Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Farm King TVR12

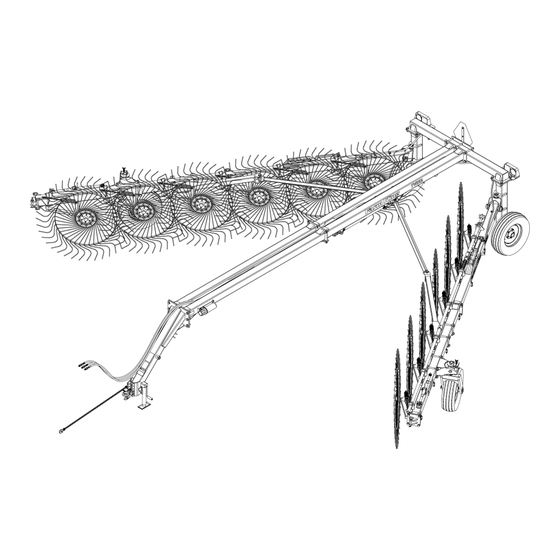

- Page 1 OPERATOR AND PARTS MANUAL Trailing V-Rake Model TVR12, TVR14, TVR16 022020 FK430...

-

Page 3: Table Of Contents

TVR12, TVR14, TVR16 V-Rake Table Of Contents Manufacturer’s Statement: For technical reasons, Buhler Industries Inc. reserves the right to modify machinery design and specifications provided herein without any preliminary notice. Information provided herein is of descriptive nature. Performance quality may depend on soil fertility, applied agricultural techniques, weather conditions, and other factors. - Page 4 Axle Axle Wheel Hub Frame - TVR12 Frame - TVR14 Frame - TVR16 Rake Wheels & Lift Arms - TVR12 Rake Wheels & Lift Arms - TVR14 Rake Wheels & Lift Arms - TVR16 Frame Underside Hitch Hydraulic Cylinders & Hoses...

-

Page 5: Warranty Registration Form

Customer / Owner Signature: Remove this Warranty Registration Form from the Operator And Parts Manual. Make two copies of the form. Send original Warranty Registration Form to Farm King. Give one copy to the customer and the dealer will keep one copy. - Page 6 Warranty Registration Form - TVR12, TVR14, TVR16 V-Rake...

-

Page 7: Introduction

Farm King equipment. READ AND UNDERSTAND THIS OPERATOR AND PARTS MANUAL BEFORE OPERATING YOUR FARM KING EQUIPMENT. If you have any questions, see your Farm King dealer. This manual may illustrate options and accessories not installed on your Farm King equipment. - Page 8 Introduction - TVR12, TVR14, TVR16 V-Rake...

- Page 9 Model Number: and maintenance procedures. Serial Number: Farm King is continually working to improve its products. Farm King reserves the right to make The serial number plate (Item 1) and manual any improvements or changes as deemed practical...

-

Page 10: Equipment Identification

Introduction - TVR12, TVR14, TVR16 V-Rake Equipment Identification LIGHTS AXLE RAKE REAR WHEEL WHEEL HYDRAULIC WING CYLINDER CLOSURE HYDRAULIC CYLINDER HITCH WING SUPPORT WHEEL LOCK JACK SUPPORT WHEEL... -

Page 11: Safety

Safety - TVR12, TVR14, TVR16 V-Rake Safety Safety Instructions Guidelines Use Safety Rules Machine Requirements And Capabilities Transport Safety Fire Prevention Maintenance Operation Starting Electrical Hydraulic System Fueling Welding And Grinding Fire Extinguishers Equipment and Safety Decals Safety Sign-Off Form... - Page 12 Safety - TVR12, TVR14, TVR16 V-Rake...

