Table of Contents

Advertisement

Quick Links

A l l t e s t I n s t r u me n t s , I n c .

5 0 0 C e n t r a l A v e .

F a r mi n g d a l e , N J 0 7 7 2 7

P : ( 7 3 2 ) 9 1 9 - 3 3 3 9

F : ( 7 3 2 ) 9 1 9 - 3 3 3 2

a l l t e s t . n e t

s s a l e s @ a l l t e s t . n e t

T h e t e s t & me a s u r e me n t

e q u i p me n t y o u n e e d a t

t h e p r i c e y o u w a n t .

A l l t e s t c a r r i e s t h e w o r l d ' s l a r g e s t s e l e c t i o n o f

u s e d / r e f u r b i s h e d b e n c h t o p t e s t & me a s u r e me n t

e q u i p me n t a t 5 0 % t h e p r i c e o f n e w .

O O u r e q u i p me n t i s g u a r a n t e e d w o r k i n g , w a r r a n t i e d , a n d

a v a i l a b l e w i t h c e r t i f i e d c a l i b r a t i o n f r o m o u r i n - h o u s e s t a f f

o f t e c h n i c i a n s a n d e n g i n e e r s .

• 1 0 + f u l l t i me t e c h n i c i a n s w i t h o v e r 1 5 0 y e a r s o f

s p e c i a l i z a t i o n

• 9 0 d a y w a r r a n t y & 5 d a y r i g h t o f r e t u r n o n a l l

e q u i p me n t

• • 1 - 3 y e a r w a r r a n t i e s f o r n e w a n d

p r e mi u m- r e f u r b i s h e d e q u i p me n t

• E v e r y u n i t t e s t e d t o O E M s p e c i f i c a t i o n s

• S a t i s f a c t i o n g u a r a n t e e d

Y o u h a v e p l a n s , w e w i l l h e l p y o u a c h i e v e t h e m.

A n y p r o j e c t . A n y b u d g e t .

t

G e t a q u o t e t o d a y !

C C a l l ( 7 3 2 ) 9 1 9 - 3 3 3 9 o r e ma i l s a l e s @a l l t e s t . n e t .

Advertisement

Chapters

Table of Contents

Summary of Contents for Anritsu MP1570A

- Page 1 T h e t e s t & me a s u r e me n t e q u i p me n t y o u n e e d a t t h e p r i c e y o u w a n t . A l l t e s t I n s t r u me n t s , I n c .

- Page 2 MP1570A SONET/SDH/PDH/ATM Analyzer Operation Manual Vol.1 Basic Operation SONET 15th Edition For safety and warning information, please read this manual before attempting to use the equipment. Keep this manual with the equipment. ANRITSU CORPORATION Document No.: M-W1720AE-15.0...

- Page 3 Safety Symbols To prevent the risk of personal injury or loss related to equipment malfunction, Anritsu Corporation uses the following safety symbols to indicate safety-related information. Ensure that you clearly understand the meanings of the symbols BEFORE using the equipment.

- Page 4 For Safety WARNING 1. ALWAYS refer to the operation manual when working near locations at which the alert mark shown on the left is attached. If the advice in the operation manual is not followed there is a risk of personal injury or reduced equipment performance.

- Page 5 Calibration 6. The performance-guarantee seal verifies the integrity of the equipment. To ensure the continued integrity of the equipment, only Anritsu service personnel, or service personnel of an Anritsu sales representative, should break this seal to repair or calibrate the equipment. If the performance-guarantee seal is broken by you or a third party, the performance of the equipment cannot be guaranteed.

- Page 6 For Safety WARNING Battery Fluid 8. DO NOT short the battery terminals and never attempt to disassemble the battery or dispose of it in a fire. If the battery is damaged by any of these actions, the battery fluid may leak. This fluid is poisonous. DO NOT touch the battery fluid, ingest it, or get in your eyes.

- Page 7 For Safety CAUTION Fuse Replacement 1. Always remove the mains power cable from the power outlet before replacing blown fuses. There is a risk of electric shock if fuses are replaced with the power cable connected. Always use new fuses of the type and rating specified on the rear panel of the instrument.

- Page 8 For Safety Class 1, 1M indicate the danger degree of the laser radiation specified below according to IEC 60825-1:2001. Class 1: Lasers that are safe under reasonably foreseeable conditions of operation, including the use of optical instruments for intrabeam viewing. Class 1M: Lasers emitting in the wavelength range from 302.5 to 4000 nm that are safe under reasonably foreseeable conditions of operation, but may be hazardous if the user employs optics...

- Page 9 For Safety Class I, IIa, II, IIIa, IIIb indicate the degree of danger of the laser radiation outlined below as defined by 21 CFR 1040.10:1995. Class I: Class I levels of laser radiation are not considered to be hazardous. Class IIa: Class IIa levels of laser radiation are not considered to be hazardous if viewed for any period of time less than or equal to 1 ×...

- Page 10 If this warning light does not turn on, the equipment may be faulty and for safety reasons should be returned to an Anritsu service center or representative for repair. The laser in the plug-in unit provided for this equipment is classified as Class 1, 1M according to the IEC 60825-1:2001 standard, or as Class I, IIIb according to the 21 CFR 1040.10:1995 standard.

- Page 11 For Safety Table 2 Laser Safety Classifications Based on FDA21 CFR 1040.10:1995 Max. Optical Pulse Width (s)/ Emitted Model Name Class Laser Aperture Output Power (W) * Repetition Rate Wavelength (nm) MP0111A 0.32 1310 Fig. 1 [1] MP0112A 1550 Fig. 1 [2] 0.32 1310 Fig.

- Page 12 For Safety Table 3 Indication Labels on Product (Ex: Label list) Type Sample Affixed to: Model Name MP0127A,MP0128A,MP0129A, MU150008A,MU150009A, Aperture Fig. 5, 6, 7 A MU150010A, MU150001A/B,MU150031A/C, MU150061A/B MP0112B, MP0127A,MP0128A,MP0129A, MU150008A,MU150009A, Explanation Fig. 3, 5, 7 B MU150010A MU150001A/B,MU150031A/C, MU150061A/B MP0111A,MP0112A,MP0113A, MP0112B, MP0127A,MP0128A,MP0129A,...

- Page 13 For Safety Laser Radiation Markings Fig. 1 Locations of Laser Beam Apertures and Affixed Labels CAUTION When only a Unit is purchased, an adhesive label is supplied with the Unit. Please, attach it to the place, shown above.

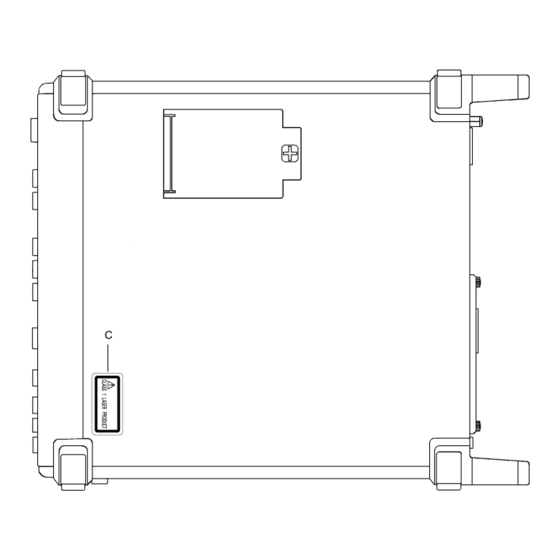

- Page 14 For Safety Fig. 2 MP0122B Front Panel of Unit and Top Panel of MP1570A (Products shipping besides U.S.A.) CAUTION When only a Unit is purchased, an adhesive label is supplied with the Unit. Please, attach it to the place, shown above.

- Page 15 For Safety Fig. 3 MP0122B Front Panel of Unit and Top Panel of MP1570A (Products shipping to U.S.A.) CAUTION When only a Unit is purchased, an adhesive label is supplied with the Unit. Please, attach it to the place, shown above.

- Page 16 For Safety Fig. 4 MP0127A, MP0128A, MP0129A, MU150008A, MU150009A, MU150010A Front Panel of Unit and Top Panel of MP1570A (Products shipping besides U.S.A.) CAUTION When only a Unit is purchased, an adhesive label is supplied with the Unit. Please, attach it to the place, shown above.

- Page 17 For Safety Fig. 5 MP0127A, MP0128A, MP0129A, MU150008A, MU150009A, MU150010A Front Panel of Unit and Top Panel of MP1570A (Products shipping to U.S.A.) CAUTION When only a Unit is purchased, an adhesive label is supplied with the Unit. Please, attach it to the place, shown above.

- Page 18 Invisible Laser radiation is Interlock emitted from this aperture Laser Fig. 6 MU150001A/B, MU150031A/C, MU150061A/B Front Panel of Unit and Top Panel of MP1570A (Products shipping besides U.S.A.) CAUTION When only a Unit is purchased, an adhesive label is supplied with the Unit.

- Page 19 Invisible Laser radiation is Interlock emitted from this aperture Laser Fig. 7 MU150001A/B, MU150031A/C, MU150061A/B Front Panel of Unit and Top Panel of MP1570A (Products shipping to U.S.A.) CAUTION When only a Unit is purchased, an adhesive label is supplied with the Unit.

- Page 20 For Safety Security Measure Functions The MP0127A, MP0128A, MP0129A, MU150001A/B, MU150008A, MU150009A, MU150010A, MU150031A/C, MU150061A/B are provided with the following security measure functions to prevent the possibility of infliction bodily injury on operators. • Laser cut-off When the cable is disconnected from the optical output section, the protective cover closes and the laser emission stops.

- Page 21 Back-up Battery the memory. This battery must be replaced by service personnel when it has reached the end of its useful life; contact the Anritsu sales section or your nearest representative. Note: The battery used in this equipment has a maximum useful life of 7 years.

- Page 22 In addition, this warranty is valid only for the original equipment purchaser. It is not transferable if the equipment is resold. Anritsu Corporation shall assume no liability for injury or financial loss of the customer due to the use of or a failure to be able to use this equipment.

- Page 23 Notes On Export Management This product and its manuals may require an Export License/Approval by the Government of the product's country of origin for re-export from your country. Before re-exporting the product or manuals, please contact us to confirm whether they are export-controlled items or not. When you dispose of export-controlled items, the products/manuals need to be broken/shredded so as not to be unlawfully used for military purpose.

