Table of Contents

Advertisement

DURAWELD

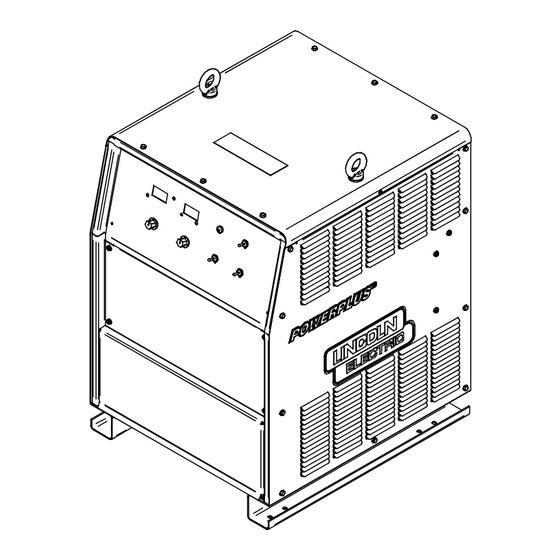

DURAWELD™ 500 K60096-1 / 76187

DURAWELD™ 350 K60107-1 / 76245

• World's Leader in Welding and Cutting•

THE SHANGHAI LINCOLN ELECTRIC COMPANY

No. 195, Lane 5008, Hu Tai Rd. Baoshan, Shanghai, PRC 201907

™

For use with machine Code

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built with

safety in mind. However, your overall

safety can be increased by proper

installation and thoughtful operation on

your part. DO NOT INSTALL, OPERATE

OR REPAIR THIS EQUIPMENT

WITHOUT READING THIS MANUAL

AND THE SAFETY PRECAUTIONS

CONTAINED THROUGHOUT. Most

importantly, think before you act and be

careful.

www.lincolnelectric.com.cn

350/500

Copyright © 2008The Shanghai Lincoln Electric Company

IM7017-1

April, 2016

Rev. 07

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Lincoln Electric DURAWELD 500

- Page 1 CONTAINED THROUGHOUT. Most importantly, think before you act and be careful. Copyright © 2008The Shanghai Lincoln Electric Company • World’s Leader in Welding and Cutting• THE SHANGHAI LINCOLN ELECTRIC COMPANY No. 195, Lane 5008, Hu Tai Rd. Baoshan, Shanghai, PRC 201907...

- Page 2 Thank you for selecting QUALITY Lincoln Electric products. Please examine the packaging and equipment for damage. Claims for material damaged in shipment must be notified immediately to the authorized dealer from whom you purchased the machine. For future reference, please record your equipment identification information in the table below. Model Name, Code &...

-

Page 3: Electric And Magnetic Fields

SAFETY WARNING ARC WELDING CAN BE HAZARDOUS. PROTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH. KEEP CHILDREN AWAY. PACEMAKER WEARERS SHOULD CONSULT WITH THEIR DOCTOR BEFORE OPERATING EQUIPMENT. BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE PERFORMED ONLY BY QUALIFIED INDIVIDUALS. ELECTRIC AND ELECTRIC SHOCK MAGNETIC FIELDS... -

Page 4: Fumes And Gases

SAFETY FUMES AND GASES WELDING SPARKS can be dangerous. can cause fire or explosion. 6.a Remove fire hazards from the welding area. If 4.a Welding may produce fumes and gases this is not possible, cover them to prevent the hazardous to health. Avoid breathing these welding sparks from starting a fire. -

Page 5: Installation

For any maintenance or repair operation it is recommended to contact the nearest technical service center or directly consult the machine division of the Shanghai Lincoln Electric Co. Ltd.. Maintenance or repairs performed by unauthorized service centers or personnel will void the manufacturer’s warranty. -

Page 6: Safety Precautions

INSTALLATION SAFETY PRECAUTIONS Open the input box on the rear of the case. Use a Read the entire installation section before starting three-phase supply line, the three live wires should go installation. through the three holes of the input wire holder and be WARNING securely clamped and fixed. -

Page 7: Gun And Cable Installation

INSTALLATION User must provide gas cylinder of appropriate type shielding gas for the process being used with the PWF wire feeder connection instructions DURAWELD™. (See Figure A. 2) WARNING Turn the DURAWELD power switch “OFF”. Connect the control cable from the PWF/LWF feeder CYLINDER may explode if damaged. -

