SCHUNK JGP-P 40 Assembly And Operating Manual

2-finger parallel gripper

Hide thumbs

Also See for JGP-P 40:

- Assembly and operating manual (68 pages) ,

- Assembly and operating manual (68 pages)

Subscribe to Our Youtube Channel

Summary of Contents for SCHUNK JGP-P 40

- Page 1 Assembly and Operating Manual JGP-P 2-finger parallel gripper Translation of Original Operating Manual...

- Page 2 Imprint Imprint Copyright: This manual is protected by copyright. The author is SCHUNK SE & Co. KG. All rights reserved. Technical changes: We reserve the right to make alterations for the purpose of technical improvement. Document number: 1469637 Version: 05.00 | 24/08/2023 | en...

-

Page 3: Table Of Contents

Table of Contents Table of Contents 1 General ..................... 5 About this manual................1.1.1 Presentation of Warning Labels ............. 1.1.2 Applicable documents ..............1.1.3 Sizes..................1.1.4 Variants ................... 1.2 Warranty ................... 1.3 Scope of delivery................. 8 1.4 Accessories ..................1.4.1 Spare parts packages .............. - Page 4 Table of Contents 5.2 Connections ..................21 5.2.1 Mechanical connection..............21 5.2.2 Pneumatic connection..............24 5.3 Attaching additional structure..............26 5.4 Mounting the sensor................28 5.4.1 Overview of sensors ..............28 5.4.2 Setting dimensions for magnetic switches ........29 5.4.3 Switch-off hysteresis for magnetic switches ........30 5.4.4 Mounting inductive proximity switch IN ..........

-

Page 5: General

General 1 General 1.1 About this manual This manual contains important information for a safe and appropriate use of the product. This manual is an integral part of the product and must be kept accessible for the personnel at all times. Before starting work, the personnel must have read and understood this operating manual. -

Page 6: Applicable Documents

Assembly and operating manuals of the accessories * The documents labeled with an asterisk (*) can be downloaded from schunk.com. 1.1.3 Sizes This operating manual applies to the following sizes: JGP-P 40 JGP-P 50 JGP-P 64 JGP-P 80 JGP-P 100... -

Page 7: Warranty

General 1.2 Warranty If the product is used as intended, the warranty is valid for 24 months from the ex-works delivery date under the following conditions: Observe the ambient conditions and operating conditions, } 2.5 [/ 11] Observe the specified maintenance intervals, } 7 [/ 51] Parts touching the workpiece and wear parts are not included in the warranty. -

Page 8: Scope Of Delivery

General 1.3 Scope of delivery The scope of delivery includes 2-finger parallel gripper JGP-P in the version ordered Accessory pack Content of the accessory pack: 2x centering sleeve for gripper fastening 4x centering sleeve for finger fastening 2 x O-ring for hose-free direct connection ID.-No. -

Page 9: Accessories

Spare parts packages allow for the maintenance and repair of individual components. For information on the range of the spare parts packages, see www.schunk.com > Service. The following spare parts packages are available for this product: Spare part package "Sealing kit"... -

Page 10: Basic Safety Notes

Use of unauthorized spare parts Using unauthorized spare parts can endanger personnel and damage the product or cause it to malfunction. Use only original spare parts or spares authorized by SCHUNK. 2.4 Gripper fingers Requirements of gripper fingers Accumulated energy can make the product unsafe and risk the danger of serious injuries and considerable material damage. -

Page 11: Ambient Conditions And Operating Conditions

Basic safety notes Execute the gripper fingers in such a way that the product reaches either the "open" or "closed" position in a de- energized state. Only change gripper fingers if no residual energy can be released. Make sure that the product and the top jaws are a sufficient size for the application. -

Page 12: Personal Protective Equipment

Basic safety notes Service personnel of Due to its technical training, knowledge and experience, service the manufacturer personnel of the manufacturer is able to perform the delegated tasks and to recognize and avoid possible dangers. 2.7 Personal protective equipment Use of personal protective equipment Personal protective equipment serves to protect staff against danger which may interfere with their health or safety at work. -

