Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Summary of Contents for Farm King RP2

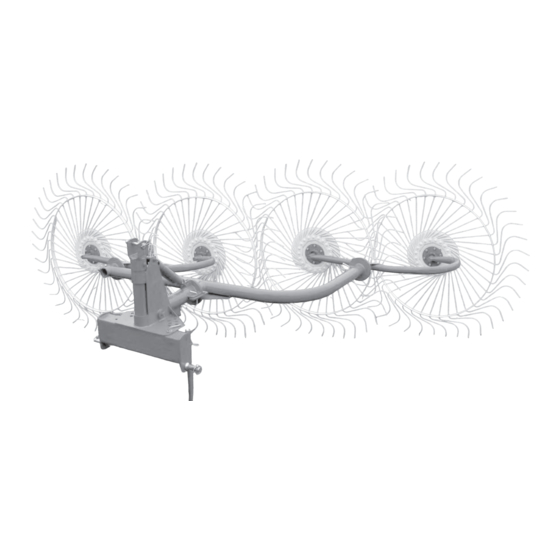

- Page 1 OPERATOR AND PARTS MANUAL Wheel Rake Model RP2, RP4, RP5 112023 FK450...

-

Page 3: Table Of Contents

RP2, RP4, RP5 Wheel Rake Table Of Contents Manufacturer’s Statement: For technical reasons, Buhler Industries Inc. reserves the right to modify machinery design and specifications provided herein without any preliminary notice. Information provided herein is of descriptive nature. Performance quality may depend on soil fertility, applied agricultural techniques, weather conditions, and other factors. - Page 4 RP2, RP4, RP5 Wheel Rake Specifications And Shipping Kit Numbers Specifications Shipping Kit And Bundle Numbers Hardware Torque Values Warranty Farm King Base Limited Warranty...

-

Page 5: Warranty Registration Form

Customer / Owner Signature: Remove this Warranty Registration Form from the Operator And Parts Manual. Make two copies of the form. Send original Warranty Registration Form to Farm King. Give one copy to the customer and the dealer will keep one copy. - Page 6 Warranty Registration Form - RP2, RP4, RP5 Wheel Rake...

-

Page 7: Introduction

Farm King equipment. READ AND UNDERSTAND THIS OPERATOR AND PARTS MANUAL BEFORE OPERATING YOUR FARM KING EQUIPMENT. If you have any questions, see your Farm King dealer. This manual may illustrate options and accessories not installed on your Farm King equipment. - Page 8 Introduction - RP2, RP4, RP5 Wheel Rake...

- Page 9 Introduction - RP2, RP4, RP5 Wheel Rake Owner’s Information Serial Number Location Please enter the model and serial number in the Thank you for your decision to purchase a Farm space provided for easy reference. King Hay Rake. To ensure maximum performance...

-

Page 10: Equipment Identification

Introduction - RP2, RP4, RP5 Wheel Rake Equipment Identification RAKE TINES RAKE SHOCK ABSORBING UPPER THREE-POINT WHEEL SPRING MOUNT PIVOT FRAME FIXED FRAME LOCKING PINS RAKE ARM AND HUB LOWER THREE-POINT STAND MOUNT RP4 HAY RAKE PICTURED... -

Page 11: Safety

Safety - RP2, RP4, RP5 Wheel Rake Safety Safety Instructions Safety Symbols Operator Safety Safety Rules Equipment Safety Transport Safety Fire Prevention Maintenance Operation Starting Electrical Hydraulic System Fueling Welding And Grinding Fire Extinguishers Equipment and Safety Decals Safety Sign-Off Form... - Page 12 Safety - RP2, RP4, RP5 Wheel Rake...

-

Page 13: Safety Symbols

• The written instructions from Farm King include the or moderate injury. It may also be used to alert Warranty Registration, Dealer Inspection Report, against unsafe practices. -

Page 14: Safety Rules

Safety - RP2, RP4, RP5 Wheel Rake Safety Rules Equipment Safety • Read and follow instructions in this manual and the • Be aware of hooking or entanglement. With the tractor’s Operators Manual before operating. rotating of the raked wheels, the teeth may hook on to clothes or other objects worn by personnel in •... -

Page 15: Transport Safety

Safety - RP2, RP4, RP5 Wheel Rake Transport Safety • Do not exceed 20 mph (32 kph) during road transportation. Reduce speed on rough roads and surfaces. • Comply with state and local laws governing highway safety and movement of machinery on public roads. -

