Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Elite EliteCUT 40s

- Page 2 USER MANUAL EliteCUT 40s Plasma Cutter SIC 40 DV INSTRUCTIONS MANUAL USER MUST ALWAYS READ AND UNDERSTAND THIS MANUAL IN ORDER TO REDUCE INJURY RISK www.ELITETOOLS.co Keep Working...

-

Page 3: Table Of Contents

CONTENT 1. SECURITY PRECAUTIONS Electric shock warning Fire hazzard Explosion hazzard Components Fumes can cause udamage to your health Electric arc radiation can damage your eyes and skin The magnetic field can cause alterations in cardiac pacemakers Improper use may cause fire or explosion Hot work material can cause severe burns Excessive noise causes hearing damage Mobile parts can cause injuries... - Page 4 CONTENT OBSERVATIONS Good ventilation Overvoltage is prohibited Overloading is prohibited 9. FRONT PANEL FUNCTIONS ELITE CUT 40S Panel frontal Panel trasero Digital panel 10. MACHINE OPERATION Good machine maintenance will avoid a high percentage of failures Tips Table of cutting parameters 11.

- Page 5 OBSERVATIONS In order to establish its safety and correct operation, please read this manual carefully before executing any operation, please keep this manual properly for future references. This product has been designed and manufactured in accor- dance with to national and international standards and meets the standard. U.

-

Page 6: Security Precautions

1. SECURITY PRECAUTIONS ELECTRIC SHOCK WARNING • Install the device in an earthed installation in accordance with current regulations and legisla- tion. • Do not expose your skin or touch the active parts with wet gloves or wet clothing. • Make sure there is insulation between you, the machine and the ground. •... -

Page 7: The Magnetic Field Can Cause Alterations In Cardiac Pacemakers

THE MAGNETIC FIELD CAN CAUSE ALTERATIONS IN CARDIAC PACEMAKERS • Persons with pacemakers should consult a physician before performing plasma cutting opera- tions. • Stay away from the power source to reduce the effect. IMPROPER USE MAY CAUSE FIRE OR EXPLOSION •... -

Page 8: Warning

PCBs can cause an explosion. • Burning plastic parts, such as the front panel, can produce poisonous gases. 3. GENERAL DESCRIPTION GENERAL TECHNICAL PARAMETERS ELITE CUT 40S MODEL CE / EN60974 - 1 STANDARS 10 - 40 AMP REGULATION RANGE... -

Page 9: Machine Dimensions

4. MACHINE DIMENSIONS 33 Cm www.ELITETOOLS.co Keep Working... -

Page 10: Machine Characteristics Inverter Plasma Cutter

5. MACHINE CHARACTERISTICS INVERTER PLASMA CUTTER This is a perfectly functioning, high performance and advanced technology digital plasma cutting machine. The Elite CUT 40 S is an ultra-portable plasma cutting system suitable for a variety of applications and requirements. Intended for manual cutting application. The Elite CUT 40 S can cut conductive metal such as low carbon steel, stainless steel, and aluminum. -

Page 11: Powerful Cutting Performance

Powerful cutting performance This machine is economical and practical since it can cut metals using compressed air as the plasma gas source. Cutting speed increases 1.8 times compared to cutting with oxyacetylene. It can cut thick steel plates such as stainless steel, copper, cast iron and aluminum conveniently and quickly. -

Page 12: System Characteristics

6. SYSTEM CHARACTERISTICS Duty Cycle Duty cycle is the percentage of time that the welding machine can deliver continuous welding current, in a period of 10 minutes. In this machine this value is 50% when the output current is set at the maximum of 220A and the ambient temperature is 40 ° C. This percentage increases as the set output current decreases and / or the ambient temperature decreases. -

Page 13: Installation Requirements

The ELITE CUT40S should be close to the corresponding power outlet. For CSA or CE standard single phase power supply, 100-260V outlet must be used. A 3m power cord is available for the Elite CUT40S. There should be a space of no less than 0.25m around the power supply to ensure adequate ventilation. -

Page 14: Air Pressure Regulator Operation

8. AIR PRESSURE REGULATOR OPERATION Filter-regulator The built-in pneumatic filter regulator is adjusted correctly out of the factory, and users do not need to HANDLE configure it in general. TORCH HEAD If users need to adjust the built-in filter reducer, the steps are as follows: start the gas flow;... -

Page 15: Observations

OBSERVATIONS Good ventilation This cutting machine can create powerful cutting current and has strict cooling requirements that cannot be met with natural ventilation. Therefore, the built-in fan is very important to enable the machine to run stable with effective cooling. The operator must ensure that the fan grids are uncovered and unlocked. -

