Table of Contents

Advertisement

Quick Links

Instructions

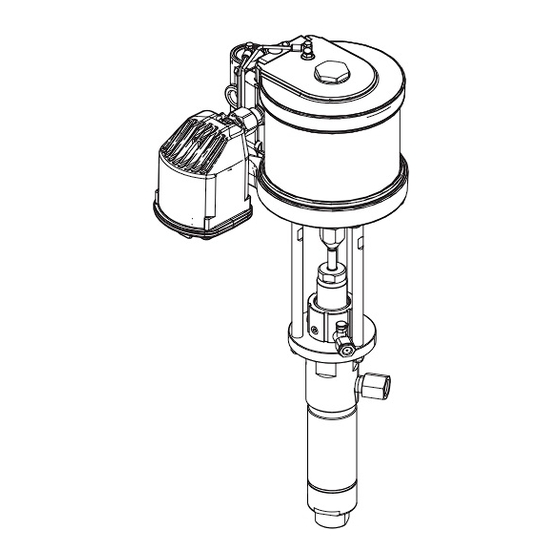

Stainless Steel 10:1 Pump

For use with EcoQuip 2

with additives to inhibit corrosion or mold. For professional use only.

Model 25P031

1100 psi (7.5 MPa, 75 bar) Maximum Fluid Working Pressure

100 psi (0.68 MPa, 6.8 bar) Maximum Air Working Pressure

Important Safety Instructions

Read all warnings and instructions in this

manual and in your EcoQuip 2 system

manual before using the equipment. Save

all instructions.

™

vapor abrasive blast equipment. Only use with water or water

3A6844B

EN

Advertisement

Table of Contents

Summary of Contents for Graco 25P031

- Page 1 Only use with water or water with additives to inhibit corrosion or mold. For professional use only. Model 25P031 1100 psi (7.5 MPa, 75 bar) Maximum Fluid Working Pressure 100 psi (0.68 MPa, 6.8 bar) Maximum Air Working Pressure...

-

Page 2: Table Of Contents

Related Manuals ......2 25P031 ....... . 11 Warnings . -

Page 3: Warnings

Warnings Warnings The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific hazard symbols and warnings not covered in this section may appear throughout the body of this manual where applicable. - Page 4 Warnings WARNING FIRE AND EXPLOSION HAZARD Flammable fumes, such as solvent, in work area can ignite or explode. To help prevent fire and explosion: • Use equipment only in well ventilated areas. • Abrasive material exiting blast nozzle can generate sparks. When flammable liquids are used near the blast nozzle or for flushing or cleaning, keep the blast nozzle at least 20 feet (6 meters) away from explosive vapors.

-

Page 5: Component Identification

Component Identification Component Identification . 1: Component Identification Key: Ground Screw Displacement Rod Enclosed Wet Cup Tie Rod Wet Cup Fill Port Coupling Nut Fluid Outlet Tie Rod Nut Fluid Inlet Air Motor Pump Lower Sight Glass Outlet Housing Muffler 3A6844B... -

Page 6: Setup

Tighten Threaded Connections Before each use, check all hoses for wear or damage. Replace as necessary. Check that all threaded connections are tight and leak-free. Wet Cup Fill the wet cup half-full of Graco TSL. Verify the level of TSL daily. 3A6844B... -

Page 7: Troubleshooting

Troubleshooting Troubleshooting 1. Follow Pressure Relief Procedure, page 6, before checking or repairing the pump. 2. Check all possible problems and causes before disassembling the pump. Problem Cause Solution • Clear any obstructions from the Pump output is low on both strokes. Air supply lines are restricted. - Page 8 Troubleshooting Problem Cause Solution The pump “bounces” at the bottom The top pilot valve or top pilot line Verify that the pilot line is fully of the stroke. fittings are leaking or damaged. engaged into the press-to-connect fittings. Verify that the fittings are tightened to 10 in-lb (1.1 N•m).

-

Page 9: Repair

Then use another wrench to tighten the coupling nut (5). Torque to 75-80 ft-lb (31-35 N•m). 5. Reconnect all fluid hoses. 6. If the ground wire is in use, verify that the ground wire is still connected. 7. Fill wet-cup (B) half full of Graco TSL. 3A6844B... -

Page 10: Disconnect The Air Motor

Repair Disconnect the Air Motor 5. Lift the air motor (1) out of the mounting bracket. 6. Refer to your air motor manual for repair 1. Disconnect the Displacement Pump Lower, page instructions. 2. Remove the tie rods (2) from the air motor (1). Connect the Air Motor 3. -

Page 11: Parts

Parts Parts 25P031 Ref. Part Description Qty. M07DNS MOTOR, air, 4.5 in. 17B185 ROD, tie (pack of 3) 24V671 LOWER, displacement, sst 104541 NUT, lock ----- ADAPTER, pump, coupler 184132 COLLAR, coupling 114499 FITTING, adapter 24D642 MUFFLER, 1050 aodd, ice-resistant 14... -

Page 12: Kits And Accessories

Kits and Accessories Kits and Accessories Part Description 17B186 Lower Repair Kit 17B181 Sealed Wet Cup Kit 17B182 Fill Port Repair Kit 25P367PKG High Pressure Stainless Steel Fluid Filter (200 mesh) 224469 - 200 mesh (filter element only) Tube Guard Kit (25P158) Ref. -

Page 13: Dimensions

Kits and Accessories Dimensions Ref. Dimension 11.5 in. (29.0 cm) 27.75 in. (70.5 cm) 10.25 in. (26.0 cm) 9.85 in. (25.0 cm) 6.85 in. (17.5 cm) 3A6844B... - Page 14 Kits and Accessories 3A6844B...

-

Page 15: Technical Specifications

Technical Specifications Technical Specifications Stainless Steel 10:1 Pump (25P031) Metric Maximum fluid working pressure 1100 psi 7.5 MPa, 75 bar Maximum compressed air inlet pressure 100 psi 0.68 MPa, 6.89 bar Minimum compressed air inlet pressure 15 psi 0.0103 MPa, 1.03 bar Maximum compressed air temperature 150°... -

Page 16: Graco Standard Warranty

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the 25P031 and is the answer not in the manual?

Questions and answers