-

Page 13: Guidelines

Understand the written instructions, rules and regulations: The signal word CAUTION on the machine and • The written instructions from Farm King include the in the manuals indicates a potentially hazardous Warranty Registration, Dealer Inspection Report, situation which, if not avoided, may result in minor Operator And Parts Manual and machine signs or moderate injury. -

Page 14: Use Safety Rules

Safety - TVR12, TVR14, TVR16 V-Rake Use Safety Rules Machine Requirements And Capabilities • Read and follow instructions in this manual and the • Fasten seat belt securely. If equipped with a folding tractor’s Operators Manual before operating. Roll-Over Protective Structure (ROPS), only fasten seat belt when ROPS is up and locked. -

Page 15: Transport Safety

Safety - TVR12, TVR14, TVR16 V-Rake Transport Safety • Do not exceed 20 mph (32 kph). Reduce speed on rough roads and surfaces. • Comply with state and local laws governing highway safety and movement of machinery on public roads. -

Page 16: Fire Prevention

Fueling components can cause a fire. Operation • The Farm King machine must be in good operating condition before use. • Check all of the items listed on the service schedule • Stop the engine and let it cool before adding fuel. No... -

Page 17: Welding And Grinding

Safety - TVR12, TVR14, TVR16 V-Rake Welding And Grinding • Always clean the machine and equipment, disconnect the battery, and disconnect the wiring from the machine controls before welding. Cover rubber hoses, battery and all other flammable parts. Keep a fire extinguisher near the machine when welding. -

Page 18: Equipment And Safety Decals

Safety - TVR12, TVR14, TVR16 V-Rake Equipment and Safety Decals Figure 2... - Page 19 Safety - TVR12, TVR14, TVR16 V-Rake Decal Identification [Figure 2] 105420 DECAL-REFERENCE PLATE BUHLER S/N (Item 4) 918280 DECAL-WARNING HIGH PRESSURE FLUID (Item 1) WARNING HIGH PRESSURE FLUID CAN PIERCE SKIN CAUSING SERIOUS INJURY OR DEATH -Relieve pressure on system before repairing or adjusting.

- Page 20 Safety - TVR12, TVR14, TVR16 V-Rake 821281 DECAL-TVR14 WHITE (Item 8) 821282 DECAL-TVR16 WHITE (Item 8) 967053 DECAL-REFLECTIVE 2 X 9 RED (Item 9) 967066 SLOW MOVING VEHICLE SIGN (Item 10)

-

Page 21: Safety Sign-Off Form

Untrained operators and failure to follow instructions can cause injury or death. Farm King follows the general Safety Standards specified by the American Society of Agricultural and Biological Engineers (ASABE) and the Occupational Safety and Health Administration (OSHA). Anyone who will be operating and / or maintaining the equipment must read and clearly understand ALL Safety, Operating and Maintenance information presented in this manual. - Page 22 Safety - TVR12, TVR14, TVR16 V-Rake...

-

Page 23: Assembly

Assembly - TVR12, TVR14, TVR16 V-Rake Assembly Component Unloading And Identification Main Frame TVR12 Models TVR14 Models TVR16 Models Hitch Rear Frame Wing Closure Arms & Hydraulic Cylinder Rear Axle Wheels Support Wheels Lift Tubes TVR12 Models TVR14 Models TVR16 Models Rake Arms &... - Page 24 Assembly - TVR12, TVR14, TVR16 V-Rake...

- Page 25 Assembly - TVR12, TVR14, TVR16 V-Rake Component Unloading And Unload the crate(s) and components on a flat level area of adequate size to assemble the equipment. Identification IMPORTANT WARNING Unload crate(s) and other components carefully to prevent damage to any of the components.

-

Page 26: Main Frame

Assembly - TVR12, TVR14, TVR16 V-Rake Main Frame TVR14 Models Figure 4 TVR12 Models Figure 3 TVR12 TVR14 Assemble the wing frame components. Attach each connection using four 3/4” x 2-1/4” hex bolts, eight 3/4” flat washers (both sides), and four 3/4”... -

Page 27: Tvr16 Models

Assembly - TVR12, TVR14, TVR16 V-Rake Assemble the center frame components. Attach NOTE: The clevis plates (Item 11, 12) must angle each connection using six 3/4” x 2-1/4” hex bolts, UP towards the hitch. twelve 3/4” flat washers (both sides), and six 3/4”... -

Page 28: Hitch

Assembly - TVR12, TVR14, TVR16 V-Rake Hitch Rear Frame Figure 6 Figure 8 FRONT Attach the hitch base (Item 1) to the hitch clevis (Item 2) using one 1/2” x 4-1/2” hex bolt (Item 3) and 1/2” lock nut [Figure 6]. - Page 29 Assembly - TVR12, TVR14, TVR16 V-Rake Figure 9 Figure 10 FRONT FRONT Position the mounting plates of the LH (Item 1) and RH (Item 2) light assemblies on top of the brackets Position the LH (Item 1) and RH (Item 2) wing of the rear axle (Item 3) [Figure 9].

