Table of Contents

Advertisement

Quick Links

Operator's Manual

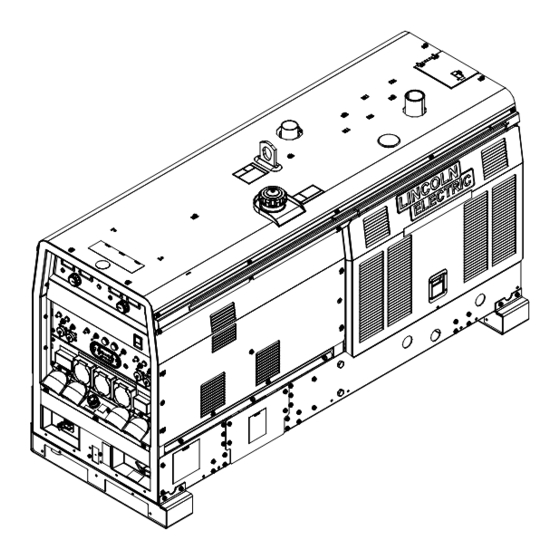

DUAL VANTAGE

Register your machine:

www.lincolnelectric.com/register

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Save for future reference

Date Purchased

Code: (ex: 10859)

Serial: (ex: U1060512345)

IM10175

| Issue D ate July-16

© Lincoln Global, Inc. All Rights Reserved.

®

700 (AU)

For use with machines having Code Numbers:

12299

Need Help? Call 1.888.935.3877

to talk to a Service Representative

Hours of Operation:

8:00 AM to 6:00 PM (ET) Mon. thru Fri.

After hours?

Use "Ask the Experts" at lincolnelectric.com

A Lincoln Service Representative will contact you

no later than the following business day.

For Service outside the USA:

Email: globalservice@lincolnelectric.com

Advertisement

Chapters

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Lincoln Electric DUAL VANTAGE 700 (AU)

- Page 1 Operator’s Manual ® DUAL VANTAGE 700 (AU) For use with machines having Code Numbers: 12299 Need Help? Call 1.888.935.3877 Register your machine: to talk to a Service Representative www.lincolnelectric.com/register Authorized Service and Distributor Locator: Hours of Operation: www.lincolnelectric.com/locator 8:00 AM to 6:00 PM (ET) Mon. thru Fri. Save for future reference After hours? Use “Ask the Experts”...

- Page 2 THANK YOU FOR SELECTING A QUALITY PRODUCT BY KEEP YOUR HEAD OUT OF THE FUMES. DON’T get too close to the arc. LINCOLN ELEC TRIC. Use corrective lenses if necessary to stay a reasonable distance away from the arc. READ and obey the Safety Data PLEASE EXAMINE CARTON AND EQUIPMENT FOR Sheet (SDS) and the warning label DAMAGE IMMEDIATELY...

- Page 3 W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 2.d. All welders should use the following procedures in order to 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199.

- Page 4 SAFETY ELECTRIC SHOCK ARC RAYS CAN BURN. CAN KILL. 3.a. The electrode and work (or ground) circuits are 4.a. Use a shield with the proper filter and cover plates to protect your electrically “hot” when the welder is on. Do eyes from sparks and the rays of the arc when welding or not touch these “hot”...

- Page 5 SAFETY WELDING AND CUTTING CYLINDER MAY EXPLODE IF SPARKS CAN CAUSE DAMAGED. FIRE OR EXPLOSION. 7.a. Use only compressed gas cylinders containing the correct shielding gas for the process used 6.a. Remove fire hazards from the welding area. If and properly operating regulators designed for this is not possible, cover them to prevent the welding sparks the gas and pressure used.

- Page 6 2004/108/EC. It was manufactured in conformity with a national standard that implements a harmonized standard: EN 60974-10 Electromagnetic Compatibility (EMC) Product Standard for Arc Welding Equipment. It is for use with other Lincoln Electric equipment. It is designed for industrial and professional use. Introduction All electrical equipment generates small amounts of electromagnetic emission.

- Page 7 DUAL VANTAGE ® 700 (AU) SAFETY Electromagnetic Compatibility (EMC) The size of the surrounding area to be considered will depend on the structure of the building and other activities that are taking place. The surrounding area may extend beyond the boundaries of the premises. Methods of Reducing Emissions Mains Supply Welding equipment should be connected to the mains supply according to the manufacturer’s recommenda-...

