Table of Contents

Advertisement

Quick Links

OPERATING INSTRUCTIONS

ARBOR PRESS FIXTURE FOR

PICOFLEX 91577

SECTION

DESCRIPTION

1.0

MACHINE DESCRIPTION

2.0

SPECIFICATION

3.0

INSTALLATION

4.0

SET UP AND OPERATION

5.0

ADJUSTMENTS / CONNECTOR ORIENTATION

6.0

MAINTENANCE

7.0

SPARE PARTS

8.0

ASSEMBLY DRAWINGS

9.0

FAULT FINDING

10.0

S.P.C. / QUALITY

11.0

MACHINERY INSTALLATION SAFETY

ASSESSMENT CHECKLIST

NOTE:

This module requires a standard Arbor Press (69020-

0660) in order to operate.

MANUAL PART NUMBER 69020-8908

69020-1908

AS.04.05.11/ ISSUE A

FILENAME: M-69020-1908

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for molex 69020-1908

- Page 1 MAINTENANCE SPARE PARTS ASSEMBLY DRAWINGS FAULT FINDING 10.0 S.P.C. / QUALITY 11.0 MACHINERY INSTALLATION SAFETY ASSESSMENT CHECKLIST NOTE: This module requires a standard Arbor Press (69020- 0660) in order to operate. MANUAL PART NUMBER 69020-8908 AS.04.05.11/ ISSUE A FILENAME: M-69020-1908...

-

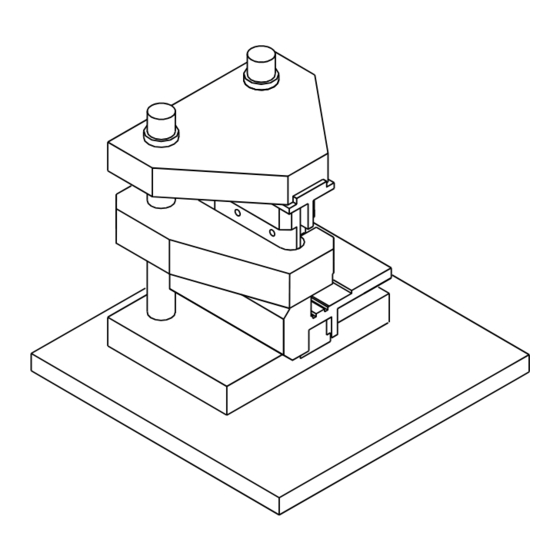

Page 2: Machine Description

69020-1908 ARBOR PRESS FIXTURE - 91577 MACHINE DESCRIPTION This is a small Arbor Press fixture for mounting into the standard European Arbor Press 69020-0660. The tooling will process Picoflex connectors in both directions. It will process the board-in version 91577 on ribbon cable in jumper and daisy chain styles. -

Page 3: Specification

69020-1908 ARBOR PRESS FIXTURE - 91577 ARBOR PRESS FIXTURE PART NO. 69020-1908 DESCRIPTION This fixture is used to terminate pre-cut ribbon cable into the 91577 Picoflex connect 4 - 26 circuit FEATURES This fixture can only be used in a standard Arbor Press part No. - Page 4 69020-1908 ARBOR PRESS FIXTURE - 91577 SPECIFICATION Electrical power supply - not required. Pneumatic power supply - not required. Actuation of unit is done using a manually pulled lever. Unit is designed for medium to low volume production, i.e. it has not been designed for one operator to use continually (R.S.I.