-

Page 30: Wing Closure Arms & Hydraulic Cylinder

Assembly - TVR12, TVR14, TVR16 V-Rake Wing Closure Arms & Hydraulic Figure 12 Cylinder Figure 11 FRONT UNDERSIDE OF MAIN FRAME FRONT Attach the rod end of the 3” x 36-1/2” cylinder (Item 1) to the 7” bolt of the slide link (Item 2) using one 1-1/4”... -

Page 31: Rear Axle Wheels

Assembly - TVR12, TVR14, TVR16 V-Rake Rear Axle Wheels Figure 13 Figure 14 FRONT Position the LH closure arm (Item 1) on the LH wing, forward of the brackets (Item 2) [Figure 13]. Position the wheel hub (Item 1) on the rear spindle Attach the LH closure arm (Item 1) to the LH wing (Item 2). -

Page 32: Support Wheels

Place two bushings (Item 1) on either end of the wheel HAC520-6 hub (Item 2). Place the hub within • TVR12, two support wheels (Item 1) the wheel assembly (Item 3). Attach the hub using • TVR14 , four support wheels (Item 2) five wheel nuts [Figure 17]. - Page 33 Assembly - TVR12, TVR14, TVR16 V-Rake Figure 18 Figure 20 Pass the support wheel axle (Item 1) through the hub, bushings, and yoke. Attach the axle to the yoke using one 1/2”-13NC x 2.125” hex bolt (Item 2), two 1/2” flat washers, and one 1/2” lock nut [Figure 18].

-

Page 34: Lift Tubes

Assembly - TVR12, TVR14, TVR16 V-Rake Lift Tubes Attach the pin connector (Item 4) to the lift tube using two 1/2” x 3” hex bolts and two 1/2” lock Figure 21 nuts [Figure 23]. The pin hole (Item 5) of the lift tube should be just ahead of the wing mount (Item 2) [Figure 23]. -

Page 35: Tvr12 Models

Assembly - TVR12, TVR14, TVR16 V-Rake TVR12 Models Figure 24 TVR12 Slide the lift tubes through the mounts on the wings [Figure 24]: • Rear lift tube (Item 1) • Forward lift tube (Item 2) Attach the lift tubes using one connector (Item 3), two 5/16”... -

Page 36: Tvr14 Models

Assembly - TVR12, TVR14, TVR16 V-Rake TVR14 Models Figure 25 TVR14 Slide the lift tubes through the mounts on the wings [Figure 25]: • Rear lift tube (Item 1) • Forward lift tube (Item 2) • Lift tube extension (Item 3) Attach the lift tubes using one connector (Item 4), two 5/16”... -

Page 37: Tvr16 Models

Assembly - TVR12, TVR14, TVR16 V-Rake TVR16 Models Figure 26 TVR16 Slide the lift tubes through the mounts on the wings [Figure 26]: • Rear lift tube (Item 1) • Forward lift tube (Item 2) • Lift tube extension (Item 3) Attach the lift tubes using one connector (Item 4), two 5/16”... -

Page 38: Rake Arms & Wheels

Assembly - TVR12, TVR14, TVR16 V-Rake Rake Arms & Wheels Figure 29 Figure 27 Install one rake arm (Item 1) to the wing mount using one 1-1/4” ID x 18 GA narrow rim washer (Item 2) and cotter pin [Figure 27]. - Page 39 Assembly - TVR12, TVR14, TVR16 V-Rake Wire Routing Figure 31 Figure 33 RH LIGHT LIGHT MODULE LH LIGHT Install the chain to the quick link (Item 1). Install the rake arm to the mount (Item 2) [Figure 31]. Route the 62” wire harness (Item 1) between the Figure 32 LH and RH rear lights [Figure 33].