-

Page 8: Table Of Contents

Remote Control ........................A-6 Auxiliary Power Receptacles ....................A-6 Standby Power Connections ..................A-6, A-7 Connection of Lincoln Electric Wire Feeders..............A-8, A-9 Connection of Wire Feeders With Control Cable (14 Pin)..........A-8 Connection of Across the Arc Wire Feeders ..............A-9 Electrical Device use with this Product................A-10 ________________________________________________________________________________ Operation.........................Section B... - Page 9 DUAL VANTAGE ® TABLE OF CONTENTS Maintenance.......................Section D Safety Precautions ....................D-1 Routine and Periodic Maintenance ...............D-1 Engine Maintenance....................D-1 Air Filter......................D-1 Service Instructions for Engine Air Cleaner............D-2 Fuel Filters ......................D-3 Cooling System....................D-3 Battery Handling .....................D-4 Charging the Battery .....................D-4 Servicing Muffler with Internal Spark Arrester ............D-4 Nameplate / Warning Decal Maintenance .............D-5 Welder / Generator Maintenance ................D-5 Engine Maintenance Components ................D-5...

- Page 10 DUAL VANTAGE ® 700 (AU) INSTALLATION INST LL TION TECHNICAL SPECIFICATIONS - DUAL VANTAGE 700 (AU) (K3995-1) Code 12299 ® INPUT - DIESEL ENGINE Make/Model Description Speed (RPM) Displacement Starting Dry Capacities cu. in. (ltrs.) System 4 cylinder High Idle 1860 199(3.3) 12VDC Battery &...

-

Page 11: Installation

SAFETY PRECAUTIONS DUAL VANTAGE ® 700 (AU) INSTALLATION FIGURE A.1 WARNING (VRD)-VOLTAGE Do not attempt to use this equipment until you REDUCTION DEVICE have thoroughly read the engine manufacturer’s SWITCHES LOCATED manual supplied with your welder. It includes IN THESE AREAS. important safety precautions, detailed engine starting, operating and maintenance instructions, and parts lists. -

Page 12: Stacking

DUAL VANTAGE ® 700 (AU) INSTALLATION STACKING HIGH ALTITUDE OPERATION DUAL VANTAGE 700 (AU) machines cannot be At higher altitudes, output derating may be necessary. For maxi- ® stacked. mum rating, derate the welder output 4% for every 300 meters (984 ft.) above 1500 meters (4920 ft.). -

Page 13: Pre-Operation Engine Service

PRE-OPERATION ENGINE SERVICE DUAL VANTAGE ® 700 (AU) INSTALLATION ENGINE COOLANT WARNING READ the engine operating and maintenance instruc- tions supplied with this machine. HOT COOLANT can burn skin. WARNING •Do not remove cap if radiator is hot. • Keep hands away from the engine muffler or HOT engine parts. -

Page 14: Muffler Outlet Pipe

DUAL VANTAGE ® 700 (AU) INSTALLATION The DUAL VANTAGE 700 (AU) is shipped with ® the negative battery cable disconnected. Before Listed in Table A.1 are copper cable sizes recom- you operate the machine, make sure the Engine mended for the rated current and duty cycle. Lengths Switch is in the OFF position and attach the dis- stipulated are the distance from the welder to work connected cable securely to the negative (-) bat-... -

Page 15: Remote Control

DUAL VANTAGE ® 700 (AU) INSTALLATION AUXILIARY POWER RECEPTACLES REMOTE CONTROL The DUAL VANTAGE 700 (AU) is equipped with a 6- auxiliary power capacity ® pin and a 14-pin connector. The 6-pin connector is for DUAL VANTAGE 700 (AU) is 20kVA of 60Hz three ®... - Page 16 DUAL VANTAGE ® 700 (AU) INSTALLATION 2. Take necessary steps to assure load is limited to the capacity of the DUAL VANTAGE 700 (AU) by ® installing a 32 amp, 415 VAC three pole circuit breaker. Loading above the rated output will reduce output voltage below the allowable -10% of rated voltage which may damage appliances or other motor-driven equipment and may result in overheat-...