- Page 24 2002/96/EC (the “WEEE Directive”) in European Union. For Products placed on the EU market after August 13, 2005, please contact your local Anritsu representative at the end of the product's useful life to arrange disposal in accordance with your initial contract and the local law.

- Page 25 CE Conformity Marking Anritsu affixes the CE conformity marking on the following product(s) in accordance with the Council Directive 93/68/EEC to indicate that they conform to the EMC and LVD directive of the European Union (EU). CE marking 1. Product Model...

- Page 26 4. Authorized representative Name: Loic Metais European Quality Manager ANRITSU S.A. France Address, city: 16/18 Avenue du Québec SILIC 720 Zone de Courtaboeuf 91951 Les Ulis Cedex Country: France...

- Page 27 C-tick Conformity Marking Anritsu affixes the C-tick mark on the following product(s) in accordance with the regulation to indicate that they conform to the EMC framework of Australia/New Zealand. C-tick marking 1. Product Model Model: MP1570A SONET/SDH/PDH/ATM ANALYZER 2. Applied Standards...

- Page 28 Power Line Fuse Protection For safety, Anritsu products have either one or two fuses in the AC power lines as requested by the customer when ordering. A fuse is inserted in one of the AC power lines. Single fuse: Double fuse: A fuse is inserted in each of the AC power lines.

- Page 29 xxviii...

- Page 30 ‘Basic Operation SONET Edition’). Basic Operation SONET Edition (this manual) Describes the basic operation of MP1570A, DSn mea- s urement and SONET measurement of up to 622M (ST S12). (The contents of this manual are basically the s ame as those of ‘Basic Operation SDH Edition’.).

- Page 31 Using This Operation Manual This Operation Manual describes the following. Operation Manual for MP1570A, Vol. 1, Basic Operation SONET Edition mainly describes the following: (1) Basic functions of MP1570A (2) TX and RX measurement of DSn signal. (3) TX and RX measurements of SONET signal up to 622M (STS- ‐ This manual is meant for SONET, therefore, the user interfaces and...

- Page 32 Using This Operation Manual Screen Names MP1570A has 4 major screens, namely, 'Setup', 'Test menu', 'Result', and 'Analyze', and each major screen has its own subscreens. (For details, see ‘Section 4 Screens and Parameter Setting’). If 'Setup' is selected as the main screen and 'Mapping' as the subscreen,...

-

Page 33: Table Of Contents

2.11 Units and Optional Items Required for TX and RX Signals..2-16 Section 3 Panel Description 3.1 Description of MP1570A Unit Panel ........... 3-3 3. 2 Description of Video Output Board Panel.......... 3-14 3.3 Description of Ethernet Board Panel..........3-15 3.4 Description of Plug-in Unit Panel............ - Page 34 CONTENTS Section 6 Other Setting about the Measurement 6.1 Setting the Measurement Channel ............6-3 6.2 Setting a Test Pattern ................6-4 6.3 Setting of Trigger Output and Alarm Detection/Removal Condition..6-5 6.4 Editing SONET Overhead ..............6-6 6.5 Changing the Overhead data per Frame..........6-13 6.

- Page 35 CONTENTS Section 9 Performance Test 9.1 About Measurement Instruments Required to Execute Performance Test .... 9-3 9.2 Self test Items ..................9-4 9.3 2/8/34/139/156M CMI/HDB3 Output Waveform ......... 9-8 9.4 1.5/45/52M AMI/B8ZS/B3ZS Output Waveform ......... 9-16 9.5 52M Optical Output Waveform ............9-20 9.6 MP0105A CMI Unit Output Waveform ..........

- Page 36 Section 1 General 1.1 Product Outline................. 1-3 1.2 Features ................... 1-4 1.3 Equipment Configuration............1-5 1.3.1 Equipment Configuration with Standard Accessories..1-5 1.3.2 Plug-in Unit Configuration ..........1-6 1.3.3 Interface Unit Configuration ..........1-8 1.3.4 Application Software Configuration........1-9 1 - 1...

- Page 37 Section 1 General 1 - 2...

-

Page 38: Product Outline

1.1 Product Outline 1.1 Product Outline MP1570A SONET/SDH/PDH/ATM Analyzer is a portable error rate measuring instrument which performs quality evaluation of digital lines. It is ideal for evaluating instruments during their manufacture and installation, and for maintenance after line installation. One unit can handle SONET, SDH, PDH(DSn) and ATM as various interfaces can be selected by combining the units. -

Page 39: Features

Section 1 General 1.2 Features The main features of MP1570A are as follows: ‐ Compact (W: 322 mm, H: 177 mm and D: 350 mm) and portable. ‐ Simple operations using a menu selection system for setting the measurement conditions. -

Page 40: Equipment Configuration

1.3 Equipment Configuration 1.3 Equipment Configuration 1.3.1 Equipment Configuration with Standard Accessories The standard configuration of MP1570A is shown in the table below. Main unit (MP1570A) Model Name Remarks MP1570A SONET/SDH/PDH/ATM Analyzer Standard accessories Model Name Remarks Z0169 Printer paper... -

Page 41: Plug-In Unit Configuration

Section 1 General 1.3.2 Plug-in Unit Configuration The table below shows the plug-in units that can be installed on MP1570A. Model/ Name Remarks Order No. MP0121A 2/8/34/139/156M Unit MP0122A 1.5/45/52M Unit Optical 1.31μm MP0122B 1.5/45/52/52M(1.31) Unit MP0123A ATM Unit MP0124A... - Page 42 1.3 Equipment Configuration Model/ Name Remarks Order No. Optical 1.55 MU150031A Optical 10G(1.55) High Power Tx Unit μ transmitter High Power Output Optical 1.55 MU150031C Optical 2.5G(1.55)/10G(1.55) High μ Power Tx Unit transmitter High Power Output Optical 1.31 MU150061A Optical 10G(1.31) Tx Unit μ...

-

Page 43: Interface Unit Configuration

Section 1 General Plug-in Unit Accessories Model Name Remarks W1722AE MP1570A Operation Manual Accessory for MP0123A Vol.3 ATM Measurement W1723AE MP1570A Operation Manual Accessory for Vol.4 2.5G/10G Measurement MP0127A/ MP0128A/ MP0129A/ MU150000A/ MU150001A/ MU150001B/ MU150002A/ MU150008A/ MU150009A/ MU150010A/ MU150017A/ MU150017B... -

Page 44: Application Software Configuration

W1323AW MX150001A Wander (MTIE, TDEV) Accessory Application Software Operation Manual MX150001A Note Make sure that all items on the configuration list are included. Contact Anritsu or one of our dealers if you find missing or damaged items. 1 - 9... - Page 45 Section 1 General 1 - 10.

-

Page 46: Section 2 Preparations Before Use

Section 2 Preparations Before Use This section describes precautions you need to know before use. You should thoroughly read this section as it contains safety information and precautions for avoiding failure during operation. 2.1 Installation Site Environmental Conditions ......2-3 2.2 Distance Between Fan Ventilation Grills and Nearby Equipment ...... - Page 47 Section 2 Preparations Before Use 2 - 2...

-

Page 48: Installation Site Environmental Conditions

‑ Where there is exposure to corrosive gasses ‑ Where there are large temperature fluctuations CAUTION If MP1570A is operated at a high temperature after being used for a long time at low temperature, there is a risk of short-circuiting caused by condensation. -

Page 49: Power Voltage

Section 2 Preparations Before Use 2.3 Power Voltage The supplied power must be in the range of AC100 V to 120 V or AC200 V to 225 V and at a frequency of 47.5 Hz to 63 Hz. It is not necessary to set the unit for 100 V and 200 V series. -

Page 50: Connecting The Peripherals

MP1570A. Turning the power on after connecting the peripherals may damage MP1570A. 2.6 Connecting Other Devices Before connecting MP1570A to other devices, confirm input and output levels. CAUTION Errors and alarms may occur for the MP1570A mainframe and interface unit by ESD. 2 - 5... -

Page 51: Inserting And Removing An Interface Unit

2.7 Inserting and Removing an Interface Unit 2.7.1 Inserting an Interface Unit (1) Turn off the power switch to MP1570A. (2) Plug in the interface unit so that the connector is firmly engaged in the slot on the front panel of the main unit. -

Page 52: Removing An Interface Unit

CAUTION Before replacing the interface unit, make sure that the power switch of MP1570A is turned off. If an interface unit is plugged in while MP1570A is turned on, it may cause a malfunction. Tighten the screws on the right and left sides after the interface unit is plugged in. -

Page 53: Inserting And Removing The Plug-In Unit

Section 2 Preparations Before Use 2.8 Inserting and Removing the Plug-in Unit 2.8.1 Inserting the Plug-in Unit (1) Turn off the power to MP1570A. (2) Insert the plug-in unit into one of the slots on the right. Slot 1 Slot 2... - Page 54 CAUTION ‑ When inserting a plug-in unit, make sure that the power switch is turned off. If a plug-in unit is inserted while MP1570A is turned on, it may cause it to malfunction. ‑ After inserting the plug-in unit, tighten the screws on the right and left sides.

-

Page 55: Removing The Plug-In Unit

Section 2 Preparations Before Use 2.8.2 Removing the Plug-in Unit (1) Turn off the power switch of MP1570A. (2) Loosen the right and left screws of the plug-in unit to be removed. Screws (3) Push the ejectors outward in the direction of the arrows. - Page 56 CAUTION ‑ When removing a plug-in unit, make sure that the power switch is turned off. Removal of a plug-in unit while MP1570A is turned on, may cause it to malfunction. ‑ Do not touch the electric-component installed sections of the plug-in units to prevent them from being damaged.

-

Page 57: Slots For Inserting Plug-In Units

*1 ... Use both Slot 4 and Slot 5. *2 ... When the MP0123A is inserted in Slot 3, Slot 1 cannot be used for insertion. NOTE ‐ The MP1570A may not start up normally for some unit combination. 2 - 12... - Page 58 2.9 Slots for Inserting Plug-in Units NOTE ‐ MP1570A will not operate if 2 units of MP0122A or MP0122B are inserted at the same time. ‐ For the unit combinations when using the MP0123A ATM unit, see the 'MP1570A SONET/SDH/PDH/ATM Analyzer Operation Manual Vol.

