Summary of Contents for Linde RYVAL 200 AC/DC dave

- Page 1 WELDING INVERTER RYVAL 200 AC/DC PULSE dave RYVAL 200 AC/DC dave OPERATING MANUAL Linde AG, Linde Gas Deutschland © RYVAL 200 AC-DC (PULSE) dave manual EN 05...

-

Page 2: Table Of Contents

GETTING STARTED ................. 11 TWO STROKE AND FOUR STROKE IN TIG MODE ....... 15 GENERAL INFORMATION ON THE WELDING MODES......16 ROUTINE MAINTENANCE & INSPECTION ..........17 10. STATEMENT OF WARRANTY ..............17 11. DISPOSAL ....................18 Linde AG, Linde Gas Deutschland ©... -

Page 3: Introduction

3/18 1. INTRODUCTION Congratulations on your new Linde AG, Linde Gas Deutschland product. We are proud to have you as our customer and will strive to provide you with the best service and reliability in the industry. This Operating Manual has been designed to instruct you on the correct use and operation of your Linde AG, Linde Gas Deutschland product. -

Page 4: Safety Instructions And Warnings

THERE IS A VERY HIGH RISK OF EXPLOSION. The operator must be aware of all the special regulations which he needs to conform to when welding in enclosed spaces with a high risk of explosion. Linde AG, Linde Gas Deutschland ©... - Page 5 User is obliged to consult with the electricity supplier if the impedance of the network at this point is that required short-circuit capacity Z = 36 mΩ and whether the device can be connected with a public low-voltage network. Linde AG, Linde Gas Deutschland ©...

-

Page 6: Technical Data

32 A with the maximum permissible fuse of 25 A. The corresponding data for such a 32 A plug are stated in the table above in brackets. Linde AG, Linde Gas Deutschland ©... -

Page 7: Equipment

Attention! Do not connect to the interconnected voltage (delta voltage) (between 2 phases)! Replacement of the plug may only be performed by Linde AG, Linde Gas Deutschland authorized service personnel. Linde AG, Linde Gas Deutschland continuously strives to produce the best product possible and therefore reserves the right to change, improve or revise the specifications or design of this or any product without prior notice. -

Page 8: Operator Controls

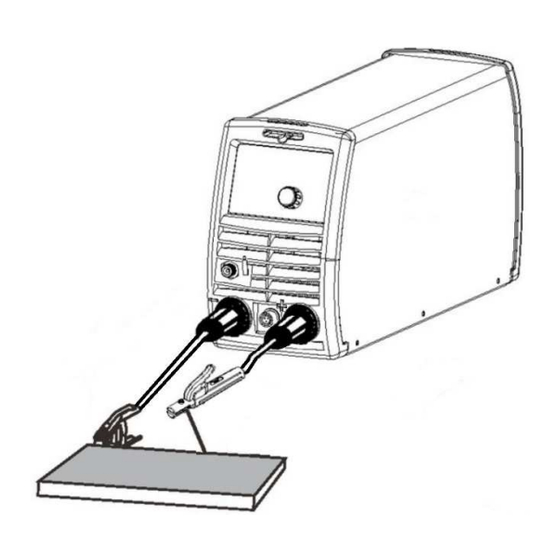

Foot Pedal Remote CTRL 3 m RYVAL incl. Connector ST 5. OPERATOR CONTROLS MAIN PARTS Fig . 1 Main parts Pos. Description Operating panel Quick connector + Gas connector of the welding torch Torch control connector Quick connector - ON/OFF switch Linde AG, Linde Gas Deutschland ©... - Page 9 9/18 Gas inlet Mains cable and plug OPERATING PANEL Fig. 2 RYVAL 200 AC/DC Pulse Dave Fig. 3 RYVAL 200 AC/DC Dave Pos. Description LED MMA LED TIG LA – Lift Arc ignition Linde AG, Linde Gas Deutschland ©...

- Page 10 LED %. If illuminated there are values in % on the display. LED Hz. If illuminated there are values in Hz on the display. LED HOT START, just for MMA, 0 – 100. LED lights up after pressing the encoder 11. Linde AG, Linde Gas Deutschland ©...

-

Page 11: Getting Started

6. Press button 5 to select AC or DC welding current. 7. It is possible to change the settings of the HOT START (increase of current during arc ignition time), ARC FORCE (an automatic increase of the Linde AG, Linde Gas Deutschland ©... - Page 12 Gas inlet connector A7 on the rear panel. 7. Switch the machine on by the ON/OFF switch A6. 8. Press the torch trigger, the solenoid valve will open; set the desired gas flow (pure argon). Linde AG, Linde Gas Deutschland ©...

- Page 13 The following table describes the influence setting the clearance effect. Clearance effect Value -5 to 0 Value +1 to +5 Shape of the current curve Penetration Deep Shallow Level of wear of the of Smaller Bigger tungsten electrode Linde AG, Linde Gas Deutschland ©...

- Page 14 P1. The set current will be displayed on the display 31. 5. The welding process ends after releasing the stepping surface P1. Linde AG, Linde Gas Deutschland ©...

-

Page 15: Two Stroke And Four Stroke In Tig Mode

To enter the second welding current press the torch button for a short time and release it. To get back to the main welding current press the torch button for a short time and release it. Linde AG, Linde Gas Deutschland ©... -

Page 16: General Information On The Welding Modes

To completely prevent the tungsten being included, you must not let the electrode touch the piece to be welded. However you use a start-up with high frequency (HF) discharge that allows striking of the electric arc at a distance. Linde AG, Linde Gas Deutschland ©... -

Page 17: Routine Maintenance & Inspection

Deutschland product supplier for the warranty repair procedure. 5. Linde AG, Linde Gas Deutschland warranty will not apply to: 6. Equipment that has been modified by any other party other than Linde AG, Linde Gas Deutschland’s own service personnel or with prior written consent obtained from Linde AG, Linde Gas Deutschland Service Department. -

Page 18: Disposal

NOTE Warranty repairs must be performed by either a Linde AG, Linde Gas Deutschland Service Centre, a Linde AG, Linde Gas Deutschland distributor or an Authorised Service Agent approved by the company Linde AG, Linde Gas Deutschland.

Need help?

Do you have a question about the RYVAL 200 AC/DC dave and is the answer not in the manual?

Questions and answers