Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for LEMKEN Zirkon 8

- Page 1 Zirkon 8 - EN - Item no. 175_4463 2/04.11 LEMKEN GmbH & Co. KG Weseler Straße 5, D-46519 Alpen / PO Box 11 60, D-46515 Alpen Telephone (0 28 02) 81-0, Fax (0 28 02) 81-220 E-mail: lemken@lemken.com, Internet: http://www.lemken.com...

- Page 3 However, this brief instruction is not a substitute for thorough study of the operating instructions. These operating instructions will help to familiarise you with the LEMKEN GmbH & Co. KG device and the options available for using it.

- Page 4 Remember that you should only use genuine LEMKEN spare parts. Reproduction parts have a negative influence on the function of the device, have a shorter ser- vice life and present risks and hazards that cannot be estimated by LEMKEN GmbH & Co. KG. They also increase the maintenance costs.

-

Page 5: Table Of Contents

Contents CONTENTS Contents ........................... 3 General information ....................9 Liability........................... 9 Guarantee........................9 Copyright ........................10 Optional accessories ....................10 Symbols used in the Operating Instructions............11 Hazard classes ......................11 Information........................11 Environmental protection ................... 11 Indication of passages....................12 Safety measures and precautions................. - Page 6 Contents 3.9.2 Requirements of the tractor..................22 3.9.3 Axle loads......................... 23 3.9.4 Check before departure ................... 28 3.9.5 Correct behaviour in road traffic ................28 3.10 Obligation of the operator ..................28 3.11 Operating the device safely..................29 3.11.1 General information ....................29 3.11.2 Personnel selection and qualifications..............

- Page 7 Contents Wheel track eliminators ....................39 Scrapers ........................39 Preparation of the Tractor ..................40 Tyres..........................40 Lift Rods........................40 Check Chains or Sway Blocks of the Three Point Linkage ........40 Pendulum compensation.................... 40 Required hydraulic equipment................... 40 Required power sources..................... 41 Three-point linkage .....................

- Page 8 10.2 Adjusting the scrapers ....................74 10.3 Clearance between scraper and roller casing ............75 11 Mounting a LEMKEN seed drill ................76 11.1 Coupling partsfor mounting a Solitair seed drill ............76 11.2 Coupling parts for mounting Saphir Seed Drill ............76 11.3 Coupling A-frame ......................

- Page 9 Contents 13 Front mounting......................81 13.1 Add-on parts for pusher on heavy-duty excavation linkage ........81 13.2 Pusher , heavy duty version..................82 13.3 Tube bar roller for front mounting ................82 14 Switching off the device ..................83 14.1 Shutting down the device in an emergency.............. 83 14.2 Disposal ........................

- Page 10 Contents 15.9.1 Tightening torques....................95 15.10 Tines..........................96 15.11 Scrapers ........................96 15.12 Cardan shaft ........................ 96 15.13 Hydraulic hoses......................97 16 Troubleshooting ...................... 98 16.1.1 General information ....................98 16.1.2 Electrical equipment ..................... 98 17 Tips for driving on public highways..............99 18 Technical data .......................

-

Page 11: General Information

Co. KG, in particular Section IX, shall apply. Liability. In line with the dimensions cited in these conditions the LEMKEN GmbH & Co. KG shall not be held liable for any personal or material damage, when such damage is caused by one or more of the following reasons: ... -

Page 12: Copyright

Infringements will result in a claim for damages. Optional accessories LEMKEN implements may be equipped with various accessories. The operating instructions below describe both series components and optional accessories. Please note: These accessories will vary depending on the type of equipment. -

Page 13: Symbols Used In The Operating Instructions

Symbols used in the Operating Instructions SYMBOLS USED IN THE OPERATING INSTRUCTIONS Hazard classes The following symbols are used in the Operating Instructions for particularly im- portant information: DANGER Denotes an imminent hazard with high risk, which will result in death or severe physical injury, if not avoided. -

Page 14: Indication Of Passages

Symbols used in the Operating Instructions Indication of passages The following symbols are used for particular passages in the operating instruc- tions: Indicates work steps Indicates enumerations... -