Page 8: Operational Features And Controls

OPERATION thermostat overheating protection device. When the SAFETY PRECAUTIONS machine detects overheating, the output will turn off, WARNING and the Thermal Indicator Light will turn “ON“. When the machine has cooled to a safe temperature, the ELECTRIC SHOCK can kill. Thermal Indicator Light will go out and the machine will ... - Page 9 11. WIRE DIAMETER SELECTION There are three diameter selection switch; 2. INPUT CABLE HOLDING BRACKET For Duraweld 500,1.0, 1.2, 1.6 can be select with this This bracket holds the three phase power cables switch. securely. For Duraweld 350,1.2,1.0, 0.8 can be select with this switch.

- Page 10 OPERATION FIGURE B.4 FOUR STEP TWO STEP 5. GAS HEATING 2A FUSE AND FUSE HOLDER This machine is equipped with AC220V(200W) heating power. This fuse is used to protect heating circuit. 6. GAS HEATING SOCKET This is output socket of Max Aux 220v power, used to connect with gas heater.

-

Page 11: Advanced Features

OPERATION S2-2 ENERGY SAVING SWITCH ADVANCED FEATURES When the Dip switch #5 is in the “OFF” position, the POWERPLUS machine will operate in power DURAWELD machine offers two DIPs (S1 and saving mode. S2)switch on the PC board, which allows the user to Note: After the machine has not been activated for have additional features. - Page 12 OPERATION adjust crater voltage potentiometer to change that value. If we adjust one proper value, flip 2/4 step switch-(ON –OFF). That will make the data be saved. In that time, the voltage meter displays the character of “don”. The default value is “15”. NOTE 5:ARC Start Voltage Offset Setting ARC Start Voltage can be adjusted.

- Page 13 OPERATION on the left LED.The parameter value is showed on the voltage meter.Through the 2/4 step switch flip,we can change the respective parameter. For example, we want to look up the Run-in speed setting value, flip the 2/4 step switch, until the “2” is displayed on the left LED of current meter.

-

Page 14: Troubleshooting

(SYMPTOMS) COURSE OF ACTION OUTPUT PROBLEMS Contact The Shanghai Lincoln Major Physical or Electrical 1. Contact your local Lincoln Electric Electric Service Dept. (8621)6673 Damage is Evident. Authorized Field Service Facility. 4530 ext 1182. 1. Check the fuse F1 on input circuit Replace control board. - Page 15 TROUBLESHOOTING PROBLEMS RECOMMENDED POSSIBLE AREAS OF MISADJUSTMENTS(S) (SYMPTOMS) COURSE OF ACTION OUTPUT PROBLEMS 1. Voltage or current “Pots” on wire Check and replace. feeder control panel damaged. 2. SCR module is damaged. Replace SCR module. The machine has low output and no control.

- Page 16 TROUBLESHOOTING PROBLEMS RECOMMENDED POSSIBLE AREAS OF MISADJUSTMENTS(S) (SYMPTOMS) COURSE OF ACTION OUTPUT PROBLEMS 1. Overheating with SCR or Choke. Wait for machine to cool down. 2. Thermostat protection. Fan motor Change fan motor. doesn't run or runs at low speed. Err 36.

- Page 17 TROUBLESHOOTING PROBLEMS RECOMMENDED POSSIBLE AREAS OF MISADJUSTMENTS(S) (SYMPTOMS) COURSE OF ACTION OUTPUT PROBLEMS 1. PC board is faulty. Check and replace. 2. Loose or bad connections on the Check and correct. Meter reading is incorrect. feedback leads 220& 221, 222& 223. 3.

- Page 18 CIRCUIT DIAGRAM DURA WELD 500 WIRING SCHEMATIC Auxiliary INPUT Transformer ~220V 1A AC 220V RECEPTACLE ~36V OUTPUT SHUNT 2A/250V DURA 500 - 600A 60mV 110V AC 220D 219A Main 220C 220C 220B 220B Transformer ELECTRODE SCR 1 201A 100Ω COIL 1 COIL 1 SCR 2 213A...

