Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for IFM Electronic PI209 Series

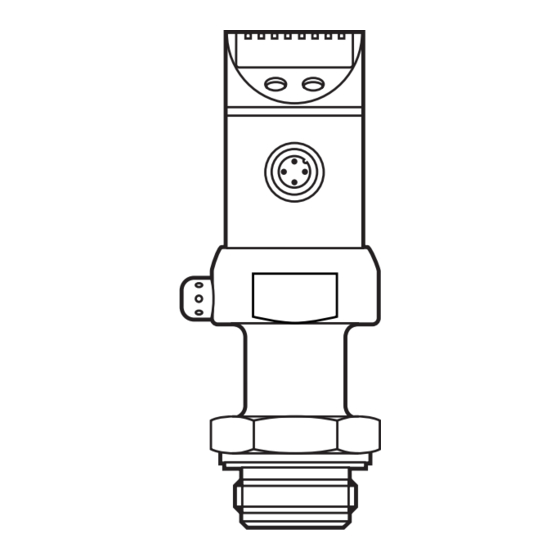

- Page 1 Operating instructions Electronic pressure sensor PI209x...

-

Page 2: Table Of Contents

Contents 1 Preliminary note ���������������������������������������������������������������������������������������������������3 1�1 Symbols used ������������������������������������������������������������������������������������������������3 2 Safety instructions �����������������������������������������������������������������������������������������������3 3 Functions and features ����������������������������������������������������������������������������������������4 3�1 Applications ���������������������������������������������������������������������������������������������������4 4 Function ���������������������������������������������������������������������������������������������������������������4 4�1 Processing of the measured signals ��������������������������������������������������������������4 4�2 Pressure monitoring / switching function �������������������������������������������������������5 4�3 Pressure monitoring/ analogue function ��������������������������������������������������������5 4�4 Diagnostic function ����������������������������������������������������������������������������������������7 5 Installation������������������������������������������������������������������������������������������������������������8 6 Electrical connection ������������������������������������������������������������������������������������������10... -

Page 3: Preliminary Note

10 Operation ���������������������������������������������������������������������������������������������������������19 10�1 Read the set parameter values �����������������������������������������������������������������19 10�2 Fault indication ������������������������������������������������������������������������������������������19 10�3 Cleaning of the filter cover �������������������������������������������������������������������������20 11 Factory setting �������������������������������������������������������������������������������������������������21 1 Preliminary note 1.1 Symbols used ► Instruction > Reaction, result […] Designation of buttons, switches or indications →... -

Page 4: Functions And Features

• The manufacturer assumes no liability or warranty for any consequences caused by tampering with the product or incorrect use by the operator� • Installation, electrical connection, set-up, programming, configuration, operation and maintenance of the product must be carried out by personnel qualified and authorised for the respective activity�... -

Page 5: 4�2 Pressure Monitoring / Switching Function

4.2 Pressure monitoring / switching function OUT1 changes its switching state if it is above or below the set switching limits (SP1, rP1)� The following switching functions can be selected: • Hysteresis function / normally open: [OU1] = [Hno] (→ fig. 1). •... - Page 6 • By teaching the analogue end point (tAEP) or setting the parameter AEP you define the measured value at which the output signal is 20 mA / 10 V (4 mA / 0 V at [InEG] / [UnEG])� Minimum distance between [ASP] and [AEP] = 25 % of the final value of the measuring range (turn down 1:4)�...

-

Page 7: 4�4 Diagnostic Function

Voltage output Factory setting Measuring range scaled U [V] U [V] P = system pressure, MAW = initial value of the measuring range, MEW = final value of the measuring range : [OU2] = [U]; : [OU2] = [UnEG] The output signal is between 0 and 10 V ([OU2] = [U]) or between 10 and 0 V ([OU2] = [UnEG]) in the set measuring range�... -

Page 8: Installation

5 Installation Ensure that no pressure is applied to the installation while mounting or removing the sensor� Please note: Display „0%“ does not mean that the system is free of pressure! Horizontal mounting recommended for high medium temperatures� Aseptoflex adapters ensure that the sensor can be connected to different process connections�... - Page 9 Mounting the Aseptoflex adapter ► Slightly grease the threads and sealing areas of the sensor and adapter with the lubricating paste (D)� The paste must be suitable and approved for the application and compatible with the elastomers used� Recommendation: Klüber paste UH1 84-201 with USDA-H1 approval for the food industry�...

