEFT BLANK. GEN020319...

-

Page 22: Warranty Procedure

4. The service dealer will then complete an invoice and send it to the Parts and Service Department at Oliver Packaging & Equipment Company. 5. The Parts and Service Manager of Oliver Packaging and Equipment Company will review the invoice and returned parts, if applicable, and approve for payment. - Page 23 THIS PAGE WAS INTENTIONALLY LEFT BLANK. GEN020319...

-

Page 24: Returned Parts Policy

This policy applies to all parts returned to the factory whether for warranted credit, replacement, repair or re-stocking. Oliver Packaging and Equipment Company requires that the customer obtain a Return Material Authorization (RMA) number before returning any part. This number should appear on the shipping label and inside the shipping carton as well.

Need help?

Do you have a question about the 705-N and is the answer not in the manual?

Questions and answers