Summary of Contents for Fristam Pumps FCM

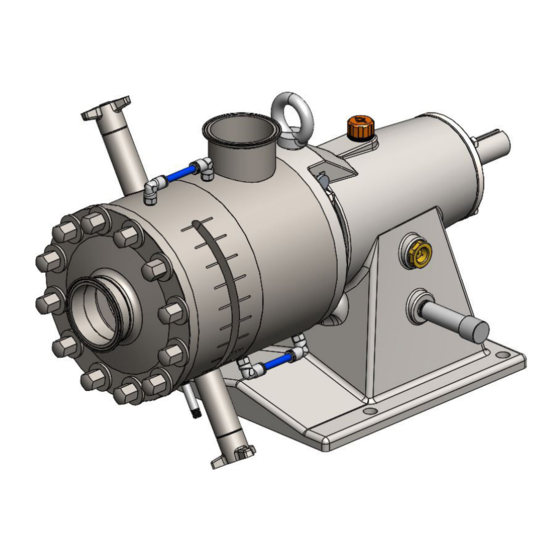

- Page 1 FCM Colloid Mill Instruction and Maintenance Manual FCM Colloid Mill (Original Instructions)

-

Page 2: Safety

FCM Colloid Mill DESCRIPTION This manual contains installation, operation and repair instructions for the Fristam FCM Colloid Mill. CAUTION: BEGIN ALL PUMP MAINTENANCE OPERATIONS BY DISCONNECTING THE ENERGY SOURCE TO THE PUMP. OBSERVE ALL LOCK OUT/TAG OUT PROCEDURES AS OUTLINED BY ANSI Z244.1-1982 AND OSHA 1910.147 TO PREVENT ACCIDENTAL START-UP AND INJURY. -

Page 3: Table Of Contents

FCM Colloid Mill TABLE OF CONTENTS Safety ..........................2 Technical Information ......................4 Pump Operations ....................... 6 Spare Parts ..........................7 Transportation ........................7 Noise Reduction ........................7 Cleaning ..........................7 Installation ..........................8 Recommended Preventive Maintenance ................12 Gap Adjustment .........................13 Drawing and Illustrations ....................14 Pump Assembly and Parts List ...................14 2VR Bearing Block Assembly and Parts List ..............15... -

Page 4: Technical Information

FCM Colloid Mill TECHNICAL INFORMATION SPECIFICATIONS Max. Inlet Pressure ....................250 PSI Max. Speed Range ....................3600 RPM Max. Viscosity....................1,000,000 cps Max. Flow Rate (product) ..................50 GPM Max. Flow Rate (CIP) ....................100 GPM Rotation ........................Reversible Mounting ......................Horizontal Max. Temperature ......................302°F Standard Fitting Size ..............3 in. cover / 3 in. housing MATERIALS OF CONSTRUCTION Major Product Contact Components .............. - Page 5 FCM Colloid Mill WOODS SURE-FLEX COUPLING ALIGNMENT TABLE A1: Woods Sure-Flex Coupling Alignment Type E Type H Sleeve Angular Angular Parallel Parallel Size Y max. - Y Y max. - Y min. min. .015 .056 1.938 .015 .070 2.375 .010 .016...

-

Page 6: Pump Operations

OPERATIONS INTENDED USE The standard Fristam FCM Colloid Mill versions are designed for use in hygienic applications. Each mill is specified according to customer specifications, including performance and materials of construction. The pump may only be used for the application it was specified for. -

Page 7: Spare Parts

Maintain good piping practices (see below). CLEANING SIP PROCESS FCM Colloid Mills should only be used for SIP (Sterilization In Place) process with the prior approval of Fristam. Suitability may depend on selected elastomers and/or process temperatures. CIP PROCESS FCM Colloid Mills are suitable for the CIP (Cleaning In Place) process. The following is a general example of the CIP process: •... -

Page 8: Installation

PIPING CAUTION: Because the FCM Mill is highly efficient, the user needs to ensure that the mill will not be over-pressurized during operation as this can cause severe damage to the mill. (Over-pressurization can occur if a valve is closed on the discharge and the mill continues to run beyond its maximum pressure rating.) The mill warranty is void for damage caused by over-pressurization. - Page 9 FCM Colloid Mill • Avoid sump areas where sediment may FIGURE 3 collect (figure 3). • Use a check or “foot” valve on the inlet side of the mill in lift applications to keep the suction piping flooded. • Avoid throttling valves in the suction piping.