-

Page 59: Inserting And Removing The Gpib/232C Board

‐ Make sure that the power switch of MP1570A is turned off before inserting the GPIB/232C board, Video output board or Ethernet board. If a board is inserted while MP1570A is turned on, it may cause it to malfunction. ‐ Insert the GPIB/232C board except when the Video output board (GPIB, RS-232C) option is inserted. -

Page 60: Removing The Board

‐ Make sure that the power switch of MP1570A is turned off before removing the GPIB/232C board, Video output board or Ethernet board. If a board is removed while MP1570A is turned on, it may cause the latter to malfunction. ‐ Insert the GPIB/232C board except when the Video output board or Ethernet board is inserted. -

Page 61: Units And Optional Items Required For Tx And Rx Signals

For sending and receiving DSn and SONET signals, the following units and optional items shown in the table below must be installed on MP1570A according to the bit rate and mapping. 2.11.1 In the case of DSn When the sent and received signals are DSn, the plug-in units shown in the table below must be installed according to the bit rate. -

Page 62: In The Case Of Sonet

2.11 Units and Optional Items Required for Tx and Rx Signals 2.11.2 In the case of SONET When the sent and received signals are SONET, the plug-in units, interface units and optional items shown in the table below must be installed according to the mapping route. - Page 63 Section 2 Preparations Before Use ( 2/4 ) STS192 STS48 STS3 STS3cSPE 139M(Async.) ×3 ×3 Bulk STS12 TUG3 34M(Async.) STS3 ×7 34M(Sync.) 45M(Async.) STS1 STS1 SPE Bulk ×7 VT6 SPE 6M(Async.) 6M(Bitsync.) ×3 Bulk ×4 VT2 SPE 2M(Async.) 2M(Bitsync.F) 2M(Bitsync.L) 2M(Bytesync.F) 2M(Bytesync.L) Bulk...

- Page 64 2.11 Units and Optional Items Required for Tx and Rx Signals ( 3/4 ) STS192 STS48 STS3 STS3cSPE 139M(Async.) ×3 ×3 Bulk STS12 TUG3 34M(Async.) STS3 ×7 34M(Sync.) STS1 STS1 SPE 45M(Async.) ×7 Bulk VT6 SPE 6M(Async.) 6M(Bitsync.) ×3 Bulk ×4 VT2 SPE 2M(Async.)

- Page 65 Section 2 Preparations Before Use ( 4/4 ) STS192 STS48 STS3 STS3cSPE 139M(Async.) ×3 ×3 Bulk STS12 TUG3 34M(Async.) STS3 ×7 34M(Sync.) STS1 STS1 SPE 45M(Async.) ×7 Bulk VT6 SPE 6M(Async.) 6M(Bitsync.) ×3 Bulk ×4 VT2 SPE 2M(Async.) 2M(Bitsync.F) 2M(Bitsync.L) 2M(Bytesync.F) 2M(Bytesync.L) Bulk...

-

Page 66: Sts3/Sts12

2.11 Units and Optional Items Required for Tx and Rx Signals (2) STS3 / STS12 ( 1/16 ) STS192 STS48 STS3 STS3cSPE 139M(Async.) ×3 ×3 Bulk STS12 TUG3 34M(Async.) STS3 ×7 34M(Sync.) STS1 STS1 SPE 45M(Async.) ×7 Bulk VT6 SPE 6M(Async.) 6M(Bitsync.) ×3... - Page 67 Section 2 Preparations Before Use ( 2/16 ) STS192 STS48 STS3 STS3cSPE 139M(Async.) ×3 ×3 Bulk STS12 TUG3 34M(Async.) STS3 ×7 34M(Sync.) STS1 STS1 SPE 45M(Async.) ×7 Bulk VT6 SPE 6M(Async.) 6M(Bitsync.) ×3 Bulk VT2 SPE 2M(Async.) ×4 2M(Bitsync.F) 2M(Bitsync.L) 2M(Bytesync.F) 2M(Bytesync.L) Bulk...

- Page 68 2.11 Units and Optional Items Required for Tx and Rx Signals ( 3/16 ) STS192 STS48 STS3 STS3cSPE 139M(Async.) ×3 ×3 Bulk STS12 TUG3 34M(Async.) STS3 ×7 34M(Sync.) STS1 STS1 SPE 45M(Async.) ×7 Bulk VT6 SPE 6M(Async.) 6M(Bitsync.) ×3 Bulk VT2 SPE 2M(Async.) ×4...

- Page 69 Section 2 Preparations Before Use ( 4/16 ) STS192 STS48 STS3 STS3cSPE 139M(Async.) ×3 ×3 Bulk STS12 TUG3 34M(Async.) STS3 ×7 34M(Sync.) STS1 STS1 SPE 45M(Async.) ×7 Bulk VT6 SPE 6M(Async.) 6M(Bitsync.) ×3 Bulk VT2 SPE 2M(Async.) ×4 2M(Bitsync.F) 2M(Bitsync.L) 2M(Bytesync.F) 2M(Bytesync.L) Bulk...

- Page 70 2.11 Units and Optional Items Required for Tx and Rx Signals STS192 ( 5/16 ) STS48 STS3 STS3cSPE 139M(Async.) ×3 ×3 Bulk STS12 TUG3 34M(Async.) STS3 ×7 34M(Sync.) STS1 STS1 SPE 45M(Async.) ×7 Bulk VT6 SPE 6M(Async.) 6M(Bitsync.) ×3 Bulk VT2 SPE 2M(Async.) ×4...

- Page 71 Section 2 Preparations Before Use ( 6/16 ) STS192 STS48 STS3 STS3cSPE 139M(Async.) ×3 ×3 Bulk STS12 TUG3 34M(Async.) STS3 ×7 34M(Sync.) STS1 STS1 SPE 45M(Async.) ×7 Bulk VT6 SPE 6M(Async.) 6M(Bitsync.) ×3 Bulk VT2 SPE 2M(Async.) ×4 2M(Bitsync.F) 2M(Bitsync.L) 2M(Bytesync.F) 2M(Bytesync.L) Bulk...

- Page 72 2.11 Units and Optional Items Required for Tx and Rx Signals ( 7/16 ) STS192 STS48 STS3 STS3cSPE 139M(Async.) ×3 ×3 Bulk STS12 TUG3 34M(Async.) STS3 ×7 34M(Sync.) STS1 STS1 SPE 45M(Async.) ×7 Bulk VT6 SPE 6M(Async.) 6M(Bitsync.) ×3 Bulk VT2 SPE 2M(Async.) ×4...

- Page 73 Section 2 Preparations Before Use ( 8/16 ) STS192 STS48 STS3 STS3cSPE 139M(Async.) ×3 ×3 Bulk STS12 TUG3 34M(Async.) STS3 ×7 34M(Sync.) STS1 STS1 SPE 45M(Async.) ×7 Bulk VT6 SPE 6M(Async.) 6M(Bitsync.) ×3 Bulk VT2 SPE 2M(Async.) ×4 2M(Bitsync.F) 2M(Bitsync.L) 2M(Bytesync.F) 2M(Bytesync.L) Bulk...

- Page 74 2.11 Units and Optional Items Required for Tx and Rx Signals ( 9/16 ) STS192 STS48 STS3 STS3cSPE 139M(Async.) ×3 ×3 Bulk STS12 TUG3 34M(Async.) STS3 ×7 34M(Sync.) STS1 STS1 SPE 45M(Async.) ×7 Bulk VT6 SPE 6M(Async.) 6M(Bitsync.) ×3 Bulk VT2 SPE 2M(Async.) ×4...

- Page 75 Section 2 Preparations Before Use STS192 ( 10/16 ) STS48 STS3 STS3cSPE 139M(Async.) ×3 ×3 Bulk STS12 TUG3 34M(Async.) STS3 ×7 34M(Sync.) STS1 STS1 SPE 45M(Async.) ×7 Bulk VT6 SPE 6M(Async.) 6M(Bitsync.) ×3 Bulk VT2 SPE 2M(Async.) ×4 2M(Bitsync.F) 2M(Bitsync.L) 2M(Bytesync.F) 2M(Bytesync.L) Bulk...

- Page 76 2.11 Units and Optional Items Required for Tx and Rx Signals STS192 (11/16 ) STS48 STS3 STS3cSPE 139M(Async.) ×3 ×3 Bulk STS12 TUG3 34M(Async.) STS3 ×7 34M(Sync.) STS1 STS1 SPE 45M(Async.) ×7 Bulk VT6 SPE 6M(Async.) 6M(Bitsync.) ×3 Bulk VT2 SPE 2M(Async.) ×4 2M(Bitsync.F)

- Page 77 Section 2 Preparations Before Use ( 12/16 ) STS192 STS48 STS3 STS3cSPE 139M(Async.) ×3 ×3 Bulk STS12 TUG3 34M(Async.) STS3 ×7 34M(Sync.) STS1 STS1 SPE 45M(Async.) ×7 Bulk VT6 SPE 6M(Async.) 6M(Bitsync.) ×3 Bulk VT2 SPE 2M(Async.) ×4 2M(Bitsync.F) 2M(Bitsync.L) 2M(Bytesync.F) 2M(Bytesync.L) Bulk...

- Page 78 2.11 Units and Optional Items Required for Tx and Rx Signals STS192 STS48 STS3 STS3cSPE 139M(Async.) ×3 ×3 Bulk ( 13/16 ) STS12 TUG3 34M(Async.) STS3 ×7 34M(Sync.) STS1 STS1 SPE 45M(Async.) ×7 Bulk VT6 SPE 6M(Async.) 6M(Bitsync.) ×3 Bulk VT2 SPE 2M(Async.) ×4...

- Page 79 Section 2 Preparations Before Use ( 14/16 ) STS192 STS48 STS3 STS3cSPE 139M(Async.) ×3 ×3 Bulk STS12 TUG3 34M(Async.) STS3 ×7 34M(Sync.) STS1 STS1 SPE 45M(Async.) ×7 Bulk VT6 SPE 6M(Async.) 6M(Bitsync.) ×3 Bulk VT2 SPE 2M(Async.) ×4 2M(Bitsync.F) 2M(Bitsync.L) 2M(Bytesync.F) 2M(Bytesync.L) Bulk...

- Page 80 2.11 Units and Optional Items Required for Tx and Rx Signals ( 15/16 ) STS192 STS48 STS3 STS3cSPE 139M(Async.) ×3 ×3 Bulk STS12 TUG3 34M(Async.) STS3 ×7 34M(Sync.) STS1 STS1 SPE 45M(Async.) ×7 Bulk VT6 SPE 6M(Async.) 6M(Bitsync.) ×3 Bulk VT2 SPE 2M(Async.) ×4...

