Table of Contents

Advertisement

Quick Links

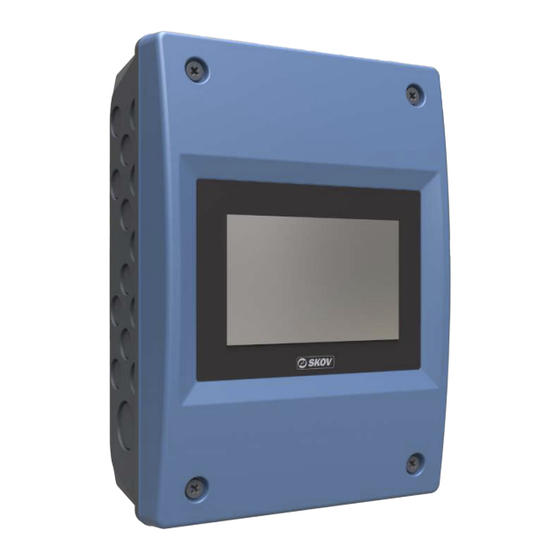

DOL 532 Tunnel

Climate

Technical Manual

English For other language variants of this document we refer to:

Español Para otras variantes del idioma de este documento, visite:

Français Pour les versions dans d'autres langues de ce document veuillez consulter:

http://docs.skov.com/1161

612991 • 2023-05-31

Software version 8.0

Advertisement

Table of Contents

Summary of Contents for Skov DOL 532 Tunnel

- Page 1 DOL 532 Tunnel Climate Technical Manual English For other language variants of this document we refer to: Español Para otras variantes del idioma de este documento, visite: Français Pour les versions dans d'autres langues de ce document veuillez consulter: http://docs.skov.com/1161 612991 •...

- Page 3 The power supply isolator is not included. Note • All rights belong to SKOV A/S. No part of this manual may be reproduced in any manner whatsoever without the expressed written permission of SKOV A/S in each case.

-

Page 4: Table Of Contents

DOL 532 Tunnel 1 Product description ............................ 6 2 Work routine .............................. 7 3 Installation guide............................ 8 Selecting components....................... 8 Slave relays .......................... 8 Setup of operation form ...................... 8 View week number........................ 9 Select type of Unit of measurements.................. 9 Connecting components...................... - Page 5 DOL 532 Tunnel 6.1.1 Climate............................ 25 6.1.1.1 Setting exhaust units (MultiStep) .................... 25 6.1.1.2 Fan settings .......................... 25 6.1.1.3 Setting outside temperature limit .................... 26 6.1.1.4 Setting of heating ........................ 26 6.1.2 Production.......................... 26 6.1.3 Network settings ........................ 26 6.1.4 UTC time............................

-

Page 6: Product Description

The ventilation is not only regulated according to the current inside and outside temperature, but also to the cooling effect of the air speed - the chill effect. This means that DOL 532 Tunnel calculates how the animals ex- perience the temperature in the house and adapts the ventilation accordingly. -

Page 7: Work Routine

DOL 532 Tunnel 2 Work routine This technical manual deals with the installation of the controller and is aimed primarily at the technicians and electricians who will be mounting, installing and testing the controller. According to current national and in Europe also EU regulations, the installation must be carried out by expert personnel. -

Page 8: Installation Guide

DOL 532 Tunnel 3 Installation guide 3.1 Selecting components There are two ways to install the controller. At the initial installation: Use Installation wizard which will guide you through all the options of the functions. If making adjustments to the existing installation: Use the menu... -

Page 9: View Week Number

DOL 532 Tunnel 3.4 View week number View of week number at the top of all pages. View week number 3.5 Select type of Unit of measurements The controller can display the units as both metric and US units. Unit of measurements 3.6 Connecting components... -

Page 10: The Menu Show Connection

DOL 532 Tunnel 3.6.2 The menu Show connection When you have selected all the components in the installation menu, the controller will show you where to con- nect the individual components. See the menu for where exactly to connect the individual components. -

Page 11: Shared Equipment

DOL 532 Tunnel 3.6.4 Shared equipment Controllers in the same network (see Network settings [} 26]) can share equipment such as outside tempera- ture sensor and outside humidity sensor. The controller where the equipment is physically connected is called the ‘Master’. The other controllers are called ‘Clients’. - Page 12 DOL 532 Tunnel Dynamic MultiStep makes it possible to reduce power consumption for the fans in the MultiStep system. It is achieved by the fans' ability to run at two speeds (Low and High) and by letting them run as long as possible at low speed.