-

Page 40: Hydraulic Hose Routing & Components

Assembly - TVR12, TVR14, TVR16 V-Rake Hydraulic Hose Routing & Components RH WING LH WING FRONT... - Page 41 CYLINDER - 3.0 X 36.50 BALL END 821151 BREATHER - 3/8 NPT MALE STEEL 821298 HOSE - 0.375 X 335L -06 SWFJIC X -06 SWFJIC - TVR12 821295 HOSE - 0.375 X 410L -06 SWFJIC X -06 SWFJIC - TVR14 821294 HOSE - 0.375 X 440L -06 SWFJIC X -06 SWFJIC - TVR16...

- Page 42 Assembly - TVR12, TVR14, TVR16 V-Rake...

-

Page 43: Operation

Operation - TVR12, TVR14, TVR16 V-Rake Operation Pre - Operation Checklist Entering The Operator’s Position Leaving The Operator’s Position Tractor Requirements Connecting To Tractor Connecting Hydraulic Hoses Work Configuration Field Operation Adjustments Windrow Width Rake Wheel Height Leveling Transport Configuration... - Page 44 Operation - TVR12, TVR14, TVR16 V-Rake...

- Page 45 Operation - TVR12, TVR14, TVR16 V-Rake Pre - Operation Checklist Entering The Operator’s Position Before operating the V-Rake for the first time and Enter the operator’s position, start the engine, and each time thereafter, check the following items: release the parking brake.

-

Page 46: Connecting To Tractor

Operation - TVR12, TVR14, TVR16 V-Rake Connecting To Tractor WARNING Always inspect the tractor’s drawbar and equipment hitch before connecting. See the tractor’s owner’s manual. Verify that the tractor’s drawbar is adjusted correctly for use with the equipment. Enter the operator’s position and move the tractor into position in front of the equipment. -

Page 47: Connecting Hydraulic Hoses

Operation - TVR12, TVR14, TVR16 V-Rake Connecting Hydraulic Hoses WARNING V-Rakes are equipped with a hydraulic system to raise the rake wheels and extend the wings. AVOID BURNS Figure 37 Hydraulic fluid, tubes, fittings and quick couplers can get hot when running equipment. Be careful... -

Page 48: Work Configuration

Operation - TVR12, TVR14, TVR16 V-Rake Work Configuration Figure 39 Transport the equipment to the area of work (see “Transport Configuration” in Operation section). Always comply with federal, state, local and provincial laws regarding the transport of farm equipment on pubic roadways. - Page 49 Operation - TVR12, TVR14, TVR16 V-Rake Figure 41 Figure 42 WORK MODE Back off the nut (Item 1) to loosen the brake discs on the front pivot wheels. The pivot wheels should be able to rotate freely [Figure 41]. Do not remove nut entirely.

-

Page 50: Field Operation

Operation - TVR12, TVR14, TVR16 V-Rake Field Operation CAUTION Make sure the tractor is properly connected to the equipment. See “Connecting To Tractor” in Operation Section. • Read operator and parts manual before operating the implement. Enter the operator’s position. See “Entering The Operator’s Position”... - Page 51 Operation - TVR12, TVR14, TVR16 V-Rake Figure 43 The tractor and V-Rake must travel in a straight path while collecting material. Before the end of the field, raise the rake wheels. IMPORTANT MATERIAL Rake wheels must be fully raised off the ground before extending or retracting wings.

-

Page 52: Adjustments

Operation - TVR12, TVR14, TVR16 V-Rake Adjustments Leveling Figure 46 Windrow Width Figure 44 FRONT Connect the V-Rake to tractor. Adjust the windrow width by changing the rear Lower the jack (Item 1) until the entire weight of rake wheel mounts (Item 1) [Figure 44]: the hitch is supported [Figure 46]. -

Page 53: Transport Configuration

Operation - TVR12, TVR14, TVR16 V-Rake Transport Configuration Figure 47 Always comply with federal, state, local and WORK provincial laws regarding the transport of farm MODE equipment on pubic roadways. Verify that the tractor / tow vehicle is approved for... - Page 54 Operation - TVR12, TVR14, TVR16 V-Rake Figure 48 Figure 50 Remove the tie rods from the storage brackets (Item 1) on the wings. Install the tie rods (Item 2) to secure the wings to the hitch [Figure 48]. Figure 49 Install the transport locks (Item 1) to the rake lift cylinders [Figure 50].

