Summary of Contents for MKN TKECOD610O

- Page 1 Read the operating instructions prior to commissioning Installation instructions Combisteamer Unit Type of energy Unit type Model SpaceCombi Team Electric Floor-standing unit TKECOD610O 4127003--0AIBE-B en-GB...

- Page 2 Fax +49 5331 89-280 Internet www.mkn.com Copyright All rights to text, graphics and pictures in this documentation are held by MKN Maschinenfabrik Kurt Neubauer GmbH & Co. KG. Distribution or duplication is only permitted with the prior written consent of MKN.

-

Page 3: Table Of Contents

Directory of contents 1 Introduction ................. 5 1.1 About this manual ................ 5 1.1.1 Explanation of signs .................. 6 1.2 Staff qualification ................ 7 1.3 Use of the unit ................... 7 1.4 Warranty .................... 7 2 Safety information .............. 8 3 Description of the unit ............. 10 3.1 Overview of the unit ............... 10 3.2 Equipment and connection data ... - Page 4 Directory of contents 7.3 Heating the unit up and rinsing it out ........... 39 8 Putting the unit into service .......... 40 8.1 Nameplate .................. 40 8.2 Filling out the commissioning report ........... 41 Installation instructions...

-

Page 5: 1 Introduction

Introduction 1 Introduction 1.1 About this manual The instruction manual is part of the unit and contains information on safe installation of the unit. Observe and adhere to the following instructions: • Read the instruction manual in its entirety prior to installation. •... -

Page 6: Explanation Of Signs

Introduction 1.1.1 Explanation of signs DANGER Imminent threat of danger Failure to comply will lead to death or very severe injuries. WARNING Possible threat of danger Failure to comply can lead to death or very severe injuries. CAUTION Dangerous situation Failure to comply can lead to slight or moderately severe injuries. -

Page 7: Staff Qualification

Introduction 1.2 Staff qualification Explanation of qualification Skilled staff • Skilled staff are those, who due to their profes- sional training, knowledge and experience as well as their knowledge of the relevant standards can assess the tasks given to them and recognize any possible dangers. -

Page 8: 2 Safety Information

Safety information 2 Safety information The unit complies with applicable safety standards. Residual risks associated with operation or risks resulting from incorrect operation cannot be ruled out and are mentioned specifically in the safety instructions and warnings. The installer must be familiar with regional regulations and observe them. - Page 9 Safety information Setup Risk of property damage and personal injury from improper setup • Ensure that the installation area has adequate load-bearing capacity. • Wear safety shoes and protective gloves. Electrical connection Risk of fire from improper connection • Observe applicable regional regulations of the electrical utility. •...

-

Page 10: 3 Description Of The Unit

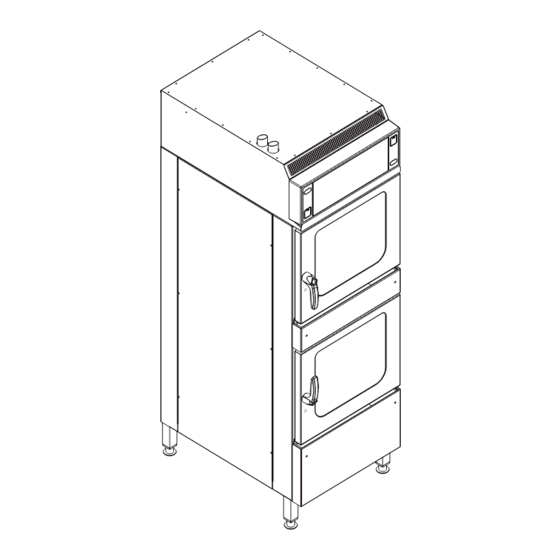

Description of the unit 3 Description of the unit 3.1 Overview of the unit Image: SpaceCombi Team a Air outlet g Discharge channel for door b Control unit h Discharge channel for unit c Cooking zone door i Equipment leg d Door handle j Nameplate e Support rack... -

Page 11: Equipment And Connection Data

Description of the unit 3.2 Equipment and connection data Size Dimensions Unit 550 x 836 x 1770 Length x Width x Height (mm) Due to construction minimum distance between unit and wall (mm) Weight Unit ≈ (kg) Emissions Sound level (db(A)) <... - Page 12 Description of the unit Size Voltage (V) Connected load (kW) 16.8 Fuse (A) Voltage (V) Connected load (kW) 18.2 Fuse (A) Voltage (V) Connected load (kW) 19.6 Fuse (A) Voltage (V) Connected load (kW) 14.8 Fuse (A) Voltage (V) Connected load (kW) 15.6 Fuse (A) Voltage (V)

- Page 13 Description of the unit Size Power optimizing system Connection terminal (mm²) Softened tap water connection Water type Softened tap water, cold Carbonate hardness CaCO < 0,9 (5) (mmol/l (°dH)) Chloride Cl (mg/l) < 100 Iron FE (mg/l) < 0.2 Connection pressure (kPa (bar)) 200 (2) —...

