Table of Contents

Advertisement

Operator's Manual

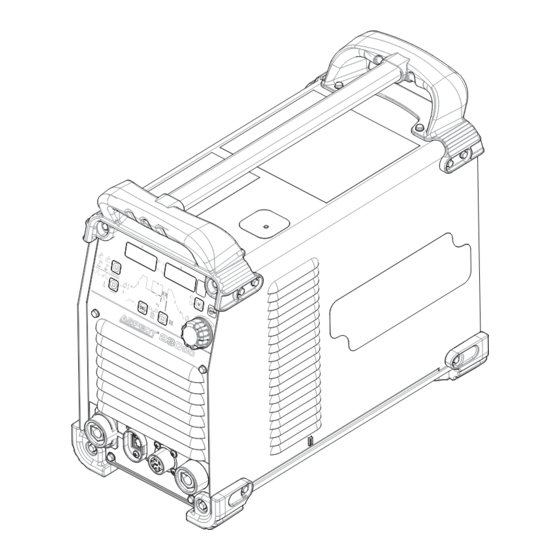

Aspect

Register your machine:

www.lincolnelectric.com/registration

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Save for future reference

Date Purchased

Code: (ex: 10859)

Serial: (ex: U1060512345)

IM10494

| Issue D ate Dec-18

© Lincoln Global, Inc. All Rights Reserved.

230 DC

®

For use with machines having Code Numbers:

12734

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Lincoln Electric Aspect 230 DC

- Page 1 Operator’s Manual Aspect 230 DC ® For use with machines having Code Numbers: 12734 Register your machine: www.lincolnelectric.com/registration Authorized Service and Distributor Locator: www.lincolnelectric.com/locator Save for future reference Date Purchased Code: (ex: 10859) Serial: (ex: U1060512345) IM10494 | Issue D ate Dec-18 ©...

-

Page 2: Safety Depends On You

THANK YOU FOR SELECTING A QUALITY PRODUCT BY KEEP YOUR HEAD OUT OF THE FUMES. DON’T get too close to the arc. LINCOLN ELEC TRIC. Use corrective lenses if necessary to stay a reasonable distance away from the arc. READ and obey the Safety Data PLEASE EXAMINE CARTON AND EQUIPMENT FOR Sheet (SDS) and the warning label DAMAGE IMMEDIATELY... - Page 3 W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 2.d. All welders should use the following procedures in order to 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199.

-

Page 4: Electric Shock Can Kill

SAFETY ELECTRIC SHOCK ARC RAYS CAN BURN. CAN KILL. 3.a. The electrode and work (or ground) circuits are 4.a. Use a shield with the proper filter and cover plates to protect your electrically “hot” when the welder is on. Do eyes from sparks and the rays of the arc when welding or not touch these “hot”... - Page 5 SAFETY WELDING AND CUTTING CYLINDER MAY EXPLODE IF SPARKS CAN CAUSE DAMAGED. FIRE OR EXPLOSION. 7.a. Use only compressed gas cylinders containing the correct shielding gas for the process used 6.a. Remove fire hazards from the welding area. If and properly operating regulators designed for this is not possible, cover them to prevent the welding sparks the gas and pressure used.

- Page 6 TABLE OF CONTENTS...

-

Page 7: Recommended Processes

ASPECT ® 230 DC INSTALLATION The Aspect ® 230 DC is an inverter based arc welding power source optimized for DC TIG (GTAW) and DC Stick (SMAW) welding. The Aspect ® 230 DC includes TIG features, Amplitude Control, High frequency and Touch Start TIG ®... - Page 8 INSTALLATION ASPECT ® 230 DC TECHNICAL SPECIFICATIONS ASPECT 230 DC ® RECOMMENDED FUSE SIZES 1 (K4346-1) INPUT MAXIMUM TIME DELAY FUSE POWER SOURCE INPUT VOLTAGE VOLTAGE / INPUT AMPERE AND CURRENT PHASE / RATING BREAKER 3-Phase NA/19/17/10/9 Max Input Amperes FREQUENCY AMPERAGE 120V/208V/230V/400V/460V...

- Page 9 ASPECT ® 230 DC INSTALLATION INSTALLATION MACHINE GROUNDING AND HIGH FREQUENCy SAFETy PRECAUTIONS INTERFERENCE PROTECTION Read entire installation section ® Locate the Aspect 230 DC away from radio controlled machinery. before starting installation. The normal operation of the Aspect ® 230 DC may adversely affect the operation of RF controlled equipment, which may result in bodily WARNING...