-

Page 17: Connection Of Wire Feeders With Control Cable (14 Pin

DUAL VANTAGE ® 700 (AU) INSTALLATION FIGURE A.2 CONNECTION OF WIRE FEEDERS WITH CONTROL CABLE (14 PIN) WARNING Set Weld Terminals Set Weld Set Mode to to Remote Terminals CV Wire to Remote Set Polarity Shut off welder before making any electrical connections. Set Polarity to Match to Match... -

Page 18: Connection Of Across The Arc Wire Feeders

DUAL VANTAGE ® 700 (AU) INSTALLATION FIGURE A.4 CONNECTION OF ACROSS THE ARC WIRE FEEDERS TO THE DUAL VANTAGE ® 700 (AU) Set Weld Terminals to 'ON' Set Weld These connections instructions apply to both the LN-25 Pro and Set Mode Terminals Activ8 models. -

Page 19: Electrical Device Use With This Product

DO NOT USE THESE DEVICES WITH THIS PRODUCT. The Lincoln Electric Company is not responsible for any damage to electrical components improperly connected to this product. A-10... -

Page 20: Operation

DUAL VANTAGE ® 700 (AU) OPERATION The DUAL VANTAGE 700 (AU) is fitted with a selec- ® table VRD(Voltage Reduction Device). The VRD oper- OPER TION ates in the CC-Stick mode reducing the OCV to <13 SAFETY PRECAUTIONS volts, increasing operator safety when welding is per- formed in environments with increased hazard of elec- tric shock such as wet areas and hot, humid sweaty Read and understand this entire section before... -

Page 21: Add Fuel

DUAL VANTAGE ® 700 (AU) OPERATION BREAK-IN PERIOD WARNING No break in period is required for the Cummins ADD FUEL engine. • Stop engine while fueling. RECOMMENDED APPLICATIONS • Do not smoke when fueling. • Keep sparks and flame away The DUAL VANTAGE 700 (AU) provides excellent from tank. -

Page 22: Welding Controls

DUAL VANTAGE ® 700 (AU) OPERATION FIGURE B.2 WELDING CONTROLS (Figure B.2) When in the TOUCH START TIG mode and when 1. OUTPUT CONTROL- The OUTPUT dial is an Amptrol is connected to the 6-Pin Connector, used to preset the output voltage or current as dis- the OUTPUT dial is used to set the maximum cur- played on the digital meters for the five welding rent range of the CURRENT CONTROL of the... - Page 23 4. ARC CONTROL DUAL VANTAGE ® 700 (AU) OPERATION - The ARC CONTROL dial is active in 10. WELD TERMINALS CONTROL SWITCH- the CV-WIRE, CC-STICK and DOWNHILL PIPE modes, and has different functions in these modes. This control is In the WELD TERMINALS ON position, the output is not active in the TIG and ARC GOUGING mode.

- Page 24 ENGINE CONTROLS: DUAL VANTAGE ® 700 (AU) OPERATION 19. DASH BOARD GAUGE 13. RUN/STOP SWITCH The dash board gauge displays 5 gauges: -RUN position energizes the engine prior to start- 3a. OIL PRESSURE ing. STOP position stops the engine. The oil pres- The gauge displays the engine oil pressure sure interlock switch prevents battery drain if the when the engine is running.

-

Page 25: Engine Operation

DUAL VANTAGE ® 700 (AU) OPERATION ENGINE OPERATION STOPPING THE ENGINE 1. Switch the RUN/STOP switch to “STOP”. This turns STARTING THE ENGINE off the voltage supplied to the shutdown solenoid. A 1. Open the engine compartment door and check that backup shutdown can be accomplished by shutting the fuel shutoff valve located to the left of the fuel off the fuel valve located on the fuel line. -

Page 26: Welder Operation

DUAL VANTAGE ® 700 (AU) OPERATION WELDER OPERATION B. For Re-Striking Electrodes Some electrodes form a cone at the end of the elec- trode after the welding arc has been broken, particu- DUTY CYCLE larly iron powder and low hydrogen electrodes. This Duty Cycle is the percentage of time the load is being cone will need to be broken off in order to have the applied in a 10 minute period. -

Page 27: Tig Welding

DUAL VANTAGE ® 700 (AU) OPERATION TIG WELDING If desired, the K930-2 TIG Module can be used with the DUAL VANTAGE 700 (AU). The settings are for ® reference. The TOUCH START TIG setting of the MODE switch is for DC TIG (Tungsten Inert Gas) welding. To initiate a DUAL VANTAGE 700 (AU) settings when using the weld, the OUTPUT CONTROL dial is first set to the... -

Page 28: Wire Welding-Cv

DUAL VANTAGE ® 700 (AU) OPERATION WIRE WELDING-CV PARALLELING Connect a wire feeder to the DUAL VANTAGE 700 (AU) ® according to the instructions in INSTALLATION When paralleling machines in order to combine their outputs, all units must be operated in the CC-STICK INSTRUCTIONS Section. -

Page 29: Auxiliary Power Operation

DUAL VANTAGE ® 700 (AU) AUXILIARY POWER OPERATION OPERATION Start the engine and set the IDLER control switch to the desired operating mode. Full power is available regardless of the welding control settings, if no weld- ing current is being drawn. SIMULTANEOUS WELDING AND AUXIL- IARY POWER LOADS It must be noted that the above auxiliary power ratings... - Page 30 DUAL VANTAGE ® 700 (AU) NOTES B-11...