Page 13: Transport

Basic safety notes 2.9 Transport Handling during transport Incorrect handling during transport may impair the product's safety and cause serious injuries and considerable material damage. When handling heavy weights, use lifting equipment to lift the product and transport it by appropriate means. Secure the product against falling during transportation and handling. -

Page 14: Protection During Handling And Assembly

Basic safety notes 2.12.1 Protection during handling and assembly Incorrect handling and assembly Incorrect handling and assembly may impair the product's safety and cause serious injuries and considerable material damage. Have all work carried out by appropriately qualified personnel. For all work, secure the product against accidental operation. Observe the relevant accident prevention rules. -

Page 15: Protection Against Electric Shock

Basic safety notes fence must be rigid enough to withstand the maximum possible movement energy. EMERGENCY STOP switches must be easily and quickly accessible. Before starting up the machine or automated system, check that the EMERGENCY STOP system is working. Prevent operation of the machine if this protective equipment does not function correctly. -

Page 16: Notes On Particular Risks

Basic safety notes 2.13 Notes on particular risks DANGER Risk of fatal injury from suspended loads! Falling loads can cause serious injuries and even death. Stand clear of suspended loads and do not step within their swiveling range. Never move loads without supervision. Do not leave suspended loads unattended. - Page 17 Basic safety notes WARNING Risk of injury due to electromagnetic interference! Electromagnetic interference can cause the product to malfunction and lead to disturbances in medical implants (e.g. pacemakers). Unexpected movements or ejected objects can cause serious injury or death. Ensure adequate shielding against magnetic fields in the immediate vicinity of the product, so that exact limits according to relevant standards, e.g.

-

Page 18: Technical Data

Technical data 3 Technical data Connection data Pressure medium Compressed air, compressed air quality according to ISO 8573‐ 1:2010 [7:4:4] Nominal operating pressure [bar] Minimum pressure [bar] without maintenance of gripping force Minimum pressure [bar] with maintenance of gripping force Maximum pressure [bar] without maintenance of gripping force... -

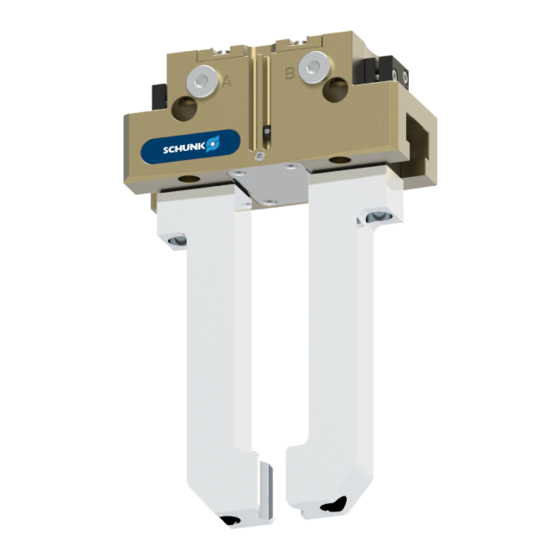

Page 19: Design And Description

Design and description 4 Design and description 4.1 Design 2-finger parallel gripper Air purge connection Base jaw Compressed air main connection Groove for magnetic switch Housing 4.2 Description Universal 2-finger parallel gripper with a high gripping force and high maximum moments due to the use of a T-slot guidance. 05.00 | JGP-P | Assembly and Operating Manual | en | 1469637... -

Page 20: Assembly And Settings

Assembly and settings 5 Assembly and settings 5.1 Installing and connecting WARNING Risk of injury due to unexpected movements! If the power supply is switched on or residual energy remains in the system, components can move unexpectedly and cause serious injuries. Before starting any work on the product: Switch off the power supply and secure against restarting. -

Page 21: Connections

Assembly and settings 5.2 Connections 5.2.1 Mechanical connection Evenness of the The values apply to the whole mounting surface to which the mounting surface product is mounted. Edge length Permissible unevenness < 100 < 0.02 > 100 < 0.05 Tab.: Requirements for evenness of the mounting surface (Dimensions in mm) Connections at the base jaws Connections at the base jaws... - Page 22 Assembly and settings Connections at the The product can be mounted from three sides. housing Connections at the housing Side A JGP-P ① Screws * ② Centering sleeve M3 / 6 Ø5 M4 / 11 Ø6 M5 / 12 Ø8 M5 / 15 Ø8 M6 / 14...

