Summary of Contents for Durr Dental VS 250 S

- Page 1 VS 250 S Installation and operating instructions 0297 9000-606-58/40 *9000-606-58/40*...

-

Page 3: Table Of Contents

....Layout of VS 250 S 60 Hz ..General safety information .. -

Page 4: Important Information

Risk of minor injuries These installation and operating instructions – NOTICE apply to: Risk of extensive material/property damage VS 250 S Order number: 7151-01; 7151-01/002; 7151-02; Other symbols 7151-02/002 These symbols are used in the document and on Warnings and symbols or in the unit: Note, e.g. -

Page 5: Copyright Information

Important information Safety Protective ground connection Dürr Dental has designed and constructed this unit so that when used properly and for the CE labelling with the number of the noti- intended purpose it does not pose any danger to fied body people or property. -

Page 6: Systems, Connection With Other

Important information The unit must not be used as a vacuum Notification requirement of ❯ cleaner. serious incidents Do not use chemicals containing chlorine or ❯ The operator/patient is required to report any foaming chemicals. serious incident that occurs in connection with Operation in operating theatres of explosive ❯... -

Page 7: Only Use Original Parts

Important information An overview of the waste keys for Dürr ACHTUNG Dental products can be found in the Erroneous operation mode due to use download area at www.duerrdental.com immediately adjacent to other devices (document no. P007100155). or with other stacked devices Do not stack the unit together with ❯... -

Page 8: Product Description

Product description Product description Overview Combination suction unit Suction and exhaust air hose Waste water hose Set of connection fittings 9000-606-58/40 2001V002... -

Page 9: Scope Of Delivery

(possible variations due to country-spe- cific requirements and/or import regulations): VS 250 S, 230 V, 50 Hz ... . . 7151-01 VS 250 S, 230 V, 50 Hz with con- nection accessories . -

Page 10: Technical Data

Product description Technical data 7151-01 / 7151-02 Electrical data 50 Hz 60 Hz Rated voltage 230, 1~ Mains frequency Nominal current Start-up current, max. Rated power Type of protection IP 21 Protection class Connections Æ 20 External suction connection (DürrConnect) External exhaust air connection Æ... - Page 11 Product description Electromagnetic compatibility (EMC) Interference emission measurements High-frequency emissions in accordance with CISPR 11 Group 1 Class B Interference voltage at the power supply connection Compliant CISPR 11:2009+A1:2010 Electromagnetic interference radiation Compliant CISPR 11:2009+A1:2010 Emission of harmonics Compliant IEC 61000-3-2:2005+A1:2008+A2:2009 Voltage changes, voltage fluctuations and flicker emis- Compliant sions...

- Page 12 Product description Immunity to interference table, near fields of wireless HF communication devices Radio service Frequency band Test level GMRS 460 430 - 470 FRS 460 LTE band 13, 17 704 - 787 GSM 800/900 TETRA 800 iDEN 820 800 - 960 CDMA 850 LTE band 5 GSM 1800...

- Page 13 Product description Electromagnetic compatibility (EMC) Interference immunity measurements SIP/SOP Immunity to electrostatic discharge IEC 61000-4-2:2008 Compliant ± 8 kV contact ± 2kV, ± 4 kV, ± 8 kV, ± 15 kV air Immunity to electrical fast transients/bursts – I/O, SIP/SOP ports IEC 61000-4-4:2012 Compliant ±...

-

Page 14: Type Plate

Product description Type plate The type plate is located on the motor housing. Type plate Evaluation of conformity This device has been subjected to conformity acceptance testing in accordance with the cur- rent relevant European Union guidelines. This equipment conforms to all relevant requirements. 9000-606-58/40 2001V002... -