-

Page 31: Accessories

DUAL VANTAGE ® 700 (AU) ACCESSORIES CCESSORIES OPTIONAL FIELD INSTALLED ACCESSORIES K2637-2 Large Trailer K2639-1 Fender Kit K2640-1 Cable Rack K2641-2 Four Wheel Trailer K857 Remote Control K857-1 Remote Control K2642-1 Polarity Multiprocess Switch K2663-1 Docking Kit K2613-5A1 Ln-25 PRO with K126 PRO Gun K126-12 K126 PRO Gun KP1696-068 Drive Roll Kit K12038-2 Invertec PC610 Plasma... - Page 32 DUAL VANTAGE ® 700 (AU) NOTES...

-

Page 33: Maintenance

DUAL VANTAGE ® 700 (AU) MAINTENANCE ENGINE MAINTENANCE M INTEN NCE Refer to the “Periodic Checks” section of the Engine Operator’s Manual for the recommended maintenance SAFETY PRECAUTIONS schedule of the following: a) Engine Oil and Filter WARNING b) Air Cleaner c) Fuel Filter - and Delivery System •... - Page 34 DUAL VANTAGE ® 700 (AU) MAINTENANCE Service Instructions Service Instructions Single- and Two-Stage Engine Air Cleaners Single- and Two-Stage Engine Air Cleaners Inspect the New Filter for Damage Inspect the New Filter for Damage Remove the Filter e Filter Inspect the new filter carefully, paying attention to asten or unlatch the the inside of the open end, which is the vice cover.

-

Page 35: Fuel Filters

DUAL VANTAGE ® 700 (AU) FIGURE D.1 MAINTENANCE FUEL FILTERS WARNING When working on the fuel system: • Keep naked lights away, do not smoke! • Do not spill fuel! ------------------------------------------------------------------------- The DUAL VANTAGE 700 (AU) is equipped with a ®... -

Page 36: Battery Handling

DUAL VANTAGE ® 700 (AU) MAINTENANCE BATTERY HANDLING CHARGING THE BATTERY GASES FROM BATTERY can explode. When you charge, jump, replace, or otherwise con- nect battery cables to the battery, be sure the polarity • Keep sparks, flame and cigarettes is correct. -

Page 37: Nameplate / Warning Decal Maintenance

NAMEPLATES / WARNING DECALS DUAL VANTAGE ® 700 (AU) MAINTENANCE MAINTENANCE Whenever routine maintenance is performed on this machine - or at least yearly - inspect all nameplates and labels for legibility. Replace those which are no longer clear. Refer to the parts list for the replacement item number. - Page 38 DUAL VANTAGE ® 700 (AU) NOTES...

-

Page 39: Troubleshooting

HOW TO USE TROUBLESHOOTING GUIDE WARNING Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual. - Page 40 DUAL VANTAGE ® 700 (AU) TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION 1. Contact your local Lincoln Major Physical or Electrical Damage Authorized Field Service is Evident. Facility. Engine will not crank 1.

- Page 41 DUAL VANTAGE ® 700 (AU) TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION Battery does not stay charged. 1. Faulty battery . 2. Faulty engine alternator. 3. Loose or broken lead in charging circuit.

- Page 42 DUAL VANTAGE ® 700 (AU) TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION Welder has some/ no output and no con- 1. Faulty remote kit. trol. Auxiliary output OK. 2. Faulty output control potentiometer. 3.

- Page 43 DUAL VANTAGE ® 700 (AU) NOTES...

- Page 44 DUAL VANTAGE ® 700 (AU) DIAGRAMS DI GR MS...

- Page 45 DUAL VANTAGE ® 700 (AU) DIAGRAMS...

- Page 46 DUAL VANTAGE ® 700 (AU) DIAGRAMS...

- Page 47 DUAL VANTAGE ® 700 (AU) DIAGRAMS...