Page 15: Safety Measures And Precautions

Safety measures and precautions SAFETY MEASURES AND PRECAUTIONS General safety instructions for the operator are specified in the chapter entitled "Safety measures and precautions". At the start of some main chapters the safety instructions, which refer to all work to be carried out in this chapter, are listed to- gether. -

Page 16: Safety Equipment On The Device

Safety measures and precautions Safety equipment on the device To protect the user and the device, the device features special safety equipment. Always keep all safety equipment in working order. Safety and warning signs 3.4.1 General information The implement features all equipment which ensures safe operation. If hazardous areas could not be completely secured with respect to operational safety, warning signs are affixed which indicate these residual risks. - Page 17 Safety measures and precautions ATTENTION: Do not remain in the operating and swivel area of the implement! ATTENTION: Danger of crushing! CAUTION: Danger through moving machine parts! CAUTION: The power takeoff shaft drive-through runs to the right! CAUTION: Do not climb onto the implement!

- Page 18 Safety measures and precautions CAUTION:do not touch any moving machine parts. Wait until they have come to a standstill! 390 0513 CAUTION: Hot surfaces!

-

Page 19: Position Of The Safety And Warning Signs

Safety measures and precautions 3.4.3 Position of the safety and warning signs... -

Page 20: Special Safety Instructions

Safety measures and precautions Special safety instructions Risk of injury due to non-observance of the currently valid occupational safety guidelines If the currently valid occupational safety guidelines are bypassed WARNING or safety equipment is rendered unusable when handling the de- vice, there is a risk of injury. -

Page 21: Hazardous Areas

Safety measures and precautions Risk of injury when freeing casualties When rescuing people trapped or injured by the device, there is a risk of additional serious injury to the casualty if the hydraulic con- nections were not connected according to their colour coding as described in the section entitled "Required hydraulic equipment". -

Page 22: Hazardous Areas During Operation Of The Implement

Safety measures and precautions 3.6.1 Hazardous areas during operation of the implement Residual risks Residual risks are particular hazards which occur when handling the device and which cannot be eliminated despite a design in accordance with safety require- ments. Residual risks are not usually obvious and may be the source of a potential injury or health hazard. -

Page 23: Hazard Caused By Hydraulic Systems

Safety measures and precautions 3.7.2 Hazard caused by hydraulic systems There is a risk of injury to body parts, in particular the face, eyes and unprotected areas of skin, caused by burns and contamination with hydraulic fluid due to hot/pressurised hydraulic fluid spraying out of leaking joints or lines, ... -

Page 24: Requirements Of The Tractor

Safety measures and precautions 3.9.2 Requirements of the tractor Ensure that the tractor with mounted device always reaches the stipulated brak- ing deceleration. Observe the permitted axle loads, gross weights and transportation dimensions, see also section entitled "Axle loads"! Observe the permitted power limit of the tractor! Risk of accidents due to inadequate steerability A tractor which is too small or which has inadequate front ballast... -

Page 25: Axle Loads

Safety measures and precautions 3.9.3 Axle loads Implements mounted to the front and rear three-point linkage must not result in the following being exceeded: permissible gross weight of tractor, permissible axle loads of tractor, the tractor's tyre load-carrying capacities. The tractor's front axle must always be loaded with at least 20 % of the tractor's curb weight. - Page 26 Safety measures and precautions Data from tractor operating instructions Take the following data from your tractor's operating instructions: Abbreviation Data Tractor kerb weight (kg) _______ kg Front axle load (kg) of empty tractor _______ kg Rear axle load (kg) of empty tractor _______ kg Data from implement operating instructions ...

- Page 27 Safety measures and precautions Data to be determined through remeasuring are Determine the following data through remeasuring: Abbreviation Data Distance (m) between centre of gravity for front _______ m mounting implement or front weight and centre of front axle Tractor wheelbase (m) _______ m Distance (m) between centre of rear axle and centre...

- Page 28 Safety measures and precautions Calculation of minimum ballasting value at front G for rear mounting V min implement x (c + d) – T x b + (0.2 x T x b) V min a + b Enter the calculated minimum ballasting value, as required at the front of the tractor, into the table.