- Page 13 DOL 532 Tunnel The livestock house's ventilation system 1 stepless unit 2 MultiStep units Ventilation sequence From low to high regulation Method of Operation Flap in stepless unit: The stepless ventilation sequence is achieved by opening and closing the flap.

-

Page 14: Setup Of Tunnel Ventilation

DOL 532 Tunnel 3.7.2.2 Setup of tunnel ventilation Setting of house area (combi-tunnel). Sectional cross area Select if the climate controller must block the change to tunnel as long as the out- Tunnel block by outside temperature side temperature is below the settings in the batch curve for outside temperature. -

Page 15: Active Functions In The Event Of Control Failure

DOL 532 Tunnel 3.7.5 Active functions in the event of control failure When installing MultiStep air outlet and side cooling, you must decide how these functions is to react in an emergency situation. MultiStep outlets Activated: When the control fails, the air outlet is active. -

Page 16: Production

DOL 532 Tunnel 3.8 Production 3.8.1 Water Number of water meters Setting the number of water meters. Setting the number of liters that runs through the water meter for every pulse. Liters pr. pulse By selecting a relay for a water meter, it is possible to shut off the water in the Water meter settings event of excessive water consumption. -

Page 17: Calibration

DOL 532 Tunnel 4 Calibration 4.1 Calibration of Air Intake and Air Outlet The controller must be adapted to the winch motor after installation. Winch motors with feedback must be calibrated by a technician, while winch motors without feedback are cali- brated automatically once the technician has set up a time for Air inlet time. -

Page 18: Calibration Of Pressure Sensor

DOL 532 Tunnel Wind direction maximum voltage Wind speed minimum voltage Wind speed maximum voltage Enter a Minimum value as well as a Maximum value to indicate the Wind speed minimum speed area within which the weather station can measure. -

Page 19: Calibration Of Nh3 Sensor

0 ppm Maximum value 10000 ppm Note: Calibration should only be carried out only by staff trained by SKOV. 4.2.4 Calibration of NH3 sensor If DOL 53 does not measure correctly, normal maintenance is carried out (replacement of filter). The sensor must be changed if this does not help. -

Page 20: Testing

DOL 532 Tunnel 5 Testing After installation of the system a thorough test must be carried out, to ensure that the system works as intended. 5.1 Testing basis components 5.1.1 Testing temperature and air humidity sensors Read the current inside temperature and humidity 1. -

Page 21: Testing Climate Functions

DOL 532 Tunnel Select the function to be tested and test the components one at a time. A colored bar at the top of the page indicates that a component is set to manual mode. After testing the components, you must set the function back to automatic control, so that the con- troller continues to operate as before. -

Page 22: Stepless Fans

DOL 532 Tunnel 5.2.1.3 Stepless fans Testing setting and placement of stepless fans The test is to show if the connected stepless fan(s) are set correctly, i.e., if they can run at minimum and maxi- mum speeds, and whether they are placed correctly. -

Page 23: Testing Relay Functions

DOL 532 Tunnel Activate MultiStep 1 Check that the swivel shutter in the chimney opens completely. When the shutter is approx 15 % open, the MultiStep 1 fan must start at full speed. Check that the fan sucks air out of the house (e.g., by means of a smoke test). -

Page 24: Emergency Inlet

DOL 532 Tunnel 5.2.1.6 Emergency inlet Then select card activate Climate equipment | Inlets Manual mode Emergency inlet Activate the emergency air inlet. Check that the emergency air inlet opens completely. 5.2.2 Testing production functions 5.2.2.1 Testing relay for 24-hour clock Select the menu Manual/auto. -