- Page 81 Section 2 Preparations Before Use ( 16/16 ) STS192 STS48 STS3 STS3cSPE 139M(Async.) ×3 ×3 Bulk STS12 TUG3 34M(Async.) STS3 ×7 34M(Sync.) STS1 STS1 SPE 45M(Async.) ×7 Bulk VT6 SPE 6M(Async.) 6M(Bitsync.) ×3 Bulk VT2 SPE 2M(Async.) ×4 2M(Bitsync.F) 2M(Bitsync.L) 2M(Bytesync.F) 2M(Bytesync.L) Bulk...

-

Page 82: Concatenation Mapping

2.11 Units and Optional Items Required for Tx and Rx Signals Concatenation Mapping STS192 STS192c Bulk ×4 STS48 STS48c Bulk ×4 STS12 STS12c Bulk ×4 STS3 STS3c Bulk Interface unit Mapping Interface MP0111A/ MP0105A MP0108A MP0112A/ MP0113A STS12-STS12c-Bulk optical ― ―... -

Page 83: Cid Pattern And Non-Frame Pattern

Section 2 Preparations Before Use (4) CID Pattern and Non-frame Pattern When the sent and received signals are the CID pattern or non-frame pattern, the plug-in units and interface units shown in the table below must be installed. Plug-in Unit Interface Unit Bit rate Interface... - Page 84 Section 3 Panel Description This section describes names and functions of parts on MP1570A and the units to be installed on it. 3.1 Description of MP1570A Panel ..........3-3 3.1.1 Front Panel ..............3-4 3.1.2 Rear Panel ..............3-8 3.1.3 Right Side Panel............. 3-12 3.2 Description of Video Output Board Panel.......

-

Page 85: Section 3 Panel Description

Section 3 Panel Description 3 - 2... -

Page 86: Description Of Mp1570A Unit Panel

3.1 Description of MP1570A Panel 3.1 Description of MP1570A Panel The names and functions of the MP1570A components are as follows. Printer Paper Cover Handle Interface Unit Handle For carrying the MP1570A unit. Printer Paper Cover Remove the cover for supplying the printer paper. -

Page 87: Front Panel

Switch used to turn MP1570A on or off. Lamp that goes on when MP1570A is in remote mode (i.e. when this unit is being controlled through the GPIB , RS-232C, or Ethernet interface). Key that is effective when MP1570A is in remote mode. Used for seeing Local it to local control mode (i.e., state in which panel controls can be used). - Page 88 3.1 Description of MP1570A Panel Printer Key used to turn the built-in printer on or off. When the built-in printer is on, the lamp of goes on. On/Off On/Off Key used to display a help screen. When is off. Help Pri n t Now Key to feed forms on the built-in printer.

- Page 89 Section 3 Panel Description Help Key used to display a help screen. When is pressed, the Help ( i) information related to the item pointed by the cursor is displayed. Key used to select error addition mode. In the mode, the lamp of Error - In single error mode, one error is added each time...

- Page 90 3.1 Description of MP1570A Panel Key used to start or stop measurement. During the measurement, the Start Start Lamp of is on. /Stop /Stop Key used to display the Setup main screen. When the Setup main screen Set Up is already displayed, this key is used to close the screen.

-

Page 91: Rear Panel

Section 3 Panel Description 3.1.2 Rear Panel Name Plate GPIB/232C Board RS-232C interface connector. RS-232C ..…. - This interface can be set to Control mode or Printer mode from the Connector 'Setup : System' screen when the RS-232C option is installed. Pin positions .. - Page 92 3.1 Description of MP1570A Panel GPIB interface connector . GPIB connector ..- This interface can be set to Control mode or Printer mode from the 'Setup : System' screen when the GPIB option is installed. Connector for AC power supply.

- Page 93 Section 3 Panel Description Clock input connector used for inputting the transmitting clock External Clock source from outside. input 50Ω Input Frequency ..2. 048MHz, 8.448MHz, 34.368MHz, 139.264MHz 1.544MHz, 44.736MHz, 155.52MHz, 622.08MHz, ±100ppm Output Level ..ECL(AC) Connector ..BNC50Ω These are input connectors for inputting the data entered from D1 DCC Interface ..

- Page 94 3.1 Description of MP1570A Panel * ..When the GPIB and RS-232C options are installed, both the GPIB interface and RS-232C interface cannot be set to Control mode or Pinter mode at the same time. 3 - 11...

-

Page 95: Right Side Panel

Section 3 Panel Description 3.1.3 Right Side Panel [FD Eject button] Slot 1 Slot 2 MP0121A MP0121A CMI/HDB3 CMI/HDB3 CMI/HDB3 CMI/HDB3 Error Error Slot 3 Output Output Input Input Output Output 2/8/34/139 2/8/34/139 /156M Unit /156M Unit MP0122A MP0122A B3ZS B3ZS B3ZS B3ZS... - Page 96 3.1 Description of MP1570A Panel Trigger input connector used when the APS test and the fame Trigger Input 50Ω capture are performed. Level ..TTL Connector ..BNC50Ω Connector that outputs clock synchronizing the error, alarm, Trigger Output 75Ω synchronized frame, and SONET signal detected in the receiving side.

-

Page 97: Description Of Video Output Board Panel

3.2 Description of Video Output Board Panel Video Output Board (GPIB) Video Output Board (RS-232C) Signal output connector to display the MP1570A screen on an external Video output CRT display (for video output option). Signals are always outputted when the Video output board is inserted. -

Page 98: Description Of Ethernet Board Panel

3.3 Description of Ethernet Board Panel Ethernet interface connector. Ethernet connector. Sets the mode of the Ethernet board. Mode SW ....Used to reset the Ethernet board. Reset ..... See ‘MP1570A Operation Manuals Vol.2 Remote Control’ for the details of Ethernet. 3 - 15... -

Page 99: Description Of Plug-In Unit Panel

Section 3 Panel Description 3.4 Description of Plug-in Unit Panel 3.4.1 MP0121A 2/8/34/139/156M Unit MP0121A CMI/HDB3 CMI/HDB3 Error Output Input Output 2/8/34/139 /156M Unit Connector for outputting 2M/8M/34M/139M/156M signals. CMI/HDB3 Output 75Ω..Bit rate ..2.048 Mbit/s 8.448 Mbit/s 34.368 Mbit/s 139.264 Mbit/s 155.520 Mbit/s Connector .. -

Page 100: Mp0122A 1.5/45/52M Unit

3.4 Plug-in Unit Panel Description 3.4.2 MP0122A 1.5/45/52M Unit MP0122A B3ZS B3ZS Error Output Input Output 1.5/45/52M Unit AMI/B8ZS Output AMI/B8ZS Input Connector for outputting 45M/52M signals. B3ZS Output 75Ω ..... Bit rate ..44.736 Mbit/s 51.84 Mbit/s Connector ..BNC75Ω Connector for outputting 1.5M signal. -

Page 101: Mp0122B 1.5/45/52/52M (1.31) Unit

Section 3 Panel Description 3.4.3 MP0122B 1.5/45/52M/52M (1.31) Unit Optical B3ZS Output Optical B3ZS Input Monitor Input Error Output MP0122B Output Input 1.5/45/52/52M (1.31) Unit 1.31 0.1-1Vp-p AMI/B8ZS AMI/B8ZS CLASS 1 LASER PRODUCT Output 100 Max 0dBm Input 100 Illuminated when an optical signal is outputted. [Lamp] ...... - Page 102 3.4 Plug-in Unit Panel Description Connector for inputting 52M optical signal. Optical Input ....... Max 0dBm Peak Bit rate ..51.84 Mbit/s Optical wavelength ..1.31μm Level ..-33~-8dBm Connector ..FC-PC(SM) connector Absolute maximum level ... 0dBm(Peak power) An input exceeding the indicated allowable input level (0 dBm) can damage the unit.

-

Page 103: Description Of The Interface Unit Panel

Section 3 Panel Description 3.5 Description of the Interface Unit Panel 3.5.1 MP0105A CMI Unit MP0105A Output Input CMI Unit A CMI signal output connector CMI Output 75Ω .... Bit rate ..155.52 Mbit/s Interface ..ITU-T G.703 Table 11, Fig 24, Fig 25 Connector .. -

Page 104: Mp0108A Nrz Unit

3.5 Description of the Interface Unit Panel 3.5.2 MP0108A NRZ Unit MP0108A Data Clock Data Clock Unit Input Input Output Output A SONET measurement signal (data) input connector. Data Input 50Ω ..Bit rate ..155.52 Mbit/s 622.08 Mbit/s Level ..ECL(terminated in 50Ω, -2 V) Code .. -

Page 105: Mp0111A Optical 156M/622M (1.31) Unit

Section 3 Panel Description 3.5.3 MP0111A Optical 156M/622M (1.31) Unit MP0111A Output Input Optical 156M/622M(1.31) Unit CLASS1 Max -8dBm -33-8/-28-8dBm LASER PRODUCT Max 0dBm Peak Illuminated when an optical signal is outputted. [Lamp] ......... A 156M/622M optical signal output connector. Output ........ -

Page 106: Mp0112A Optical 156M/622M (1.55) Unit

Connector ..FC-PC(SM)Connector Absolute maximum level ..0dBm(peak power) An input exceeding the absolute maximum allowable input level (0 dBm) can damage MP1570A. Label indicating the class of the laser beam outputted from output connector (b). The label shown here indicates that this unit belongs to Class 1 of the IEC 60825-1 standard. -

Page 107: Mp0113A Optical 156M/622M (1.31/1.55) Unit

Section 3 Panel Description 3.5.5 MP0113A Optical 156M/622M (1.31/1.55) Unit Output Input MP0113A 1.31 1.55 Optical 156M/622M(1.31/1.55) Unit CLASS1 Max -8dBm Max -3dBm -33-8/-28-8dBm LASER PRODUCT Max 0dBm Peak Illuminated when an optical signal is outputted. [Lamp] ......... A 156M/622M optical signal output connector. Output 1.31μm .... - Page 108 Connector ..FC-PC(SM)Connector Absolute maximum level ..0dBm(peak power) An input exceeding the absolute maximum allowable input level (0 dBm) can damage MP1570A. Label indicating the class of the laser beam outputted from output connector (b). The label shown here indicates that this unit belongs to Class 1 of the IEC 60825-1 standard.

- Page 109 Section 3 Panel Description 3 - 26.

- Page 110 Section 4 Screen Description and Parameter Setting This Section describes the screens of MP1570A and procedures to set the measurement conditions. 4.1 Main Screen................4-3 4.1.1 Main Screen Configurations ........... 4-3 4.1.2 Main Screen Selection............ 4-3 4.1.3 Main Screen Layout............4-5 4.2 Subscreens................