-

Page 55: Maintenance

Maintenance - TVR12, TVR14, TVR16 V-Rake Maintenance Service Schedule Chart Lubrication Recommendations Locations Rake Wheels Rake Wheels / Tines Chain / Spring Storage And Return To Service Storage Return To Service Decal Installation... - Page 56 Maintenance - TVR12, TVR14, TVR16 V-Rake...

- Page 57 Maintenance - TVR12, TVR14, TVR16 V-Rake Service Schedule Chart WARNING Instructions are necessary before operating or servicing equipment. Read and understand the Operator And Parts Manual and safety signs (decals) on equipment. Follow warnings and instructions in the manuals when making repairs, adjustments or servicing. Check for correct function after adjustments, repairs or service.

- Page 58 Maintenance - TVR12, TVR14, TVR16 V-Rake Troubleshooting Chart Problem Cause Service Procedure Check hydraulic oil level. Fill Hydraulic oil level low. hydraulic oil as needed. Check all hoses and Damaged hydraulic hose or connections. Repair or replace loose connection. Hydraulic functions not as needed.

-

Page 59: Lubrication

Maintenance - TVR12, TVR14, TVR16 V-Rake Lubrication Locations Recommendations IMPORTANT Always use a good quality multi-purpose / lithium base grease when lubricating the equipment. Fluid such engine oil, hydraulic fluid, • Always use a hand-held grease gun. coolants, grease, etc. must be disposed of in an •... - Page 60 Maintenance - TVR12, TVR14, TVR16 V-Rake Figure 51 PIVOT WHEEL Apply two to three pumps of grease to all lubrication points. Repeat for multiple locations of each component [Figure 51]: • Wing Pivots (Item 1) • Rake Wheel Hubs (Item 2) •...

-

Page 61: Rake Wheels

Maintenance - TVR12, TVR14, TVR16 V-Rake Rake Wheels IMPORTANT Rake Wheels / Tines Periodically check all rake tines for wear or damage. Take note of tine orientation in regards to direction Figure 52 of rotation when replacing rake wheels or tines. - Page 62 Maintenance - TVR12, TVR14, TVR16 V-Rake Figure 55 FRONT Install one 0.313” x 2” eye bolt and quick link (Item 1) to the pre-drilled hole before the tube mount (Item 2) [Figure 55]. Figure 56 Install the chain to the quick link (Item 1) [Figure...

-

Page 63: Storage And Return To Service

Maintenance - TVR12, TVR14, TVR16 V-Rake Storage And Return To Service Return To Service After the equipment has been in storage, it is Storage necessary to follow a list of items to return the Sometimes it may be necessary to store the equipment to service. - Page 64 Maintenance - TVR12, TVR14, TVR16 V-Rake...

-

Page 65: Parts Identification

Parts Identification - TVR12, TVR14, TVR16 V-Rake Parts Identification Always give your dealer the Model, Color and Serial Number of your machine to assist them in ordering and obtaining the correct parts. Use the exploded view and tabular listing of the area of interest to exactly identify the required part. - Page 66 Parts Identification - TVR12, TVR14, TVR16 V-Rake...

- Page 67 Parts Identification - TVR12, TVR14, TVR16 V-Rake Support Wheel Yoke ITEM PART NUMBER DESCRIPTION QTY. 84048 1/2" SAE FLAT WASHER (PL) 812364 1/2" LOCK NUT (PL) 820704 WELDMENT - SUPPORT WHEEL AXLE 821128 PLATE - AXLE RETAINER 821129 PIN COTTER 0.25 X 2.75 PL 821130 BOLT HEX 0.50-13NC X 2.125 GR5PL...

