Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Tatu Marchesan STP2

- Page 1 I N S T RU C T I O N S M A N UA L STP²...

- Page 2 IDENTIFICATION Dealer: Owner: Firm / Farm: City: State: No. of the Certificate of Guarantee: Serial / No.: Date: Invoice No.: Product: Notes:...

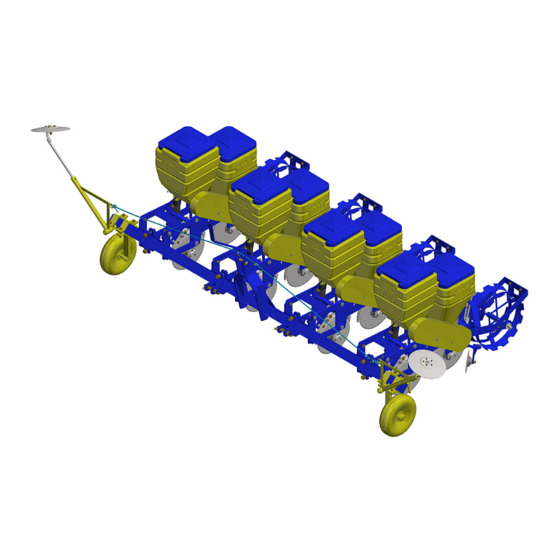

- Page 3 Introduction The STP² planter features quality, efficiency, low cost, easy operation and low maintenance. It was designed to plant great grains such as: corn, soybean, rice, beans, sorghum, cotton with linter/delinted, peanut and so on. The row units have a parallelogram for a greater flexibility of the moving parts that work over the soil, so it is possible to work through the soil unevenness.

-

Page 4: Table Of Contents

Table of contents 1. To the owner 2. To the operator 4 to 8 3. Data sheet 4. Components 5. Row unit versions 6. Assembly 12 to 15 7. Set-up instructions 16 to 20 Positioning the row units on the frame Preparing the tractor Centralizing and leveling the planter Setting the planter to transport position... -

Page 5: To The Owner

To the owner The acquisition of any TATU product assures to the original purchaser the following rights: • Warranty certificate; • Instructions manual; • Technical assistance by the dealer on equipment delivery. However, the owner must check the condition of the equipment on delivery, as well as knowing the warranty terms. -

Page 6: To The Operator

To the operator Dear user! Respect the ecology. Do not throw trash away. This gesture of goodwill helps to protect our environment. Be careful with the environment Products such as oil, fuel, filters, batteries and others are spilled to the soil and can penetrate to the underground layers, compromising nature. - Page 7 To the operator Never use your bare hands to check hydraulic leaks, the high pressure can cause injuries. Never attempt to change the adjustments, clean or lubricate the equipment when the same is switched on or in movement. Be careful while driving on slopes. Risk of overturn. Prevent that chemical products (i.e.: fertilizers, treated seeds) make any contact with your skin or clothes.

- Page 8 To the operator • Only trained and qualified personnel are allowed to operate the equipment. • While working or during transportation, only the presence of the operator is allowed on the tractor. • Do not allow children to play or to get over the equipment while it is operating, during transportation or storage.

- Page 9 To the operator Transportation over truck or trailer Marchesan does not advise the equipment traffic on highways, because this practice involves serious security risks in addition to being prohibited by the current existing traffic law. The transportation for long distances should be done on truck, trailer or other by following these safety guidelines: •...

- Page 10 To the operator Safety decals The safety decals warn about the equipment points that require more attention and they should be kept in good repair. If these decals become damaged or illegible, replace them. Marchesan provide decals, upon request and indication of their respective serial number.

-

Page 11: Data Sheet

Data sheet STP² Marchesan Implementos e Máquinas Agrícolas “TATU” S.A. -

Page 12: Components

Components 01 - Frame 06 - Seed hoppers 02 - Iron supporting wheels 07 - Double discs (Fertilizer/Seeds) 03 - Row marker discs 08 - Covering discs 04 - Parallelogram 09 - Iron gauge wheels 05 - Fertilizer hoppers Check the "Optional" pages. STP²... -

Page 13: Row Unit Versions

Row unit versions Version with supporting/gauge wheels • Supporting wheel made of iron or rubber. • Gauge wheel made of iron or rubber. • Double disc or furrower shank for fertilizer. STP² Marchesan Implementos e Máquinas Agrícolas “TATU” S.A. -

Page 14: Assembly

Assembly To facilitate transportation, the planters leave the factory semi-assembled, being necessary the placement of a few components, according to the instructions below: • Choose a clean place and check the parts using the list that comes inside the package. •... - Page 15 Assembly • For frames with 1800 or 2800 mm, fasten the supporting wheels (D) on the frame (B) ends using the supports (E), bolts, spring washers and nuts. • For frames with 3200 or 3600mm, the supporting wheels are independent, thus they can be assembled either on the end of the frame as well as between the row units, depending on the number of row units and spacing that is being used.