- Page 29 Safety measures and precautions Calculation of actual rear axle load T H tat H tat V tat Enter the value for the calculated actual rear axle load and the permissible rear axle load as given in the tractor's operating instructions into the table. Tyre load-carrying capacity ...

-

Page 30: Check Before Departure

Safety measures and precautions 3.9.4 Check before departure Before driving with the implement raised, lock the control lever of the control unit; otherwise it may drop and the implement may be unintentionally lowered. Mount and check the transport equipment such as the lighting system, warning signs and protective devices. -

Page 31: Operating The Device Safely

Safety measures and precautions The operating instructions are an important component of the device. Ensure that the operating instructions are always ready available at the installa- tion location of the device and are kept for the entire service life of the device. ... -

Page 32: Personnel Selection And Qualifications

Safety measures and precautions When actuating the external control for the three-point attachment, do not walk between the tractor and device! It is prohibited to be within the hazardous area of the machine and to climb up on the implement while it is operating! ... -

Page 33: Hydraulic System

Safety measures and precautions 3.11.3 Hydraulic system The hydraulic system is under high pressure. When connecting hydraulic cylinders and motors, ensure that the specified hydraulic hose connection is used. When connecting the hydraulic hoses to the tractor hydraulics, make sure that the hydraulic system is depressurised on both the tractor and the implement. - Page 34 Safety measures and precautions The cardan shaft may only be fitted or removed with the power take-off and engine switched off and the ignition key removed. Always ensure that the cardan shaft is fitted and secured properly. Attach the chains to secure the cardan shaft guard against rotation. ...

-

Page 35: Handing Over The Device

Handing over the device HANDING OVER THE DEVICE As soon as the device is delivered, ensure that it corresponds with the order package. Also check the type and completeness of any supplied accessories. When the device is handed over, your dealer will explain how it works. ... -

Page 36: Design And Function

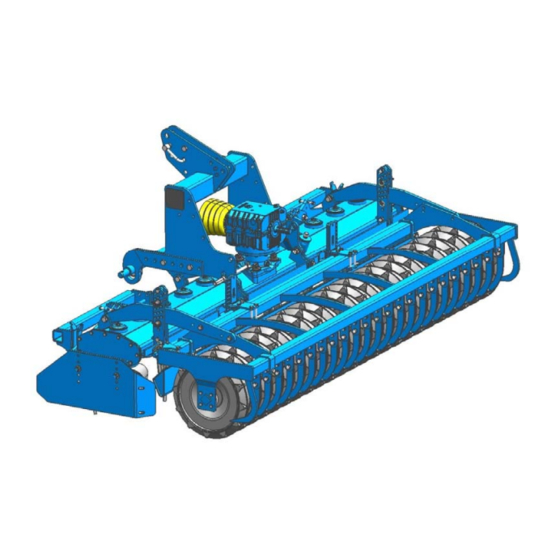

Design and function DESIGN AND FUNCTION Overview 1 Three-point headstock 2 Gearbox recess 3 Knife tines 4 Side blade 5 Power takeoff shaft drive- through 6 Roller Levelling beam... -

Page 37: Function

The three-point headstock with top link pin and drawbar complies with ISO 730. The drawbar L2/Z2 complies with category 2. The drawbar L3/Z3 complies with category 3. The drawbar L2/Z3 complies with category 3N. Upper link pin Zirkon 8/250 With light-duty version Cat. 2 Zirkon 8/300 headstock... -

Page 38: Side Blades

Roller 5.2.4 Side blades The height-adjustable side blades (1) and the extensions (2) prevent the outer tines from building up ridges. 5.2.5 Power takeoff shaft drive-through The rotational speed and direction of rota- tion for the power takeoff shaft drive- though (1) corresponds to the rotational speed and direction of rotation for the trac- tor power takeoff shaft. -

Page 39: Levelling Beam

Roller 5.2.7 Levelling beam The levelling beam ensures that the ground is evenly levelled. The levelling beam can be attached either in front of the knife tines or between the tines and the trailing roller. -

