Table of Contents

Advertisement

Quick Links

.

Instruction Manual

Oil-free Scroll Vacuum Pump

GVSU-1000

This instruction manual includes very important warnings, cautions and operating

procedure in order to operate this pump safely and efficiently.

Be sure to read this instruction manual thoroughly and fully understand before

operation.

After reading it, store it in a convenient place for immediate and future reading.

※Before use, be sure to fill in the blank spaces below for future repair and after-service.

Serial No.

Who sold it to you

Purchase date

When you began

operation

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Anest Iwata GVSU-1000

- Page 1 Instruction Manual Oil-free Scroll Vacuum Pump GVSU-1000 This instruction manual includes very important warnings, cautions and operating procedure in order to operate this pump safely and efficiently. Be sure to read this instruction manual thoroughly and fully understand before operation.

-

Page 3: Important Information

Important information Be sure to read this instruction manual to understand how to operate equipment correctly. Only operators, who fully understand warnings, cautions and instructions, are to operate the equipment. Improper operation (mishandling) can cause serious bodily injury, death, fire or explosion. Store this manual in a convenient place for immediate and future reference. -

Page 4: For Safe Operation

If crane with sufficient allowable load moisture comes into and tact with the capacity (GVSU-1000 mass 170kgs) electric source connection, it can cause while paying attention to stability of fire or bodily injury due to short-circuit or Be careful about suspended load. - Page 5 For safe operation WARNING Danger of short-circuit and Danger of short-circuit and electric shock electric shock Fit firmly proper round type crimp-style Be sure to fit cable gland to hole of PG 16 terminal to electric source cable using at motor terminal box. crimp tool and connect to motor terminal Protect cable If not, it can cause short-circuit fire or...

- Page 6 For safe operation CAUTION Danger of overheating Danger of overheating Install in a well-ventilated area. Poor ventilation Operate at ambient temperature of 5℃ can disrupt cooling and cause accident, failure ~40℃. or bodily injury such as burns since this Operating at a temperature range other vacuum pump is an air-cooled type.

- Page 7 For safe operation CAUTION Danger of vacuum break and Danger of abnormal sound and pollution failure Be sure to close isolation valve between Open inlet to atmosphere for about 5 vacuum pump and vacuum system seconds before restarting vacuum pump. (chamber) during start-up and stop.

- Page 8 Where to attach warning stickers here to attach warning stickers Always keep warning stickers clean and legible. If they become dirty or detached, replace them with new ones. If you need replacement stickers, contact the distributor from who you purchased your vacuum pump.

-

Page 9: Table Of Contents

Contents Important information ......................1 For safe operation ........................2 Contents............................7 1. Before use ..........................8 1.1 Check the product ......................8 2. Name and structure of each section ..................9 3. Installation ..........................10 3.1 Wiring ..........................12 3.2 Test operation ......................... -

Page 10: Before Use

1. Before use 1.1 Check the product ・Check that the package is right-side-up before opening. ・Check that the model of the product is the same as the one you ordered. How to read model name GVSU:model G V S U – 1 0 0 0 Displacement (swept volume) 1000:1000 L/min ・Check that there is no damage. -

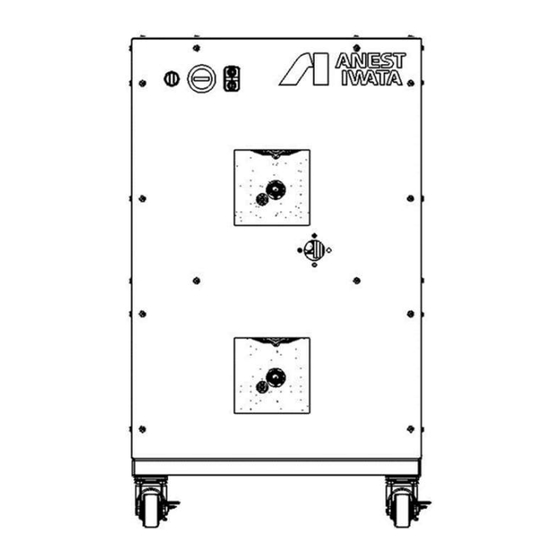

Page 11: Name And Structure Of Each Section

2. Name and structure of each section Selector Switch Hour meter On-Off switch Control Box Outlet Rc 1/2 Inlet Rc 1 Vacuum pump x2 Casters Electrical cable port Fixed Scroll FS Orbiting Scroll OS Housing Connected Flange Motor Inlet Outlet Back-up Material P-seal Structure of vacuum pump... -

Page 12: Installation

3. Installation WARNING Danger of electric shock Install in an area which is not exposed to moisture such as rain or steam. If moisture comes into and tact with the electric source connection, it can cause fire or Avoid moisture bodily injury due to short-circuit or electric shock. - Page 13 Installation space For the maintenance, keep the space as below drawing around vacuum pump. Over 60 cm Over 50 cm Over 50 cm Over 50 cm -11-...

-

Page 14: Wiring

Important When building vacuum pump into vacuum system, pay attention to space for maintenance, ambient temperature and piping. Be sure to fix vacuum pump on solid and level floor. If you have any questions, contact our distributor from who you purchased your vacuum pump. 3.1 Wiring WARNING Danger of short-circuit and electric shock... - Page 15 CAUTION Motor burnout Please check electric source and voltage before wiring Terminal block. The motor specification is three-phased AC460V (60Hz). Other related parts have single voltage. Connection alteration inside motor, improper wiring to motor and Check voltage application of incorrect voltage can cause breakdown such as motor burnout. Danger of problem recurrence and failure If protective device activates, be sure to turn off electric source and inspect causes to solve the problem.