- Page 23 Assembly and settings Side C JGP-P ⑤ Screws * ③ Centering sleeve M2.5 Ø5 Ø6 Ø8 Ø8 Ø10 Ø12 Ø12 Ø14 Ø16 Ø22 * DIN EN 4762, max. strength class 8.8 Connections for additional structure Connections at the housing, Sizes: A - to 100, B - from 125 JGP-P ①...

-

Page 24: Pneumatic Connection

Assembly and settings 5.2.2 Pneumatic connection NOTE Observe the requirements for the compressed air supply, [/ 18]. } 3 In case of compressed air loss (cutting off the energy line), the components lose their dynamic effects and do not remain in a secure position. However, the use of a SDV-P pressure maintenance valve is recommended in this case in order to maintain the dynamic effect for some time. - Page 25 Assembly and settings JGP-P Main air connections * Air purge connection * M3 / 4 M3 / 3.9 M5 / 5 M3 / 5 M5 / 6 M5 / 6 M5 / 6 M5 / 6 G1/8 / 7 M5 / 6 G1/8 / 7 M5 / 6 G1/8 / 7...

-

Page 26: Attaching Additional Structure

Assembly and settings 5.3 Attaching additional structure Gripper with additional structure Product Centering sleeve Additional structure Gripper finger Workpiece For supporting things like workpieces, an additional structure can be attached to the gripper. The locating surface of the additional structure may not exceed the recess of the cover. - Page 27 Attach additional structure within the recess (4), [/ 21]. } 5.2.1 ð Zwischen Greifer und Zusatzaufbau Zentrierhülsen (3) verwenden. Zentrierhülsen können bei SCHUNK bestellt werden. ð Bei den Baugrößen 50 – 100 werden für die Befestigung des Zusatzaufbaus die Gewindebohrungen (5) der Abdeckung verwendet.

-

Page 28: Mounting The Sensor

– The assembly and operating manual and catalog datasheet are included in the scope of delivery for the sensors and are available at schunk.com. Information on handling sensors is available at schunk.com or from SCHUNK contact persons. 5.4.1 Overview of sensors... -

Page 29: Setting Dimensions For Magnetic Switches

Assembly and settings 5.4.2 Setting dimensions for magnetic switches * Setting dimension I1, from product bottom edge (1) to front sensor (2) The setting dimension applies for the following sensors: Programmable magnetic switch MMS 22-PI2 Programmable magnetic switch MMS-P 22 Programmable magnetic switch MMS 22-PI1 Analog magnetic switch MMS 22-A JGP-P... -

Page 30: Switch-Off Hysteresis For Magnetic Switches

The magnetic switch MMS 22-PI1 can be adjusted and taught in two ways. "Standard mode" allows for quick installation on the T-nut preset by SCHUNK in the groove or the defined setting dimension "l1." In "Optimal Mode", the sensor identifies the optimal position in the groove itself. -

Page 31: Mounting Inductive Proximity Switch In

Assembly and settings 5.4.4 Mounting inductive proximity switch IN NOTE The sensor cannot be used for sizes smaller than size 64. Position "Gripper open" or "Gripper closed" Slide the sensor 1 (1) through the bracket (2) and into the housing until it stops. Tighten the screw (3) on the bracket (2). - Page 32 Assembly and settings ð Part gripped (I.D. gripping): Slide control cam (6) inwards until the sensor (1) no longer responds. ð Move the control cam (6) back towards the outside until the sensor (1) begins to switch. Screw the expander bolt (4) back in to fix the switching point. For tightening torque see following table Open the product and close it again in order to test its function.