- Page 111 Section 4 Screen Description and Parameter Setting 4 - 2...

-

Page 112: Main Screen

4.1 Main Screen 4.1 Main Screen 4.1.1 Main Screen Configurations MP1570A displays the following main screens, and each main screen displays its own subscreens. Setup main screen ..... for setting up the measurement Test menu main screen ..for selecting the test items Result main screen .... - Page 113 Section 4 Screen Description and Parameter Setting Displaying the ‘Result’ Main Screen The Result main screen is displayed when is pressed while its Result lamp is off. The Result main screen and Test Menu or Analyze screen Test (i.e. two- or three-division screen) is displayed if the lamp of Menu is on.

-

Page 114: Main Screen Layout

4.1 Main Screen 4.1.3 Main Screen Layout MP1570A can display single, two-division and three-division screens as follows: Single-screen Display Displays a screen from the Setup, Test menu, Result and Analyze main screens. Screens other than Setup contain the mapping information at the Mapping Route and Channel Information top. - Page 115 Section 4 Screen Description and Parameter Setting Two-division Display MP1570A can simultaneously display two screens from the Test menu, Result and Analyze main screens. (Setup main screen cannot be displayed simultaneously with the other screens.) Test The lamps of , and show the displayed screen.

-

Page 116: Subscreens

4.2 Subscreens 4.2 Subscreens Each main screen can show the following subscreens that are set in accordance with the target and purpose of measurement. 4.2.1 Subscreens of ‘Setup’ Main Screen Display Description Selects the type of signal, the interface, and measurement Mapping conditions, according to the measured item,. -

Page 117: Subscreens Of 'Test Menu' Main Screen

Section 4 Screen Description and Parameter Setting 4.2.2 Subscreens of ‘Test menu’ Main Screen Display Description Sets the measurement conditions of trouble search. Trouble search Sets the conditions of manual measurement. Manual Sets the type and time interval of pointer sequence Pointer sequence measurement. -

Page 118: Subscreens Of 'Analyze' Main Screen

4.2 Subscreens 4.2.4 Subscreens of ‘Analyze’ Main Screen Display Description Analyzes the trouble search measurement result. Trouble search Displays the error and alarm measurement result on graphs. Error / Alarm Displays the overhead monitor result together with the path ・ OH monitor trace, payload, pointer value, and K1/K2 byte monitor result. -

Page 119: Selecting A Subscreen

Section 4 Screen Description and Parameter Setting 4.2.5 Selecting a Subscreen (1) Move the cursor to the subscreen selection field on the main screen (on the right panel of the main screen). Subscreen selection field (2) Press , and the subscreen selection window is displayed. (3) Move the cursor with to the desired subscreen item. -

Page 120: Setting Parameters Through Windows

4.3 Setting the Measurement Conditions through Windows 4.3 Setting Parameters through Windows Measurement conditions displayed on the screen are set through windows or one-shot entry as described in 4.4, depending on the contents of the entry. The windows include item selection, numeric entry and character entry windows as follows: 4.3.1 Setting through Item Selection Window By selecting an item an item selection window is displayed for setting... -

Page 121: Setting 'Yes/No' Dialog Box

Section 4 Screen Description and Parameter Setting 4.3.2 Setting ‘Yes/No’ Dialog Box A ‘Yes/No’ dialog box for operator confirmation is displayed for some selection items. Example..Changing the ‘Config’ from ‘SONET/DSn’ to ‘CID pattern’ on the ‘Setup:Mapping’ screen. (1) Move the cursor to 'Config' and press (2) An item selection window is opened. -

Page 122: Setting Through Numeric Entry Window

4.3 Setting the Measurement Conditions through Windows 4.3.3 Setting through Numeric Entry Window The numeric entry window is displayed for setting the measurement conditions by numeric entry. The operation procedure in this window is as follows: Example ... Setting the number of a frame to ‘6,401’, when selecting ‘Burst’ as an alarm(AIS-L) item on the ‘Test menu : Manual’... -

Page 123: Setting Through Character Entry Window

Section 4 Screen Description and Parameter Setting 4.3.4 Setting through Character Entry Window A character entry window is opened if settings are required for an item, as in the case of saving data which requires a file name entry. Operation procedure in this window is described below. - Page 124 4.3 Setting the Measurement Conditions through Windows The character entry window has the following function characters. Function Operation character < Moves the setting position cursor to the left. Moves the cursor to the right end if it is located at the left end of the setting character field.

-

Page 125: One-Shot Entry

Section 4 Screen Description and Parameter Setting 4.4 One-shot Entry One-shot entry allows an entry to be completed when is pressed without any window for setting. Here is an example. Example ...Alternating On/Off setting of marker on the 'Analyze : Error/Alarm' screen by one-shot entry. - Page 126 Section 5 Basic Setting and Application Examples of Connection This Section describes the applications of connections and the basic setup performed on the 'Setup : Mapping' screen, through measurement examples. in this section represent front panel keys. 5.1 Setting Basic Parameters ............5-3 5.2 DSn Monitoring ...............

-

Page 127: Section 5 Basic Setting And Application Examples Of Connection

Section 5 Basic Setting and Application Examples of Connection 5 - 2... -

Page 128: Setting Basic Parameters

5.1 Setting Basic Parameters ‘Setup : Mapping’ screen When the MP1570A and the equipment to be tested are connected, basic parameters, such as a signal type, an interface, and a frame structure, are set on the ‘Setup : Mapping’ screen. The explanations for each parameter are shown below. - Page 129 156M ..Select “156M” when using 156M interface of the interface unit. (e) Monitor input ..Set it to “ON” when using electric NRZ interface. The MP1570A reproduces a clock from the received NRZ data, and measures the NRZ data. This parameter can be set when the optical interface of the MP0122B is selected as the receiving interface.

- Page 130 (g) Mapping ..Specifies the mapping of the measurement channel. (h) Mixed payload ..On the mapping including TUG3 or STS1 SPE, MP1570A allows the setting of mapping for TUG3 or STS1 SPE channels without the measurement channel which is different from that of the measurement channel.

- Page 131 Section 5 Basic Setting and Application Examples of Connection MUX/DEMUX..Set the hierarchical configuration of PDH/DSn. The selected rate is the lowest stage. (k) Frame..Sets the frame On/Off for the PDH/DSn lowest stage.When “MUX/DEMUX” is set to On, it sets the lowest stage frame On/Off.

- Page 132 (o) DSX..Specifies DSx when the bit rate is 1.5M, 45M, or 52M. (p) Clock..Selects the clock source for transmission. (q) Monitor mode..Set it to “ON” when connecting the MP1570A to the monitoring point of the equipment to be tested. 5- 7...

-

Page 133: Dsn Monitoring

In the following example, the 139M DSn signal, that is, the muitiplexed 2M signal, is measured by the monitor output of LTE (Line Terminal Equipment) in-service mode. 5.2.1 Connection Connect MP1570A and LTE monitor output as shown in the figure Bit rate..2M below. TS....30ch CRC-4 .. -

Page 134: Initial Setting

5.2 PDH Monitoring 5.2.2 Initial Setting 'Setup : Mapping' screen Here is the initial setting procedure for the measurement structure described on the previous page. (1) Open the 'Setup : Mapping' screen. (2) Setup the screen parameters as follows: (a) [Operation mode]... Select the ‘Tx&Rx’ operation mode. (b) Config.... -

Page 135: Sonet Monitoring

Turn off the power switch of MP1570A and install the MP0111A, MP0112A, or MP0113A Optical Interface Unit. (ii) Branch the LTE main output signal to be inputted to the MP1570A with an optical fiber coupler. (iii) Confirm that the input level of the optical signal does not exceed the absolute maximum rating (0 dBm at peak power). -

Page 136: (Measurement Of Lte Output Through A Coupler)

5.3 SONET Monitoring (Measurement of LTE output through a coupler) CAUTION Remember that the input level of the optical signal to the optical interface unit or the MP0122B must not exceed the absolute maximum rating (0 dBm at peak power). Excessive input level can damage the internal devices and circuit. -

Page 137: Initial Setting

Section 5 Basic Setting and Application Examples of Connection 5.3.2 Initial Setting 'Setup : Mapping' screen Here is the initial setting procedure for the measurement structure described on the previous page. (1) Open the 'Setup : Mapping' screen. (2) Setup the screen parameters as follows: (a) [Operation mode].. - Page 138 5.3 SONET Monitoring (Measurement of LTE output through a coupler) Mapping.....The mapping selection window below is displayed if you move the cursor here and press Select ‘STS12-STS3cSPEc-Bulk’ with The mapping differs according to the installed plug-in units, optical interface unit, and optional items. (g) Clock ....

-

Page 139: Sonet Monitoring (Through-Mode Monitoring)

5.4 SONET Monitoring (Through-mode monitoring) Here is the measurement procedure of the SONET signal of STS3- STS3-STS1SPE-45M(Async.) measured in the through mode. 5.4.1 Connection Connect the input and output of LTE and MP1570A as shown in the figure below. Bit rate .....45M MUX structure...45M-1.5M 45M Frame ..Cbit... -

Page 140: Sonet Monitoring (Through-Mode Monitoring)

(0 dBm at peak power). Excessive input level can damage the internal devices and circuit. In through mode measurement, make sure before making the connections that the output level from the optical interface unit of MP1570A does not exceed the absolute maximum rating level. 5- 15... -

Page 141: Initial Setting

Section 5 Basic Setting and Application Examples of Connection 5.4.2 Initial Setting 'Setup : Mapping' screen Here is the initial setting procedure for the measurement structure described on the previous page. (1) Open the 'Setup : Mapping' screen. (2) Setup the screen parameters as follows: (a) [Operation mode].. - Page 142 5.4 SONET Monitoring (Through-mode monitoring) OH overwrite ..Converts the overhead of the received signal to the preset data, and sends it. The overhead to be edited is selected from “All”, “TOH”, “POH”, “K1/K2”, and “S1” (“K1/K2” and “S1” are available when option-22 (K1/K2 Overwrite Through) is installed).