Page 40: First Use

First use FIRST USE CAUTION Always wear safety shoes when performing any adjusting work. Before work starts, all safety devices must be checked to make sure that they are working properly and then used or operated in accordance with these operating instructions. -

Page 41: Rear Levelling Beam

First use Rear levelling beam Before adjusting the levelling beam, always move the side blades into the working position. The rear levelling beam (4) must be adjusted so that it is approx. 2 cm above the ground. It must be positioned even higher if too much soil is banked up. Wheel track eliminators The wheel track eliminators (4) must be adjusted so that they are located approx. -

Page 42: Preparation Of The Tractor

Preparation of the Tractor PREPARATION OF THE TRACTOR Tyres The pressure - especially in the rear tractor tyres - must be equal. In heavy condi- tions it may be necessary to add wheel weights and/or water ballast. (See manu- facturer’s instructions). Lift Rods Adjust lift rods to equal length. -

Page 43: Required Power Sources

Preparation of the Tractor Required power sources Damage to electrical components The tolerance range for the power supply is between 10 V and 15 CAUTION V. Overvoltage and undervoltage will result in malfunctions and under certain circumstances may destroy electrical or electronic components. -

Page 44: Three-Point Linkage

Preparation of the Tractor Three-point linkage Loss of the implement The tractor's three-point linkage category and the category of the WARNING draw rail and top link pin must match. Otherwise, the draw rail and the top link pin may slip out of the linkage when driving over une- ven ground or due to vibrations. - Page 45 Preparation of the Tractor Danger to life if three-point linkage category is too small If a draw rail or a top link pin is used with a category that is too small, these components may be overloaded and break. As a re- sult, the implement may fall down and injure or kill people in the DANGER immediate vicinity.

-

Page 46: Hydraulic System

Preparation of the Tractor Hydraulic system 7.8.1 Transport Lowering the three-point linkage CAUTION The device may be damaged if the three-point linkage of the trac- tor is lowered due to an incorrect setting or operation. For transport always switch the hydraulic system of the tractor to "position control". -

Page 47: Coupling And Uncoupling

Coupling and uncoupling COUPLING AND UNCOUPLING Before mounting and dismounting always: DANGER switch off the PTO shaft and tractor engine. pull on the handbrake. remove the ignition key. Coupling Risk of injury when coupling the device WARNING There is a risk of body parts being crushed between the tractor and device The tractor must be secured against unintentionally rolling away. - Page 48 Coupling and uncoupling Risk of injury from unsecured top link pin If the top link pin is not secured, it may slip out or get lost. CAUTION As a result, the device may fall down or be damaged. As a result, people in the immediate vicinity may be injured. ...

- Page 49 Coupling and uncoupling Switch the tractor's three point linkage to position control. Connect the tractor's lower control link to the implement’s drawbar (1). Lock the lower control link. Mount the upper control link such that it rises slightly towards the implement while operating.

-

Page 50: Uncoupling

Coupling and uncoupling Uncoupling The circular spike harrow must always be parked on solid and level ground. In combination with a hydraulic three-point linkage and mounted seed drill the hy- draulic three-point linkage with the seed drill must be fully lowered before disman- tling the circular spike harrow. -

Page 51: Adjustments

Adjustments ADJUSTMENTS Risk of accident when making adjustments When making any adjustments to the device, there are risks of crushing, cutting, clamping and striking your hands, feet and body on heavy and occasionally compressed and/or sharp-edged parts. Always park implement on the ground. DANGER ... -

Page 52: Cardan Shaft

Adjustments DANGER Switch off the power take-off before carrying out adjustment work. Cardan shaft 9.1.1 General information The Zirkon circular spike harrows are equipped with a cardan shaft with cam shift- ing clutch as an overload safeguard. Care must be taken to ensure that the car- dan shaft protection (3) is secured against also rotating by hooking-in the chains (4). -

Page 53: Changing The Distance Between The Implement And The Tractor

Adjustments 9.1.2 Changing the distance between the implement and the tractor Before changing the distance between the implement and the DANGER tractor, you must perform the following steps: Switch off the power take-off and tractor engine. Apply the handbrake. ... -