-

Page 33: Mounting Mms 22 Magnetic Switch

Assembly and settings 5.4.5 Mounting MMS 22 magnetic switch CAUTION Risk of damage to the sensor during assembly! Observe the maximal tightening torque. Position "Gripper open" or "Part gripped (I.D. gripping)" Bring product in the position to be set. If necessary remove T-nut (3). Turn the sensor 1 (1) into the groove (2). -

Page 34: Mounting Programmable Mms 22-Pi2 Magnetic Switch

Assembly and settings 5.4.6 Mounting programmable MMS 22-PI2 magnetic switch CAUTION Risk of damage to the sensor during assembly! Observe the maximal tightening torque. NOTE If there is no T-nut available, slide the sensor according to dimension I1 into the groove (2), } 5.4.2 [/ 29]. -

Page 35: Mounting Programmable Mms 22-P 22 Magnetic Switch

Assembly and settings 5.4.7 Mounting programmable MMS 22-P 22 magnetic switch CAUTION Risk of damage to the sensor during assembly! Observe the maximal tightening torque. NOTE If there is no T-nut available, slide the sensor according to dimension I1 into the groove (2), } 5.4.2 [/ 29]. -

Page 36: Mounting Mms 22-Pi1 Programmable Magnetic Switch

The magnetic switch MMS 22-PI1 can be adjusted and taught in two ways. "Standard mode" allows for quick installation on the T-nut preset by SCHUNK in the groove or the defined setting dimension "l1." In "Optimal Mode", the sensor identifies the optimal position in the groove itself. - Page 37 Assembly and settings ð The sensor 1 (1) has been taught in. Repeat steps for sensor 2. Alternatively for size 40 – 160, except size 50: Setting the sensor in "Standard mode" Turn the sensor 1 (1) into the groove (2). OR: Slide the sensor 1 (1) into the groove (2) until the sensor 1 (1) stops at the T-nut (3).

-

Page 38: Mounting The Magnetic Switch Mms 22-Iol

Assembly and settings 5.4.9 Mounting the magnetic switch MMS 22-IOL CAUTION Risk of damage to the sensor during assembly! Observe the maximal tightening torque. NOTE If there is no T-nut available, slide the sensor according to dimension I1 into the groove (2), see following table. Turn the sensor (1) into the groove (2). - Page 39 Assembly and settings JGP-P l1* [mm] 80 IS 43.8 100 AS 100 IS 125 AS 125 IS 160 AS 33.5 160 IS 78.5 05.00 | JGP-P | Assembly and Operating Manual | en | 1469637...

-

Page 40: Mounting Analog Mms 22-A Magnetic Switch

Assembly and settings 5.4.10 Mounting analog MMS 22-A magnetic switch CAUTION Risk of damage to the sensor during assembly! Observe the maximal tightening torque. NOTE If there is no T-nut available, slide the sensor according to dimension I1 into the groove (2), } 5.4.2 [/ 29]. - Page 41 During the monitoring, the first and last 15% of the nominal stroke will not produce a change in the analog signal. It is therefore not possible to monitor the end positions. If you have questions, please contact SCHUNK. JGP-P Stroke 1...

- Page 42 Assembly and settings NOTE Only valid for size 50! The gripper is too fast without throttling, which means that teaching the sensor does not work reliably. Fixed throttle valves or other throttle valves with a diameter of 0.8 mm can be used for the teaching process.

-

Page 43: Mounting Analog Position Sensor Aps-Z80

With O.D. gripping the "Gripper closed" position and with I.D. gripping the "Gripper opened" position cannot be queried. Should you have questions, do not hesitate to contact SCHUNK. Actual signal Optimum signal Stroke [mm] Analog signal on O.D. - Page 44 Assembly and settings Move product to the "gripper open" position. Loosen clamping spindle (4) and remove the switching cam (6) for inductive sensing from the base jaw by turning the adjusting spindle (5). Slide control cam (7) from the mounting kit into the base jaw. ð...