-

Page 143: Loop Back Test

Here is the procedure for receiving/sending the mapping ‘STS1- STS1SPE-Bulk’ signal and testing it through the measurement system containing a loop back. 5.5.1 Connection Connect the input and output of LTE and MP1570A as shown in the figure below. (ii) (iii) Loop-Back Bit rate .. - Page 144 (iii) Connect the LTE input connector and the B3ZS output connector of MP0122A or MP0122B to the BNC (75 ohm unbalance) cable. B3ZS Output MP0122A B3ZS Input B3ZS Output MP0122B B3ZS Input (iv) Turn on the power switch of MP1570A after performing the connections in steps (ii) and (iii). 5- 19...

-

Page 145: Initial Setting

Section 5 Basic Setting and Application Examples of Connection 5.5.2 Initial Setting 'Setup : Mapping' screen (1) Open the 'Setup : Mapping' screen. (2) Setup the screen parameters as follows: (a) [Operation mode]..Select the ‘Tx&Rx’ operation mode. (b) Config....Select the ‘SONET/DSn’ configuration. (c) Meas. - Page 146 5.5 Loop-Back Test (e) Mapping... Set the mapping to ‘STS1- STS1 SPE-Bulk’ The mapping selection window is displayed if you move the cursor to 'Mapping' and press . Select ‘STS1- STS1 SPE-Bulk’ with The mapping differs according to the installed plug-in unit, optical interface unit and optional items.

-

Page 147: End-To-End Measurement

Section 5 Basic Setting and Application Examples of Connection 5.6 End-to-End Measurement Here is the end-to-end measurement procedure using one unit each of MP1570A at the transmitting side and receiving side of one line. 5. 6.1 Connection Connect MP1570A and the line as shown in the figure below. -

Page 148: End-To-End Measurement

Turn off the power switch of MP1570A at both transmitting and receiving sides, and install MP0121A. (ii) Connect the CM1/HDB3 output connector of MP0121A of MP1570A at the transmitting side to the input connector of LTE at the transmitting side, with the BNC (75 ohm unbalance) cable. MP0121A... -

Page 149: Initial Setting

Section 5 Basic Setting and Application Examples of Connection 5.6.2 Initial Setting 'Setup : Mapping' screen Set MP1570A at the transmitting and receiving sides as follows. (1) Open the 'Setup : Mapping' screen. (2) Setup the screen parameters as follows: (a) [Operation mode] .. - Page 150 (g) Frame ....Turn off the bottom layer frame of DSn. (h) Clock ....Set ‘External’ as the transmitting signal clock source. No need of setting for MP1570A at receiving side. Monitor mode ..Turn off the monitor mode on connecting with the main output of LTE.

-

Page 151: Mux Evaluation Test

Here is the evaluation procedure for the DEMUX (Multiplexer) which multiplexes the 1.5M DSn signal to output the 156M SONET signal. 5. 7.1 Connection Connect the MUX to MP1570A as shown in the figure below. Bit rate ..1.5M Interface ..Electric B8ZS MUX structure.. - Page 152 LASER PRODU CT Output Max 0dBm Input MP0123A Unit AMI/B8ZS Output (v) Connect the MUX output connector and the optical input connector of the interface unit. MP0113A Optical Input (vi) After the connection, turn on the power switch of MP1570A. 5- 27...

- Page 153 1.5M Framed..Set the 1.5M frame to ‘D4’. (g) Code ....Set the 1.5M code to ‘B8ZS’. (h) Clock ....Select ‘Internal’ as the transmitting signal clock source (built-in clock of MP1570A). DSx ....Select the DSx of 1.5M output signal 5 - 28...

-

Page 154: Mux Evaluation Test

5.7 MUX Evaluation Test Rx (receive) side setting Rx Bit rate ..Set the Rx bit rate to ‘156M’. (k) Mapping .... Set the mapping to ‘STS3-STS3-STS1SPE- VTG-VT1.5-VT1.5SPE-1.5M(Async.)’ The mapping selection window is displayed if you move the cursor to 'Mapping' and press Select the mapping with , and press... -

Page 155: Connection

Here is the evaluation procedure for the DEMUX (Demultiplexer) which de-multiplexes the 622M SONET signal to the 2M DSn signal. 5.8.1 Connection Connect the DEMUX to MP1570A as shown in the figure below. Bit rate .....622M Interface ..Optical (1.55μm) Mapping .. -

Page 156: Demux Evaluation Test

(v) Connect the Master Reference Clock of the DEMUX to the DCS input 120ΩBalanced connector of the MP1570A. (vi) Connect the DEMUX output connector to the input connector of CMI/HDB3 of MP0121A. MP0121A HDB3 Balanced Input (vii) After the connection, turn on the power switch of MP1570A. 5- 31... -

Page 157: Initial Setting

Section 5 Basic Setting and Application Examples of Connection 5.8.2 Initial Setting 'Setup : Mapping' screen Here is the initial setting procedure for the measurement described on the previous page. (1) Open the 'Setup : Mapping' screen. (2) Setup the screen parameters as follows: (a) [Operation mode] .. - Page 158 5.8 DEMUX Evaluation Test The mapping window differs according to the installed plug-in unit, optical interface unit and optional items. Mixed payload .... Select ‘ON’ and press when you specify a different mapping (DSn signal) to TUG3 of the rest of two channels of the main channel set in (e). The mixed payload mapping edition screen is displayed.

- Page 159 Section 5 Basic Setting and Application Examples of Connection (g) Dummy STM-1 ... Set the payload data of SONET frame (including POH) of channels other than the main channel of the mapping set in step (e). See ‘6.7.2 Setting Dummy STM‘...

- Page 160 5.8 DEMUX Evaluation Test Rx side setting Rx Bit rate ..Set the Rx bit rate to 2M. (m) DEMUX .... Set the DEMUX structure of the DSn signal. In this example, set it to ‘64k’. It is displayed when MUX/DEMUX option item is installed.

- Page 161 Section 5 Basic Setting and Application Examples of Connection 5 - 36.

- Page 162 Section 6 Other Settings about the Measurement This Section describes the settings except the basic settings described in ‘Section 5 Application Examples and Basic Setting’. in this manual represent front panel keys. 6.1 Setting the Measurement Channel......... 6-3 6.2 Setting a Test Pattern............. 6-4 6.3 Setting of Trigger Output and Alarm Detection/Removal Condition........

- Page 163 Section 6 Other Settings about the Measurement 6.11 Setting the Non Frame Pattern..........6-29 6.11.1 Bit rate : PDH/DSn (2/8/34/139M, 1.5/45M) ....6-29 6.11.2 Bit rate : SONET (52/156/622M) ........6-30 6.12 Adding Error and Alarm ............6-31 6.12.1 Adding Alarm ..............6-31 6.12.2 Adding Error ..............

-

Page 164: Setting The Measurement Channel

6.1 Setting the Measurement Conditions 6.1 Setting the Measurement Channel 'Mapping' screen The 'Mapping' screen allows the setting of channels for error and alarm measurements. The 'Mapping' screen appears on the upper part of the 'Test menu', 'Result', and 'Analyze' main screens. Set the channels as follows: (1) The mapping route is displayed on the ‘Mapping’... -

Page 165: Setting A Test Pattern

Section 6 Other Settings about the Measurement 6.2 Setting a Test Pattern 'Test Menu : Manual' screen The test pattern to be inserted into the payload of measurement channel can be set on the 'Test Menu : Manual' screen. Here is the setting procedure. -

Page 166: Setting Of Trigger Output And Alarm Detection/Removal Condition

6.3 Setting of Trigger Output and Alarm Detection/Removal Condition 6.3 Setting of Trigger Output and Alarm Detection/Removal Condition 'Setup : Measurement condition' screen The SONET trigger output, alarm detection condition, and removal condition can be set. (The DSn signal alarm detection and removal conditions cannot be set.) For the allowed alarm types and setting values, see 'Appendix E Alarm Detection and Removal Conditions'. -

Page 167: Editing Sonet Overhead

Section 6 Other Settings about the Measurement (d) [Trigger output] ....Selects trigger output type. The trigger types are shown below: (i) OFF: Does not output trigger. (ii) Capture: Output the trigger selected on the “OH capture”, “APS capture”, “Frame capture”, or “IP capture” screen of Capture: Analyze screen. -

Page 168: K1 Byte And K2 Byte

6.4 Editing SONET Overhead 6.4.2 K1 Byte and K2 Byte 'Test menu : Manual' screen The K1 byte and K2 byte can be set on the 'Test menu : Manual' screen, as binary numbers or in plain language. For generating the APS sequence pattern, see '7.11 APS (Automatic Protection Switch) Test'. -

Page 169: Other Overheads

Section 6 Other Settings about the Measurement Bit 5- 8 (3) On the test menu : S1 test screen, set the S1 send method. Set the sequence of S1 bytes set on table shown above. In addition, select "Single" or "Repeat" to perform the sequence. Move the cursor to the square and press to output S1 programmable data. - Page 170 6.4 Editing SONET Overhead (2) When bit rate is 156M: 1 A1 X18 X19 2 B1 X22 X23 E1 X25 X26 X28 X29 3 D1 X32 X33 D2 X35 X36 D3 X38 X39 4 H1 5 B2 K1 X55 X56 K2 X58 X59 6 D4 X62 X63 D5 X65 X66 D6 X68 X69 7 D7 X72 X73 D8 X75 X76 D9 X78 X79 8 D10 X82 X83 D11 X85 X86 D12 X88 X89...

-

Page 171: Editing The Overhead

Section 6 Other Settings about the Measurement TOH#3 1 A1 X18 X19 2 X21 X22 X23 X24 X25 X26 X27 X28 X29 3 X31 X32 X33 X34 X35 X36 X37 X38 X39 4 H1 5 B2 B2 X54 X55 X56 X57 X58 X59 6 X61 X62 X63 X64 X65 X66 X67 X68 X69 7 X71 X72 X73 X74 X75 X76 X77 X78 X79 8 X81 X82 X83 X84 X85 X86 X87 X88 X89... - Page 172 6.4 Editing SONET Overhead (a) Select ....Sets at 'SONET'. (b) Default ... Returns the TOH and POH send data to the default data (Added path trace and DCC eternal are not initialized). For the initial value of each byte, see 'Appendix D Initial Values'.

