Summary of Contents for Teac TD-275T

- Page 1 DIGITAL TRANSDUCER INDICATOR TD-275T OPERATION MANUAL Please read this book carefully before using this product TEAC CORPORATION September , 2011 D01137600B...

- Page 2 Introduction Thank you very much for purchasing TD-275T digital indicator unit. To ensure optimum performance and proper and safe operation, please read this book carefully and understand it thoroughly before using the instrument. Information and data about this product, contained in this book, are simply for reference purposes; the Company does not guarantee any intellectual property rights or any other rights of a third party regarding this information or data.

- Page 3 IEC60947-1 and IEC60947-3 requirements near the product. The switch or breaker installed must also indicate that it functions to shut off the power to the TD-275T. Double insulation or reinforced insulation must be provided between the TD-275T and an external device connected to it and between the external device and its power source.

- Page 4 Broken or defective TD-275T shall be repaired or replaced in accordance with the service standards set out by TEAC. In any case, our liability for damages resulting from any defect or deficiencies in TD-275T shall be limited to repair or replacement of TD-275T.

-

Page 5: Table Of Contents

Contents 1. NAMES OF PARTS AND FUNCTIONS ····································· - 9 - 1-1 Front Panel ··········································································· - 9 - 1-1-1 Digital Display Screen (TOP Screen) ················································· - 9 - 1-1-2 Graph Display Screen ····························································· - 11 - 1-1-3 Display of Operation Panel························································· - 12 - 1-2 Rear Panel ···········································································... - Page 6 4. CALIBRATION OF SENSOR ············································· - 22 - 4-1 Calibration of Load ··································································· - 22 - 4-2 Before Calibration ···································································· - 23 - 4-3 Sensor Calibration ··································································· - 23 - 4-3-1 Equivalent Input Calibration························································ - 24 - 4-3-2 Real Load Calibration ····························································· - 24 - 4-3-3 TEDS Calibration··································································...

- Page 7 7. WORK SETTINGS ······················································ - 33 - 7-1 Setting Work and Switching to a Different Work ········································ - 33 - 7-2 Various Settings for Each Work ······················································· - 33 - 7-2-1 Measuring Start Condition Settings················································· - 34 - 7-2-2 Measuring Stop Condition Settings ················································· - 34 - 7-2-3 Measuring Time Settings ··························································...

- Page 8 8-9 Recorded Data Format ································································ - 54 - 9. SYSTEM SETTINGS ···················································· - 55 - 9-1 LCD Settings········································································· - 55 - 9-2 IN/OUT (IN/OUT check)································································ - 55 - 9-3 Initializing Settings ··································································· - 56 - 9-4 Backlight Off Timer Settings ·························································· - 57 - 9-5 Clock Settings ·······································································...

- Page 9 10-2-6 Control Commands ······························································ - 65 - 11. OVERSCALE/ERROR DISPLAYS ······································· - 70 - 11-1 Errors Related to Load Sensor ······················································· - 70 - 11-2 Errors During Load Sensor Calibration················································ - 71 - 12. HARDWARE INSTALLATION··········································· - 72 - 13. SPECIFICATIONS ····················································· - 73 - 14.

-

Page 10: Names Of Parts And Functions

1. Names of Parts and Functions 1-1 Front Panel 1-1-1 Digital Display Screen (TOP Screen) Hold display Power Lamp HI-HI/LO-LO limit values HI/LO limit values Judgment result Status display Judgment result detail button Measured value display Reset button Work display Start button Change view button CF card slot... - Page 11 Judgment result : If you set the judgment function, a measured value is judged to display the result. Judgment settings Display Description None Judgment is not performed. Load: HI/LO limits The measured value is larger than the HI limit value. The measured value is within the HI and LO limit values.

-

Page 12: Graph Display Screen

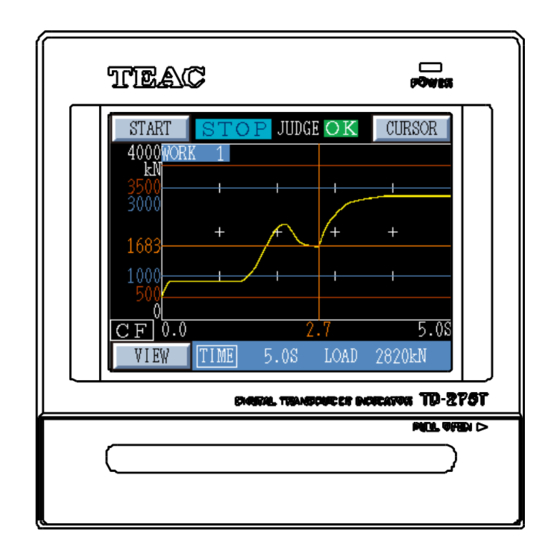

Digital zero load button : Sets an input load value as digital zero. CF card slot : When you insert the CF card to or remove it from the indicator, pull the cover toward you to open it. 1-1-2 Graph Display Screen Cursor button Start button Graph range... -

