WPG MRTALP4625DC3 Operating Instructions Manual

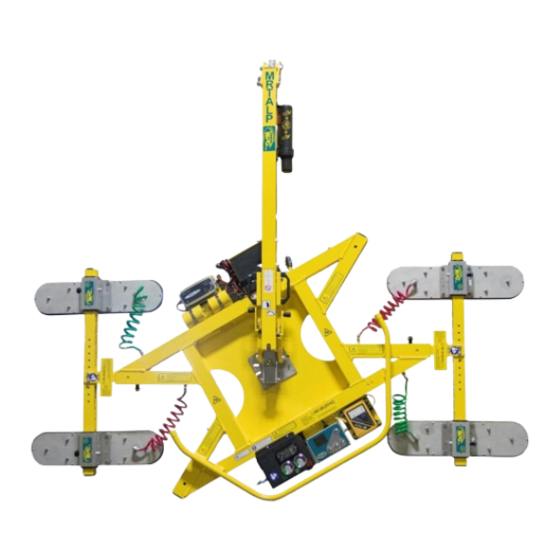

Low-profile manual rotator / tilter 600 dc-voltage, with intelli-grip technology & pad frame t-arm assemblies (available with remote control system)

Hide thumbs

Also See for MRTALP4625DC3:

- Operating instructions manual (52 pages) ,

- Operating instructions manual (51 pages) ,

- Operating instructions manual (48 pages)

Table of Contents

Advertisement

Quick Links

KEEP FOR FUTURE REFERENCE

OPERATING INSTRUCTIONS

908 West Main St – P.O. Box 368

MODEL NUMBERS: MRTALP4625DC3,

Laurel, MT USA 59044

MRTALP410TDC3

406-628-8231 (phone)

800-548-7341 (phone)

SERIAL NUMBER: ___________

406-628-8354 (fax)

(please see serial label and record number here)

LOW-PROFILE MANUAL ROTATOR / TILTER 600

DC-VOLTAGE, WITH INTELLI-GRIP

®

TECHNOLOGY

& PAD FRAME T-ARM ASSEMBLIES

(AVAILABLE WITH REMOTE CONTROL SYSTEM)

READ ALL INSTRUCTIONS AND SAFETY RULES

BEFORE OPERATING THIS LIFTER

DESIGNED FOR MATERIALS HANDLING PROFESSIONALS

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for WPG MRTALP4625DC3

- Page 1 KEEP FOR FUTURE REFERENCE OPERATING INSTRUCTIONS 908 West Main St – P.O. Box 368 MODEL NUMBERS: MRTALP4625DC3, Laurel, MT USA 59044 MRTALP410TDC3 406-628-8231 (phone) 800-548-7341 (phone) SERIAL NUMBER: ___________ 406-628-8354 (fax) (please see serial label and record number here) LOW-PROFILE MANUAL ROTATOR / TILTER 600 DC-VOLTAGE, WITH INTELLI-GRIP ®...

-

Page 3: Table Of Contents

TABLE OF CONTENTS SPECIFICATIONS ......................3 SAFETY ..........................4 OPERATING FEATURES ....................5 ASSEMBLY ........................6 ..................7 NSTALL EMOVE SSEMBLIES .................... 8 NSTALL EMOVE ACUUM ....................... 8 OSITION ACUUM ................8 EPOSITION THE ROSS EMBERS Connecting/Disconnecting Vacuum Hoses ..........................9 INTENDED USE ...................... - Page 4 MAINTENANCE ......................24 ® ................... 24 NTELLI IAGNOSTIC ODES ......................28 NSPECTION CHEDULE Infrequent Use ..................................29 ..........................30 ESTING Operational Tests ................................... 30 Load Test ....................................30 12-V ....................30 ATTERY SSESSMENT 12-V ....................31 ATTERY ECHARGE ..................31 OTIFICATION UZZER ATTERY...