-

Page 45: Mount The Flexible Position Sensor Fps

Assembly and settings 5.4.12 Mount the flexible position sensor FPS The flexible position sensor FPS consists of an evaluation unit and one of the following sensors: MMS 22-A-5V FPS-S M8 CAUTION Risk of damage to the sensor during assembly! Observe the maximal tightening torque. 5.4.12.1 Mounting the MMS 22-A-5V Note: In order to mount the sensor MMS 22-A-5V, no additional attachment kit is required. - Page 46 Assembly and settings Fix the control cam (7) with the clamping spindle (4). It must not be possible to move the control cam after assembly. For sizes 125-1, 200-1 and 200-2: Slide spacer (8) into the bracket (2) to the stop. Slide the sensor (1) to the stop into the bracket (2).

-

Page 47: Mounting Analog Position Sensor Aps-M1

Assembly and settings 5.4.13 Mounting analog position sensor APS-M1 To be able to mount the sensor, the gripper has to be retrofitted with a special mounting kit. For sizes 64 and 80, the clamping brackets from the mounting kit must be mounted. Move product to the "gripper open"... - Page 48 Assembly and settings Setting dimension l3 of the base jaw (2) up to the front of the control cam (1) JGP-P Setting dimension l3 [mm] 64-1 64-2 80-1 80-2 100-1 100-2 125-1 125-2 160-1 160-2 200-1 200-2 240-1 240-2 300-1 05.00 | JGP-P | Assembly and Operating Manual | en | 1469637...

-

Page 49: Troubleshooting

Unused air connections open. Close unused air connections. Flow control valve closed. Open the flow control valve. Component part defective. Replace component or send it to SCHUNK for repair. 6.2 Product is not executing the complete stroke Possible cause Corrective action Dirt deposits between cover and piston. -

Page 50: Product Does Not Achieve The Opening And Closing Times

Compressed air can escape. Check seals, if necessary, disassemble the product and replace seals. Component part defective. Replace component or send it to SCHUNK for repair. Too much grease in the mechanical Clean and lubricate product. movement space. -

Page 51: Maintenance

Maintenance 7 Maintenance 7.1 Notes Original spare parts Use only original spare parts of SCHUNK when replacing spare and wear parts. Replacement of the housing and base jaws The base jaws and the guides in the housing are matched to each other. -

Page 52: Lubricants/Lubrication Points (Basic Lubrication)

Maintenance 7.3 Lubricants/Lubrication points (basic lubrication) During maintenance, treat all greased areas with lubricant. Thinly apply lubricant with a lint-free cloth. SCHUNK recommends the lubricants listed. Lubricant point Lubricant Metallic sliding surfaces Rivolta F.L.G. GT-2 All seals Rivolta F.L.G. GT-2 Cylinder surfaces Rivolta F.L.G. -

Page 53: Lubricate Product

Maintenance 7.4 Lubricate product WARNING Risk of injury due to moving parts! When moving the gripper fingers, body parts may get squashed/ hit causing severe injuries. Do not interfere with moving parts during operation. Observe position and direction of movement of the gripper fingers. -

Page 54: Replace Seal. (Variant Without Gripping Force Maintenance)

Maintenance 7.5 Replace seal. (variant without gripping force maintenance) Remove all compressed air lines, [/ 24]. } 5.2.2 Remove product from the system/machine. Remove the cover (10). Mark the installation position of the base jaws (3) on the housing (2). Remove the screws and the cover (4). Unscrew screw (6) and take cylinder piston (8) out of the housing (2). -

Page 55: Replace Seal. (Variant With Gripping Force Maintenance "O.d. Gripping")

Carefully dismantle the product. NOTE During assembly, the cylinder piston must be aligned precisely. We therefore recommend having SCHUNK change the seals. Remove all compressed air lines, [/ 24]. } 5.2.2 Remove product from the system/machine. - Page 56 Maintenance Insert base jaws (3) into the housing (11). IMPORTANT! Observe installation position of the base jaws (3) in the housing (11). Insert wedge hook (1) into the housing (11). Insert spring (10) and spacer (4) into the housing (11). Place the cylinder piston (5) in the housing (11) and while doing so, observe the installation position of the magnets, [/ 59].