- Page 48 DUAL VANTAGE ® 700 (AU) DIAGRAMS...

- Page 49 DUAL VANTAGE ® 700 (AU) DIAGRAMS...

- Page 50 DUAL VANTAGE ® 700 (AU) DIAGRAMS...

- Page 51 DUAL VANTAGE ® 700 (AU) DIAGRAMS...

- Page 52 DUAL VANTAGE ® 700 (AU) DIAGRAMS...

- Page 53 DUAL VANTAGE ® 700 (AU) DIAGRAMS F-10...

- Page 54 DUAL VANTAGE ® 700 (AU) DIAGRAMS F-11...

- Page 55 DUAL VANTAGE ® 700 (AU) DIAGRAMS F-12...

- Page 56 DUAL VANTAGE ® 700 (AU) DIAGRAMS F-13...

- Page 57 DUAL VANTAGE ® 700 (AU) DIAGRAMS F-14...

- Page 58 Dual Vantage 700-AU (Cummins) - 12299...

- Page 59 Contents Engine Driven Welders Vantage Dual Vantage 700-AU (Cummins) - 12299 Index of Sub Assemblies - 12299..................1 Miscellaneous Items ......................3 Case Front & Insert Assembly.....................5 Control Panel Assembly ......................7 Output Panel Assembly .....................11 Power Module Asbly, Fuel Tank, & Rectifier Mounting ............14 Base, Battery, &...

- Page 60 THIS PAGE INTENTIONALLY LEFT BLANK...

-

Page 61: Index Of Sub Assemblies - 12299

Index of Sub Assemblies - 12299 PART NUMBER DESCRIPTION P-821-A INDEX OF SUB ASSEMBLIES P-821-B.2 MISCELLANEOUS ITEMS P-821-C CASE FRONT & INSERT ASSEMBLY P-821-D CONTROL PANEL ASSEMBLY P-821-E OUTPUT PANEL ASSEMBLY P-821-F POWER MODULE ASBLY FUEL TANK & RECTIF P-821-G BASE BATTERY &... - Page 62 Index of Sub Assemblies - 12299 P-821-A.jpg Dual Vantage 700-AU (Cummins) - 12299...

-

Page 63: Miscellaneous Items

Miscellaneous Items PART NUMBER DESCRIPTION 9SG7432 CONTROL HARNESS 9SM21321-10 ENGINE AIR CLEANER ASSEMBLY 9SS27427 EXHAUST PIPE OUTLET 9SS27501 EXHAUST CLAMP 9SS9225-45 THREAD FORMING SCREW 9SS28899 FASTENER PACKAGE 9SM20610-2 MOUNTING BRACKET Dual Vantage 700-AU (Cummins) - 12299... - Page 64 Miscellaneous Items No Image Dual Vantage 700-AU (Cummins) - 12299...

-

Page 65: Case Front & Insert Assembly

Case Front & Insert Assembly PART NUMBER DESCRIPTION 9SL15032-1 CASE FRONT & INSERT ASBLY 9SG6468-1 CASE FRONT 9ST11525-7 SPEED NUT 9SL15034-3 CASE SIDE INSERT 9ST11525-5 SPEED NUT1/4-20 9SS9225-68 THREAD FORMING SCREW (CUTTING) 9SS28621 COVER PLATE 9SS9225-68 THREAD FORMING SCREW (CUTTING) 9SS9225-64 SELF TAPPING SCREW 9SG6978-4... - Page 66 Case Front & Insert Assembly P-821-C.jpg Dual Vantage 700-AU (Cummins) - 12299...

-

Page 67: Control Panel Assembly

Control Panel Assembly PART NUMBER DESCRIPTION 9SG6978-4 CONTROL PANEL ASSEMBLY 9SG6970-1 CONTROL PANEL 9SS9262-27 PLAIN WASHER 9SCF000010 #10-24HN 9SE106A-1 LOCKWASHER 9SM19685-53 CONNECTOR & LEAD ASBLY 9SM22778-3 KNOB 9SM22778-2 KNOB 1.5" 9ST13483-7 O RING 011 9SM22778-1 KNOB 1.0" 9SM19685-54 CONNECTOR & LEAD ASSEMBLY 9SM19685-48 CONNECTOR AND LEAD ASSEMBLY 9SS12021-70... - Page 68 Control Panel Assembly PART NUMBER DESCRIPTION 9SS13146-1 START BUTTON 9ST10800-38 SWITCH-TOGGLE 9SS22061-4 SEALING BOOT 9ST10800-39 SWITCH-TOGGLE 9SS22061-4 SEALING BOOT 9SG7168 DECAL CARRIER 9SG7637-3 WELD CONTROL PC BD ASBLY 9SS8025-100 SELF TAPPING SCREW 9SL11924-4 PCB BRACKET ASSEMBLY 9ST9187-13 #10-24HLN-1817/1-NYLON INSERT 9ST10800-39 SWITCH-TOGGLE 9SG7432 CONTROL HARNESS...