-

Page 5: Specifications

Intelli-Grip ® 7.0‒7.6 ASME Standard BTH-1: Design Category "B", Service Class "0" (see www.wpg.com for more information) different !!–CE–!! This symbol appears only when a CE Standard is from other applicable standards. CE requirements are mandatory in the European Union, but may be optional elsewhere. -

Page 6: Safety

SAFETY Wear personal protective equipment that is appropriate for the load material. Follow trade association guidelines. Use the lifter only in an approved O (see INTENDED USE). PERATING NVIRONMENT Do not use a lifter that is damaged, malfunctioning, or missing parts. Do not use a lifter if the sealing edge of any vacuum pad is cut or otherwise damaged. -

Page 7: Operating Features

OPERATING FEATURES Features shown here are underlined on their first appearance in each section following. 1 LIFT POINT 11 RADIO RECEIVER (optional) 21 AIR FILTERS 2 INSTRUCTIONS CANISTER 12 INTELLI-GRIP ® CONTROL UNIT 22 STROBE LIGHT 3 LIFT BAR 13 “POWER” BUTTON 23 TILT RELEASE LEVER 4 ROTATION RELEASE LEVER 14 “RELEASE”... -

Page 8: Assembly

ASSEMBLY 1) Remove all vacuum lifter restraints and save them with the shipping container for future use. 2) If necessary, assemble the lift bar as shown. Tighten both bolts (2) securely. 3) Adjust the lift point to optimize the lifter's hang angle: 3.1) Remove the retaining bolt (3) and loosen the pivot bolt (4). -

Page 9: T O Install /Remove T-Arm Assemblies

5) Connect the electrical connectors. Install the 9-volt battery for the notification buzzer as directed in the N OTIFICATION UZZER (see MAINTENANCE). ATTERY 6) Assemble the pad frame for optimal load support (see next section). Remove the pad covers and save them for future use (if applicable). 7) Before you place the lifter in service, perform Operational and Load Tests (see MAINTENANCE). -

Page 10: T O Install /Remove Vacuum Pads

NSTALL EMOVE ACUUM 1) Position a sliding/movable pad mount on the T-arm assembly. 2) Use the cotterless hitch pin to secure the pad mount. 3) Install the other pad mounts likewise. Notes: Use only 2 pads on each T-arm assembly. Pads must be arranged symmetrically, to keep the lifter balanced. -

Page 11: Connecting/Disconnecting Vacuum Hoses

Connecting/Disconnecting Vacuum Hoses • To connect a vacuum hose, push the male and female ends of the quick connector together until they lock. Make sure quick connectors seal completely and all vacuum hoses function correctly. • To disconnect the vacuum hose, move the release ring on the female end until the quick connector separates. -

Page 12: Intended Use

INTENDED USE HARACTERISTICS Do NOT lift explosives, radioactive substances or other hazardous materials. Make sure the vacuum lifter is intended to handle each load, according to these requirements: • The load weight must not exceed the Maximum Load Capacity. • The load must be a single piece of relatively nonporous material with a flat and relatively smooth contact surface. -

Page 13: Disposal Of The Lifter

• The work environment is limited by the Maximum Operating Elevation and Operating Temperatures. Metal particles and similar environmental contaminates could result in vacuum pump failure. • The lifter is not designed to be watertight: Do not submerge the lifter or use it in unsuitable weather. -

Page 14: Operation

OPERATION EFORE SING THE IFTER Determine whether the vacuum lifter is capable of each intended task (see SPECIFICATIONS and INTENDED USE). Then complete the following preparations: Taking Safety Precautions Read all directions and safety rules before using lifter. • Be trained in all industry and regulatory standards for lifter operation in your region. Always wear appropriate personal protective equipment. -

Page 15: Performing Inspections And Tests

Performing Inspections and Tests Always check battery energy before using lifter (see MAINTENANCE). • Follow the I and T (see NSPECTION CHEDULE ESTING MAINTENANCE). • Always perform a V before placing a lifter in service ACUUM (see MAINTENANCE). Examine air filters regularly and service when needed. •... -

Page 16: T O Attach The Pads To A Load

TTACH THE ADS TO A Positioning the Lifter on the Load 1) Make sure that the contact surfaces of the load and the vacuum pads are clean (see MAINTENANCE). Attach lifter to load as directed below. Failure to follow instructions can result in load damage or personal injury. -