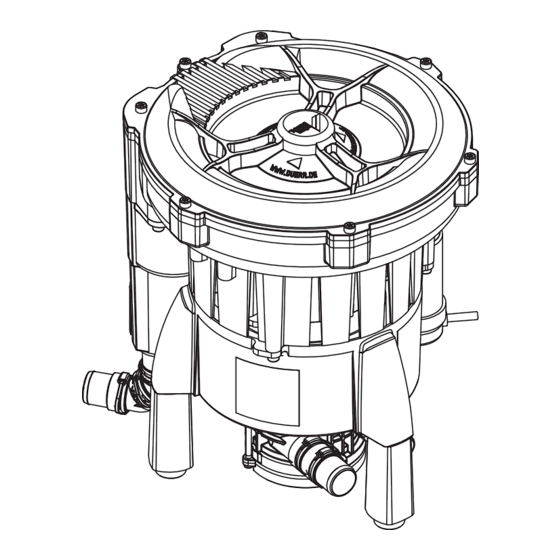

Page 15: Operation

Product description Operation Fig. 1: VS 250 S turbine Motor Waste water connection Suction connection Separation Exhaust air connection Exhaust air noise reducer This suction unit is a suction machine with integrated separation. Separation in the treatment unit is therefore no longer necessary. - Page 16 Product description The rest of the mixture passes to the cyclone separator, where it is set into a spiral motion. In this first stage, the resulting centrifugal forces force the fluid constituents and any remaining solid particles against the outside wall of the separation chamber of the cyclone separator. This initially only effects a "coarse separation"...

-

Page 17: Assembly

Assembly Hose materials Assembly For waste connections and suction lines only use the following hose types: – Flexible spiral hoses made of PVC with inte- Requirements grated spiral or equivalent hoses Depending on the suction system, different – Hoses that are resistant to dental disinfectants installation options are available. -

Page 18: System Components

Assembly System components Current consumption of Cross-section unit [A] The system components listed below are required or recommended for various procedures > 25 and < 32 or for installation. > 32 and < 40 Rinsing unit > 40 and < 50 It is recommended that the suction system is >... -

Page 19: 8 Installation

11 Control box (accessory) plied. This will prevent vibrations from being transmitted to the pipe system. Layout of VS 250 S 60 Hz The connection between the pipe line and unit ❯ suction connection should be kept as short as possible and straight, without bends. -

Page 20: Electrical Connections

Assembly Electrical connections Connect mains cable to mains connection. ❯ Control box Actuation via a hose manifold or connection to other components in the treatment unit is only permitted via the Dürr Dental control box (see "3.2 Optional items"). The appendant connection plans and circuit dia- grams can be found in the installation and oper- ating instructions of the control box. -

Page 21: 10 Commissioning

Assembly 10 Commissioning In many countries technical medical prod- ucts and electrical devices are subject to regular checks at set intervals. The owner must be instructed accordingly. Turn on the unit power switch or the main ❯ surgery switch. Carry out a function check of the system. ❯... -

Page 22: Usage

Usage The following are required for disinfection/clean- Usage ing: ü Non-foaming disinfectant/cleaning agent that is compatible with the materials. 11 Disinfection and cleaning ü Unit care system, e.g. OroCup To pre-clean, suck up 2 litres of water with the ❯ NOTICE care system. - Page 23 Usage Securing ring Protective strainer Hose adapter 9000-606-58/40 2001V002...

-

Page 24: 12 Maintenance

Usage 12 Maintenance All maintenance work must be performed by a qualified expert or by one of our Service Techni- cians. WARNING Infection due to contaminated unit Clean and disinfect the suction before working on the unit. ❯ Wear protective equipment when working (e. g. impermeable gloves, protective goggles and ❯... -

Page 25: Troubleshooting

Troubleshooting Troubleshooting 13 Tips for operators and service technicians Any repairs exceeding routine maintenance may only be carried out by qualified personnel or our service. WARNING Infection due to contaminated unit Clean and disinfect the suction before working on the unit. ❯... - Page 26 Troubleshooting Error Possible cause Remedy Leak in the suction line Check and if necessary ❯ establish leak-tightness of suction system and connec- tions. * Mechanical sluggishness of tur- Disassemble the unit and ❯ bine caused by soiling clean the turbine. * Only to be done by service technicians.

-

Page 27: 14 Transporting The Unit

Troubleshooting 14 Transporting the unit WARNING Infection due to contaminated unit Disinfect the unit before transport. ❯ Close all media connections. ❯ Wear protective equipment to avoid any risk of infection (e.g. liquid-tight protective gloves, protective goggles, face mask). Before disassembly, clean and disinfect the ❯... -

Page 28: Appendix

Appendix Appendix 15 Handover record This document confirms that a qualified handover of the medical device has taken place and that appropriate instructions have been provided for it. This must be carried out by a qualified adviser for the medical device, who will instruct you in the proper handling and operation of the medical device. Product name Order number (REF) Serial number (SN) - Page 32 Hersteller/Manufacturer: DÜRR DENTAL SE Höpfigheimer Str. 17 74321 Bietigheim-Bissingen Germany Fon: +49 7142 705-0 www.duerrdental.com info@duerrdental.com...

Need help?

Do you have a question about the VS 250 S and is the answer not in the manual?

Questions and answers