Page 13: Display Of Operation Panel

1-1-3 Display of Operation Panel TD-275T is equipped with the touch panel LCD display for initializing sensors or performing various operations. On this panel, the setting selection display, the strain display, the graph display, or other can be selected. Settings screen... -

Page 14: Rear Panel

・ The provided AC power cord is only intended for use within Japan, rated for 10 A at 125 V AC. If you want to use the TD-275T at a voltage exceeding the specified voltage or overseas, be sure to use another AC power cord that is more appropriate for your operating ・... -

Page 15: Sensor Signal Input Connector

1-2-5 Sensor Signal Input Connector Strip about 5 mm of insulation off each signal wire and lightly twist the bare wire to fit the terminal hole. Use a mini screwdriver to connect the wires. Applicable wire is 1.5φ or less (AWG 28 – 16). Pull the connected cable lightly and check that the cable is securely clamped. -

Page 16: Control Signal Input/Output Connector

1-2-6 Control Signal Input/Output Connector In/Out Signal Name In/Out Signal Name Load Digital Zero Work Select 1 Work Select 2 - Reserved Measurement Start/Stop Work Select 3 Work Select 4 - Reserved Hold Command External Judgment Reset Reset Signal COM -... -

Page 17: Input Signal Timing

B1: (Work Select 1) External entry of a work number. It is necessary to set this entry prior to A3 B2 (Work Select 2) “Measurement Start/Stop.” B3 (Work Select 3) Note that this entry is available only if “SETTINGS”→”WORK INPUT”→”EXT INPUT” B4 (Work Select 4) is chosen. -

Page 18: Connection

For 6-wire load cell, short-circuit +EXC with +SENSE and -EXC with –SENSE; and connect to terminal No.3 (+EXC) and terminal No.5 (-EXC). 2-2 Connecting TEDS Memory TD-275T You need to connect TEDS memory to TD-275T when using a TEDS sensor. ←Inside Outside→... -

Page 19: Connecting Voltage Output (V-Out)

2-3 Connecting Voltage Output (V-OUT) V-OUT is not isolated from the internal circuit. Use a TD-275T shield cable for connecting V-OUT with an external ←Inside Outside→ device and keep an extended wiring cable as short as possible. + V-OUT Do not short-circuit the voltage output; and do not External applying external voltage. -

Page 20: Connecting External Input

+5V power supply is electrically isolated TTL open collector from TD-275T internal power supply ON when IN is ‘H’ Because a current of approx. 8 mA flows into the external contact when it is turned ON, use a contact element which withstands 10 mA or more. -

Page 21: Setting Mode Configuration

3. Setting Mode Configuration 3-1 Screen Configuration Graph display screen Digital display screen (TOP screen) Settings screen From “WORK INPUT” and "HIGH “ “HI LOW LIMT” From “DETAIL SET” Detail settings screen Meas. display (COMMON) screen To Graph range, Grid settings, Strain display, etc. -

Page 22: Setting Screen Hierarchy

3-2 Setting Screen Hierarchy Settings HI LO Limit Detail settings Meas. display Graph range Grid settings Grid settings Strain display WORK settings Operating condition 1 Measuring start Measuring start load Measuring stop Measuring stop load Hold settings Inflection point Maximum,Minimum select Maximum,Minimum Criterion settings Load detection... -

Page 23: Calibration Of Sensor

It is a calibration method using the data stored in a TEDS memory in which the rated output value (mV/V) and the rated capacity of a strain gage sensor are recorded. Two types of TEDS-compatible memories are available: 1 kBit and 4 kBit. TD-275T supports only 4 kBit memory. - 22 -... -