-

Page 68: Support Wheel

Parts Identification - TVR12, TVR14, TVR16 V-Rake Support Wheel... - Page 69 Parts Identification - TVR12, TVR14, TVR16 V-Rake ITEM PART NUMBER DESCRIPTION QTY. 81628 1/2" X 3 1/4" HEX BOLT (PL) 84048 1/2" SAE FLAT WASHER (PL) 84050 3/4" S.A.E. FLAT WASHER (PL) 84583 SCREW IN GREASE FITTING 812365 3/4" LOCK NUT (PL) 813228 0.50"...

-

Page 70: Support Wheel Hub

Parts Identification - TVR12, TVR14, TVR16 V-Rake Support Wheel Hub... - Page 71 Parts Identification - TVR12, TVR14, TVR16 V-Rake ITEM PART NUMBER DESCRIPTION QTY. 84583 SCREW IN GREASE FITTING 821103 HUB - HAC520-6 BARE 821104 BEARING - H520-6 CONE 821105 BEARING - H520-6 CUP 824106 WHEEL STUD NUT-WB25 919309 WHEEL BOLT-WB16 967707...

-

Page 72: Axle

Parts Identification - TVR12, TVR14, TVR16 V-Rake Axle... - Page 73 Parts Identification - TVR12, TVR14, TVR16 V-Rake ITEM PART NUMBER DESCRIPTION QTY. 81527 1/4" X 1" HEX BOLT (PL) 81684 3/4" X 2 1/4" HEX BOLT (PL) 84050 3/4" S.A.E. FLAT WASHER (PL) 84498 1/4" LOCK NUT (PL) 84583 SCREW IN GREASE FITTING...

-

Page 74: Axle Wheel Hub

Parts Identification - TVR12, TVR14, TVR16 V-Rake Axle Wheel Hub... - Page 75 Parts Identification - TVR12, TVR14, TVR16 V-Rake ITEM PART NUMBER DESCRIPTION QTY. 967716 DUST CAP 967712 BEARING CONE 967711 BEARING CUP 919312 HUB BARE 968412 BEARING CUP 967208 BEARING CONE 967707 OIL SEAL 919309 WHEEL BOLT 915665 WHEEL NUT...

-

Page 76: Frame - Tvr12

Parts Identification - TVR12, TVR14, TVR16 V-Rake Frame - TVR12... - Page 77 Parts Identification - TVR12, TVR14, TVR16 V-Rake ITEM PART NUMBER DESCRIPTION QTY. 12779 #9 HAIR PIN CLIP (PL) 81215 SPRING PIN 0.188DIA X 1.50LG 81525 1/4" X 3/4" HEX BOLT (PL) 81549 5/16" X 3/4" HEX BOLT (PL) 81684 3/4" X 2 1/4" HEX BOLT (PL) 84050 3/4"...

-

Page 78: Frame - Tvr14

Parts Identification - TVR12, TVR14, TVR16 V-Rake Frame - TVR14... - Page 79 Parts Identification - TVR12, TVR14, TVR16 V-Rake ITEM PART NUMBER DESCRIPTION QTY. 12779 #9 HAIR PIN CLIP (PL) 81215 SPRING PIN 0.188DIA X 1.50LG 81525 1/4" X 3/4" HEX BOLT (PL) 81549 5/16" X 3/4" HEX BOLT (PL) 81684 3/4" X 2 1/4" HEX BOLT (PL) 84050 3/4"...

-

Page 80: Frame - Tvr16

Parts Identification - TVR12, TVR14, TVR16 V-Rake Frame - TVR16... - Page 81 Parts Identification - TVR12, TVR14, TVR16 V-Rake ITEM PART NUMBER DESCRIPTION QTY. 12779 #9 HAIR PIN CLIP (PL) 81215 SPRING PIN 0.188DIA X 1.50LG 81525 1/4" X 3/4" HEX BOLT (PL) 81549 5/16" X 3/4" HEX BOLT (PL) 81684 3/4" X 2 1/4" HEX BOLT (PL) 84050 3/4"...

- Page 82 Parts Identification - TVR12, TVR14, TVR16 V-Rake Lift Arms - TVR12...