Page 54: Shortening The Cardan Shaft

Adjustments Decouple the implement. Move the tractor a few metres forwards. Undo the fastening bolts (9). Change the length. Secure the fastening bolts (9) with Loctite. Tighten the fastening bolts (9) with a torque of 648 Nm. ... -

Page 55: Manual Gearbox

Adjustments Hold the cut section of the outer protec- tive tube (2) over the outer profile tube (8) and cut off the outer profile tube (8) at right angles. Hold the cut section of the inner protecti- ve tube (2) over the inner profile tube (9) and cut off the inner profile tube (9) at right angles. - Page 56 Adjustments The power harrows Zirkon 8 are equipped in standard with the gear wheel pair 19/22 (entry/exit). With 1000 rpm power takeoff shaft speed the rotor speed will be 300 1/min or 400 1/min. The manual gearbox (1) features a shifting lever (2), which can be switched to two locking positions (for two rotor speed settings).

-

Page 57: Rotor Speeds

Adjustments DANGER After switching off the power takeoff shaft the flywheel still runs and it presents a danger. Do not get too close to the implement during this period. 9.2.2 Rotor speeds The following rotor speeds are possible, depending on the power takeoff shaft speed: Manual gearbox Change gear train... -

Page 58: Changing Rotor Speeds / Gears

Adjustments The recommended working speed for the rotor speeds is available in the following diagram. Recommended working speed depending on rotor speed Rotor speed per minute If another pair of gears was mounted, this is marked as such on the label. Dia- gram field I is for light to medium ground and diagram field II for heavy to very heavy ground. - Page 59 Adjustments Before changing gears, switch off the power takeoff shaft, switch off the tractor engine and remove the ignition key! Make sure that the transmission is cold! WARNING It is forbidden to stand under a machine that has been raised. Risk of injury or danger to life! ...

- Page 60 Adjustments Remove the shaft (4). Remove gearwheel (5) first and then gearwheel (6). Mount both gearwheels in opposite posi- tions. Mount the shaft (4) again. When mounting the shaft, make sure that the seal is not dam- aged.

-

Page 61: Horizontal Position

Adjustments Horizontal position During work, the implement should be horizontal. The adjustment required to en- sure this is made by adjusting the length of the tractor's upper link. If the tractor's power take-off is at a downwards or upwards incline towards the rear instead of parallel with the ground, the implement must be adjusted using the tractor's upper link so that the gearbox input shaft, when lowered into the working position, is parallel with the power take-off. -

Page 62: Knife Tines With Quick-Coupling System

Adjustments Knife tines with quick-coupling system The tines (1) can be manually changed after releasing the locking bar (2) using a size 24 open end wrench as follows. Rotate the locking bar (2) using an open-end wrench through 90°. ... -

Page 63: Change In The Direction Of Rotation Of The Rotors

Adjustments Change in the direction of rotation of the rotors The direction of rotation may only be changed when the tractor power take-off is switched off and the tractor engine is at a standstill. The direction of rotation of the rotors with quick-change tines can be changed by moving the gearbox (1) to the side. -

Page 64: Side Blade

Adjustments First, screw in all of the centring nuts (4) a little. Then tighten the centring nuts (4) with a tightening torque of 240 Nm. If the centring nuts (4) are not properly tightened, the tractor power take-off must not be switched on. ... -

Page 65: Retracting The Side Blades

Adjustments 9.7.1 Retracting the side blades For road transportation, the side blades (2) of the 3 m and 3.5 m wide rotary har- rows are to be retracted to ensure that the maximum permissible transport width is not exceeded. Remove the spring pin (7). ... -

Page 66: Extending The Side Blades

Adjustments 9.7.2 Extending the side blades Before the next work assignment and befo- re the tractor power take-off is switched on, the side blades (2) must be folded down as follows: Remove the spring pin (7) and guide pin (6). -

Page 67: Side Blade Extension

Adjustments Side blade extension Bolt the side blade extensions (4) at the rear onto the side blades (2). After undoing the bolts (5) each side blade extension in the slots, under the washers (6), can be moved slightly forward or backward! The distance to the roller should be as small as possible. -