-

Page 10: Electrical Connection

Welding adapter ► First weld the adapter, then mount the sensor� Follow the instructions included with the adapter� 6 Electrical connection The unit must be connected by a qualified electrician� The national and international regulations for the installation of electrical equipment must be adhered to�... -

Page 11: Operating And Display Elements

7 Operating and display elements 3 4 5 6 Mode/Enter 1 to 8: Indicator LEDs - LED 1 to LED 6 = system pressure in unit of measurement as indicated on the label� LEDs 5 to 6 not used for units with 3 adjustable units of measurement� - LED 7 not used�... -

Page 12: Menu

8 Menu 8.1 Menu structure... -

Page 13: 8�2 Menu Explanation

8.2 Menu explanation SP1/rP1 Maximum / minimum value for system pressure, at which output 1 changes its switching status� Output function for OUT1: • Switching signal for the limit values: hysteresis function [H ��] or window function [F ��], normally open [� no] or normally closed [� nc] each� •... -

Page 14: Parameter Setting

9 Parameter setting During the parameter setting process the unit remains in the operating mode� It continues its monitoring function with the existing parameters until parameter setting has been terminated� 9.1 Parameter setting general Each parameter setting requires 3 steps: Selecting parameter ►... - Page 15 ► Press [Set] and keep it pressed until the valid code no� is displayed� ► Press [Mode/Enter] briefly� Delivery by ifm electronic: no access restriction� • Locking / unlocking The unit can be locked electronically to prevent unintentional wrong settings�...

-

Page 16: 9�2 Configuring The Display (Optional)

9.2 Configuring the display (optional) ► Select [Uni] and set the unit of measurement: - [bAr], [mbAr], - [MPA], [kPA], - [PSI], - [InHO] (only PI2096, PI2097, PI2098, PI2099), - [mWS] (only PI2096, PI2097, PI2099), - [mmWS] (only PI2098)� ► Select [SELd] and set the display mode: - [P]: Pressure in the unit set in Uni�... -

Page 17: 9�3�2 Setting The Switching Limits

9.3.2 Setting the switching limits ► Select [SP1] and set the value at which OUT1 switches� ► Select [rP1] and set the value at which OUT1 switches back� rP1 is always lower than SP1� The unit only accepts values which are lower than SP1�... -

Page 18: 9�4 User Settings (Optional)

9.4 User settings (optional) 9.4.1 Zero-point calibration ► Select [COF] and set a value between -5% and 5% of the final value of the measuring range� The internal measured value “0” is shifted by this amount� As an alternative: Automatic adaptation offset (setting range 0 bar ±5%); e�g� in the event of a deviation of the mounting location of the sensor and the zero point level for level measurement�... -

Page 19: 9�5 Service Functions

9.5 Service functions 9.5.1 Reading the min./max. values for the system pressure ► Select [HI] or [LO], press [Set] briefly� [HI] = maximum value, [LO] = minimum value� Delete memory: ► Select [HI] or [LO]� ► Press [SET] until [----] is displayed� ►... -

Page 20: 10�3 Cleaning Of The Filter Cover

10.3 Cleaning of the filter cover If viscous and residues producing media clog the filter cover of the sensor (and thus reduce the measuring accuracy slightly), you can clean it� ► Unscrew the filter cover (B) (use a pair of pliers with plastic-covered jaws for this)�... -

Page 21: Factory Setting

11 Factory setting Factory setting User setting 25% VMR* 23% VMR* ASP / tASP 0% VMR* AEP / tAEP 100% VMR* COF / tCOF bAr / mbAr SELd * = the indicated percentage of the final value of the measuring range (VMR) of the corresponding sensor in bar / mbar is set�...

Need help?

Do you have a question about the PI209 Series and is the answer not in the manual?

Questions and answers