Page 24: Before Calibration

4-2 Before Calibration ◇ Setting bridge voltage Set a bridge voltage in accordance with the specifications of a sensor. Note that selecting an incorrect bridge voltage may damage the sensor. From the TOP screen, select “SETTINGS”→“DETAIL SET”→“SENSOR CAL.”→“LOAD-CELL”→“BV” to set a bridge voltage. -

Page 25: Equivalent Input Calibration

Pushing on the Load sensor 1 screen advances to the Load sensor 2 screen, and pushing on the Load sensor 2 screen returns to the Load sensor 1 screen. Load sensor 1 screen Load sensor 2 screen Prior to each calibration, select “ZERO BAL” on the Load sensor screen to perform zero adjustment. Be sure to perform the zero adjustment to record an initial zero point of a connected sensor. -

Page 26: Teds Calibration

When read is completed, the rated output of the sensor as well as display value (rated capacity) and its unit are displayed on the screen. Then push the “UPDATE" button to complete the calibration. Caution) You need to connect a TEDS-capable sensor to TD-275T if performing TEDS calibration. - 25 -... - Page 27 In TEDS calibration, TD-275T displays rated capacity values as shown in the table below. The TEDS calibration data is stored in TD-275T. Thus, if any changes to display values are required after the calibration is performed, return to the Equivalent input calibration screen and change the value of “DISPLAY” and its decimal point position.

-

Page 28: Selecting Load Unit

4-3-4 Selecting Load Unit From the Load sensor 1 screen, select “UNIT.” Set the unit of load. Available settings: N, kN, g, kg, kPa, MPa, Nm, or NONE. Load unit screen 4-3-5 Adjusting Zero Point From the Load sensor 1 screen, select “ZERO BAL.” Be sure to perform the zero adjustment to record an initial zero point of a connected sensor. -

Page 29: Setting Digital Offset (Tare)

4-3-7 Setting Digital Offset (Tare) From the Load sensor 2 screen, select “DIG. OFFSET.” The digital offset function displays a value obtained by subtracting a set digital offset value from a measured value. This function is disabled for the real load calibration. INVALID: The digital offset function is disabled. -

Page 30: Sensor Settings

5. Sensor Settings Specify load sensor settings for a minimum scale value, digital and analog filters, a zero limit value, constant judgment, and load color display. From the TOP screen, select “SETTINGS”→“DETAIL SET”→“SENSOR SET.” The Load sensor screen allows you to determine settings for “MIN SCALE”, “ZERO LIMIT”, “ANALOG FLT”, “DIGITAL FLT”, “CONST. -

Page 31: Analog Filter Settings

5-3 Analog Filter Settings From the Load sensor screen, select “ANALOG FLT.” This analog filter has a cutoff frequency of 10Hz, 30Hz, 100Hz or 300Hz, and is connected upstream of the A/D converter. When necessary, such as when load values are unstable, select an appropriate frequency. -

Page 32: Measurement Display Settings

6. Measurement Display Settings From the TOP screen, select “SETTINGS”→“DETAIL SET”→“VIEW.” The Meas. Display (COMMON) screen allows you to determine settings for “GRAPH SET.”, “GRID”, and “STRAIN.” Meas. display (COMMON) screen 6-1 Graph Range Settings From the Meas. display (COMMON) screen, select “GRAPH SET.” Set the graph range. -

Page 33: Strain Display

The screen allows you to check the load sensor, and displays signals from the load sensor in units of the amount of strain. It is recommended that you note down the strain value shown in “Strain display” when integrating TD-275T with your system. -

Page 34: Work Settings

7. Work Settings 7-1 Setting Work and Switching to a Different Work To select a work number and set the work, select “SETTINGS” →”DETAIL SET”→“WORK”→“Work No.” (1 to 16). Set the operating condition for each work number. Work settings allow you to program a maximum of 16 operating conditions. To switch to a different work, select “SETTINGS”→”WORK INPUT”... -

Page 35: Measuring Start Condition Settings

7-2-1 Measuring Start Condition Settings As a measuring start condition, select “START SIGNAL” (the START button on the screen or an external measuring start/stop signal) or “START+LOAD.” From the TOP screen, select “SETTINGS”→”DETAIL SET”→“WORK” →”Work No.” (1 to 16)→“MEAS. START.” START SIGNAL : Measurement is started through a start signal (when the START button on the screen or an external measuring start/stop signal is turned ON). - Page 36 be recorded on a CF card. Select the “CONT.SET.” button to set the wait time. The wait time is a time interval between when a measuring time expires and when the next measurement is performed. On the graph display screen, each time a measuring time expires, erase the plotted graph so that a new graph is plotted for each measurement.