- Page 83 Parts Identification - TVR12, TVR14, TVR16 V-Rake ITEM PART NUMBER DESCRIPTION QTY. 81558 5/16" X 2 3/4" HEX BOLT GR5 (PL) 81627 1/2" X 3" HEX BOLT (PL) 84039 WASHER - 3/8" SAE FLAT (PL) 86171 3/8" X 1 1/4" HEX BOLT (PL) 812363 3/8"...

- Page 84 Parts Identification - TVR12, TVR14, TVR16 V-Rake Lift Arms - TVR14...

- Page 85 Parts Identification - TVR12, TVR14, TVR16 V-Rake ITEM PART NUMBER DESCRIPTION QTY. 81558 5/16" X 2 3/4" HEX BOLT GR5 (PL) 81627 1/2" X 3" HEX BOLT (PL) 84039 WASHER - 3/8" SAE FLAT (PL) 86171 3/8" X 1 1/4" HEX BOLT (PL) 812362 5/16"...

- Page 86 Parts Identification - TVR12, TVR14, TVR16 V-Rake Lift Arms - TVR16...

- Page 87 Parts Identification - TVR12, TVR14, TVR16 V-Rake ITEM PART NUMBER DESCRIPTION QTY. 81558 5/16" X 2 3/4" HEX BOLT GR5 (PL) 81627 1/2" X 3" HEX BOLT (PL) 84039 WASHER - 3/8" SAE FLAT (PL) 86171 3/8" X 1 1/4" HEX BOLT (PL) 812362 5/16"...

- Page 88 Parts Identification - TVR12, TVR14, TVR16 V-Rake Rake Wheel Arms...

- Page 89 Parts Identification - TVR12, TVR14, TVR16 V-Rake ITEM PART NUMBER DESCRIPTION QTY. 84062 GREASE FITTING 0.250NF STRAIGHT 812639 WASHER 0.625 SAE FLAT BS PL 820694 WELDMENT - WHEEL ARM RH 820695 WELDMENT - WHEEL ARM LH 820717 BEARING - TAPERED ROLLER 30204...

- Page 90 Parts Identification - TVR12, TVR14, TVR16 V-Rake Rake Wheels...

- Page 91 Parts Identification - TVR12, TVR14, TVR16 V-Rake ITEM PART NUMBER DESCRIPTION QTY. 81914 3/8" X 1" CARRIAGE BOLT (PL) 812363 3/8" LOCK NUT (PL) 820709 FLANGE - RAKE WHEEL CENTER 820710 PLATE - RAKE TINE FASTENER 820711 RING - 60IN WHEEL OUTER 820713 TINE - 60IN RAKE WHEEL 7.5MM...

-

Page 92: Frame Underside

Parts Identification - TVR12, TVR14, TVR16 V-Rake Frame Underside... - Page 93 Parts Identification - TVR12, TVR14, TVR16 V-Rake ITEM PART NUMBER DESCRIPTION QTY. 12779 #9 HAIR PIN CLIP (PL) 84039 WASHER - 3/8" SAE FLAT (PL) 86170 3/8" X 1" HEX BOLT (PL) 812363 3/8" LOCK NUT (PL) 812365 3/4" LOCK NUT (PL) 815250 P-CLAMP FOR 3/4 OD, .406 HOLE...

-

Page 94: Hitch

Parts Identification - TVR12, TVR14, TVR16 V-Rake Hitch... - Page 95 Parts Identification - TVR12, TVR14, TVR16 V-Rake ITEM PART NUMBER DESCRIPTION QTY. 820614 WELDMENT - HITCH 812364 1/2" LOCK NUT (PL) 811691 1/2" X 4 1/2" HEX BOLT (PL) 910287 HOOK & SAFETY CHAIN ASSEMBLY 905040 HITCH BASE 905041 CLEVIS BOLT-ON 967228 BOLT HEX 1.000NC X 4.00 GR5PL...