-

Page 57: Replace Seal. (Variant With Gripping Force Maintenance "I.d. Gripping")

Maintenance 7.7 Replace seal. (variant with gripping force maintenance "I.D. gripping") WARNING Risk of injury due to spring forces! Products that use spring force or have gripping force maintenance contain parts that are under spring tension. This can cause components to move unexpectedly when being dismantled, which may result in serious injuries. - Page 58 Maintenance Insert the cylinder piston (4) into the housing (10) and while doing so, observe the installation position of the magnets, } 7.8 [/ 59]. Tighten screw (8). Secure the screw with medium-strength threadlocker. Tightening torque: } 7.9 [/ 60] Insert spring (7) into the housing (10). In doing so, observe the alignment of the spring in relation to the cylinder piston.

-

Page 59: Installation Position Of The Magnets In The Piston

Maintenance 7.8 Installation position of the magnets in the piston The installation position of the piston in the housing depends on the size and variant. The magnets (1) attached to the piston can either point upwards (A) or downwards (B). Installation position of the piston in the housing, A: Magnet (1) above, B: Magnet below JGP-P Variant without maintenance of gripping... -

Page 60: Tightening Torques

Maintenance 7.9 Tightening torques Position of the item numbers: } 7.10 [/ 61] JGP-P Item 40 Item 41 Item 45 Item 46 Item 51 JGP-P 40 0.27 – – – JGP-P 50 – – – JGP-P 64 – – – JGP-P 80 –... -

Page 61: Assembly Drawing

Maintenance 7.10 Assembly drawing JGP-P 40 – 240 standard Position of the magnets in the piston depends on the variant and size, [/ 59]. } 7.8 Not for JGP-P 40/50 05.00 | JGP-P | Assembly and Operating Manual | en | 1469637... - Page 62 Maintenance JGP-P 300 standard * Position of the magnets in the piston depends on the variant and size, } 7.8 [/ 59]. 05.00 | JGP-P | Assembly and Operating Manual | en | 1469637...

- Page 63 Maintenance JGP-P 40 – 160 with maintenance of gripping force O.D. gripping (A) and I.D. gripping (B) Position of the magnets in the piston depends on the variant and size, } 7.8 [/ 59]. Not for JGP-P 40/50 05.00 | JGP-P | Assembly and Operating Manual | en | 1469637...

- Page 64 Maintenance JGP-P 200 – 300 with maintenance of gripping force O.D. gripping (A) and I.D. gripping (B) Position of the magnets in the piston depends on the variant and size, } 7.8 [/ 59]. 05.00 | JGP-P | Assembly and Operating Manual | en | 1469637...

-

Page 65: Translation Of The Original Declaration Of Incorporation

8 Translation of the original declaration of incorporation in terms of the Directive 2006/42/EG, Annex II, Part 1 Section B. Manufacturer/ SCHUNK SE & Co. KG Distributor Toolholding and workholding | Gripping technology | Automation technology Bahnhofstr. 106 - 134... -

Page 66: Ukca Declaration Of Incorporation

UKCA declaration of incorporation 9 UKCA declaration of incorporation in accordance with the Supply of Machinery (Safety) Regulations 2008. Manufacturer/ SCHUNK Intec Limited Distributor Clamping and gripping technology 3 Drakes Mews, Crownhill MK8 0ER Milton Keynes We hereby declare that on the date of the declaration the following partly completed machine complied with all basic safety and health regulations found in the "Supply of Machinery (Safety) Regulations 2008". -

Page 67: Information On The Rohs Directive, Reach Regulation And Substances Of Very High Concern (Svhc)

"on the restriction of the use of certain hazardous substances in electrical and electronic equipment (RoHS)", or fulfill their intended function only as part of one. Therefore products from SCHUNK do not fall within the scope of the directive at this time. REACH Regulation Products from SCHUNK fully comply with the regulations of Regulation (EC) No. 1907/2006... - Page 68 SCHUNK SE & Co. KG Toolholding and workholding | Gripping technology | Automation technology Bahnhofstr. 106 - 134 D-74348 Lauffen/Neckar Tel. +49-7133-103-0 Fax +49-7133-103-2399 info@de.schunk.com schunk.com Folgen Sie uns I Follow us Wir drucken nachhaltig I We print sustainable...

Need help?

Do you have a question about the JGP-P 40 and is the answer not in the manual?

Questions and answers