- Page 37 ◇ Stopping Continuous Measurement Continuous measurement can be stopped in the following ways: ・ Turn OFF the external measuring start/stop signal. ・ When the continuous measurement is started through the START button, push the START button again. ◇ Switching to a Different Work Number during Continuous Measurement When you select “STOP+CONT.”, you can switch to a different work number for each measuring time.

-

Page 38: Measuring Time Settings

7-2-3 Measuring Time Settings Set the maximum measuring time. From the TOP screen, select “SETTINGS”→”DETAIL SET”→“WORK” →”Work No.” (1 to 16)→“MEAS. TIME.” COMMON : The measuring time which is set by selecting ”SETTINGS”→“DETAIL SET”→“SENSOR CAL.”→“TIME” from the TOP screen is applied. BY WORK : The measuring time which is set by using the “SETTINGS”... -

Page 39: Sample Hold

7-2-4-1 Sample Hold Holds the load value at a certain point when the hold command signal (external A5 signal pin) is turned ON during a measuring period. The limits are set as discussed in “7-2-5 Setting the Load Limits.” Compares the held load value against the HI LO limits and HI_HI LO_LO limits and outputs the judgment result. From the TOP screen, select “SETTINGS”→”DETAIL SET”→“WORK”... -

Page 40: Peak Hold

7-2-4-2 Peak Hold Holds the maximum load value obtained during a measuring period. Compares the peak held load value against the HI LO limits and HI_HI LO_LO limits and outputs the judgment result. The limits are set as discussed in “7-2-5 Setting the Load Limits.” From the TOP screen, select “SETTINGS”→”DETAIL SET”→“WORK”... -

Page 41: Inflection Point Hold

7-2-4-3 Inflection Point Hold Captures the change of the slope of the load value during a measuring period and holds the value. Compares the load value held at the inflection point against the HI LO limits and HI_HI LO_LO limits and outputs the judgment result. - Page 42 ◇ Detection of Inflection Point In the Inflection point screen, set the load difference E, detection time A, detection time B and detection start load value. START : Set a start load value from which the inflection point detection is started.

-

Page 43: Maximum/Minimum Value Hold

7-2-4-4 Maximum/Minimum Value Hold Holds the load value at the moment when the maximum or minimum value is attained during a measuring period. Compares the held load value against the HI LO limits and HI_HI LO_LO limits and outputs the judgment result. The limits are set as discussed in “7-2-5 Setting the Load Limits.”... - Page 44 ◇ Maximum and Minimum Settings When you select the “Max, Min” button on the Hold settings screen, the Maximum, Minimum select screen is displayed. Select “MAXIMUM” to set the maximum hold mode, or “MINIMUM” to set the minimum hold mode. Then, determine the following settings.

-

Page 45: Setting The Load Limits

7-2-5 Setting the Load Limits Criteria for comparison and judgment can be set for load values (HI/LO and HI_HI/LO_LO limits) on a work-by-work basis. Comparison and judgment are performed against values held under each hold condition. From the TOP screen, select “SETTINGS”→“DETAIL SET”→“WORK” → ”Work No.”... -

Page 46: Measuring Display Settings

HYSTERESIS SETTING screen When constant judgment is enabled, the hysteresis function for judging against HI and LO limit values and HH and LL limit values becomes effective. Set a hysteresis value by using the key to place the cursor over a digit you want to change, and using the key to set a desired value, and then push the “Update”... -

Page 47: Graph Range Settings

From the “Meas. display” screen, select “SETTINGS.” In the “Meas.display (BY WORK)” screen, set the measuring display conditions (“GRAPH SET.”, “GRID”, “GRAPH DISP.”, “ANALYSIS”) for this work. Meas.display (BY WORK) 7-2-6-1 Graph Range Settings From the Meas. display (COMMON) screen, select “GRAPH SET.” Set the graph range. -

Page 48: Measuring Display Settings From The Graph Screen

7-2-6-3 Measuring Display Settings from the Graph Screen When you push the TIME mark on the Graph screen, a shortcut to the Meas. Display screen is provided. This shortcut allows you to change the display range or grids directly from the Graph screen. When you push the TIME mark on the Graph screen, a shortcut to the Meas. -