Page 25: Service

DOL 532 Tunnel 6 Service 6.1 Settings 6.1.1 Climate 6.1.1.1 Setting exhaust units (MultiStep) MultiStep is a method for controlling one or more exhaust units in steps. DOL 532 T can control up to eight Mul- tiSteps. Step 1 Step 2... -

Page 26: Setting Outside Temperature Limit

DOL 532 Tunnel 6.1.1.3 Setting outside temperature limit The maximum opening of the air inlet for as long as the outside temperature is be- Inlet limit low the settings in the curve for outside temperature. Outside temperature Ventilation limitation via outside temperature can be adjusted to the age of the ani- mals over two curve points. - Page 27 Netmask and gateway must only be set when selecting Static IP. The controller is set to Static IP by default. SKOV A/S recommends that you follow a standard network setup (also see FarmOn- line Explorer Technical manual). Note that if the connection between the ‘Master’ and the ‘Client’ controllers is interrupted, the ‘Client’...

-

Page 28: Utc Time

DOL 532 Tunnel House 2 House 1 6.1.4 UTC time The controller uses two different time settings. A user-selectable local time (menu button | Settings | System | ) and the so-called UTC time (Coordinate Universal Time), which is the internal time in the Adjust date and time controller, for example, used for time-stamping of alarms. -

Page 29: Backup Of Historical Data

DOL 532 Tunnel It is possible to save and load a backup of the current settings and report page. It can be done either on the controller's internal CPU module, SD card, or USB stick. If settings are to be copied to other controllers, use an SD card or a USB stick. - Page 30 DOL 532 Tunnel It is possible to make a daily backup of the controller data. Activate the function under Daily backup SD card USB stick. When the settings and the report page are saved on the SD card, the house name, date, and time are automatically added.

-

Page 31: Software Update

See the status of the SD card or USB stick. SD card status USB stick status SKOV A/S recommends that you always save the setup on a USB stick before updating a program. 6.4 Software update Important information Loading a new program usually takes up to two minutes. -

Page 32: Carrying Out The Software Update

DOL 532 Tunnel Menu Function Setpoint Management Batch day no. Number of set animals Climate Temperature setpoint Heater temperature setpoint* Humidity setpoint* Minimum ventilation Maximum ventilation Production Number of dead animals Silo 1, 2, 3, 4, 5 If there are animals in the house, climate and production functions which need to be run manually during the update must be activated now. -

Page 33: Check After Software Update

6.5.1.1 Adaptive control From the factory the controller is set to adaptive control. SKOV recommend the use of adaptive control. Adaptive control is used for, for example, ventilation, tunnel cooling, heating and humidity control (as an alterna- tive to PID control). - Page 34 DOL 532 Tunnel At adaptive control the climate controller will maintain a setting by continuing to adjust the control to maintain the required level. Furthermore, it will take into account variable parameters, such as outside temperature and adapt the control to the changed conditions.

-

Page 35: P-Band Adjustment

DOL 532 Tunnel Slow Medium Fast Fast Medium Slow Figure 9: The regulation takes place within a band. The narrower the band, the faster the regulation can adjust the deviation between setting and measuring point. From the factory the adaption time is set to Medium but it can be changed to Fast and Slow . -

Page 36: Ventilation

DOL 532 Tunnel At PID control the climate controller will maintain the required setting by continuing to adjust the control. Figure 12: PID control is a stable control as the climate controller continuously adapts the control to the required setting. 6.5.2 Ventilation... -

Page 37: Inlet Without Feedback

DOL 532 Tunnel 6.5.2.2 Inlet without feedback In livestock houses with curtain openings, it can be difficult to change the curtain Stop fan if inlet below position due to the negative pressure when the fans are running. It is possible to stop the fans temporarily while the curtain run at smaller curtain openings than stated here. -

Page 38: Cooling

DOL 532 Tunnel Selection of how quickly the system should start to regulate to adapt to changing Adaptive reaction conditions in the livestock house ( Fast/Medium/Slow Control mode Control mode selection: ( Adaptive – self learning/PID – user settings See the section Adaptive control [} 33] for a general description of adaptive control. -