- Page 19 CIRCUIT DIAGRAM DURAWELD 350 WIRING SCHEMATIC Auxiliary Transformer BLACK ~220V 1A AC 220V BLUE RECEPTACLE ~36V 110V AC SHUNT 2A/250V DURA 500 - 600A 60mV 220D 219A Main 220C 220C ELECTRODE 220B 220B Transformer SCR 1 201A 100Ω SCR 2 COIL 1 COIL 1 203A...

- Page 20 Before any examination and repair, please turn off the 3-Phase Input Power first, especially when changing the auxiliary transformer. • World’s Leader in Welding and Cutting• THE SHANGHAI LINCOLN ELECTRIC COMPANY No. 195, Lane 5008, Hu Tai Rd. Baoshan, Shanghai, PRC 201907 www.lincolnelectric.com.cn...

- Page 21 P‐7017 2016.06 PARTS LIST FOR DURAWELD 500...

- Page 22 P‐7017 PA‐1 ILLUSTRATION OF SUB‐ASSEMBLIES DURAWELD 500 ...

- Page 23 P‐7017 PA‐2 DURAWELD 500 For code: 76187 Do Not use this Parts List for a machine if its code number is not listed. For any code numbers not listed, contact the Service Department via: china_service@lincolnelectric.com.cn. Use the Illustration of Sub-Assemblies page and the table below to determine which sub assembly page and column the desired part is located on for your particular code machine.

- Page 24 Case Front Assembly P‐7017 PB‐1 DURAWELD 500 ...

- Page 25 Case Front Assembly P‐7017 PB‐2 ITEM DESCRIPTION PART NO. QTY. Front Panel G5894-2 Control Panel Decal M24915-5 Knob T13639-6 O Ring T13483-34 Potentiometer Spacer S18280 Pot Harness (Not Shown), Includes: G7702-8 Potentiometer T10812-119 Display PCB Assembly M25153-2 M4 Screw (Not Shown) S28798-3 Toggle Switch, SPST T10800-4...

- Page 26 P‐7017 PC‐1 SCR Heatsink & Fan Bracket Assembly DURAWELD 500 ...

- Page 27 P‐7017 PC‐2 SCR Heatsink & Fan Bracket Assembly ITEM DESCRIPTION PART NO. QTY. Fan Bracket Weld Assembly L13199-3 M5X0.85 Hex Washer Head Phillips (Not Shown) S26641-4 Fan Motor, Includes: M20713-2 Motor (with Capacitor) Terminal Size 0.4 - 1.0 M4 Screw (Not Shown) S28798-3 Aluminum Fan blade D=350mm(Inner D=8mm) L13328-1...

- Page 28 P‐7017 PD‐1 Base & Center Assembly DURAWELD 500 ...

- Page 29 P‐7017 PD‐2 Base & Center Assembly ITEM DESCRIPTION PART NO. QTY. Transformer & Choke Assembly, Includes: G6105-2 Balance Choke Weld Assembly M21548-3 Output Choke Weld Assembly M21483-4 M8X1.25 Hex Head Screw (Not Shown) S26641-8 M8 Plain Washer (Not Shown) S26638-4 M8 Lock Washer (Not Shown) S26639-4...

- Page 30 P‐7017 Case Back Assembly PE‐1 DURAWELD 500 ...

- Page 31 P‐7017 Case Back Assembly PE‐2 ITEM DESCRIPTION PART NO. QTY. Case Back Insert Assembly G6233-3 Aux Transformer M21437-13 M5X0.85 Hex Washer Head Phillips (Not Shown) S26641-4 M5 Plain Washer (Not Shown) S26638-3 M5 Lock Washer (Not Shown) S26639-3 M5X0.8 Hex Nut (Not Shown) S26640-3 Input Block M20720-6...

- Page 32 P‐7017 PF‐1 Wraparound Assembly DURAWELD 500 ...

- Page 33 P‐7017 PF‐2 Wraparound Assembly ITEM DESCRIPTION PART NO. QTY. Top Roof L13196-3 M5X0.85 Hex Washer Head Phillips (Not Shown) S26641-4 ST4.8X1.6 Washer Faced Hex Self (Not Shown) S26738-2 Label, Case Top (Not Shown) M20952 Left Side Panel L13194-3 M5X0.85 Hex Washer Head Phillips (Not Shown) S26641-4 ST4.8X1.6 Washer Faced Hex Self (Not Shown) S26738-2...

Need help?

Do you have a question about the DURAWELD 500 and is the answer not in the manual?

Questions and answers