Page 16: Fire Prevention

Fueling components can cause a fire. Operation • The Farm King machine must be in good operating condition before use. • Check all of the items listed on the service schedule • Stop the engine and let it cool before adding fuel. No... -

Page 17: Welding And Grinding

Safety - RP2, RP4, RP5 Wheel Rake Welding And Grinding • Always clean the machine and equipment, disconnect the battery, and disconnect the wiring from the machine controls before welding. Cover rubber hoses, battery and all other flammable parts. Keep a fire extinguisher near the machine when welding. -

Page 18: Equipment And Safety Decals

Safety - RP2, RP4, RP5 Wheel Rake Equipment and Safety Decals Figure 2 Farm King logo (not pictured) Decals [Figure 2]: Dange of hooking or entanglement (Item 1) • With the rotating of the rake wheels, the rake tines may hook on to clothes or other objects worn by personnel in charge. -

Page 19: Safety Sign-Off Form

Untrained operators and failure to follow instructions can cause injury or death. Farm King follows the general Safety Standards specified by the American Society of Agricultural and Biological Engineers (ASABE) and the Occupational Safety and Health Administration (OSHA). Anyone who will be operating and / or maintaining the equipment must read and clearly understand ALL Safety, Operating and Maintenance information presented in this manual. - Page 20 Safety - RP2, RP4, RP5 Wheel Rake...

-

Page 21: Operation

Operation - RP2, RP4, RP5 Wheel Rake Operation Pre - Operation Checklist Entering The Operator’s Position Leaving The Operator’s Position Tractor Requirements Connecting To Tractor Work Configuration Field Operation Adjustments Collect Method Spread Method Turn Method Transport Configuration... - Page 22 Operation - RP2, RP4, RP5 Wheel Rake...

- Page 23 Operation - RP2, RP4, RP5 Wheel Rake Pre - Operation Checklist Entering The Operator’s Position Before operating the Rake for the first time and Enter the operator’s position, start the engine, and each time thereafter, check the following items: release the parking brake.

-

Page 24: Connecting To Tractor

Operation - RP2, RP4, RP5 Wheel Rake Connecting To Tractor Figure 3 Always inspect the tractor’s hitch and equipment’s hitch before connecting. Move the tractor drawbar into the storage position or remove (if necessary) to prevent interference with operation (see the tractor’s operator’s manual for the correct procedure). - Page 25 Operation - RP2, RP4, RP5 Wheel Rake The equipment can be leveled front to back by adjusting the top link (see the tractor’s operator’s manual for the correct procedure). Adjust the lower link sway chains or blocks on the tractor to restrict side movement of the equipment when operating.

-

Page 26: Work Configuration

Operation - RP2, RP4, RP5 Wheel Rake Work Configuration Figure 5 Transport the equipment to the area of work (see ARM LOCKING “Transport Configuration” in Operation section). DEVICE Always comply with federal, state, local and provincial laws regarding the transport of farm equipment on pubic roadways. - Page 27 Operation - RP2, RP4, RP5 Wheel Rake Use the tractor hydraulic lift to lower the rake until IMPORTANT the rake wheels slightly contact the ground. Figure 6 Releasing the frame lock will allow the rake frame to tilt upwards (against the springs) following the profile of the terrain.

-

Page 28: Field Operation

Operation - RP2, RP4, RP5 Wheel Rake Field Operation Figure 8 Make sure the tractor is properly connected to the equipment. See “Connecting To Tractor” in UNCLEARED Operation Section. GROUND DIRECTION Enter the operator’s position. See “Entering The OF TRAVEL Operator’s Position”... -

Page 29: Adjustments

Operation - RP2, RP4, RP5 Wheel Rake Adjustments The working width for each collection method can be adjusted by changing the rake wheel angle. There are three methods of material collection Rotate the pivot frame left or right in relation to the including: fixed frame [Figure 9]. -

Page 30: Spread Method

Operation - RP2, RP4, RP5 Wheel Rake Spread Method Turn Method Figure 11 Figure 12 UNCLEARED UNCLEARED GROUND GROUND DIRECTION DIRECTION OF TRAVEL OF TRAVEL COLLECTED COLLECTED MATERIAL MATERIAL (WINDROW) (WINDROW) Spread Method: The main arm is angled opposite Turn Method: Rake arms are all angled in the... -