Page 49: Cf (Compact Flash) Settings

8. CF (Compact Flash) Settings The CF screen allows you to determine settings for storing onto a compact flash card. From the TOP screen, select “SETTINGS”→”DETAIL SET”→“CF.” When recorded data is stored, the filename (if date is set) and timestamp are generated based on the system clock. Make sure that the system clock is accurate. -

Page 50: Filename Settings

When you select “STORE”, the recorded data is stored on the CF card. Once the store has been finished, the filename is displayed. Push “OK” to confirm. Caution) The CF mark is displayed to indicate that a CF card is inserted. During the CF card is being accessed, the CF mark is shown in yellow. -

Page 51: Remaining Alert And Limit Settings

Example: If 6000 files are recorded under Work No. 2, the files are saved under two different folders as follows: to 5000 files ¥WORK2¥TD001¥TD0001.CSV to TD5000.CSV 5001 to 6000 files ¥WORK2¥TD002¥TD0001.CSV to TD1000.CSV If more than one measurement was performed in one second or less, select “COUNT.”... -

Page 52: Decimation

“2 k.” Decimation screen 8-5 Saving a Setup File From the CF screen, select “SAVE SETTING.” Various setting information of TD-275T is saved in a setup file (TD-CNF.PRM) on a CF card. Filename: TD_CNF.PRM Target directory: ¥ (root directory) CF Save settings screen When you push “Save”... -

Page 53: Loading A Setup File

After determining the settings for sensor calibration, load the settings. ・ It is recommended to use a setup file with the same version of firmware currently installed in TD-275T. Using firmware with a different version can lead to errors because of the difference in specifications. -

Page 54: Installing And Removing A Cf Card

Make sure that the LED indicator, located to the right of the CF card slot, goes up. d) Close the CF card slot cover on the front panel. When a CF card is recognized by TD-275T, a CF mark is displayed on the screen. When a CF card is inserted, a CF mark is displayed. -

Page 55: File Erase And Format

To erase files stored on the CF card or format the CF card, use your PC. You can not erase files stored on the CF or format the CF card directly from TD-275T. If the CF card is full, use another new CF card or erase the files stored on the CF card or format the card. -

Page 56: System Settings

9. System Settings The System settings screen allows you to determine settings for the backlight and contrast of the LCD, the backlight timer, check of external IN/OUT signals, the clock, the system information, the buzzer, key lock, system reboot, and optional board (if installed). -

Page 57: Initializing Settings

9-3 Initializing Settings From the System settings 1 screen, select “INITIALIZE.” This function is used to reset various settings of TD-275T to their defaults. System initialize screen Push the “INITIALIZE” button on the System initialize screen and then push the “OK”... -

Page 58: Backlight Off Timer Settings

9-6 System Information From the System settings 2 screen, select "SYSTEM INFO." This should display various version and configuration information for your TD-275T. When you contact us for help, you may need to provide the system information. System information screen... -

Page 59: Buzzer Settings

9-7 Buzzer Settings From the System settings 2 screen, select “BUZZER.” Specify whether or not the buzzer sounds when pushing on the touch panel. INVALID : The buzzer does not sound. VALID : The buzzer sounds. Buzzer settings screen 9-8 LANG (言語) Select which language you want to use: Japanese or English. -

Page 60: Settings When An Optional Board Is Installed

◇ Option settings The option settings are enabled only when an optional board is installed in the option slot provided on the back of TD-275T. Select “SETTINGS”→”DETAIL SET”→“SYSTEM.” When an optional board is installed, a button for setting the option appears. -

Page 61: Output Adjustment

10-1-1 DA Output Adjustment From the DA settings screen, select “ADJUST” to adjust DA output. The DA output adjust screen allows you to set load values at DA zero and at DA full scale. Set values by selecting an item (“ZERO” is selected in the figure on the left), using the key to place the cursor over a digit you want to change, and using the... -

Page 62: Voltage And Current Output Connections

・ Connect an external device (with a load resistance of 2 kΩ or more) to the "V"+ (plus) and the "V"- (minus) for voltage output. ・ Connect an external device to the "I"+ (plus) and the "I"- (minus) for current output. TD-275T ←Inside Outside→... -

Page 63: Setting Rs-232C Interface

RS-232C interface is used to read out the indicated values or recorded data from TD-275T. It is useful when connecting TD-275T with a computer, a process controller or a sequencer, etc. to perform tasks such as control, aggregation, recording, etc. -

Page 64: Parity Settings

10-2-3 Parity Settings From the RS-232C settings screen, select “PARITY” to set a communication error detection code. Available settings: None, Odd, or Even. Parity setting Screen 10-2-4 Communication Specifications ◇ Standard Signal level : Based on RS-232C Transmitting distance : Approx. 10 m Transmitting method : Asynchronous, Full duplex Transmitting speed... - Page 65 ◇ Cable connection sample Cross cable connection sample D-Sub D-Sub RS-232C 9-pin 25-pin option female male SHELL SHELL Note: - 64 -...