-

Page 5: Installation

69020-1908 ARBOR PRESS FIXTURE - 91577 INSTALLATION Remove Arbor Press fixture from the packing crate. Remove all packing material. Loosen nuts A and B. Raise platen up to allow entry of fixture. Place Arbor Press fixture into Euro Arbor Press checking height is correct for fixture. -

Page 6: Setup And Operation

69020-1908 ARBOR PRESS FIXTURE - 91577 SET UP AND OPERATION After installing this Arbor Press, no further setting-up is required. Using the Arbor Press for production. 4.2.1 Check orientation of connector then place it into the base track, slide it to the right until it meets the end stop screw. - Page 7 69020-1908 ARBOR PRESS FIXTURE - 91577 ADJUSTMENTS / CONNECTOR ORIENTATION Adjustments - First circuit leading/trailing 5.1.1 No adjustments are required between first circuit leading or first circuit trailing. End Stop Adjustment 5.2.1 If the connector end stop needs adjustment then this can be done by loosening the nut and rotating the screw to obtain a good position.

-

Page 8: Maintenance

69020-1908 ARBOR PRESS FIXTURE - 91577 MAINTENANCE All maintenance to be carried out by a qualified engineer. Clean and remove all foreign matter. Inspect parts for damage and replace unserviceable parts. Lightly oil mechanical touching parts. To check any settings, do test samples and obtain results from Q.A. -

Page 9: Spare Parts

69020-1908 ARBOR PRESS FIXTURE - 91577 SPARE PARTS NUMBER GROUP GROUP DESCRIPTION 69127-5157 Insertion Blade 69127-5151 Support Plate Refer to assembly drawing for other parts on the Arbor Press (see section 8.0). Group A - available Ex-stock from Molex Group B - available on a lead time. -

Page 10: Assembly Drawings

69020-1908 ARBOR PRESS FIXTURE - 91577 ASSEMBLY DRAWINGS Drawing number 69020-1908 - Arbor Press Module Drawing number 69020-1905 – Sub Assy Arbor Press Fixture Drawing number 69020-1925 - G.A. of Die Set OPTIONAL EXTRA Drawing Number 69020-1935 - Assey of connector clamp. - Page 11 69020-1908 ARBOR PRESS FIXTURE - 91577 AS.04.05.11/ ISSUE A FILENAME: M-69020-1908...

- Page 12 69020-1908 ARBOR PRESS FIXTURE - 91577 AS.04.05.11/ ISSUE A FILENAME: M-69020-1908...

- Page 13 69020-1908 ARBOR PRESS FIXTURE - 91577 AS.04.05.11/ ISSUE A FILENAME: M-69020-1908...

- Page 14 69020-1908 ARBOR PRESS FIXTURE - 91577 AS.04.05.11/ ISSUE A FILENAME: M-69020-1908...

- Page 15 69020-1908 ARBOR PRESS FIXTURE - 91577 AS.04.05.11/ ISSUE A FILENAME: M-69020-1908...

- Page 16 69020-1908 ARBOR PRESS FIXTURE - 91577 AS.04.05.11/ ISSUE A FILENAME: M-69020-1908...

-

Page 17: Fault Finding

69020-1908 ARBOR PRESS FIXTURE - 91577 FAULT FINDING Bad Termination Inconsistent termination heights. Die set not functioning. Inconsistent bad terminations. Bad Terminations 9.1.1 Check lever is pulled fully down before it comes up again. 9.1.2 Check connector is pushed up to end stop properly before handle is pulled.. - Page 18 69020-1908 ARBOR PRESS FIXTURE - 91577 Inconsistent bad termination. 9.4.1 These are normally caused by the operator. Check and review process that the operator is using, looking for “bad use” problems. AS.04.05.11/ ISSUE A FILENAME: M-69020-1908...

- Page 19 Press. Copies of results can be obtained from M.A.T.E. Customer Service if required. 10.2 The Molex minimum requirement for Cpk is 1.66. This unit therefore exceeds this figure. 10.3 When using this Arbor Press always: Q.A samples on installation to ensure...

- Page 20 69020-1908 ARBOR PRESS FIXTURE - 91577 11.0 MACHINERY INSTALLATION SAFETY ASSESSMENT CHECKLIST 11.1 The following eleven pages must be used after installation of the new electric powered hand tool unit. If these sheets are not used then your own company approved installation assessment system must be used.

Need help?

Do you have a question about the 69020-1908 and is the answer not in the manual?

Questions and answers