-

Page 16: Test Operation

3.2 Test operation CAUTION Danger of cap to fly Remove cap from inlet If the rotation of the vacuum pump is opposite, operation with cap being fitted can cause cap to fly by exhaust impetus, resulting in accident, failure, or bodily injury from contact Remove cap with flying objects. - Page 17 ③ Check pump’s rotation direction Check that cooling fan is turning and cooling air is flowing in that direction as indicated. Outlet of cooling air Inlet of cooling fan Important Vacuum pump turns counter-clockwise when viewed from motor side. Check that air comes out from water separator & silencer-mounted rubber hose. If air does not come out from rubber hose, stop vacuum pump, turn off electrical source and change 2 out of 3 wires of electrical source connection.

-

Page 18: Connection To Vacuum System (Chamber)

But if pipe length becomes longer, use a larger size exhaust pipe. Make sure that exhaust piping is not clogged during pump operation. Make sure that pressure at outlet does not exceed atmospheric pressure at any conditions. Leak valve Chamber Vacuum pump Outlet duct Inlet Outlet Isolation valve GVSU-1000 -16-... -

Page 19: Operation

4. Operation Be sure to use the procedure below to start up or shut down the pump. ・When you do not use air-flush device, proceed 4.1 Standard operation [page 19]. ・When you use air-flush device, proceed 5.1 Air-flush operation [page 20]. WARNING Danger of explosion and ignition Do not evacuate gas which is hazardous to humans or explosive, flammable, or... - Page 20 Danger of failure and bodily injury Change air-flush port only after vacuum pump is stopped. If you change it during vacuum pump operation, it can cause vacuum pump failure and Change after vacuum bodily injury. pump is stopped CAUTION Danger of vacuum break and pollution Be sure to close isolation valve between vacuum pump and vacuum system (chamber) during start-up and stop.

-

Page 21: Standard Operation

4.1 Standard operation 4.1.1 Start-up ① Check that cap of inlet is removed. ② Close isolation valve in order to prevent the drawback of debris attached to the inside of vacuum pump into vacuum chamber due to pressure differential, resulting in vacuum break and pollution. -

Page 22: Air-Flush Operation

5. Option 5.1 Air-flush operation Air-flush operation requires on optional vapor handling set. This pump is equipped with air-flush port. Before evacuating vapor, read precautions below completely and be sure to understand the contents. Purpose of air-flush Evacuating moisture or humid gas by vacuum pump can cause condensed water to remain in pump. This remaining water can cause failure of ultimate pressure or pump. -

Page 23: Preparation

5.1.1 Preparation Before starting air-flush operation, first stop vacuum pump and proceed in accordance with the following procedure. Never try to do air-flush operation during operation. Fit air-muffler ① Stop vacuum pump. ② Remove water separator & silencer from outlet. ③... -

Page 24: When Returning To Standard Operation

5.1.3 When returning to standard operation Before starting air-flush operation, first stop vacuum pump and proceed in accordance with the following procedure. Never perform this procedure during operation. Remove air-muffler ① Stop vacuum pump. ② Remove water separator & silencer from outlet. ③... -

Page 25: Maintenance And Inspection

6. Maintenance and inspection WARNING Danger of failure and bodily injury Conduct periodical maintenance and inspection. If not, it can cause insufficient performance, failure of vacuum pump, and bodily injury. Conduct periodical maintenance and inspection Danger of burns Conduct maintenance and inspection only after vacuum pump becomes cool enough. -

Page 26: Daily Maintenance And Inspection

6.1 Daily maintenance and inspection Conduct the following daily maintenance and inspection. Items Contents Measures Abnormal sound Ask specialist to repair. Abnormal vibration Ask specialist to repair. Vacuum pump itself Abnormal temperature Ask specialist to repair. Cooling fins are dirty or clogged Blowing air, cleaning Smooth turning Ask specialist to repair. -

Page 27: Maintenance

6.2 Maintenance When maintenance interval has elapsed, be sure to contact our distributor who sold it to you. This vacuum pump requires maintenance conducted only by our authorized specialist. Never try to disassemble, reassemble or alter on user’s side. We are not responsible for any accidents caused by disassembly, reassembly or alteration which was done by the user or non-specialist. -

Page 28: Problems And Remedies

7. Problems and remedies If something goes wrong, refer to the following chart and remedy problems. If you cannot solve your problems, please contact our distributor who sold it to you. Problems Causes Remedies Protective device (or breaker) ※Inspect and repair. activates. -

Page 29: Disposal

8. Disposal When a vacuum pump is disposed, please comply with local law and/or regulations such as the Waste Disposal Low. 9. Specifications 9.1 Specifications Item GVSU-1000 Pump model GVSU-500B x 2 Back-up material Silicon rubber 37.0 Displacement at 60Hz... -

Page 30: Dimensions

9.2 Dimensions 9.3 Performance data -28-... -

Page 31: Warranty

Initial period of warranty – Parts and Labor. Anest Iwata Air Engineering warrants and represents all products shall be free from defects for the first twelve (12) months from the date of shipment by Anest Iwata Air Engineering, or eight thousand (8,000) hours of use, whichever occurs first. - Page 32 ANEST IWATA Air Engineering, Inc. Manufacturer 9525 Glades Drive West Chester, Ohio 45069 U.S.A. http://anestiwata.com/ Tel: 513-755-5130 Fax: 513-755-1889...

Need help?

Do you have a question about the GVSU-1000 and is the answer not in the manual?

Questions and answers