Page 68: Adjusting The Working Depth

Adjustments 9.9.2 Adjusting the working depth The wheel track eliminators are set to approx. 5 cm deeper than the bout of the tractor. Adjust the working depth of the wheel track eliminator as follows: Raise the implement to relieve the load- ing on the wheel track eliminator (1). -

Page 69: Relocation At The Side

Adjustments 9.10.1 Relocation at the side On the bracket (3), move the feed disc (1) to the required working width. Tighten the bolts (4) to a torque of 197 Nm. 9.10.2 Adjusting the working depth Unlock the pin (5). ... -

Page 70: Power Take-Off

Adjustments Without levelling beam but with roller = rol- ler mounted in front position Without levelling machine but with roller and seed drill = roller mounted in rear posi- tion, protective tube (1) fitted 9.12 Power take-off The tractor's power take-off may not be switched on until the rotary harrow has been lowered until it is only a few centi- metres above the ground and the side bla-... -

Page 71: Levelling Beam

Adjustments 9.13 Levelling beam CAUTION Before adjusting the levelling beam, always move the side blade into the working position. The circular spike harrow can be equipped at the rear or front with a levelling beam (1). 9.13.1 Rear-mounted levelling beam Set the levelling beam (1) using the rough- turning gauge (2) so that the lower edge of the levelling beam is about 2 cm over the... -

Page 72: Track Markers

Adjustments 9.14 Track markers CAUTION Before operating the track marker always make sure that no-one is standing in the danger zone. For a more precise access run for the cir- cular spike harrow, in particular, in combi- nation with a seed drill, track markers are available that can be bolted onto the carri- ers (2). - Page 73 Adjustments Find the adjusting dimensions in the following table. The dimensions refer to a marking groove in the centre of the tractor track. Zirkon Distance from middle of seed drill to track Distance from outer seeding coul- groove 8/250 250 cm 125 cm + ½...

-

Page 74: Shear Device

Adjustments 9.14.1 Shear device The track marker is safeguarded against overloading by a shear bolt (9). If a shear bolt fractures, the remains of the bolt must be removed first before a new shear bolt is fitted. Use M10x45 / 8.8 shear bolts only with article number 301 3240. -

Page 75: Rollers

Rollers ROLLERS 10.1 General information The Zirkon can be fitted with a range of rollers: Tube bar roller RSW 400 or RSW 540 Trapeze packer roller TPW 500 Trapezoidal disc roller TSW 500 Toothed packer roller ZPW 500 Tube bar rollers are maintenance-free. -

Page 76: Adjusting The Scrapers

Rollers 10.2 Adjusting the scrapers The adjustable scrapers (1) for the size 500 rollers are adjusted using setting nuts (2) or eccentric nuts (3). Adjust the setting nuts (2) for the toothed packer rollers using a 19 mm wrench and the eccentric nuts (3) using a 24 mm wrench. -

Page 77: Clearance Between Scraper And Roller Casing

Rollers 10.3 Clearance between scraper and roller casing The clearance between the scraper (1) and the roller casing (5) must be set in line with the following schedule. The adjusting instructions apply to all toothed packer rollers, trapezoidal packer rollers and trapezoidal disk rollers. Heat-treated scraper (1) Plastic scraper (1) (must make contact with roller casing (5) -

Page 78: Mounting A Lemken Seed Drill

Mounting a LEMKEN seed drill MOUNTING A LEMKEN SEED DRILL 11.1 Coupling partsfor mounting a Solitair seed drill Zirkon circular spike harrows are available with coupling parts for attaching a Soli- tair seed drill. The coupling parts come with a top safety hook (1) and two lower support plates (2). -

Page 79: Coupling A-Frame

Mounting a LEMKEN seed drill 11.3 Coupling A-frame A corresponding coupling A-frame (4) is available for mounting seed drills equipped with a coupling A-frame. -

Page 80: Hydraulic Excavation Linkage

Hydraulic excavation linkage HYDRAULIC EXCAVATION LINKAGE 12.1 Adaptation of hydraulic excavation linkage To achieve the most favourable centre-of- gravity attachment of a mounted device, e.g. a seed drill, the lower control arms (1) can be shortened by adjusting their length. The bore line (2) can be used for this pur- pose. -