Page 16: Front Panel Functions Elite Cut 40S

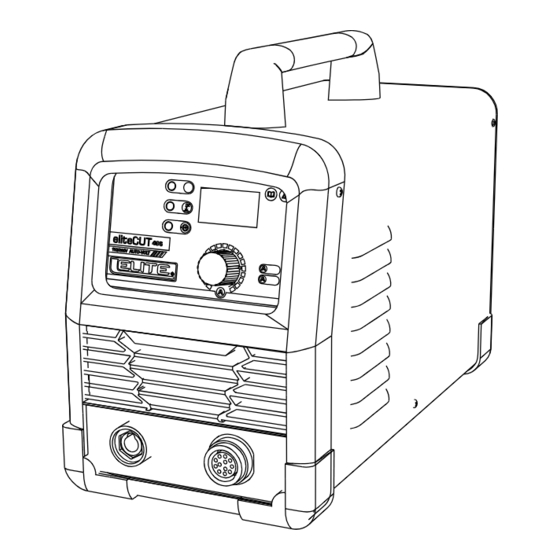

FRONT PANEL FUNCTIONS ELITE CUT 40S Front Panel Definition Function To adjust the output current value Current Knob To connect the work cable Quick connector Torch socket To connect the torch Definition Function To turn on and off the machine... -

Page 17: Machine Operation

10. MACHINE OPERATION 1.Turn on the machine's power switch and the power indicator will light. 2.Select the proper working mode and proper function. 3.Push the trigger of the cutting torch, the cutting machine will start to work. 4.Adjust the cutting current according to the thickness of the workpiece. 5.Put the copper nozzle of the cutting torch in contact with the workpiece (For models with pilot arc function, keep approximately 2mm between the copper nozzle of the torch and the workpie- ce) and push the torch trigger. -

Page 18: Tips

Please clean the splashes on the nozzle promptly, as it will affect the cooling effect of the nozzle. Clean the dust and splashes on the torch head after daily use to ensure a good cooling effect. TIPS: The workpiece is not cut completely This can be caused by: •... -

Page 19: Electrode And Nozzle Replacement

11. ELECTRODE AND NOZZLE REPLACEMENT When the following circumstances occur, the electrode and nozzle must be replaced. Otherwise there will be a strong arc on the nozzle that will break the nozzle and the electrode, or even burn the torch. Different model nozzles are different, so make sure the nozzle is the same model when replacing it. -

Page 20: Daily Cutting Machine Check

Daily cutting machine check Daily cable check www.ELITETOOLS.co Keep Working... -

Page 21: Periodic Control

Periodic Control The periodic inspection must be carried out by qualified professionals to guarantee safety. The switchboard and the cutting machine must be turned off before the periodic check to avoid accidents with personal injury such as electric shock and burns. Due to discharge of capacitors, the check should be done 5 minutes after the machine is turned off. -

Page 22: Pay Attention To Maintenance

Pay attention to maintenance A regular check should be carried out to ensure long-term normal use of the machine. Take care when performing the periodic check, including inspecting and cleaning the interior of the machi- ne. In general, a regular check should be done every 6 months, and should be done every 3 months if the cutting environment is dusty or with oily smoke. -

Page 23: Problem Solution

12. PROBLEM SOLUTION To Prevent serious injury: Shut off the Welder, disconnect the power, and discharge the torch to ground before adjusting, cleaning, or repairing the unit. To make sure discharge all capacitors before performing any internal procedures. WARNING Trouble Experienced Possible reasons Likely Solutions Verify that circuit breaker hasn’t been... - Page 24 Trouble Experienced Possible reasons Likely Solutions Increase output current through clockwise Output current is too low adjusting the knob. Make sure proper input power is supplied Choose material with proper thickness. Or change to a more powerful plasma Material being cut is too cutter to cut the material with thickness thick exceeds the limit...

- Page 25 Fault Code List Fault Code Fault Description Fault Cause And Elimination Ambient temperature is too high, or machine reaches its limit of duty cycle. Allow the machine cool down with fan running. And check Overheat for obstructions blocking air flow and keep enough space between any obstacles and the vents on all sides of the machine Input voltage is too high or too low.

-

Page 26: Complete 2 Year Warranty

13. COMPLETE 2 YEAR WARRANTY If this Elite product fails due to a defect in material or workmanship within 2 years from the date of purchase, return it to any Elite Authorized Distribution Store, Elite Service Centers or other Elite Point of Sale for repair. free of charge (or replaced if repair is impossible).

Need help?

Do you have a question about the EliteCUT 40s and is the answer not in the manual?

Questions and answers