Page 17: Powering Up The Lifter

Powering up the Lifter Press the lifter's power button ( The vacuum pump will run for a few seconds, as a normal function of the Intelli-Grip ® self-diagnostics. To use the Remote Control System, hold the transmitter power button ( ) briefly to activate the radio transmitter. -

Page 18: Sealing The Pads On The Load

Sealing the Pads on the Load Press the “attach” button ( ) on the lifter. Keep “attach” function activated throughout lift. To use the Remote Control System, press the “attach” button ( ) on the radio transmitter. The vacuum pump will run until the vacuum pads seal completely. If the lifter takes too long to attach, the notification buzzer chirps and the LCD screen displays “Vacuum not increasing normally”, along with a diagnostic code (see MAINTENANCE). -

Page 19: Vacuum Level On Optimal Surfaces

Vacuum Level on Optimal Surfaces clean, smooth, nonporous When the lifter is attached to surfaces, it should be able to maintain sufficient vacuum for lifting, except when used above the Maximum Operating Elevation. If it does not, check for faults in the vacuum generating system (see MAINTENANCE: ACUUM Vacuum Level on Other Surfaces contaminated, rough or porous... -

Page 20: Ift And Ove The Oad

IFT AND OVE THE Lift bar must be vertical to lift load. About the Tilt Linkage Unbalanced loads may tilt unexpectedly during lifter operation. The tilt linkage minimizes operator effort and automatically holds a balanced load in either the upright or the flat position. However, an unbalanced load may tilt unexpectedly, resulting in load damage or personal injury. -

Page 21: Controlling The Lifter And Load

2) Stop using the lifter until the cause of the vacuum loss is identified: • Inspect the vacuum pads for damage and perform the V (see MAINTENANCE). ACUUM • When necessary, inspect the entire vacuum generating system. 3) Correct any faults before resuming normal operation of the lifter. Controlling the Lifter and Load When the lifter is ready, use the hoisting equipment to raise the lifter and load as needed. -

Page 22: T O Rotate The Load

OTATE THE Never disengage rotation and tilt latches at the same time, because this could result in load damage or personal injury. Make sure load is positioned correctly on lifter (as previously directed) Never rotate load that is oriented in flat position. Never rotate load when lifter is attached “above center”... -

Page 23: T O Tilt The Load

ILT THE Never disengage rotation and tilt latches at the same time, because this could result in load damage or personal injury. Make sure load is positioned correctly on lifter (as previously directed) 1) Make sure the load has enough clearance to tilt without contacting anyone or anything. -

Page 24: T O Release The Pads From The Load

ELEASE THE ADS FROM THE Make sure load is at rest and fully supported before releasing vacuum pads. 1) Hold the “function” button ( ) and the “release” button ) to break the vacuum seal. If not, follow the directions on the LCD screen. -

Page 25: After Using The Lifter

FTER SING THE IFTER 1) Press the power button ( ) and the “function” button ) to power down the vacuum lifter. Caution: Do not set lifter on surfaces that could soil or damage vacuum pads. 2) Use the hoisting equipment to lower the lifter gently onto a stable support. -

Page 26: Maintenance

(none) Fault is detected in modular circuit board. If code does not clear automatically, service is required. “Firmware updater detected (#)” (none) (none) Service tool is connected. Remove it before resuming lifter use and contact WPG. Rev 5.2/9-19 MRTALP4-DC3: 35058... - Page 27 Strobe Buzzer Light Code On-Screen Message Pattern Activity Explanations/Directions “Module revision not compatible” 1 chirp (none) Make sure lifter is used within Operating every 2 Temperatures (see SPECIFICATIONS). Then power seconds lifter down and up again. If code persists, the modular circuit board is incompatible or it has failed.

- Page 28 Strobe Buzzer Light Code On-Screen Message Pattern Activity Explanations/Directions “Power-down reminder” 2 chirps on briefly Power down to prevent 12V battery discharge when lifter is not in use. “Auto power-down disabled” (none) (none) Automatic power-down is prevented. Power down lifter and power up again. If code persists, service is required.