- Page 69 Control Panel Assembly PART NUMBER DESCRIPTION 9SG7168 DECAL CARRIER 9SS25569 DOOR PADDLE LATCH 9SS9225-68 THREAD FORMING SCREW (CUTTING) 9ST13534-11 PILOT LIGHT 9ST13534-6 PILOT LIGHT 9SM19685-51 CONNECTOR AND LEAD ASSEMBLY 9SS9225-68 THREAD FORMING SCREW (CUTTING) Dual Vantage 700-AU (Cummins) - 12299...

- Page 70 Control Panel Assembly P-821-D.jpg Dual Vantage 700-AU (Cummins) - 12299...

-

Page 71: Output Panel Assembly

Output Panel Assembly PART NUMBER DESCRIPTION 9SG4983-35 OUTPUT PANEL ASSEMBLY 9SG6971-4 OUTPUT PANEL (AU) 9SG7594-1 BOOT 9SS28342-2 CIRCUIT BREAKER 9SS28342 CIRCUIT BREAKER 9SS28387-2 MOUNTING STRAP 9SS9262-27 PLAIN WASHER 9SE106A-1 LOCKWASHER 9SCF000010 #10-24HN 9SG7594 BOOT 9SS28343 9SS28387-1 MOUNTING STRAP 9SS9262-27 PLAIN WASHER 9SE106A-1 LOCKWASHER 9SCF000010... - Page 72 Output Panel Assembly PART NUMBER DESCRIPTION 9SS9262-1 PLAIN WASHER 9SM20007 OUTPUT STUD COVER 9SS25669 OUTPUT STUD COVER PLATE 9SS9225-68 THREAD FORMING SCREW (CUTTING) 9SS21130-50 PUSH BUTTONE-STOP IDEC 4NC 9SS28114 MOUNTING STRAP 9ST11267-A INSULATOR 9ST11267-B INSULATOR 9SCF000035 1/4-20X1.75RHS 9SS9262-98 PLAIN WASHER 9SE106A-2 LOCKWASHER 9SCF000017...

- Page 73 Output Panel Assembly P-821-E.jpg Dual Vantage 700-AU (Cummins) - 12299...

-

Page 74: Power Module Asbly, Fuel Tank, & Rectifier Mounting

Power Module Asbly, Fuel Tank, & Rectifier Mounting PART NUMBER DESCRIPTION 9SG7436 POWER MODULE ASSEMBLY 9SG6566-1 FUEL TANK TRAY 9ST11525-7 SPEED NUT 9SG7020 FUEL TANK BAFFLE 9SS9225-64 SELF TAPPING SCREW 9SL16070-1 CAPACITOR ASSEMBLY 9SM22747 CAPACITOR BRACKET 9SS13490-171A FILTER CAPACITOR 9SS11604-65 SET SCREW 9SL9170 CAPACITOR MOUNT... - Page 75 Power Module Asbly, Fuel Tank, & Rectifier Mounting PART NUMBER DESCRIPTION 9SM22071 9SS9225-92 THREAD FORMING SCREWCUTTING(1/4-20X.50) 9SS10404-138 RESISTOR-WW100W505% 9SS22168 HEAT SINK HOLDER 9SCF000191 #10-24X7.50RHS 9SS9262-27 PLAIN WASHER 9SE106A-1 LOCKWASHER 9SCF000010 #10-24HN 9SE106A-2 LOCKWASHER 9SCF000017 1/4-20HN 9SM15045-108 ACOUSTICAL FOAM 9SS9225-64 SELF TAPPING SCREW 9SE106A-2 LOCKWASHER 9SCF000017...