- Page 14 Description of the unit Basic control setting Basic setting Parameter Standard Adjustment Explanation value range Actual voltage 100 — 500 V Set the local, mean voltage between the line conductors. Date/time yyyy - mm - dd Year - Month - Day hh : mm Hour : Minute Altitude...

- Page 15 Description of the unit Basic control setting (Advanced) Basic setting Parameter Standard Adjustment Explanation value range Generator operation 0 = No If a generator is used to supply electricity 1 = Yes Vapour elimination 0 = Low Sets the vapour elimination level 1 = Normal 2 = High Time format...

-

Page 16: 4 Transporting The Unit

Transporting the unit 4 Transporting the unit CAUTION Risk of property damage and personnel injury from tipping equipment • Do not linger next to or behind raised equipment. • Move raised equipment carefully. ATTENTION Risk of physical damage from improper transport •... -

Page 17: Unpacking The Unit

Transporting the unit 4.2 Unpacking the unit CAUTION Risk of injury from sharp edges • Wear protective gloves. When unpacking the unit, inspect it for transport damage. Do not install damaged units or put into service. 1. Remove the packaging. 2. -

Page 18: 5 Setting Up The Unit

Setting up the unit 5 Setting up the unit CAUTION Risk of crushing from improper setup • Protect the unit and work area during setup and alignment. CAUTION Risk of fire from failure to observe applicable regional fire prevention regulations •... -

Page 19: Minimum Clearances

Setting up the unit 5.1 Minimum clearances Image: Minimum clearances to walls, ceiling or units All dimensions in mm * Depending on the kitchen ventilation system and the material composition of the ceiling The following clearances from walls, ceilings or other equipment must be maintained when installing the unit: •... -

Page 20: Placing The Unit On The Equipment Legs

Setting up the unit 5.3 Placing the unit on the equipment legs Requirement The floor must support the weight of the unit 1. Use appropriate lifting gear to lift the unit. 2. Set up the unit in accordance with the planning drawing. 3. - Page 21 Setting up the unit Image: Arrangement of the floor plates (view from above) a Equipment leg with castors c Cooking zone door b Equipment leg d Floor plate A special fastening set, which secures the unit against tilting, is supplied by the manufacturer or is available as an accessory. The fastening set comprises two floor fastenings and all the necessary components for screwing or bonding them to the floor.

- Page 22 Setting up the unit Floor without steam barrier In the case of floors without a steam barrier, the floor plates are screwed to the floor with the enclosed screws. Image: A: Position of the floor plate; B: Floor plate screwed to the floor a Cap nut d Floor plate b Holding plate...

- Page 23 Setting up the unit Floor with steam barrier In the case of floors with a steam barrier, the floor plates are not screwed to the floor but glued with the enclosed adhesive. Image: A: Position of the floor plate; B: Floor plate glued to the floor a Cap nut d Floor plate b Holding plate...

-

Page 24: 6 Connecting The Unit

Connecting the unit 6 Connecting the unit DANGER Risk of personal injury and physical damage from electric shock • Prior to working on the unit, ensure that the unit has been disconnected from the mains. • Do not operate the unit with the housing open. CAUTION Risk of injury from sharp edges •... -

Page 25: Making The Electrical Connection

Connecting the unit Attaching the rear panel ATTENTION Risk of physical damage from leaky housing • Check seals when attaching the housing parts. • Replace damaged gaskets. 1. Carefully press in the rear panel. 2. Screw in the screws on the rear panel. The rear panel must be in contact with the unit on all sides. - Page 26 Connecting the unit Permanent connection CAUTION Risk of property damage and personal injury from improper installation • In the case of a permanent electrical connection, install an all-phase disconnect switch before the unit. Install an all-phase disconnect switch if the unit will be connected permanently to the electric mains.

-

Page 27: Connecting The Power Connection Cable

Connecting the unit Potential equalisation Image: Symbol for potential equalisation The unit can be included in a potential equalisation system by means of appropriately sized wiring. 6.2.1 Connecting the power connection cable DANGER Risk of personal injury and physical damage from electric shock •... -

Page 28: Connecting The Power Optimizing System

Connecting the unit Requirements Unit not live Power connection cable not live Rear panel opened 1. Route the power connection cable into the unit through the cable gland. 2. Connect the power connection cable in accordance with the wiring diagram. 3. - Page 29 Connecting the unit Image: Connecting the power optimisation system a Connection terminals for power c Cable gland optimisation system b Power connection cable for power optimisation system Requirement Unit not live Power connection cable not live Housing opened 1. Pull the power connection cable into the unit through the cable gland.