-

Page 173: Setting Path Trace

Section 6 Other Settings about the Measurement 6.4.6 Setting Path Trace 'Setup : OH preset' screen You can set the path trace generation for J0, J1, and J2 on the 'Setup : OH preset' screen. Here is the setting procedure. (1) Open the 'Setup : OH preset data' screen. -

Page 174: Changing The Overhead Data Per Frame

6.5 Changing the Overhead Data per Frame 6.5 Changing the Overhead Data per Frame 'Setup : OH change data' screen You can set the change of overhead data per frame in two ways on the 'Setup : OH change data' screen. Here are the setting procedures. (1) Open the 'Setup : OH change data' screen. -

Page 175: Setting The Orderwire And The Dcc Interface

6.6 Setting the Orderwire and the DCC Interface ‘Setup : System’ screen 6.6.1 Setting the Orderwire The MP1570A can do the order wire using E1 byte and E2 byte that are used for TOH sound signal of SONET. Here is the procedure for setting the order wire. -

Page 176: Setting The Dcc Interface

If it’s set to Off or it’s not selected as the interface, Data set on the ‘Setup : OH preset’ screen is inserted in the DCC byte. Note Refer to ‘3.1 Description of MP1570A Unit Panel’ for the connection and the layout of the pins of the DCC interface connector. 6- 15... -

Page 177: Editing Dummy Channel

Section 6 Other Settings about the Measurement 6.7 Editing Dummy Channel This section describes the setting of channels other than the SONET signal measurement channel. Edit the dummy channel of MP1570A in 2 ways according to the type as follows: (dummies of main channel) without measurement... -

Page 178: Setting Sts Pointer And Vt Pointer

6.7 Editing Dummy Channel Setting STS Pointer and VT Pointer Only the SS bit is allowed for the pointers except the measurement channel. Set the pointers on the 'Setup : Dummy preset' screen. (d) Sets the SS bit value for the STS Pointer. Move the cursor to SS bit and press . -

Page 179: Setting The Path Trace

Section 6 Other Settings about the Measurement Setting the Path Trace Edit the path trace for channels other than the measurement channel on the 'Setup : Dummy preset' screen. Select the path trace type to be set. (‘J1-HP’ is J1 of STS3, and ‘J1-LP’... -

Page 180: Setting The Mixed Payload

6.7 Editing Dummy Channel Setting the Mixed Payload On the mapping including TUG3 or STS1SPE, MP1570A allows the setting of mapping for TUG3 STS1SPE channels without the measurement channel which is different from that of the measurement channel. Here is the setting procedure. -

Page 181: Setting Dummy Sts

Section 6 Other Settings about the Measurement 6.7.2 Setting Dummy 'Setup : Mapping' screen Dummy selects either Copy or Dummy as follows: Copy ..Inserts the same pattern as that of STS3 with measurement channel. Dummy ..The mapping includes Bulk mapping of the layer with measurement channel. -

Page 182: Setting The Tandem Connection

6.8 Setting the Tandem Connection 6.8 Setting the Tandem Connection This section describes the tandem connection. 6.8.1 Setting the Type 'Setup : Tandem' screen The 'Setup : Tandem' screen allows the setting of whether byte or is to be are used as tandem connection, along with the setting of the type. -

Page 183: Editing The Tandem Connection Byte

Section 6 Other Settings about the Measurement 6.8.2 Editing the Tandem Connection Byte 'Setup : Tandem' screen The 'Setup : Tandem' screen allows the editing of the tandem connection byte of the measurement channel. The meshed area below shows the bits that you can edit on the screen. Z5-HP (Type1) Data LInk* FLAG... - Page 184 6.8 Setting the Tandem Connection Here is the setting procedure. (1) Open the 'setup : Tandem' screen. (2) Move the cursor to the desired tandem connection type and press (3) The numerical selection window appears. Move the cursor with and set the value with Default ...

-

Page 185: Setting The Measurement Conditions

Section 6 Other Settings about the Measurement 6.8.3 Setting the Measurement Conditions 'Setup : Measurement condition' screen Here is the procedure for setting error and alarm measurements to On/Off, and alarm detection and removal conditions for tandem connection. (1) Open the 'Setup : Measurement condition' screen. (2) Set each measurement item to On or Off. -

Page 186: Selecting The Signalling Pattern

6.9 Editing the Signaling 6.9 Editting the Signalling 'Setup : Signaliing preset' screen The installation of optional item 09 allows the presetting of the signaling bit. 6.9.1 Selecting the Signalling Pattern (1) Open the ‘Setup : Signalling preset’ screen. (2) Set the screen parameters. (a) Signalling Tx .. -

Page 187: Editing The Signalling Bits

Section 6 Other Settings about the Measurement 6.9.2 Editing the Signalling Bits The bits meshed on the figure below can be preset. 8-Multiframe Setting TS13 TS17 TS21 TS10 TS14 TS18 TS22 TS11 TS15 TS19 TS23 TS12 TS16 TS20 TS24 64-Multiframe Setting (Fs) (Fs) (Fs) - Page 188 6.9 Editing the Signaling Here is the setting procedure. (1) Open the 'Setup : Signaling preset' screen. (2) Setup the screen parameters. (a) Default ..Sets the signaling bit at the default value. (b) Presets the signaling bit..Move the cursor to the desired bit and press .

-

Page 189: Setting The Cid Pattern

Section 6 Other Settings about the Measurement 6.10 Setting the CID Pattern 'Setup : Mapping' screen Here is the measuring procedure for CID pattern. (1) Open 'Setup : Mapping' screen. (2) Move the cursor to ‘Config.’, and press (3) The item selection window appears. Select 'CID pattern'. (4) Set the screen parameters. -

Page 190: Setting The Non Frame Pattern

6.11 Setting the Non Frame Pattern 6.11 Setting the Non Frame Pattern 'Setup : Mapping' screen This section describes the procedure to generate a test pattern without information on the frame including overhead for performing Bit Error Rate Test (BERT). 6.11.1 Bit rate : PDH/DSn (2/8/34/139M, 1.5/45M) (1) Open the 'Setup: Mapping ' screen and set the bit rate to 2M, 8M, 34M, 139M, 1.5M, or 45M. -

Page 191: Bit Rate : Sonet(52/156/622M)

Section 6 Other Settings about the Measurement 6.11.2 Bit rate : SONET(52/156/622M) (1) Open the 'Setup : Mapping' screen. (2) Move the cursor to ‘Config.’, and press (3) The item selection window appears. Select 'Non frame pattern'. (a) Bitrate ....Sets the bit rate. (b) Clock ...... -

Page 192: Adding Error And Alarm

6.12 Adding Error and Alarm 6.12 Adding Error and Alarm ‘Test menu : Manual’ screen When adding errors and alarms to the Tx signal, the type and the insertion rate of the errors and the alarms to be added are set on the ‘Test menu : Manual’... -

Page 193: Adding Error

Section 6 Other Settings about the Measurement 6.12.2 Adding Error (1) Open the ‘Test menu : Manual’ screen. (2) Set the screen parameters as follows. (a) [Error] ......Select error to be added to the Tx signal. If ‘Bit all’ is selected, the error is added to the all Tx signals. If ‘Bit info’... -

Page 194: Setting Pointer

6.13 Setting Pointer 6.13 Setting Pointer ‘Test menu : Manual’ screen This section describes the procedure to set STS Pointer value and VT Pointer value of the Tx signal of the measurement channel, and to offset the payload by C bit. 6.13.1 Setting and Changing Pointer Value STS Pointer value and VT Pointer value of the Tx SONET signal are set on the ‘Test menu : Manual’... -

Page 195: Changing Pointer By Justification

Section 6 Other Settings about the Measurement 6.13.2 Changing Pointer by Justification The generation of positive and negative justification is set on the ‘Test menu : Manual’ screen. (1) Open the ‘Test menu : Manual’ screen. (2) Set the screen parameters as follows. (a) Move the cursor and press . -

Page 196: Offsetting Payload By C Bit

6.13 Setting Pointer 6.13.3 Offsetting Payload by C bit The payload of the measurement channel can be set with C bit (C1 bit/C2 bit). It is set in the unit of ppm. The offset value is set on the ‘Test menu : Manual’ screen. (1) Open the ‘Test menu : Manual’... - Page 197 Section 6 Other Settings about the Measurement 6 - 36.

-

Page 198: Section 7 Measurement And Analysis

Section 7 Measurement and Analysis This Section describes measurement and analysis. Before you perform the measurements and analysis, the connection and initial setting of measurement route must be completed as explained in ‘Section 5 Application Examples and Basic Settings’. 7.1 Continuity Test of All Channels by Trouble Search Function....7-3 7.1.1 Setting and Starting Search .............7-3 7.1.2 Displaying Search Result............7-5 7.1.3 Analysis of the Search Results..........7-7... - Page 199 Section 7 Measurement and Analysis 7.7 Monitor ..................7-38 7.7.1 Monitoring Overheads ............. 7-38 7.7.2 Monitoring the Pointer and K1/K2 Bytes ........7-39 7.7.3 Monitoring the Path Trace ............7-41 7.7.4 Monitoring the Payload ............7-42 7.7.5 Monitoring Tandem Connection..........7-43 7.7.6 Monitoring the Frame............

-

Page 200: Continuity Test Of All Channels By Trouble Search Function

7.1 Continuity Test of All Channels by Trouble Search Function 7.1 Continuity Test of All Channels by Trouble Search Function MP1570A can perform the conduction test on all channels for the mapping route set on the 'Setup : Mapping' screen with its trouble (error and alarm) search function. - Page 201 Section 7 Measurement and Analysis (5) After the measurement, the measurement result is displayed on the ‘Result’ screen and ‘Analyze’ screen. Note When the trouble search function is used in the Tx/Rx mode, the channel to be searched is restricted as shown below. If there is a mapping of the transmitting side that corresponds to the mapping of the receiving side, only the mapping is searched.

-

Page 202: Displaying Search Result

7.1 Continuity Test of All Channels by Trouble Search Function 7.1.2 Displaying Search Result 'Result : Trouble search' screen (1) Open the 'Result : Trouble search' screen. (The 'Result : Trouble search' screen appears if you press while the 'Test menu : Result Trouble search' screen is open.) (2) The screen displays the trouble search measurement results. - Page 203 Section 7 Measurement and Analysis (a) STS3#** ..displays the channel under measurement (The channel automatically changes during the measurement, i.e. '#**' following AUG changes to #01, #02, to #xx.)..Trouble search is started if you move the cursor here and press The channel number for which trouble has occurred blinks on the screen if you search with...

-

Page 204: Analysis Of The Search Results

7.1 Continuity Test of All Channels by Trouble Search Function 7.1.3 Analysis of the Search Results 'Analyze : Trouble search' screen The 'Analyze : Trouble search' screen displays the detailed error and alarm data for each channel and error and alarm detection path (NG path) according to the trouble measurement results. - Page 205 Section 7 Measurement and Analysis (c) Route # ..shows each hierarchy channel of the displayed route. Move the cursor to the desired figure and press The window for numeric entry is displayed. displayed route is changed if you change the channel. (d) Trouble content ..