- Page 76 Power Module Asbly, Fuel Tank, & Rectifier Mounting PART NUMBER DESCRIPTION 9SG7234-1 IDLER PCB MOUNT BRACKET ASSBLY 9SS9225-68 THREAD FORMING SCREW (CUTTING) 9SE106A-2 LOCKWASHER 9SCF000017 1/4-20HN 9SS10404-132 RESISTORWW25W105% 9SCF000009 #10-24X3.00RHS 9ST4479-A INSULATING WASHER 9SS9262-27 PLAIN WASHER 9SE106A-1 LOCKWASHER 9SCF000010 #10-24HN 9ST13637-5 DIODE-BRIDGE35A800VF-W1-PH 9SS10773-7...

- Page 77 Power Module Asbly, Fuel Tank, & Rectifier Mounting PART NUMBER DESCRIPTION 9SM22796 LOWER RECTIFIER MTG BRACKET 9SL11132-2 THREE PHASE BRIDGE RECTIFIER 9SE106A-3 LOCKWASHER 9ST14815-19 METRIC HEX NUT 9SS9262-121 PLAIN WASHER 9ST11525-7 SPEED NUT 9SCF000028 5/16-18X1.25HHCS 9SS9262-121 PLAIN WASHER 9SE106A-14 LOCKWASHER 9SCF000029 5/16-18HN 9SS22415-15...

- Page 78 Power Module Asbly, Fuel Tank, & Rectifier Mounting P-821-F.jpg Dual Vantage 700-AU (Cummins) - 12299...

-

Page 79: Base, Battery, & Lift Frame Assembly

Base, Battery, & Lift Frame Assembly PART NUMBER DESCRIPTION 9SG6586-3 BASE ASSEMBLY 9SG6955 BASE 9SL12454-6 SUPPORT 9SS24485 RUBBER MOUNT 9SS9225-64 SELF TAPPING SCREW 9SS9262-98 PLAIN WASHER 9ST9187-16 1/4-20 HLN 9SL12454-7 STATOR SUPPORT 9SM22708 STEEL SKID ASBLY 9SS9225-64 SELF TAPPING SCREW 9ST11525-7 SPEED NUT 9SS9225-64... - Page 80 Base, Battery, & Lift Frame Assembly PART NUMBER DESCRIPTION 9ST12380-12 BUSHING 9SM15046-105 ACOUSTICAL FOAM 9ST11525-7 SPEED NUT 9SL8904-8 BATTERY & HOLD DOWN ASSEMBLY 9SM17798-5 BATTERY PANEL 9SS22018-2 BATTERY BRACKET 9ST11827-31 CARRIAGE BOLT 9ST9187-6 LOCKNUT 9SM9399-15 BATTERY 9ST14654 CAP-PLASTIC 9SS9225-64 SELF TAPPING SCREW 9SS8070-50 BATTERY CABLE (POSITIVE) 9SS20191-1...

- Page 81 Base, Battery, & Lift Frame Assembly P-821-G.jpg Dual Vantage 700-AU (Cummins) - 12299...

-

Page 82: Engine Assembly

Engine Assembly PART NUMBER DESCRIPTION 9SG3990-9 ENGINE ASSEMBLY 9SM22560 ENGINE 9SG4480-3 RIGHT ENGINE FOOT 9ST14731-5 METRIC HEX HD SCREW-M10 X 1.5 9SS17400-1 LOCKWASHER-METRIC 9SG4480-4 LEFT ENGINE FOOT 9ST14731-5 METRIC HEX HD SCREW-M10 X 1.5 9SS17400-1 LOCKWASHER-METRIC 9SL16072 9SL15971 MUFFLER MTG BRACKET 9ST14731-5 METRIC HEX HD SCREW-M10 X 1.5 9SS17400-1... - Page 83 Engine Assembly PART NUMBER DESCRIPTION 9SS17400-3 METRIC LOCKWASHER 9SM24146 MAGNETIC PICKUP 9SM25074 CRANKSHAFT PULLEY ASSEMBLY 9SM25097 BELT BX-47 9SS24662 OIL DRAIN VALVE 9SS25362-1 HOSE NIPPLE 9ST10642-264 FLEX TUBE 9SS10888-27 HOSE CLAMP 9ST10642-333 FLEX TUBE 9ST10642-334 FLEX TUBE 9SS29250 BARB 9SS10888-35 HOSE CLAMP 9SM19794-3 FUEL STRAINER...

- Page 84 Engine Assembly P-821-H.jpg Dual Vantage 700-AU (Cummins) - 12299...