- Page 29 In case of suspected leak, check for fault(s) in vacuum system (see relevant ASSEMBLY, OPERATION and MAINTENANCE topics). In case of high elevation, contact WPG for directions. V040 “Lockout (vacuum sensor error)” continuous (none) Once “Power Save”...

-

Page 30: Inspection Schedule

NSPECTION CHEDULE Perform inspections according to the following frequency schedule. If any fault is found, correct it and perform the next most frequent inspection before using the vacuum lifter. Frequent Periodic Action Every Lift (20-40 hours) (250-400 hours) Examine vacuum pads for contaminates or ... -

Page 31: Infrequent Use

Frequent Periodic Action Every Lift (20-40 hours) (250-400 hours) Inspect entire electrical system for damage, wear or contamination that could be hazardous, in compliance with all local codes and regulatory standards. Caution: Use appropriate cleaning methods for each electrical part, as specified by codes and standards. -

Page 32: Testing

ESTING initially following any repair Perform the following tests when you place the lifter in service Correct any fault and retest before using the lifter. Operational Tests • Perform the V to follow. ACUUM • Test all features and functions of the lifter (see OPERATING FEATURES, OPERATION and MAINTENANCE). -

Page 33: 12-Volt Battery Recharge

12-V ATTERY ECHARGE Charge the battery whenever the battery gauge shows reduced energy (see previous section). Caution: Make sure the lifter is powered down. Make sure power source has ground fault circuit interrupter. Identify the input voltage marked on the battery charger and plug it in to an appropriate power source. -

Page 34: Vacuum Pad Maintenance

ACUUM AINTENANCE Pad-to-Load Friction Coefficient The friction coefficient represents the lifter's ability to resist load slippage. The Maximum Load Capacity assumes a friction coefficient of 1, based on testing of clean, new, standard If the lifter is used under other rubber vacuum pads on clean, dry, regular glass. -

Page 35: Vacuum Test

ACUUM Test the vacuum system for leakage according to the preceding I and T NSPECTION CHEDULE ESTING 1) Clean the face of each vacuum pad as previously directed. 2) Use a test load with weight equal to the Maximum Load Capacity, a clean, smooth, nonporous surface and other appropriate L (see INTENDED USE). -

Page 36: T O Replace Sealing Ring In Vpfs10T Pads

VPFS10T P EPLACE EALING ING IN If the lifter has VPFS10T vacuum pads, replace sealing rings as follows: 1) Remove the old sealing ring. Make sure the entire vacuum pad is clean, including the mounting groove. 2) Place the inside edge of a new sealing ring against the inside edge of the mounting groove. -

Page 37: Eplace Ad Nserts In Vpfs625 Pads

VPFS625 P EPLACE NSERTS IN If the lifter has VPFS625 vacuum pads, replace pad inserts as follows: 1) Remove the lock nuts and washers that secure the top plate to the face plate of the pad assembly. 2) Remove the top plate. 3) Remove the old pad insert. - Page 38 6) Reinstall the top plate, washers and lock nuts. 7) Tighten all lock nuts securely. Note: Replace worn nuts as needed. Rev 5.2/9-19 MRTALP4-DC3: 35058...

-

Page 39: Replacement Parts List

* Length as required; vacuum hose is sold by the foot (approx. 30.5 cm). See SERVICE MANUAL #36105 for additional parts. SERVICE ONLY WITH IDENTICAL REPLACEMENT PARTS, AVAILABLE AT WPG.COM OR THROUGH AN AUTHORIZED WPG DEALER Rev 5.2/9-19 MRTALP4-DC3: 35058... -

Page 40: Limited Warranty

• the product has been damaged, misused, or neglected. If a problem is not covered under warranty, WPG will notify the customer of costs prior to repair. If the customer agrees to pay all repair costs and to receive the repaired product on a C.O.D. - Page 41 Rev 5.2/9-19 MRTALP4-DC3: 35058...

- Page 42 Rev 5.2/9-19 MRTALP4-DC3: 35058...

Need help?

Do you have a question about the MRTALP4625DC3 and is the answer not in the manual?

Questions and answers