Page 31: Transport Configuration

Operation - RP2, RP4, RP5 Wheel Rake Transport Configuration Figure 13 Always comply with federal, state, local and provincial laws regarding the transport of farm equipment on pubic roadways. Verify that the tractor / tow vehicle is approved for PIVOT... - Page 32 Operation - RP2, RP4, RP5 Wheel Rake Figure 14 Figure 15 TRANSPORT ARM LOCKING MODE DEVICE The arm locking devices are released by removing the pin (Item 1) and removing the locking bracket Release the locking device (Item 1) on the hitch and (Item 2) [Figure 15].

- Page 33 Operation - RP2, RP4, RP5 Wheel Rake Figure 16 Figure 17 TRANSPORT MODE 12 - 16 in. (30 - 40 cm) FRAME LOCKING DEVICE Use the tractor hydraulic lift to raise the rake until the lowest point is twelve to sixteen inches off the ground [Figure 16].

- Page 34 Operation - RP2, RP4, RP5 Wheel Rake...

-

Page 35: Maintenance

Maintenance - RP2, RP4, RP5 Wheel Rake Maintenance Service Schedule Chart Lubrication Recommendations Locations Rake Wheels Storage And Return To Service Storage Return To Service Decal Installation... - Page 36 Maintenance - RP2, RP4, RP5 Wheel Rake...

- Page 37 Maintenance - RP2, RP4, RP5 Wheel Rake Service Schedule Chart WARNING Instructions are necessary before operating or servicing equipment. Read and understand the Operator And Parts Manual and safety signs (decals) on equipment. Follow warnings and instructions in the manuals when making repairs, adjustments or servicing. Check for correct function after adjustments, repairs or service.

-

Page 38: Lubrication

Maintenance - RP2, RP4, RP5 Wheel Rake Lubrication Locations Recommendations IMPORTANT Always use a good quality multi-purpose / lithium base grease when lubricating the equipment. Fluid such engine oil, hydraulic fluid, • Always use a hand-held grease gun. coolants, grease, etc. must be disposed of in an •... - Page 39 Maintenance - RP2, RP4, RP5 Wheel Rake Figure 19 Apply two to three pumps of grease to all lubrication points. Repeat for multiple locations of each component [Figure 19]: • Rake wheel hubs (Item 1) Grease daily (or every 8 hours of use).

-

Page 40: Rake Wheels

Maintenance - RP2, RP4, RP5 Wheel Rake Rake Wheels Periodically check all rake tines for wear or damage. Figure 20 DIRECTION OF TRAVEL DIRECTION OF ROTATION Rake Wheels Remove the M10 x 25 mm hex bolts (Item 1), 10 mm washers, and M10 nuts from the rake wheel. -

Page 41: Storage And Return To Service

Maintenance - RP2, RP4, RP5 Wheel Rake Storage And Return To Service Return To Service After the equipment has been in storage, it is Storage necessary to follow a list of items to return the Sometimes it may be necessary to store the equipment to service. - Page 42 Maintenance - RP2, RP4, RP5 Wheel Rake...

-

Page 43: Parts Identification

Parts Identification - RP2, RP4, RP5 Wheel Rake Parts Identification Always give your dealer the Model, Color and Serial Number of your machine to assist them in ordering and obtaining the correct parts. Use the exploded view and tabular listing of the area of interest to exactly identify the required part. - Page 44 Parts Identification - RP2, RP4, RP5 Wheel Rake...

-

Page 45: Hitch, Arm - Rp2

Parts Identification - RP2, RP4, RP5 Wheel Rake Hitch, Arm - RP2 ITEM PART NUMBER DESCRIPTION QTY. R17011102 JACK R17012201 3 POINT HITCH R17010405 ARM CARRIER R12120503 PIN Ø12 L.125 R3040201 CLIP PIN 3X60 R17010801 ARM WITH HUB R3011615 SCREW TE M14X40 R3030610 WASHER Ø18... -

Page 46: Hitch - Rp4, Rp5

Parts Identification - RP2, RP4, RP5 Wheel Rake Hitch - RP4, RP5... - Page 47 Parts Identification - RP2, RP4, RP5 Wheel Rake ITEM PART NUMBER DESCRIPTION QTY. R18030417 BASE R3020319 NUT M14 R3030610 WASHER Ø18 R18030451 R3040201 SPLIT PIN 3X60 R18033298 PIN 3° P R3010221 SCREW TE M14X100 R18033268 R18030418 FRAME HOLDERS HITCH R3030115 WASHER Ø24...