-

Page 30: Connecting To The Potential Equalisation Circuit

Connecting the unit 6.2.3 Connecting to the potential equalisation circuit Image: Connecting to the potential equalisation circuit 1. Run and attach potential equalisation line to the identified terminal. 2. Fill out the commissioning report. 6.3 Connecting the kitchen management system The units can be connected with a RJ45 plug to a kitchen management system. - Page 31 Connecting the unit Image: Connecting the kitchen management system a RJ45 socket d Network cable b RJ45 plug e Ferrite ring c Cable gland Requirement Unit not live Housing opened 1. Pull the network cable into the unit through the cable gland. 2.

-

Page 32: Making The Basic Control Setting

Connecting the unit 6.4 Making the basic control setting Image: Main menu a Stand-by button e Language selection button b Information bar f "Equipment functions" button c FlexiHelp button g "autoChef" button d "myCooking" button 6.4.1 Changing the basic control setting By entering the password "2100", the basic settings for the installation can be displayed and changed. -

Page 33: Making The Water Connection

Connecting the unit 6.5 Making the water connection Installation work with tap water Installation work on tap water lines and the unit may only be performed by a specialist company, which is approved by the water utility company in the particular region. The applicable regional regulations, standards and guidelines must be observed, as well as the connection conditions imposed by the water utility company responsible. -

Page 34: Connecting The Tap Water Connection Line

Connecting the unit 6.5.1 Connecting the tap water connection line Image: Water connection a Softened tap water d Tap water connection b Connection line e Backflow preventer c Soft water connection f Tap water Requirement Water pressure complies with the specified range (see "Equipment and connection data") Backflow preventer installed The connection lines are pressure-tight and suitable for tap water... -

Page 35: Connecting Softened Tap Water To Both Connections

Connecting the unit 6.5.2 Connecting softened tap water to both connections Image: Connecting softened tap water to both connections a Backflow preventer d T-piece b Connection line e Seal c Dirt filter f Softened tap water If only softened tap water is available at the installation site, use a T- piece to connect both water connections on the unit to each other. -

Page 36: Connecting The Wastewater Line To A Permanent Connection

Connecting the unit Professional qualification for wastewater specialist Installation work on wastewater lines and the unit may only be carried out by a wastewater specialist from the specialist company assigned to the work. 6.6.1 Connecting the wastewater line to a permanent connection Image: Wastewater line with vacuum breaker to a permanent connection a Sewer system d Pipe clamp... -

Page 37: Connecting Wastewater Line To Collection Basin (Optional)

Connecting the unit 6.6.2 Connecting wastewater line to collection basin (optional) Image: A: Collection basin; B: Wastewater connection a Wastewater line f Fastening screw (fitted to building) b Locknut g Wastewater line (in building) c Adjustable foot h Wastewater connection d Waste trap i Sewer system e Collection basin... -

Page 38: 7 Checking Operation

Checking operation 7 Checking operation DANGER Risk of personal injury and physical damage from unsuccessful operational check • Do not put the unit into service. • Contact customer service. Requirement Power connection made Water connection made Wastewater connection made Unit cleaned 7.1 Checking the controls 1. -

Page 39: Heating The Unit Up And Rinsing It Out

Checking operation 7.3 Heating the unit up and rinsing it out 1. Switch on the unit. 2. Tap the "Manual cooking" button. The Manual cooking menu is displayed. 3. Run the Steaming cooking mode for 15 minutes at 100 °C. 4. Rinse out the cooking zone thoroughly with clear water. 5. -

Page 40: 8 Putting The Unit Into Service

Function successfully tested Housing closed 1. Instruct operator. 2. Fill out the Commissioning report. 8.1 Nameplate c d e MKN Maschinenfabrik Kurt Neubauer GmbH & Co. KG, Halberstädter Str. 2a, D-38300 Wolfenbüttel Typ: Item-Nr.: Bez.: www.mkn.com Image: Nameplate information... -

Page 41: Filling Out The Commissioning Report

Putting the unit into service 8.2 Filling out the commissioning report General information Information from the nameplate entered? Type: Desig.: Item no.: (if present) Obvious damage to the unit? What and where?: Unit levelled? General information Unit fastened to the floor? Secured against tilting Secured against sliding Floor screw fitting... - Page 42 Putting the unit into service Basic control setting 80 % power set? 100 % 80 % Current voltage set? Voltage: Audible signal volume set? Quiet Loud Signal tone selected? Volume unit set? fl.oz. (Imperial) fl.oz. (U.S.) Power optimisation system set? Water filter maintenance set? No maintenance message Maintenance message at:...

- Page 43 Putting the unit into service Function check Controls are functioning? Monitoring of the cooking zone door is functioning? Unit heated up and rinsed out? Final notes Was the unit put into service? Comments: Operator trained? Electrical installation was provided by: Signature Company Installer...

- Page 44 Putting the unit into service Installation instructions...

- Page 48 www.mkn.com...

Need help?

Do you have a question about the TKECOD610O and is the answer not in the manual?

Questions and answers