-

Page 85: Generator Assembly

Generator Assembly PART NUMBER DESCRIPTION 9SL10742-27 GENERATOR ASSEMBLY 9SL10501-21 ROTOR & SHAFT ASBLY 9SM19796 COUPLING DISC 9SS8042 COUPLING DISC BACKING PLATE 9SS14233 COUPLING CLAMP RING-INSIDE 9ST8833-2 HEX HD CAP SCREW 9SE106A-8 LOCKWASHER 9SM9300-181 BEARING 9SM22633 BLOWER ASBLY 9ST14731-5 METRIC HEX HD SCREW-M10 X 1.5 9SS17400-1 LOCKWASHER-METRIC 9SG3088-36... - Page 86 Generator Assembly PART NUMBER DESCRIPTION 9ST14731-5 METRIC HEX HD SCREW-M10 X 1.5 9SS17400-1 LOCKWASHER-METRIC 9SM21315-7 BRUSH HOLDER & BRACKET ASBLY 9SS9225-8 THREAD FORMING SCREW (ROLLING) 9SL11614-8 STATOR COWLING 9SS9225-68 THREAD FORMING SCREW (CUTTING) 9SS22415-12 TRIM SEAL 9SL11614-9 STATOR COWLING 9SS9225-68 THREAD FORMING SCREW (CUTTING) 9ST9054 WASHER...

- Page 87 Generator Assembly PART NUMBER DESCRIPTION 9SCF000017 1/4-20HN 9SS29946 SHELF SUPPORT BRACKET 9SS9225-64 SELF TAPPING SCREW 9SM24813 SHAFT HUB ASBLY 9SM24812 SHAFT COUPLING 9ST9447-123 SOCKET HEAD CAP SCREW 9SE106A-6 LOCKWASHER Dual Vantage 700-AU (Cummins) - 12299...

- Page 88 Generator Assembly P-821-J.jpg Dual Vantage 700-AU (Cummins) - 12299...

-

Page 89: Radiator & Case Back Asbly

Radiator & Case Back Asbly PART NUMBER DESCRIPTION 9SL16279 RADIATOR & CASE BACK ASBLY 9SG7001 CASE BACK 9SG3115-12 RADIATOR 9ST11827-26 CARRIAGE BOLT 9SS9262-121 PLAIN WASHER 9ST9187-15 5/16-18HLN-SS 9ST11525-7 SPEED NUT 9SL15965-1 FAN SHROUD 9SS9225-64 SELF TAPPING SCREW 9SE106A-14 LOCKWASHER 9SS9262-121 PLAIN WASHER 9SG7433 HOSE... - Page 90 Radiator & Case Back Asbly P-821-K.jpg Dual Vantage 700-AU (Cummins) - 12299...

-

Page 91: Covers Assembly

Covers Assembly PART NUMBER DESCRIPTION 9SL13116-10 ROOF ASSEMBLY 9SG6466-1 ROOF 9ST14882-1 DOOR BUMPER 9SM20278 RADIATOR CAP COVER ASSEMBLY 9ST12584-6 RIVET 9ST13086-205 FUEL WARNING DECAL 9SS25896-1 WARNING DECAL 9SL12084 FUEL TROUGH 9SL16212 AIR CLEANER BRACKET 9SS24739-40 STAINLESS STEEL SCREW 9ST13597-6 BUTTON PLUG 9SG6604-1 CASE SIDE 9SS24739-40... - Page 92 Covers Assembly PART NUMBER DESCRIPTION 9SS27368-6 LOGO DECAL 9SM21908-1 FAMILY NAME LOGO Dual Vantage 700-AU (Cummins) - 12299...

- Page 93 Covers Assembly P-821-L.jpg Dual Vantage 700-AU (Cummins) - 12299...

- Page 94 WARNING Do not touch electrically live parts or Keep flammable materials away. Wear eye, ear and body protection. electrode with skin or wet clothing. Insulate yourself from work and AVISO DE ground. Spanish PRECAuCION No toque las partes o los electrodos Mantenga el material combustible Protéjase los ojos, los oídos y el bajo carga con la piel o ropa moja-...

- Page 95 WARNING Keep your head out of fumes. Turn power off before servicing. Do not operate with panel open or Use ventilation or exhaust to guards off. remove fumes from breathing zone. AVISO DE Spanish PRECAuCION Los humos fuera de la zona de res- Desconectar el cable de ali- No operar con panel abierto o piración.

- Page 96 Lincoln Electric for advice or information about their use of our products. We respond to our customers based on the best information in our possession at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such information or advice.

Need help?

Do you have a question about the DUAL VANTAGE 700 (AU) and is the answer not in the manual?

Questions and answers