- Page 10 FCM Colloid Mill ALIGNMENT In most cases, the mill will be shipped with a drive unit mounted on a baseplate. The drive and mill are aligned at the factory; however, this alignment should be checked after installation (Figure 7). Misalignment between the mill and drive can result in premature bearing failure or other damage. If the mill is not shipped with a drive unit, use a flexible coupling between the mill and drive unit.

- Page 11 FCM Colloid Mill ELECTRICAL CONNECTIONS Have an electrician connect the drive motor using sound electrical practices. Ensure that proper motor overload protection is provided. The size of the drive selected should meet the requirements of the operating conditions. A change in conditions (for example, higher viscosity product, higher differential pressure can overload the motor.

-

Page 12: Recommended Preventive Maintenance

FCM Colloid Mill RECOMMENDED PREVENTIVE MAINTENANCE RECOMMENDED SEAL MAINTENANCE Visually inspect mechanical seal daily for leakage. Replace mechanical seal annually under normal duty. Replace mechanical seal as often as required under heavy duty. When replacing ANY seal part, it is important to replace ALL seal wear parts. -

Page 13: Gap Adjustment

FCM Colloid Mill ADJUSTING THE GAP It is not necessary to disassemble the mill in order to change the width of the gap. The casing channel is marked with minimum (0.2 mm) and maximum (2.0 mm) values and percentages in between. -

Page 14: Drawing And Illustrations

FCM Colloid Mill FCM ASSEMBLY AND PARTS LIST Item No Description Cover, 3" Clamp Stator Rotor Casing Housing Bearing Block As DWG# 1265000725 Acorn Nut Washer Stud, 48mm Lon Stud, 158mm Lo O-Ring, Viton O-Ring, Viton Stud, 122mm Lo Spacer... -

Page 15: 2Vr Bearing Block Assembly And Parts List

FCM Colloid Mill 2VR BEARING BLOCK ASSEMBLY AND PARTS LIST DWG# 1265000726 Item No Description Part Number Shaft, 2VR BB 1321000404 Bearing Block, 2VR 1310600284 Front Bearing Cover, 2VR BB 1303000018 Rear Bearing Cover, 2VR BB 1303000019 Bearing Isolator 1812000047... -

Page 16: Double Mechanical Assembly

FCM Colloid Mill DOUBLE MECHANICAL SEAL ASSEMBLY DOUBLE MECHANICAL SEAL ASSEMBLY DOUBLE MECHANICAL SEAL CROSS-SECTION 1265000730... -

Page 17: Pump Disassembly

FCM Colloid Mill MILL DISASSEMBLY REMOVE THE COVER, STATOR, AND CASING • Before disassembly, adjust the stator to the maximum gap. • Disconnect the flush water supply from the pump. • Disconnect the top flex push-to- connect flush water tube from the casing. -

Page 18: Seal Replacement

FCM Colloid Mill SEAL REPLACEMENT MECHANICAL SEAL REMOVAL • Place the housing seal side up on an even surface. • Loosen the 2 seal retainer bolts • Remove the seal retainer. • Remove the flush seal from the shaft. •... -

Page 19: Pump Assembly

FCM Colloid Mill MILL ASSEMBLY HOUSING INSTALLATION • Slide the housing over the shaft until it meets the flange. Be careful not to damage the seal. • Install the flange bolts and tighten to the proper torque. • Install the rotating seal onto the shaft. -

Page 20: Stator Assembly

FCM Colloid Mill STATOR DISASSEMBLY (OPTIONAL, AS NEEDED) • Remove the gap adjustment handles without marring their outside diameters. • Remove the other 8 cover nuts and washers. • Remove the cover from the casing. • Inspect the cover gasket for damage. - Page 21 FCM Colloid Mill...

-

Page 22: Pump Maintenance Record

FCM Colloid Mill MAINTENANCE RECORD DATE SERVICE PERFORMED PERFORMED BY... -

Page 23: Warranty

All orders are subject to acceptance by Fristam Pumps USA Limited Partnership. Each Fristam Pumps item is warranted to be free from manufacturing defects for a period of one (1) year from the date of shipment, providing it has been used as recommended and in accordance with recognized piping practice, and providing it has not been worn out due to severe service, such as encountered under extremely corrosive or abrasive conditions. - Page 24 FCM Colloid Mill 2410 Parview Road • Middleton, WI 53562-2524 © 2022 Fristam Pumps USA 1-800-841-5001 • 608-831-5001 Part #: 1050000364 Website: www.fristam.com/usa Drawing # 12500000?? Email: fristam@fristampumps.com...

Need help?

Do you have a question about the FCM and is the answer not in the manual?

Questions and answers