-

Page 10: Input Connection

ASPECT ® 230 DC INSTALLATION equivalent shielding. Flexible helically-wrapped metallic conduit is generally not suitable. INPUT VOLTAGE SELECTION 8. When the welder is enclosed in a metal building, several good The Aspect ® 230 DC automatically adjusts to work with the input earth driven electrical grounds (as in 5 above) around the voltages listed on the rating plate. -

Page 11: Output Connections

ASPECT ® 230 DC INSTALLATION OUTPUT CONNECTIONS FIGURE A.2 6-PIN REMOTE CONTROL CONNECTOR Function Wiring REMOTE POTENTIOMETER, 10K 6-PIN REMOTE REMOTE POTENTIOMETER, WIPER CONTROL REMOTE POTENTIOMETER, COMMON CONNECTOR FOR REMOTE TRIGGER, COMMON HAND/FOOT TRIGGER, INPUT AMPTROL. GROUND 1. Twist-Mate Electrode / Gas Output Connector 2. - Page 12 ASPECT ® 230 DC INSTALLATION AIR COOLED TIG TORCH WITH WIRED FOOT PEDAL CONNECTION DIAGRAM Refer to the following connection diagrams for specific information on connecting water cooled and air cooled torches. REGULATOR FLOWMETER GAS HOSE TO WORK STUD K2394-1 Ground Clamp Set (Includes electrode holder and cable) WORK CLAMP WORK PIECE...

-

Page 13: Case Front Controls

ASPECT ® 230 DC OPERATION OPERATION CASE FRONT CONTROLS CASE BACK CONTROLS (See figure B.1) (See figure B.2) FIGURE B.1 FIGURE B.2 1. User Interface – For selecting process and parameters 7. Input Power Cord 2. Control Knob – Used to control machine output setting and to 8. -

Page 14: Graphic Symbols That Appear On This Machine Or In This Manual

ASPECT ® 230 DC OPERATION GRAPHIC SYMBOLS THAT APPEAR ON THIS MACHINE OR IN THIS MANUAL CIRCUIT BREAKER SAVE THREE PHASE 3 PHASE INVERTER HIGH TEMPERATURE INPUT POWER SINGLE MENUS OPEN CIRCUIT RECALL CONNECTION PHASE VOLTAGE INPUT VOLTAGE SEQUENCER GTAW EXIT PULSE MENU... -

Page 15: User Interface Controls

ASPECT ® 230 DC OPERATION USER INTERFACE CONTROLS Process FIGURE B.3 This switch allows the user to set the desired process. (See Figure B.4) 1. High-Frequency TIG ® 2. Touch Start TIG 3. Stick – Soft Mode (7018 style electrodes) 4. - Page 16 ASPECT ® 230 DC OPERATION 4-Step Functionality 1. 2-Step (See Figure B.6 and B.7) – With 2-step trigger and a TIG welding mode selected, the following weld sequence will occur. (See Figure B.9) If a standard foot amptrol is connected, it will take control of FIGURE B.9 most sequencer functions, but pre-flow, starting current, finishing current, and post-flow can be defined.

-

Page 17: Sequencer Functions

ASPECT ® 230 DC OPERATION SEQUENCER FUNCTIONS PULSE SEQUENCER FUNCTIONS The sequencer allows for customization of the TIG welding operation. To access the pulse menu, select the Pulse Sequencer button once Pressing the “SEL” button will cycle through the process graph (See and then cycle through the Sequencer with the SEL button. -

Page 18: Memory Selection

ASPECT ® 230 DC OPERATION MEMORy SELECTION: Saving Memory Settings The memory function allows the operator to save up to 9 specific In order to save process settings into a memory location it is first welding procedures. This memory switch has two functions: necessary to press the memory button so that the “memory save”... - Page 19 ASPECT ® 230 DC OPERATION Memory Recall Settings Status Lights: (See Figure B.17) (See Figure B.19) In order to recall process settings it is first necessary to press the There are 4 status lights located between the voltage and amperage memory button twice so that the “memory recall”...

- Page 20 ASPECT ® 230 DC OPERATION Hold Select button for 5 seconds to enter Menu “GTAW.” 5 Seconds Setup Menu "GTAW" TIG Settings TIG Settings Press SEL to cycle through & rotate knob to change then SEL to save ‘A” to exit Description Display Item...

- Page 21 ASPECT ® 230 DC OPERATION Hold Pulse button for 5 seconds to enter Menu “SMAW.” 5 Seconds Setup Menu "SMAW" Stick Settings Display Item Choices Description 0-75 for soft stick FRCE Arc Force Specify your Arc Force setting 75-200 for crisp stick 0-75 for soft stick Specify your Hot Start setting HSTR...