- Page 16 Assembly • Couple the row units (F) on the frame (A) using a hitch guide fastener (G), bolts, spring washers and nuts. • Fasten the fertilizer (H) and seed (I) hoppers to their respective supports with bolts, flat washers, spring washers and nuts. For fastening the fertilizer hoppers, note the placement of the inner support NOTE plates (J), as shown below.

- Page 17 Assembly • Then, fasten the marker support (J) using flat washers and cotter pins. The arms (K) are assembled on the support and locked using bolts (L). For frames with 3200 or 3600 mm, the row markers are independent from NOTE the supporting wheels.

-

Page 18: Set-Up Instructions

Set-up instructions Positioning the row units on the frame Even number of row units: Set the frame center and measure half of a spacing to the right and half to the left, placing on these points the first two row units; from these rows, set the other ones with one spacing to each side. -

Page 19: Preparing The Tractor

Set-up instructions Preparing the tractor • It is recommended to use counterweights on the front part of the tractor. • Adjust the front and rear gauges to have the same opening (tires center). Centralizing and leveling the planter To facilitate the adjustments, the planter must be centralized with the tractor, which is done as follows: •... -

Page 20: Setting The Planter To Transport Position

Set-up instructions Setting the planter to transport position • Totally lift the planter to activate the hydraulic system. NOTE • It is recommended to fill up the planter on the working place only to avoid overloads to the hydraulic lift system during the transportation. •... -

Page 21: Graphite Powder Use

Set-up instructions Correct seed rate Consider that the amount of plants in the harvest is always smaller than the number of seeds distributed in the planting operation, due to the following factors: germination rate, plagues, diseases and others. Therefore, we recommend the distribution of some more seeds related to the plants/ hectare that is wanted to obtain on the crop. -

Page 22: List Of Standard Seed Plates

Set-up instructions Recommendations: • The graphite should not be combined before the seed treatment. • The graphite should not be combined to the insecticide to apply in the seeds. • For non-treated seeds, use only half of the graphite mentioned on the previous page. -

Page 23: Adjustments And Operations

Adjustments and operations Seeds distribution The seed distribution is done through slotted seed plates that are horizontally positioned. The amount and size of the holes/slots and the thickness of the seed plates can vary according to the grain size and the desired plant amount. Adjust the seed rate per linear meter through the sprocket combinations of the Drive shaft {A} and Driven shaft {B} (Scheme 01). - Page 24 Adjustments and operations CORN (Standard seed plate) STP² Number of seeds in 10 For planting corn: Drive / Driven linear meters Serial number 05.03.03.2127 - Seed 14 x 22 plate with a thickness of 4.5 mm and 28 16 x 22 holes of Ø...

- Page 25 Adjustments and operations BEAN (Standard seed plate) STP² Number of seeds per For planting bean: Drive / Driven linear meter Serial number 05.02.02.0407 - Seed 14 x 22 plate with a thickness of 5.5 mm and 40 16 x 22 slots of 9 x 14 mm.

- Page 26 Adjustments and operations Calculation of the amount of seeds/meter for the seed plates The amount of seeds for every seed plate can be found by making the calculation below, which has a factor for every sprocket combination (scheme 01). STP² Factor* Drive / Driven 14 x 22...

-

Page 27: Fertilizer Distribution

Adjustments and operations Fertilizer distribution The fertilizer distribution is done through the individual coil pitch augers and the different amount are obtained through the Drive {C} and Driven {D} sprockets. (Scheme 02). The definition of the sprockets of the Scheme 02 (Fertilizer) is done after the ones on the Scheme 01 (Seed) has been defined. - Page 28 Adjustments and operations Fertilizer distribution STP² Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

- Page 29 Adjustments and operations Fertilizer distribution STP² Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

- Page 30 Adjustments and operations Fertilizer distribution STP² Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

- Page 31 Adjustments and operations Fertilizer distribution STP² Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

- Page 32 Adjustments and operations Fertilizer distribution STP² Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

- Page 33 Adjustments and operations Fertilizer distribution STP² Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

- Page 34 Adjustments and operations Fertilizer distribution STP² Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

- Page 35 Adjustments and operations Important The data on the previous tables (seed and fertilizer) can vary due to several factors. Therefore, carefully observe the following procedures. Practical test of seed and fertilizer distribution The most indicated way to assess the amount of seed and fertilizer rate is performing the test on the same field the plantation will take place, following these steps: •...

