Table of Contents

Advertisement

Quick Links

TABLE OF CONTENTS:

1.00

BEAMS & CONNECTORS:

1.10

1.11

1.12

1.20

1.30

2.00

2.10

Vertical Beam Pattern (Top & Bottom Row)

2.20

Horizontal Beam Pattern (Row 1 & Row 3)

2.30

3.00

3.10

3.20

3.30

3.31

3.40

3.41

3.42

3.43

Revision History:

Date

17 Jun 2021

Bracket installation update

30 Sep 2021

General revision and update

email:

info@matsing.com

MS-18H90

Date

Prepared by

30 Sep 2021

Ray Ling

INSTRUCTION MANUAL MS-18H90

Description

website:

Instruction Manual

Approved by

Pavel

www.matsing.com

Document nos

MS-18H90-IM-001

Revision

Revised by

nos.

RayLing

RayLing

Page

Revision

2

01

02

1

/

7

Advertisement

Table of Contents

Summary of Contents for Matsing MS-18H90

- Page 1 Approved by Document nos Revision 30 Sep 2021 Ray Ling Pavel MS-18H90-IM-001 INSTRUCTION MANUAL MS-18H90 TABLE OF CONTENTS: 1.00 BEAMS & CONNECTORS: 1.10 Plan View Resultant Beam Direction 1.11 Beam 1 to 6 (Row 1), Beam 13 to 18 (Row 3) 1.12...

- Page 2 1.00 BEAMS & CONNECTORS: 1.10 Plan View Resultant Beam Direction 1.11 Beam 1 to 6 (Row 1), Beam 13 to 18 (Row 3) 0˚ BEAM 1 - 6 BEAM 13 - 18 (Row 1) (Row 3) Plan View Resultant Beam Directions Frequency: 1695 –...

- Page 3 1.20 Plan View Connector Layout MS-18H90 PLAN VIEW CONNECTOR LAYOUT 1.30 Connector Ports Table Row 1 BEAM 6 BEAM 5 BEAM 4 BEAM 3 BEAM 2 BEAM 1 PORT 11 PORT 12 PORT 9 PORT 10 PORT 7 PORT 8...

- Page 4 2.20 Horizontal Beam Pattern (Row 1 & Row 3) 2.30 Horizontal Beam Pattern (Row 2)

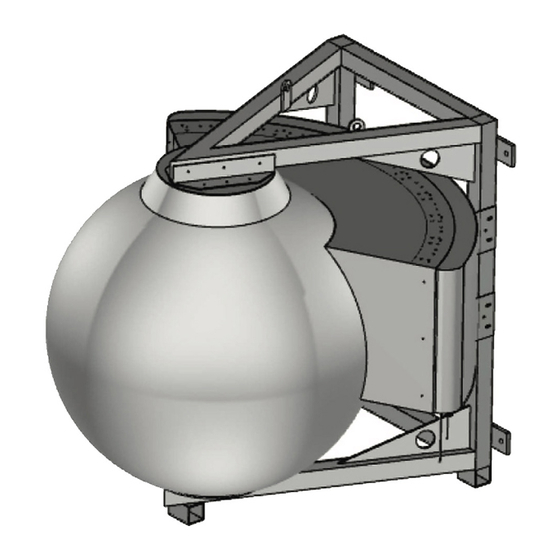

- Page 5 3.00 TRANSPORTATION / INSTALLATION 3.10 Transportation (From Point to Point) Strictly comply to the Local authority and regulatory on Workplace Safety and Health Control and Measure when moving and transportation of large or heavy equipment, appropriate material handling machine should be use. (Risk Assessment apply for Forklift or Pallet Truck Lifting) 3.20 Bracket Mounting...

- Page 6 3.30 Installation using a crane Strictly comply to the local authority and regulatory on Workplace Safety and Health Control and Measure when performing lifting of large or heavy equipment, appropriate material handling machine should be used and only certified personnel should perform the task. (Risk Assessment requirement applies for both Up-Lifting and Down-Lifting.) 3.31 Lifting the Antenna...

- Page 7 3.40 Antenna Installation With reference to Item 5.2 Bracket Mounting Procedure, End user is required to Custom-Make the additional supporting bracket and tighten it to the existing Antenna bracket to meet the deployment needs. 3.41 Antenna Leveling After the Antenna is mounted to the bracket, it is required to be adjusted to 0˚ (Zero Degree) with ≤0.2˚...

Need help?

Do you have a question about the MS-18H90 and is the answer not in the manual?

Questions and answers