-

Page 48: Arms - Rp4, Rp5

Parts Identification - RP2, RP4, RP5 Wheel Rake Arms - RP4, RP5 FIVE WHEEL RAKE FOUR WHEEL RAKE... - Page 49 Parts Identification - RP2, RP4, RP5 Wheel Rake ITEM PART NUMBER DESCRIPTION QTY. R17011401 FOUR WHEEL RAKE FRAME R12120503 PIN Ø12 R3040201 SPLIT PIN 3X60 R18030404 RIGHT WHEEL ARM R18033283 LEFT WHEEL ARM R18031198 FIVE WHEEL RAKE FRAME R3011260 SCREW TE M10X35 R3020201 SELF-LOCKING NUT.

-

Page 50: Rake Wheels

Parts Identification - RP2, RP4, RP5 Wheel Rake Rake Wheels... - Page 51 Parts Identification - RP2, RP4, RP5 Wheel Rake ITEM PART NUMBER DESCRIPTION QTY. R12860001 CORTECO 52X25 R12240119 BEARING 30205 R3020328 NUT M10 R3090101 GREASE M8X1 R3030227 WASHER Ø10 R12150103 R3011209 SCREW TE M10X25 R12240118 BEARING 30204 R3020210 NUT SLOTTED M18X1.5...

- Page 52 Parts Identification - RP2, RP4, RP5 Wheel Rake...

- Page 53 Specifications And Shipping Kit Numbers - RP2, RP4, RP5 Wheel Rake Specifications And Shipping Kit Numbers Specifications Shipping Kit And Bundle Numbers Hardware Torque Values Metric Chart Imperial Chart...

- Page 54 Specifications And Shipping Kit Numbers - RP2, RP4, RP5 Wheel Rake...

-

Page 55: Specifications

Specifications And Shipping Kit Numbers - RP2, RP4, RP5 Wheel Rake Specifications MODEL RRP2 RRP4 RRP5 Rake Wheels Working Width 52” (131 cm) 102” (260 cm) 134” (340 cm) Transport Width 91” (230 cm) 93” (235 cm) 93” (235 cm) -

Page 56: Hardware Torque Values

Specifications And Shipping Kit Numbers - RP2, RP4, RP5 Wheel Rake Hardware Torque Values Metric Chart NOTE: Do not use the values listed in the charts if a different torque value or tightening procedure is specified in this manual for a specific application. Torque values listed are for general use only. -

Page 57: Imperial Chart

Specifications And Shipping Kit Numbers - RP2, RP4, RP5 Wheel Rake Hardware Torque Values (Cont’d) Imperial Chart NOTE: Do not use the values listed in the charts if a different torque value or tightening procedure is specified in this manual for a specific application. Torque values listed are for general use only. - Page 58 Specifications And Shipping Kit Numbers - RP2, RP4, RP5 Wheel Rake...

- Page 59 Warranty - RP2, RP4, RP5 Wheel Rake Warranty Farm King Base Limited Warranty Repair Parts Limited Warranty What Is Not Covered Authorized Dealer And Labor Costs Warranty Requirements EXCLUSIVE EFFECT OF WARRANTY AND LIMITATION OF LIABILITY...

- Page 60 Warranty - RP2, RP4, RP5 Wheel Rake...

- Page 61 If Farm King determines that it will pay labor costs for warranty work, it will do so by issuing a credit to the dealer’s or distributor’s account.

- Page 62 Corrections of defects and improper workmanship in the manner, and for the applicable time periods, provided for herein shall constitute fulfillment of all responsibilities of Farm King to the purchaser, and Farm King shall not be liable in negligence, contract, or on any other basis with respect to the subject equipment.

- Page 64 www.farm-king.com 1260 Clarence Avenue Winnipeg MB, R3T 1T2 Ph.: 204.661.8711 | Fax: 204.654.2503 E-mail: info@buhler.com www.farm-king.com Equipment shown is subject to change without notice. ©2023 Buhler Trading Inc. Printed in Canada TSX:BUI a division of Buhler Industries Inc.

Need help?

Do you have a question about the RP2 and is the answer not in the manual?

Questions and answers