Summary of Contents for Nibe DRAZICE TO-20

- Page 1 OPERATING AND INSTALLATION MANUAL ELECTRIC WATER HEATER TO - 20 Družstevní závody Dražice-strojírna s.r.o. Dražice 69, 294 71 Benátky nad Jizerou tel.: +420 / 326 370 911 fax: +420 / 326 370 980 e-mail: export@dzd.cz...

-

Page 2: Table Of Contents

CONTENTS TECHNICAL SPECIFICATION OF PRODUCT ....................4 FUNCTION DESCRIPTION ........................4 ADVICE FOR CUSTOMERS ........................4 1.2.1 HOT WATER CONSUMPTION ..................... 4 1.2.2 ENERGY SAVING ......................... 4 1.2.3 EMERGENCY POWER CONSUMPTION ..................4 DESIGN AND GENERAL HEATER DIMENSIONS ................... 5 OPERATION AND FITTING INSTRUCTIONS .................... - Page 3 CAREFULLY READ THIS MANUAL BEFORE INSTALLING THE WATER HEATER! Dear Customer, Družstevní závody Dražice - strojírna s.r.o., would like to thank you for your decision to use a product of our brand. With this guide, we will introduce you to the use, construction, maintenance and other information on electrical water heaters.

-

Page 4: Technical Specification Of Product

1 TECHNICAL SPECIFICATION OF PRODUCT FUNCTION DESCRIPTION After the heater is connected to electric network, the heating element starts heating water. The element is turned on and off by a thermostat. Thermostat can be set as per your need within the range from 5 °C to 74 °C. -

Page 5: Design And General Heater Dimensions

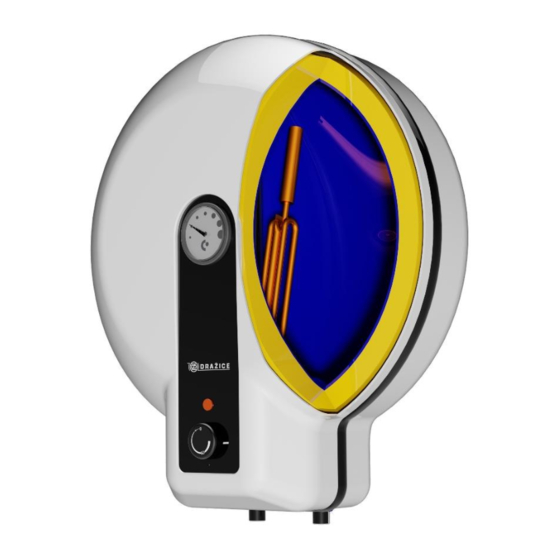

DESIGN AND GENERAL HEATER DIMENSIONS The heater tank is made of a steel plate and tested by 1.5 multiple of operation pressure value. The inner surface of the tank is provided (except the stainless coil) with anticorrosion protection of enameled glaze. In the bottom part of the tank there are wells for placing the heating, regulation and safety element of the water heater (heating element with right thread G 5/4", thermostat sensor and thermal fuses). -

Page 6: Operation And Fitting Instructions

2 OPERATION AND FITTING INSTRUCTIONS OPERATING CONDITIONS The tank shall only be used in accordance with the conditions specified on the performance plate and in instructions for electric wiring. Besides legally acknowledged national regulations and standards, also conditions for connection defined in local electric and water works have to be adhered to, as well as the installation and operation manual. -

Page 7: Plumbing Fixture

TO 20 VOLUME MAX OPERATING OVERPRESSURE IN THE TANK ELECTRICAL CONNECTION 1/N/PE ~ 230 V / 50 Hz INPUT 2200 EL. PROTECTION IP 44 MAX OPERATING TEMPERATURE OF HOT WATER °C (HW) RECOMMENDED HOT WATER (HW) °C TEMPERATURE HEIGHT OF THE HEATER HEATER DIAMETER MAX WEIGHT OF THE HEATER WITHOUT WATER TIME OF EL. - Page 8 It is necessary to check the safety valve each time before putting it into operation. It is checked by manual moving of the membrane from the seat, turning the make-and-break device button always in the direction of the arrow. After being turned, the button must click back into a notch. Proper function of the make-and-break device results in water draining through the safety valve outlet pipe.

-

Page 9: Electric Wiring

ELECTRIC WIRING 2.4.1 ELECTRIC INSTALLATION GENERAL INFORMATION The electric wiring scheme is attached to the water heater on the inner side of the removable front guard (Figure 4). The degree of protection of electric parts of the heater is IP 44. Power input of electric element is 2200 W. It is necessary to observe the below requirements during the electric wiring: •... -

Page 10: First Heater Commissioning

FIRST HEATER COMMISSIONING Before opening the power supply, the tank must be filled with water. The process of first heating must be executed by licensed professional who has to check it. Both the hot water outlet pipe and safety armature parts may be hot. During the heating process the pressurized connection water that increases its volume due to heating must drip off the safety valve. -

Page 11: Inspection, Maintenance & Care For The Appliance

Drainage of service water shall be performed after closing the shut-off valve in the cold water supply piping (through the discharge valve for safety valve combination), and with simultaneous opening of all hot water valves of connected fittings. Hot water may outflow during the drainage! If there is a risk of frost it has to be considered that not only the water in the hot water heater and in the hot water piping may get frozen but also the water in the entire cold water supply piping. -

Page 12: Most Frequent Function Failures And Their Causes

MOST FREQUENT FUNCTION FAILURES AND THEIR CAUSES FAILURE SYMPTOM SOLUTION • • Water in tank is cold Light on Heating element failure Water in the tank is not • • Light on Heating element failure warm enough • Thermostat failure - the safety fuse turned off electricity supply •... -

Page 13: Disposal Of Packaging Material And Functionless Product

DISPOSAL OF PACKAGING MATERIAL AND FUNCTIONLESS PRODUCT A service fee for providing return and recovery of packaging material has been paid for the packaging in which the water heater was delivered. The service fee was paid pursuant to Act No 477/2001 Coll., as amended, at EKO-KOM a.s. The client number of the company is F06020274.

Need help?

Do you have a question about the DRAZICE TO-20 and is the answer not in the manual?

Questions and answers