- Page 22 ASPECT ® 230 DC OPERATION Hold both Select and Pulse buttons for 5 seconds to enter Menu “SYS.” 5 Seconds Then press ‘SEL’ to cycle through. To change, rotate knob then press ‘SEL’ to save “A’ to exit Setup Menu “SYS” System Settings Display Item...

- Page 23 ASPECT ® 230 DC OPERATION Appendix A.1 Volt and Amp meter display while welding and idle. While welding, the machine will show actual voltage and amperage on the meters. When the welding arc is extinguished, the meters will display (and flash) the final voltage and amperage of that weld for 5 seconds. Figure B.25 ---- A.2 Green Mode...

- Page 24 ASPECT ® 230 DC OPERATION A.4 4-Step Trigger with Restart Sequence 4-Step trigger with restart can be enabled in setup menu “GTAW” by switching 4RST to ON. If 4RST is ON, a TIG mode is selected, and 4-step is selected on the output section of the machine, the following sequence will occur. (3A) This sequence is the same as 4-step, except when the switch is released during the finishing current, welding current will ramp up again to the operating amperage.

- Page 25 ASPECT ® 230 DC ACCESSORIES GENERAL OPTIONS / K2266-1 – TIG-Mate ™ 17 Air Cooled TIG Torch Starter Pack. One complete easy-to-order kit packaged in its own portable car- ACCESSORIES rying case. Includes: PTA-17 torch, parts kit, Harris flowmeter/regulator, 10 ft. gas hose, Twist-Mate™ adapter, work clamp and cable.

-

Page 26: Overload Protection

ASPECT ® 230 DC MAINTENANCE MAINTENANCE OVERLOAD PROTECTION Safety Precautions FAN-AS-NEEDED (F.A.N.) The Aspect ® 230 DC has the F.A.N. circuit feature, which means the WARNING cooling fan will operate only as needed to assure proper machine cooling. This helps reduce the amount of dust and dirt drawn into the ELECTRIC SHOCK can kill. -

Page 27: Troubleshooting

ASPECT ® 230 DC TROUBLESHOOTING TROUBLESHOOTING HOW TO USE TROUBLESHOOTING GUIDE Step 1. LOCATE PROBLEM (SYMPTOM). Look under the column labeled “PROBLEM (SYMPTOMS)”. This WARNING column describes possible symptoms that the machine may exhibit. Find the listing that best describes the symptom that the Service and Repair should only be performed by Lincoln machine is exhibiting. - Page 28 ASPECT ® 230 DC TROUBLESHOOTING TIG WELDING ISSUES Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION Poor starting Poor work clamp connection Check and secure work connection Start current is too low Increase start current Black area along weld bead Oily or organic contamination on work piece...

- Page 29 ASPECT ® 230 DC TROUBLESHOOTING STICK WELDING ISSUES Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION Poor starting Hot start may be set too low Access “SMAW”menu (see operation section) and increase “HSTR” setting Poor work clamp connection Check and secure work connection Current may be set too high for electrode size Adjust current...

- Page 30 ASPECT ® 230 DC TROUBLESHOOTING OPEN CIRCUIT VOLTAGE (OCV) ISSUES Note: Do not connect a meter to machine output terminals to measure voltage in TIG mode as hi-freq produced by machine may damage meter. When trigger is closed in TIG mode, machine displays OCV on left meter for approximately 3 seconds then output will turn off if a weld is not made.

- Page 31 ASPECT ® 230 DC TROUBLESHOOTING HI FREQUENCy ISSUES Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION No hi-freq Wrong Process setting Verify Process is set for hi-freq TIG Preflow time set too long Set for typical 0.5 second preflow time Faulty PC Boards or connections Contact your local Lincoln Authorized Field Service...

- Page 32 ASPECT ® 230 DC DIAGRAMS...

- Page 33 ASPECT ® 230 DC DIAGRAMS...

- Page 34 WARNING Do not touch electrically live parts or Keep flammable materials away. Wear eye, ear and body protection. electrode with skin or wet clothing. Insulate yourself from work and AVISO DE ground. Spanish PRECAuCION No toque las partes o los electrodos Mantenga el material combustible Protéjase los ojos, los oídos y el bajo carga con la piel o ropa moja-...

- Page 35 WARNING Keep your head out of fumes. Turn power off before servicing. Do not operate with panel open or Use ventilation or exhaust to guards off. remove fumes from breathing zone. AVISO DE Spanish PRECAuCION Los humos fuera de la zona de res- Desconectar el cable de ali- No operar con panel abierto o piración.

- Page 36 Lincoln Electric for advice or information about their use of our products. We respond to our customers based on the best information in our possession at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such information or advice.

Need help?

Do you have a question about the Aspect 230 DC and is the answer not in the manual?

Questions and answers