Page 81: Mounting An Attachment

Hydraulic excavation linkage 12.2 Mounting an attachment WARNING Danger of tipping After setting the length of the upper link (8), secure the upper link with the locknut. Perform the following steps to mount an attachment: Pull out the spring pin (6). ... -

Page 82: Lowering The Attachment

Hydraulic excavation linkage With the attachment raised, close the shut-off valve (9). 12.3 Lowering the attachment Lower the attachment (seed drill) as fol- lows: Open the shut-off valve (9) with the trac- tor control valve closed. Switch the tractor control unit to the "Lo- wer"... -

Page 83: Front Mounting

Front mounting FRONT MOUNTING 13.1 Add-on parts for pusher on heavy-duty excavation linkage Zirkon can also be used in a front-mounted position. Add-on parts (1) are avail- able for this purpose, if the Zirkon has already been equipped with a dual-acting hydraulic excavation linkage. -

Page 84: Pusher , Heavy Duty Version

Front mounting 13.2 Pusher , heavy duty version The pusher (4) is mounted at the rear to the circular spike harrow's three-point tower using the upper link (5). It is recom- mended for use if the circular spike harrow is to be used in front mounting position only. -

Page 85: Switching Off The Device

Switching off the device SWITCHING OFF THE DEVICE 14.1 Shutting down the device in an emergency In an emergency shut down the device via the tractor. Switch the tractor engine off. Remove the ignition key. Damage caused by improper storage of the device If incorrectly or improperly stored, the device may be damaged, CAUTION e.g. -

Page 86: Maintenance And Repairs

Maintenance and repairs MAINTENANCE AND REPAIRS 15.1 Special safety instructions 15.1.1 General Risk of injury when carrying out maintenance and repair work There is always the risk of injury when carrying out maintenance and repair work. WARNING Use suitable tools, suitable climbing aids, platforms and support elements. -

Page 87: Immobilise The Implement For Maintenance And Repairs

Maintenance and repairs 15.1.4 Immobilise the implement for maintenance and repairs Risk of accidents when tractor starts up Injuries may occur if the tractor starts moving during maintenance and repair work. Switch off the tractor engine before carrying out any work on the WARNING implement. -

Page 88: Working Under The Raised Device

Maintenance and repairs 15.1.7 Working under the raised device Risk of accident due to lowering and extending of compo- nents and devices It is extremely dangerous to work under raised or next to retracted WARNING components and devices. Always secure the tractor to prevent it from rolling away. Re- move the ignition key and secure the tractor to prevent it from being started up by unauthorised persons. -

Page 89: Environmental Protection

Maintenance and repairs Risk of accident due to tool slipping off If applying a large force, e.g. when loosening bolts, the tool may WARNING slip off. This may result in hand injuries on sharp-edged parts. Avoid applying a large force by using suitable auxiliary equip- ment (e.g. -

Page 90: Daily Check

Replace damaged or defective hydraulic hoses im- mediately. The hydraulic hoses must be replaced 6 years after the date of manufacture at the latest. Only used hydraulic hoses approved by Lemken. Check that all safety equipment is functioning pro- Safety equipment perly. -

Page 91: Oil Changing

Maintenance and repairs Risk of accident from spurting hydraulic fluid Fluid (hydraulic fluid) which escapes under high pressure may WARNING penetrate your skin and cause severe injuries. If injuries occur, call a doctor immediately. When searching for leaks, use suitable aids to prevent eye inju- ries. - Page 92 Maintenance and repairs Lubricants Only the following lubricants may be used: 3 l mineral oil Mobilube HD 85W-140 (Mobil) BP Energear FE SAE 80W-140 (BP) Deagear EP-C SAE 85W-140 (DEA) Shell Spirax HD 85W-140 (SHELLl)

-

Page 93: Change Gear Train

Maintenance and repairs 15.5.2 Change gear train Gearbox Filling opening with oil-level gauge Vent screw Drain screw Lubricants Only the following lubricants may be used: 2.2 l mineral oil Mobilube HD 85W-140 (Mobil) BP Energear FE SAE 80W-140 (BP) Deagear EP-C SAE 85W-140 (DEA) Shell Spirax HD 85W-140 (SHELLl) -