Page 39: Humidity

DOL 532 Tunnel Time between each bleed-off process. Runtime between bleed off (pad rinsing) Bleed-off time (pad The period in which bleed off must run. cleaning) Setting the control mode to PID - user settings or Adaptive - self learning. -

Page 40: Humidity Control At Adaptive Ventilation Mode

DOL 532 Tunnel At Humidity heat. Heat mode Setting of control mode: PID or adaptive. See also the sections Humidity control at PID heat mode [} 41] and Humidity con- trol at adaptive heat mode [} 40]. 6.5.5.1.1 Humidity control at adaptive ventilation mode... -

Page 41: Humidity Control At Pid Heat Mode

DOL 532 Tunnel 6.5.5.1.4 Humidity control at PID heat mode The proportional band according to which heating is controlled. P band Reaction to too high humidity. Integration time (short) Long time = slow heat supply. Short time = fast heat supply. - Page 42 DOL 532 Tunnel Adjust the pressure by making a curve course for the required pressure. Negative pressure (Pa) Nominal output 53,200 m3/h Outlet 25 % 13,300 m3/h Air inlet (flap position) % Figure 15: Adjustment of negative pressure 1: Air inlet (flap position) This negative pressure curve is ideal for a given system, depending on the type of winch motor used.

-

Page 43: Activation Of Cycle Time At Tunnel Ventilation

DOL 532 Tunnel For each curve point, the corresponding values are shown. Press the buttons Previous curve point Next curve point access all curve points. Select a value and press for access to change it. Press the button to see the previous and next curve View curve point during the setup. - Page 44 DOL 532 Tunnel 100.0 100.0 100.0 Table 3: Curve values for stepless unit The air outlet’s flap position and fan speed % Flap % Vent % Output % Fan speed Vent Output for the stepless fan Output Flap Flap position for air outlet With Dynamic MultiStep, two setups must be performed for the stepless units for low regulation and high regula- tion, respectively.

-

Page 45: Troubleshooting Instructions

DOL 532 Tunnel 7 Troubleshooting instructions • Is there 230 V current on terminals A1+ A2 (if not, check installation fuses and fault current relay) • Is the change-over switch of the fan speed controller MAN/AUT set on AUT? • Is the controller set to automatic control? •... -

Page 46: Temperature Sensor Control Table

DOL 532 Tunnel Ping test accepted. Ping test not accepted. 7.2 Temperature sensor control table 7.2.1 Table relating to DOL 114 temperature sensor control °C °F °C °F °C °F -40.0 0.00 42.8 4.60 82.4 6.80 -31.0 0.50 44.6 4.70 84.2... - Page 47 DOL 532 Tunnel 7.2.2 Table relating to DOL 12 temperature sensor control °C kΩ* °C kΩ* °C kΩ* 82.50 8.08 20.71 5.29 10.72 3.73 76.84 7.96 20.09 5.22 10.45 3.67 70.60 7.83 19.48 5.15 10.19 3.61 63.97 7.68 18.90 5.07 9.94...

-

Page 48: Technical Data

DOL 532 Tunnel 8 Technical data Electrical V AC Rated voltage 115*, 200* and 230/240 (*not speed controller) V AC Operating voltage 103.5-264 Frequency 50/60 Output Max. current consumption Main module Configurable main module. Number 0-10 V: -11 inputs and 2 outputs – or - 9 inputs and 4 outputs –... -

Page 49: Dimensioned Sketch

DOL 532 Tunnel 8.1 Dimensioned sketch Technical Manual... -

Page 50: Functionality

DOL 532 Tunnel 9 Functionality System software Tunnel mode MultiStep Dynamic MultiStep tunnel Tunnel MultiStep Minimum ventilation in % and m /animal PID control (or P-band) Stir fan control Display of user-offset for temperature setpoint Number of room heating units... - Page 52 SKOV A/S • Hedelund 4 • Glyngøre • DK-7870 Roslev Tel. +45 72 17 55 55 • www.skov.com • E-mail: skov@skov.dk...

Need help?

Do you have a question about the DOL 532 Tunnel and is the answer not in the manual?

Questions and answers