Subscribe to Our Youtube Channel

Summary of Contents for Zimmer SWM1000 Series

- Page 1 INSTALLATION AND OPERATING INSTRUCTIONS Angular pivot unit SWM1000 DDOC00964 THE KNOW-HOW FACTORY www.zimmer-group.com...

-

Page 3: Table Of Contents

11.3.1 Adjusting the shock absorber for the 0°/90° position ............................14 11.4 Setting the sensors ..........................................14 12 Error diagnosis ................................... 15 13 Maintenance ....................................16 14 Decommissioning/disposal ..............................16 15 Declaration of Incorporation ..............................17 Zimmer GmbH • Im Salmenkopf 5 • 77866 Rheinau, Germany • +49 7844 9138 0 • www.zimmer-group.com... -

Page 4: Supporting Documents

Ö The warning symbols are assigned according to the type of danger. INFORMATION This category contains useful tips for handling the product efficiently. Failure to observe these tips will not result in damage to the product. This information does not include any information relevant to health or workplace safety. Zimmer GmbH • Im Salmenkopf 5 • 77866 Rheinau, Germany • +49 7844 9138 0 • www.zimmer-group.com... -

Page 5: Safety Notices

• Use of the product under extreme conditions, such as aggressive fluids or abrasive dusts • Additional drilled holes or threads Ö Zimmer GmbH shall accept no liability for any damage caused by improper use. The operator bears sole responsibility. ► Make sure that the power supply is disconnected before you mount, adjust, modify, maintain or repair the product. -

Page 6: Proper Use

► Operate the product only when it is in a technical condition that corresponds to the guaranteed parameters and operating conditions. Ö Zimmer GmbH shall accept no liability for any damage caused by improper use. The operator bears sole responsibility. -

Page 7: Product Description

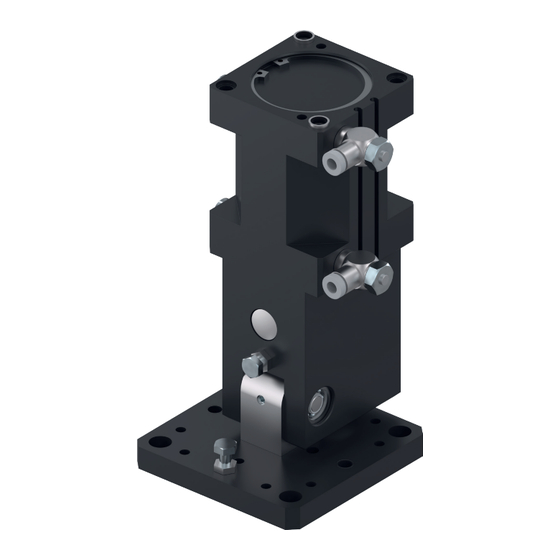

Pneumatic cylinder Joint Stop screw Bearing pin Connecting plate 5.1 Type plate A type plate is attached to the housing of the product. The article number and the confirmation number are shown on the type XX-XXXXXX plate. Article number Confirmation number Zimmer GmbH • Im Salmenkopf 5 • 77866 Rheinau, Germany • +49 7844 9138 0 • www.zimmer-group.com... -

Page 8: Technical Data

7 Accessories/scope of delivery INFORMATION If any accessories not sold or authorized by Zimmer GmbH are used, the function of the product cannot be guaranteed. Zimmer GmbH accessories are specifically tailored to the individual products. ► For optional accessories and those included in the scope of delivery, refer to our website. -

Page 9: Installation

► Install the product on an appropriate mounting surface in accordance with the flatness specifications. ► Make sure that the mounting piece is sufficiently rigid. ► Observe the tightening torque of the mounting screws. ► Verify the permitted load capacity of the required screw connections in accordance with VDI 2230. Zimmer GmbH • Im Salmenkopf 5 • 77866 Rheinau, Germany • +49 7844 9138 0 • www.zimmer-group.com... -

Page 10: Installing The Product

The figure shows the delivered state of the product. Several connections are available for the energy supply. ► If using the alternative connections, close off the connections pictured with corresponding grub screws. Flow control valve Zimmer GmbH • Im Salmenkopf 5 • 77866 Rheinau, Germany • +49 7844 9138 0 • www.zimmer-group.com... -

Page 11: Installing Accessories

► Before installation, check whether the application is suitable in terms of weight. ► Position the application on the product with the straight pins. ► Install the application on the product using suitable mounting screws. Zimmer GmbH • Im Salmenkopf 5 • 77866 Rheinau, Germany • +49 7844 9138 0 • www.zimmer-group.com... -

Page 12: Commissioning

► Swivel the product to the desired position by hand. ► Screw the stop screw in or out to specify the swivel angle. ► Tighten the lock nut. Stop screw Lock nut Zimmer GmbH • Im Salmenkopf 5 • 77866 Rheinau, Germany • +49 7844 9138 0 • www.zimmer-group.com... -

Page 13: Setting The Swivel Time Without Shock Absorbers

► Enter the operating temperature settings for the shock absorbers. • After approximately 30 cycles in the cycle time that is selected later, the shock absorber reaches operating temperature. • If a break time of > 1 minute is exceeded, no shock absorber warm-up is required. INFORMATION ► Check to ensure that there is uniform swivel movement and exhaust air flow-controlled movement to the end positions. ► If necessary, readjust the adjustment screws and shock absorbers. Zimmer GmbH • Im Salmenkopf 5 • 77866 Rheinau, Germany • +49 7844 9138 0 • www.zimmer-group.com... -

Page 14: Adjusting The Shock Absorber For The 0°/90° Position

Shock absorber 11.4 Setting the sensors NOTICE To ensure reliable sensing, only those sensors sold by Zimmer GmbH and listed as accessories may be used. ► Note that switching point shifts may occur if the sensors are exposed to an additional, external magnetic field. INFORMATION ► More information can be found in the installation and operating instructions of the sensor. -

Page 15: Error Diagnosis

► Increase the air pressure to maximum. ► Try to repeat the process. • Seals overflowing ► Please contact Customer Service. • Moving components lubricated too ► Please contact Customer Service. heavily Zimmer GmbH • Im Salmenkopf 5 • 77866 Rheinau, Germany • +49 7844 9138 0 • www.zimmer-group.com... -

Page 16: Maintenance

► Have maintenance work be performed by Customer Service whenever possible. Ö Dismantling and reassembling the product without authorization may result in complications, as special installation equipment is required in some cases. Zimmer GmbH accepts no liability for any resulting malfunctions or damage. 14 Decommissioning/disposal INFORMATION When the product reaches the end of its operational phase, it can be completely disassembled and disposed of. -

Page 17: Declaration Of Incorporation

Machinery and an EC Declaration of Conformity has been drawn up in accordance with Annex II 1 A. Kurt Ross Rheinau, Germany, 3/26/2019 Authorized representative for the (Place and date of issuance) Martin Zimmer compilation of relevant technical (Legally binding signature) documents Managing Partner Zimmer GmbH • Im Salmenkopf 5 • 77866 Rheinau, Germany • +49 7844 9138 0 • www.zimmer-group.com...

Need help?

Do you have a question about the SWM1000 Series and is the answer not in the manual?

Questions and answers