Advertisement

Quick Links

Technical Support and E-Warranty Certificate www.vevor.com/support

DIAMOND CORE DRILL

USER MANUAL

We continue to be committed to provide you tools with competitive price.

"Save Half", "Half Price" or any other similar expressions used by us only represents an

estimate of savings you might benefit from buying certain tools with us compared to the major

top brands and doses not necessarily mean to cover all categories of tools offered by us. You

are kindly reminded to verify carefully when you are placing an order with us if you are

actually saving half in comparison with the top major brands.

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for VEVOR Z1Z-9230

- Page 1 Technical Support and E-Warranty Certificate www.vevor.com/support DIAMOND CORE DRILL USER MANUAL We continue to be committed to provide you tools with competitive price. "Save Half", "Half Price" or any other similar expressions used by us only represents an estimate of savings you might benefit from buying certain tools with us compared to the major top brands and doses not necessarily mean to cover all categories of tools offered by us.

- Page 3 CustomerService@vevor.com This is the original instruction, please read all manual instructions carefully before operating. VEVOR reserves a clear interpretation of our user manual. The appearance of the product shall be subject to the product you received. Please forgive us that we won't inform you again if...

- Page 4 The symbols used in this manual are intended to alert you of the possible risks. Please fully read the safety signs and instructions below. The warning themselves do not prevent the risks and can not be a substitute for proper methods of avoiding accidents. This symbol, placed before a safety comment, indicates a kind of precaution, waning, or danger.

-

Page 5: General Power Tool Safety Warnings

This product is subject to the provision of European Directive 2012/19/EC. The symbol showing a crossed-out wheeled bin indicates that the product requires separate refuse collection in the European Union. This symbol applies to the product and all accessories marked with this symbol. Products marked as such may not be discarded with normal domestic waste, but must be taken to a collection point for recycling electrical and electronic devices. - Page 6 Save all warnings and instructions for future reference. The term "power tool" in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool. 1) Work area safety a) Keep work area clean and well lit. Cluttered or dark areas invite accidents. b) Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust.

- Page 7 b) Use personal protective equipment. Always wear eye protection. Protective equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries. c) Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power source and/or battery pack, picking up or carrying the tool.

- Page 8 e) Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before use. Poorly maintained power tools cause many accidents. f) Keep cutting tools sharp and clean.

-

Page 9: Handling Instructions

6. Take care of the downward direction in the high position, safety belt and safety cap, etc., are recommended. 7. In order to avoid unintentional electric shock, please check the grounding condition of electrified body in working area before operating, it is not allowed to operate the tool under the uncertain condition, once the drill bit touched the electrified body in the wall, floorboard or baseboard, the electrified outer shell of drill may cause personal injuries. - Page 10 3. There should be some water in the water switch of drill. 4. Material: When drilling on the reinforced concrete, if the drill bit touches the steel bar, the current will suddenly increase, the motor will vibrate, and the bit will be overloaded. At this time, the drill thrust should be reduced properly.

-

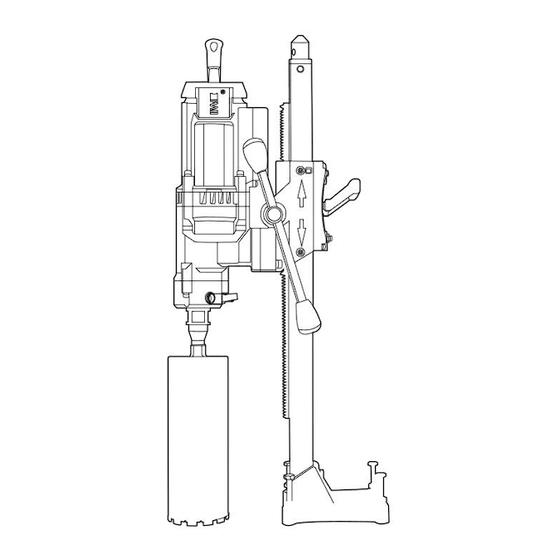

Page 11: Main Technical Parameter

4. STRUCTURE, FEATURE AND USAGE Z1Z-9230 is a portable diamond core drill, suitable for diamond bits 20-230mm stand-alone. Equipped with safety friction clutch, it is easy to use, safe and reliable. Using the diamond thin-wall drill bit produced by our company, this equipment can drill a full range of reinforced concrete, brick, and other materials, with no dust, no vibration, high precision, fast drilling speed and other advantages. - Page 12 worn about 7mm, it must be replaced. Only use the original, otherwise the commutator may be damaged and both brushes must be replaced at the same time. If you find serious sparks or serious wear and burn of the commutator during operation, please check and repair the commutator or replace a new rotor.

-

Page 13: Standard Accessory

Heavy sparks 1.Rotor winding is on short 1.Repair or replace rotor. and ring sparks circuit or open circuit 2.Adjust the spring pressure occur 2.Brush spring positioned 3.Replace a new rotor on commutator improperly or ill contacting of motor 3.Commutator worn seriously Drill vibrated 1.The base fixed loosened 1.Reassemble and fix the... - Page 14 9. MAIN PART LIST AND THE BREAKDOWN DRAWING THE PARTS LIST OF Z1Z-9230 ENGINEERING DRILL...

- Page 16 Part list for Z1Z-9230 Descripition Descripition M5x30 Hexagon socket head cap 2# gear screw Retaining ring for shaft D15 Spring washer 5 Middle cover Flat washer 5 Water seal FB38x62x8 Bearing 6202-2RZ Bearing pressing plate Water seal cover Cross recessed countersunk φ38.8xφ3.1xφ45 O-ring...

- Page 17 Cross pan head tapping Flat washer 8 screw ST4.2x13 Circuit protector 12A Spring washer 8 Hexagon socket head cap Switch(DELIXI DZ47s D25) screw M8x30 Cable press board Track block 1 Switch box cover Iron track block 1 Jacket Track bar Cross pan head tapping Cross countersunk head screwST3.5x16...

- Page 18 Hexagon socket head cap Bakelite ball M12 screw M8x25 Operating rod sleeve Cap screw Rack operating lever Column...

- Page 20 Technical Support and E-Warranty Certificate www.vevor.com/support...

Need help?

Do you have a question about the Z1Z-9230 and is the answer not in the manual?

Questions and answers

Qual a Voltagem de Z1Z-9230

The voltage of the VEVOR Z1Z-9230 is 220-230V for EU and 120V for US/AUS.

This answer is automatically generated