- Page 206 7.1 Continuity Test of All Channels by Trouble Search Function (e) Print ..selects the contents to be printed (For printing, press Print Now Display ..Trouble for the currently displayed route After ...Trouble for the route that comes after the currently displayed route Before ..Trouble for the route that comes before the currently displayed route...

-

Page 207: Display Of Ng Paths (Paths For Which Errors And Alarms Were Detected)

Section 7 Measurement and Analysis Display of NG Paths (paths for which errors and alarms were detected) Here is the procedure for displaying the NG path routes to be taken on completion of the measurement. (1) Open the 'Analyze : Trouble search' screen. (The 'Analyze : Trouble search' screen is displayed when you press while the 'Result : Result... -

Page 208: Manual Measurement

7.2.1 Setting and Starting the Measurement 'Test menu : Manual' screen (1) Connect the MP1570A and the equipment to be examined as described in the ‘Section 5’ and ‘Section 6’. (2) Open the 'Test menu : Manual' screen. -

Page 209: Displaying The Error And Alarm Measurement Results

Section 7 Measurement and Analysis Note Start Press to stop the measurement. /Stop ‑ ‑ If you change the alarm detection and removal conditions, the system clock, and the graph resolution during the measurement, data is discarded, and a measurement is started from the beginning. 7.2.2 Display and Analysis of the Error and Alarm Measurement Results Here is the procedure for displaying and analyzing the error and alarm measurement results obtained by manual measurement explained in... - Page 210 7.2 Manual Measurement (Measurement of One Channel on a Mapping Route) (b) Alarm ..selects the display pattern of alarm measurement results. Second ..displays the number of seconds for which the alarm is to be generated. Frame ..displays the frame at which the alarm has occurred.

- Page 211 Section 7 Measurement and Analysis (4) Measured results are displayed as shown in the examples below. (f) [Alarm measurement results] ..displays alarm measurement results in accordance with the setting in (b). (g) [Error measurement results] ..displays the error measurement results in accordance with the setting in (c).

-

Page 212: History Display Of The Errors And Alarms

7.2 Manual Measurement (Measurement of One Channel on a Mapping Route) History Display of the Errors and Alarms The detected errors and alarms detected during the measurement can be memorized (History display). Here is the setting procedure. (1) press History during the measurement. -

Page 213: Displaying The Error And Alarm Of

Section 7 Measurement and Analysis Displaying the Error and Alarm of Channel 'Result : Simultaneous' screen The errors and alarms of STS1, VT6SPE (7ch), VT2SPE (21ch), and VT1.5SPE (28ch) mapped to the specified TUG3 or STS1 can be detected and displayed. Here is the procedure for performing this measurement. -

Page 214: Analysis Of The Error And Alarm Measurement Results

7.2 Manual Measurement (Measurement of One Channel on a Mapping Route) Analysis of the Error and Alarm Measurement Results 'Analyze : Error Alarm' screen The measurement results obtained by the manual measurement can be displayed on a bar graph. By displaying the graph, time the error and alarm occur and their frequency can be analyzed. - Page 215 Section 7 Measurement and Analysis Setting the graph (a) [Abscissa scale] ..selects the abscissa scale from 1s, 1min, 15min, and 60min. (b) [Alarm] ..selects the alarm to be displayed. Move the cursor to the left-hand side of the graph and press .

- Page 216 7.2 Manual Measurement (Measurement of One Channel on a Mapping Route) (h) [Moving maker] ….. Move the cursor here and press move the cursor..Moves the maker to left..Moves the maker to right. Set the marker to on or off in step (i) (i) [Search] ..

-

Page 217: Displaying The Justification Count

Section 7 Measurement and Analysis Note The 'Log memory full' condition will suspend Error/Alarm graph creation. In particular, if the graph resolution is set at '1s', the graph creation for a screen may be stopped halfway. 7.2.3 Displaying the Justification Count 'Result : Justification' screen The type of the pointer change detected during the measurement and the counting result can be displayed. - Page 218 7.2 Manual Measurement (Measurement of One Channel on a Mapping Route) (c) +PJC ..displays the positive pointer justification count or rate. (d) -PJC ..displays the negative pointer justification count or rate. (e) Consecutive ..displays the pointer change or rate caused by three pointers that had the same pointer.

-

Page 219: Display Of Performance Measurement Results

Section 7 Measurement and Analysis 7.3 Display of Performance Measurement Results 'Result : Performance' screen The MP1570A can evaluate a line in accordance with the standard of the performance measurement stipulated by ITU-T. - The MP1570A can automatically generate the error and alarm patterns corresponding to the detective conditions of each performance parameter. -

Page 220: Measurement

/Stop shown according to the selected standard. - Supplement - On Performance measurement, the MP1570A handles the error measurement results (related to MS-REI) only at concatenation mapping (involving STS3cSPE-Bulk) for the specified bit rate. The related measurements are as follows: ・G.826... -

Page 221: When You Select G.821 For Performance

Section 7 Measurement and Analysis When you select G.821 for performance: When you select G.821 for performance on the 'Setup : Measurement condition' screen, the following performance measurement results are displayed In case of G.821, no parameters have to be set. EC....Error Count ES ....Ratio between... -

Page 222: When You Select G.826 For Performance

7.3 Display of Performance Measurement Results When you select G.826 for Performance: (1) When you select G.826 for performance on the 'Setup : Measurement condition' screen, set a parameter shown below (a) Error ….. Specify the type of the error to be measured. BIP ….. -

Page 223: When You Select M.2100 For Performance

Section 7 Measurement and Analysis When you select M.2100 for performance: (1) When you select M.2100 for performance on the 'Setup : Measurement condition' screen, set the threshold for judging the received signal and transmitted signal (a) Rx threshold ..sets the threshold for judging the received signal. -

Page 224: When You Select M.2101 For Performance

7.3 Display of Performance Measurement Results Judgement results ≤ Acceptable Measured results ≤ Degraded < Measured results ≤ Unacceptable Measured results The display priority is Unacceptable > Degraded > Acceptable. When you select M.2101 for performance: (1) Set the parameters as shown below when you select M.2101 for performance on the 'Setup : Measurement condition' screen. -

Page 225: When You Select M.2110 For Performance

Section 7 Measurement and Analysis (2) The performance measurement results are displayed as follows: EC ..Error Count SES ..Severe Error Seconds US ..Unavailable Seconds Test..Judgement results for the thresholds set in (a) and The display priority is Unacceptable > Degraded > Acceptable. - Page 226 7.3 Display of Performance Measurement Results (2) Performance measured results for received and transmitted signals are displayed as follows: 2-hour, 24-hour, 7-day ..ES and SES judgement results are displayed for 2 hours, 24 hours, and 7 days. ES ... Error Seconds SES ..

-

Page 227: When You Select M.2120 For Performance

Section 7 Measurement and Analysis When you select M.2120 for Performance: (1) Set the parameters as shown below when you select M.2101 for performance on the 'Setup : Measurement condition' screen. (a) Layer ..sets the measured item range of M.2120. (b) Threshold .. -

Page 228: Error Performance Check

7.3 Display of Performance Measurement Results 7.3.3 Error Performance Check The MP1570A can generate errors and alarms exceeding the threshold of each performance measurement parameter. Here is the procedure for measurement. (1) Open the 'Test menu : Performance check' screen. -

Page 229: Delay Measurement

(3) Start the measurement by pressing /Stop Note The time required to receive a signal after it is sent by MP1570A is measured using Delay Measurement. We recommend that you check device to be examined is connected properly before the measurement. - Page 230 7.4 Delay Measurement (a) [Measurement time] . selects the display mode of measurement time. Start ..... displays time which measurement was started. Elapsed ....displays elapsed time after measurement was started. (b) [Measured results] ... displays the latest measured results......

-

Page 231: Pointer Sequence Test

Section 7 Measurement and Analysis 7.5 Pointer Sequence Test 'Test menu : Pointer sequence' screen MP1570A allows specific pointer sequence tests by applying the justification to the signal to be transmitted. Here is the procedure for the test. (1) Open the 'Test menu : Pointer sequence' screen. - Page 232 Manual ....Once the measurement is started, it continues Start until you press /Stop sets the measurement time if you select 'Single' or 'Repeat'. (3) MP1570A allows specific pointer sequence tests by applying the justification to the signal to be transmitted. Start the Start measurement by pressing after setting the parameters in (2).

-

Page 233: Capturing Overheads

Section 7 Measurement and Analysis 7.6 Capturing Overheads "Analyze : OH capture" screen MP1570A can take in 1,023 frames of SONET overhead bytes arbitrarily to the internal memory, and display them. Here is the procedure for capturing, analyzing, and storing the data. - Page 234 7.6 Capturing Overheads ‑ In the example shown above, the overhead bytes are captured in the position of frame No.41, using "OOF" as a trigger. Therefore, 1,023 frames are captured continuously, from 40 frames before "OOF" is detected. Analyzing the Captured Data (e) [Data scroll] …..

-

Page 235: Monitor

Section 7 Measurement and Analysis 7.7 Monitor ‘Analyze : OH monitor’ screen 7.7.1 Monitoring Overheads Here is the procedure for monitoring the and POH of the SONET signal. (1) Open the 'Analyze : OH monitor' screen (2) Setup the screen parameters as follows: (d) (f) (a) Type....Set the monitor type to 'OH'. -

Page 236: Monitoring The Pointer And K1/K2 Bytes

7.7 Monitor 7.7.2 Monitoring the Pointer and K1/K2 Bytes Here is the procedure for monitoring the pointer, K1 byte and K2 byte of SONET. This function is available only while SONET signal is being received. (1) Open the 'Analyze : OH monitor' screen. (2) Setup the screen parameters as follows: (a) Type .... - Page 237 Section 7 Measurement and Analysis (i) Pause ....sets the display updating to on or off of....updates the display. This function is turned off if you move the cursor here and press ....does not update the display. This function is turned on if you move the cursor here and press 7 - 40...

-

Page 238: Monitoring The Path Trace

(not lit):CRC-7 error does not exist. (d) TIM ....displays whether or not an TIM exists. When TIM errors detected by the MP1570a does not coincide with the path trace data set up on the 'Setup : OH preset' screen, it is regarded as an error. -

Page 239: Monitoring The Payload