-

Page 96: Hydraulic Cylinders & Hoses

Parts Identification - TVR12, TVR14, TVR16 V-Rake Hydraulic Cylinders & Hoses... - Page 97 CYLINDER - 3.0 X 36.50 BALL END 821151 BREATHER - 3/8 NPT MALE STEEL 821298 HOSE - 0.375 X 335L -06 SWFJIC X -06 SWFJIC - TVR12 821295 HOSE - 0.375 X 410L -06 SWFJIC X -06 SWFJIC - TVR14 821294 HOSE - 0.375 X 440L -06 SWFJIC X -06 SWFJIC - TVR16...

- Page 98 Parts Identification - TVR12, TVR14, TVR16 V-Rake Frame Shims - TVR12 ITEM PART NUMBER DESCRIPTION QTY. 821626 SHIM - MAIN FRAME 821628 SHIM - HITCH BOLT 821630 SHIM - AXLE BOLT 821629 SHIM - WING BOLT...

- Page 99 Parts Identification - TVR12, TVR14, TVR16 V-Rake Frame Shims - TVR14, TVR16 ITEM PART NUMBER DESCRIPTION QTY. 821626 SHIM - MAIN FRAME 821628 SHIM - HITCH BOLT 821630 SHIM - AXLE BOLT 821629 SHIM - WING BOLT...

- Page 100 Parts Identification - TVR12, TVR14, TVR16 V-Rake...

-

Page 101: Specifications And Shipping Kit Numbers

Specifications And Shipping Kit Numbers - TVR12, TVR14, TVR16 V-Rake Specifications And Shipping Kit Numbers Specifications Shipping Kit And Bundle Numbers Hardware Torque Values Metric Chart Imperial Chart... - Page 102 Specifications And Shipping Kit Numbers - TVR12, TVR14, TVR16 V-Rake...

-

Page 103: Specifications

Specifications And Shipping Kit Numbers - TVR12, TVR14, TVR16 V-Rake Specifications MODEL TVR12 TVR14 TVR16 Rake Wheels Working Width 329” 377” 415” Transport Width 100” Length 299” 363” 399” Rake Wheel Size 60” Tine Size 7.5 mm Tires ST205 - 75R15 W/ 15 X 5 X 5 RIM Windrow Width 36”... -

Page 104: Hardware Torque Values

Specifications And Shipping Kit Numbers - TVR12, TVR14, TVR16 V-Rake Hardware Torque Values Metric Chart NOTE: Do not use the values listed in the charts if a different torque value or tightening procedure is specified in this manual for a specific application. Torque values listed are for general use only. - Page 105 Specifications And Shipping Kit Numbers - TVR12, TVR14, TVR16 V-Rake Hardware Torque Values (Cont’d) Imperial Chart NOTE: Do not use the values listed in the charts if a different torque value or tightening procedure is specified in this manual for a specific application. Torque values listed are for general use only.

- Page 106 Specifications And Shipping Kit Numbers - TVR12, TVR14, TVR16 V-Rake...

-

Page 107: Warranty

Warranty - TVR12, TVR14, TVR16 V-Rake Warranty Farm King Base Limited Warranty Repair Parts Limited Warranty What Is Not Covered Authorized Dealer And Labor Costs Warranty Requirements EXCLUSIVE EFFECT OF WARRANTY AND LIMITATION OF LIABILITY... - Page 108 Warranty - TVR12, TVR14, TVR16 V-Rake...

-

Page 109: Farm King Base Limited Warranty

If Farm King determines that it will pay labor costs for warranty work, it will do so by issuing a credit to the dealer’s or distributor’s account. - Page 110 Corrections of defects and improper workmanship in the manner, and for the applicable time periods, provided for herein shall constitute fulfillment of all responsibilities of Farm King to the purchaser, and Farm King shall not be liable in negligence, contract, or on any other basis with respect to the subject equipment.

- Page 112 www.farm-king.com 1260 Clarence Avenue Winnipeg MB, R3T 1T2 Ph.: 204.661.8711 | Fax: 204.654.2503 E-mail: info@buhler.com www.farm-king.com Equipment shown is subject to change without notice. ©2020 Buhler Trading Inc. Printed in Canada TSX:BUI a division of Buhler Industries Inc.

Need help?

Do you have a question about the TVR12 and is the answer not in the manual?

Questions and answers