-

Page 66: Communication Format

10-2-5 Communication Format Request is a command sent from a host computer to TD-275T and Response is data sent from TD-275T to a host computer. All characters are ASCII, except [CR] and [LF]. ([CR]:Carriage Return (0x0D)、[LF]:LineFeed (0x0A)) Request S C A N... - Page 67 Communication speed On a transmission of load and displacement, C54 or beyond requires a communication speed of 19200 bps or more. Processings when the transmission is stopped by flow control When the transmit buffer has enough free space, the current value is written into the transmit buffer. After the transmit buffer is full, the current value is not written into the transmit buffer.

- Page 68 ◇ TR_ACQ_DAT command Function : To acquire the recorded data Argument : none Data is transmitted as characters (ASCII) BIN Data is transmitted as binary (float) BIN_S Data is transmitted as binary (short) Description ・ When no argument is specified, the recorded data is transmitted as characters. Order in which data is transmitted the number of data per line, the number of lines transmitted Measurement data...

- Page 69 ◇ VERBOSE command Function : To set how the status is transmitted Argument : Mode 0 or 1 Description When Mode 0 is specified, !ACQ_START and !ACQ_END messages are not returned. When Mode 1 is specified, !ACQ_START and !ACQ_END messages are returned. When no argument is specified, the VERBOSE mode setting (0 or 1) and OK are returned.

- Page 70 ◇ ACQ_RESET command Function : To reset the measurement status Argument : none Description The command is effective only when the measurement screen is displayed. The command is equivalent to pushing the RESET button on the screen where the measured values are displayed.

-

Page 71: Overscale/Error Displays

11. Overscale/Error Displays This section describes overscales and errors which may be displayed on each screen. 11-1 Errors Related to Load Sensor LOAD: This error indicates that an input signal from the load sensor exceeds +3.0 mV. It also indicates that a sensor signal exceeds 3.0 mV/V. The sensor and the cables require to be checked. -

Page 72: Errors During Load Sensor Calibration

11-2 Errors During Load Sensor Calibration ◇ Errors during real load calibration Input-range over error This error shows that the signal from the sensor exceeds the input range (3 mV/V) of the indicator. This 3 mV/V includes the zero point of the sensor. Input-range over error screen Zero balance error This error shows that during zero point measurement, the signal from the... -

Page 73: Hardware Installation

Guide rail 3.Push the TD-275T into the panel cut-out area from the front side of the panel. 4. Put the guide rails that were removed in Step 2, back in place from the rear side, and then secure them with the two screws. -

Page 74: Specifications

13. Specifications Load Sensor Input 1) Input/Range : Strain gauge sensor ±3.0 mV/V Input connector : Screw connection-type terminal (pitch 5.08 mm, 12P) 2) Excitation Voltage : 2.5 V DC (±10%)/10 V DC (±10%) Current: 30 mA 3) Calibration method : Equivalent Input/TEDS/Real Load Calibration range : 0.5 to 3.0 mV/V... - Page 75 7) Options : Only one option can be installed (except CF card) RS-232C : Signal level RS-232C Conformity Electrical transmission distance Approx. 10m Transfer method Start/Stop synchronization, Full duplex Transfer speed 4800/9600/19200/38400/57600/115200 bps Bit pattern Start bit 1 bit Character length 8 bits Stop bit 1 bit...

-

Page 76: Dimensions

14. Dimensions +0.5 92 0 Panel cutout dimensions パネルカット寸法 * Recommended board thickness: 1.6 to 3.0 mm ※推奨板厚:1.6mm~3.0mm 23.6 (Please consult us regarding other baord thicknesses.) (推奨板厚範囲以外は別途相談下さい。) SERIAL NO. MADE IN JAPAN (121) (17.5) 91 105 24.1 TD-275T 質量:1.05kg(接続ケーブルを除く)...

Need help?

Do you have a question about the TD-275T and is the answer not in the manual?

Questions and answers