Page 94: Oil Change Intervals

Free-flowing grease The following quantities of free-flowing grease are to be adhered to when chan- ging it: Zirkon 8/250 18 l Olit 00 (BP) Zirkon 8/300 22 l Olit 00 (BP) - Page 95 Maintenance and repairs Pay attention to cleanliness when changing the free-flowing grease. Dis- pose of drained free-flowing grease in proper manner. Do not mix free- flowing grease with other greases! CAUTION Before checking the oil level and the free-flowing grease level, switch off the power takeoff shaft, switch off the tractor engine and remove the ignition key!

-

Page 96: Lubrication

Maintenance and repairs 15.7 Lubrication The lubricating points must be lubricated in accordance with the maintenance chart using universal lubricating grease. Lubrication chart Every 25 Every 50 Before a winter After a winter break break Operating hours Track marker disk bea- ring (2x) Hydr. -

Page 97: Bolts

Maintenance and repairs 15.9 Bolts After the first few hours of use - but after eight hours of use at latest - all nuts and bolts must be tightened. After this, nuts and bolts must be checked after every 50 hours of operation to check that they are secure. -

Page 98: Tines

Maintenance and repairs 15.10 Tines Worn tines are to be replaced in good time. Risk of accident when implement lowered Performing work under raised components/implements or next to WARNING swivelled-in components/implements is life-threatening. Always secure the tractor against rolling away, remove the igni- tion key and and secure the tractor against any unauthorised start-up. -

Page 99: Hydraulic Hoses

Maintenance and repairs 15.13 Hydraulic hoses Check hydraulic hoses regularly. At least 6 years after the date stated on the hy- draulic hoses they must be changed. Porouse or defective hydraulic hoses must be changed immediately. Use hydraulic hoses only, which are accepted by Lem- ken! Important: Do not clean this implement with a Pressure Washer during the first 6 weeks. -

Page 100: Troubleshooting

Troubleshooting TROUBLESHOOTING Before carrying out troubleshooting, it is essential to ensure that CAUTION the implement is parked on the ground the power take-off and tractor engine are switched off the ignition key is removed. Only then can the fault be repaired. 16.1.1 General information Fault Cause... -

Page 101: Tips For Driving On Public Highways

- they may not be driven on public highways when mounted to the tractor. On the Zirkon 8/300 the side blades must be folded-in before being transported. For transportation on public highways the hydraulic excavation linkage must be completely raised and the shutoff valve (1) locked. -

Page 102: Technical Data

Technical data TECHNICAL DATA Working Weight kg Weight kg Transport Centre of gravity width Change gear Manual gear- width distance mm train Zirkon 8/250 Zirkon 8/300 Zirkon 8/350 Zirkon 1.015 1.036 8/400... -

Page 103: Noise, Airborne Sound

Noise, Airborne Sound NOISE, AIRBORNE SOUND The noise level of the implement does not exceed 70 dB (A) during work. NOTES As the version of equipment is depending from the order, the equipment of your implement and its description concerned may deviate in some cases. To ensure a continuously updating of the technical features, we reserve the right to modify the design, equipment and technique. -

Page 104: Index

Index INDEX Axle loads ......................23 Cardan shaft ......................50 Change in the direction of rotation of the rotors............ 61 Check Chains ....................... 40 Coupling ....................... 45 Coupling A-frame....................77 Coupling parts ...................... 76 DESIGN AND FUNCTION..................34 Feed discs ......................66 First use........................ - Page 105 Index Protective equipment.................... 67 Pusher ........................81 Pusher ........................82 Quick-coupling system ..................60 REPAIRS......................84 Rollers ........................73 Rotor speeds ......................55 Rotors ........................61 Scrapers ....................... 74 Seed drill....................... 76 Shear device......................72 Side blade......................62 Side blade extension .................... 65 Side blades......................

Need help?

Do you have a question about the Zirkon 8 and is the answer not in the manual?

Questions and answers