Summary of Contents for Joto E-HP-JLF-3243

- Page 1 Joto Large Format Heat Press Model No.: E-HP-JLF-3243 OPERATOR’ S MANUAL Bringing images to life...

-

Page 2: Safety

Proceed with caution when using the heat press. To reduce the likelihood of circuit overload, Joto recommends to use a dedicated circuit if possible. Make sure that the cord is safely secured so it cannot be pulled or tripped over. -

Page 3: Table Of Contents

Reproduction of this manual requires written consent from Joto. Errors and amendments of technical details excepted, all rights reserved. Joto is not liable for any direct or indirect damages caused by the use of this product. Table of Contents Safety............2... -

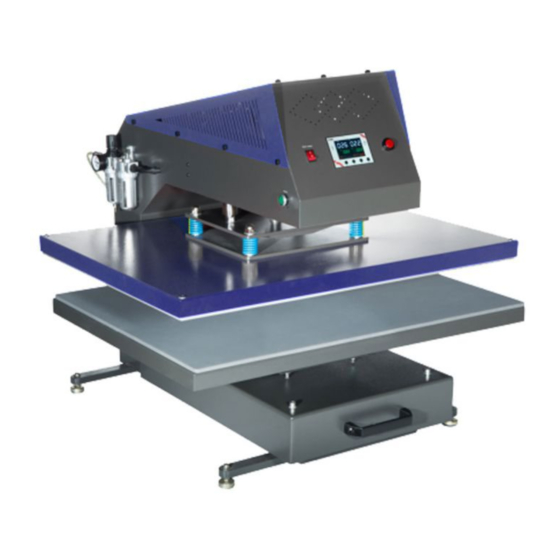

Page 4: Large Format Heat Press Overview

Heat Press Overview Technical Specs Model No.: E-HP-JLF-3243 Machine Type: Large Format 31.5” x 43.3” Machine Size: 48.22” x 51.02” x 39.13” (1225mm x 1296mm x 994mm) Printable Articles: Up to 0.78” (20mm) Thickness Controller GY-06 Digital Controller Voltage: 220v/ 1 Phase/ 120v/ 1 Phase Power: 8.1kw... -

Page 5: Machine Parts Diagram

Machine Parts Diagram GY-06 Digital Controller Air filter Valve Emergency Stop Button Power Switch Connection Plate Start Swith Large Format Handle www.jotoimagingsupplies.com 1-800-565-5686 Blaine, WA | Las Vegas, NV | Antioch TN | Coquitlam, BC | Brampton, ON... -

Page 6: Setting Up Your Heat Press

Setting Up Your Large Format How to Read The Display 1.) Turn on Heat Press, display screen will switch on 2.) Right side PV value = Current Temperature 3.) Left side PV value = Current Time 4.) Right side SV value = Set Press Temperature 5.) Left side SV value = Set Press Time Setting Press Temperature Press the corresponding number of SV to start. -

Page 7: Operating Instructions

Operating Instructions Pressing a images to your substrate Ensure that the air supply is connected to the press. Turn on the Main Power Switch. Adjust the air pressure to 0.6-0.8Mpa. Heat platen will open automatically. Draw out the under plate and place the substrate on top of the under plate. Set the appropriate Press Temperature, and Time as per your transfer paper, transfer vinyl or sublimation instructions. -

Page 8: Heat Pressing Guide

Heat Pressing Guide Transfer Vinyls MultiCut One-4-All MultiCut Premium Temperature: 265˚F Temperature: 310-330˚F Time: 3-5 seconds Time: 45 seconds Peel: Warm (Cotton) Peel: Warm/Cool MultiCut New Flock MultiCut Lustre Temperature: 310-330˚F Temperature: 310-330˚F Time: 15 seconds Time: 15-20 seconds Peel: Warm Peel: Hot to Cold MultiCut Nylon MultiCut Style... - Page 9 Heat Pressing Guide Sublimation Items Sublimatable Ceramic iLumipiX Photo Tiles Panels Temperature: 400˚F Temperature: 400˚F Time: 360-420 seconds Time: 65-150 seconds Peel: Hot Method: Substrate face down Time may varied based on size. Scan the QR code on the left for Image face up instructions or visit our website.

-

Page 10: Maintenance

Note: This heat press should not be set to exceed 400˚F (200˚C). Setting the press temperature to above 400˚F (200˚C) may cause a fire hazard. If your mug press stops working, please contact Joto at 1-800-565-5686 so we can help you troubleshoot. -

Page 11: Troubleshooting

Troubleshooting Printing Process A. The color is a little bit light: The temperature is too low, the pressure is uneven, or the time is too short. B. The picture is vague: The printing time is long, causing the spread of ink. C. -

Page 12: Expanded View

Expanded Diagram www.jotoimagingsupplies.com 1-800-565-5686 Blaine, WA | Las Vegas, NV | Antioch TN | Coquitlam, BC | Brampton, ON... - Page 13 Expanded Diagram Serial Part Name Serial Part Name Adapter plate welding plug 7 GB_FASTENER_WASHER_PWNA 12 PLC Digital Time & Temp. 25 Open slider Control Plate electrode 1 Front sealing plate 1 Anti-shake sleeve 1 Conical machine feet GB_FASTENER_SCREWS_ Drawing board stiffener HSHCS M12X25-N Rack panel 1 40 Heating pipe 1020...

-

Page 14: Circuit Diagram

Circuit Diagram www.jotoimagingsupplies.com 1-800-565-5686 Blaine, WA | Las Vegas, NV | Antioch TN | Coquitlam, BC | Brampton, ON... -

Page 15: Warranty

HEREBY DISCLAIMS, THE OBLIGATIONS OF JOTO UNDER THIS WARRANTY ARE EXPRESSLY LIMITED TO THE FOLLOWING: a. JOTO will repair or replace at its option, free of charge, any product, component of its products, and any component it sells separately which is installed in JOTO’s heat presses, within twenty-four months and sixty months for the heating platen after shipment by same. -

Page 16: Contact

Bringing images to life www.jotoimagingsupplies.com Tel: 1-800-565-5686 Fax: 1-800-565-5622 Coquitlam, BC | Brampton, ON Blaine, WA | Las Vegas, NV |Antioch TN...

Need help?

Do you have a question about the E-HP-JLF-3243 and is the answer not in the manual?

Questions and answers