-

Page 36: Auxiliary Calculation For Fertilizer Distribution

Adjustments and operations Auxiliary calculation for fertilizer distribution To distribute other amounts of fertilizer in different spacings and areas from those presented in the tables we suggest a quick calculation, where all used data can be changed to ones of your own interest. Use the formula below, which contains the following elements: A = Area to be fertilized (m²). -

Page 37: Opening The Furrows For Fertilizer And Seeds

Adjustments and operations Opening the furrows for fertilizer and seeds The opening of the furrows is done using the double discs (A), which have adjustable and flexible internal scrapers (B) to remove the earth that accumulates on the inner part of the discs. -

Page 38: Row Units Pressure And Gauge Wheels Adjustment

Adjustments and operations Row units pressure and gauge wheels adjustment For a better oscillation of the row units during the crop and to reduce the slippage index of the gauge wheels, use the adjustment on the rods with springs (A). To do so, apply pressure to the springs using the cotter pins (B). -

Page 39: Row Markers

Adjustments and operations Row markers The row marker utilization is very important to achieve an uniform spacing in the plantation, thus facilitating the cultivation and harvest. To adjust the marker discs it is just necessary to loosen up the bolts (A) and displace the marker to the desired position. - Page 40 Adjustments and operations WARNING BEFORE STARTING TO RAISE OR MOVE THE PLANTER, CHECK FOR PEOPLE OR ANIMALS NEAR OR UNDER THE PLANTER, ESPECIALLY IN THE ROW MARKER ACTION AREA. STP² Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

-

Page 41: Operations - Important Points

Adjustments and operations Operations - Important points • Retighten nuts and bolts after the first day of planting. Check the conditions of all pins and cotter pins. Then, retighten every 24 working hours. • Carefully observe the lubrication intervals. • Keep the lower arms of the tractor hydraulic lift adjusted. •... -

Page 42: Optional

Optional Seed plates Optionally, MARCHESAN supplies slotted, perforated or blind seed plates for several crops, according to the list below: Amount of Hole/slot Serial Seed plates Thickness holes/slots dimension number Corn 24 holes Ø 11 mm 4.5 mm 05.02.02.0351 Corn 24 holes Ø... -

Page 43: Furrower For Corn

Optional Furrower for corn • When the planter is equipped with a furrower rod for the fertilizer, acquire a shank of 8" (B) and fasten it to the rod (A). • When the planter is assembled with a double disc for the fertilizer, acquire the complete furrower rod with a shank of 8"... -

Page 44: Set For Planting Peanut

Optional Set for planting peanut Versatile with adjustments that allows plantation of several sizes of grains. On this system, the seed falls by gravity. The dosing plates (A and B) also goes with the set to allow a distribution of a greater or smaller amount of seeds. -

Page 45: Set For Semi-Tillage Plantation

Optional Set for semi-tillage plantation The kit for a semi-tillage plantation is optionally supplied. Assemble it as follows: • Couple the hitch (A) to the frame (B) using the fixation elements: hitch guide fastener (C), bolt (D), spring washers and nuts that can be found on the frame structure. Fasten the drawbar supplement (E) using the fixation elements: bolt (F), spring washer and nut. -

Page 46: Maintenance

Maintenance Lubrication In order to reduce the wearing caused by the friction in the moving parts of the equipment, it is necessary to make a correct lubrication, as indicated below: • Be certified about the lubricant quality, with relation to its efficiency and purity, avoiding the use of products contaminated by water, earth and others. -

Page 47: Fertilizer Metering System Maintenance

Maintenance Fertilizer metering system maintenance For the correct maintenance of the fertilizer metering system or to make any type of repair on its inner part, proceed as follows: • Loosen up the bolts that fasten the polyethylene hoppers and remove them. •... - Page 48 Maintenance Cleaning the seed metering It is necessary to make a general cleaning in each seed metering daily. To do this, remove the seed plate and observe the metering mechanism operation. By doing so, the best planting will be assured. When using graphite powder NOTE with treated/inoculated seeds, it...

-

Page 49: Important

Important MARCHESAN S/A reserves the right at any time to make improvements ATTENTION in the design, material or specifications of machinery, equipment or parts without thereby becoming liable to make similar changes in machinery, equipment or parts previously sold. Images are for illustration purposes only. Some illustrations in this manual appear without the safety devices, removed to allow a better view and detailed instructions. -

Page 50: Notes

Notes STP² Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

Need help?

Do you have a question about the STP2 and is the answer not in the manual?

Questions and answers