Advertisement

OPERATOR'S MANUAL

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

SERVICE KITS

Refer to Model Description Chart to match the pump material options.

637303-XX for fluid section repair (see page 4). Note: This kit also con-

tains several air motor seals which will need to be replaced.

637374-X major air valve assembly (see page 7).

637421 for air section repair (see page 6).

PUMP DATA

Models

. . . . . . . . . .

see Model Description Chart for "-XXX".

Pump Type

. . . . . . .

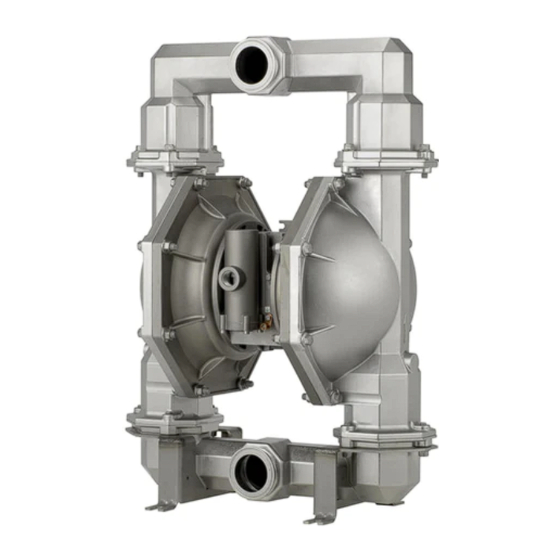

Metallic Air Operated Double Diaphragm

Material

. . . . . . . . . .

See Model Description Chart.

. . .

PM30A-CSS-XXX-C02

Weight

PM30S-CSS-XXX-C02

Maximum Air Inlet Pressure

Maximum Material Inlet Pressure

Maximum Outlet Pressure

. . . . . . . . . .

Maximum Flow Rate

. . . . . . . . . . . . . .

flooded inlet

. . . . . . . . . . . . .

Displacement / Cycle @ 100 p.s.i.g.

Maximum Particle Size

. . . . . . . . . . . .

Maximum Temperature Limits

E.P.R. / EPDM

. . . . . . . . . . .

Santoprene

. . . . . . . . . . .

R

PTFE

. . . . . . . . . . . . . . . . .

Dimensional Data

. . . . . . . . . . . . . . . .

Mounting Dimensions

. . .

10-5/32" x 12-1/16" (258 mm x 306 mm)

Noise Level @ 70 p.s.i., 50 c.p.m.

Tested with 67263 muffler assembly installed.

The pump sound pressure levels published here have been updated to an Equivalent

Continuous Sound Level (L

) to meet the intent of ANSI S1.13-1971, CAGI-PNEU-

Aeq

ROP S5.1 using four microphone locations.

NOTICE: All possible options are shown in the chart however certain com-

binations may not be recommended, consult a representative or the fac-

tory if you have questions concerning availability.

3" DIAPHRAGM PUMP

1:1 RATIO (METALLIC)

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

. . .

227.5 lbs (103.2 kgs)

. . .

267.2 lbs (121.2 kgs)

. . . . . . . . .

120 p.s.i.g. (8.3 bar)

. . . . .

10 p.s.i.g. (.69 bar)

120 p.s.i.g. (8.3 bar)

237 g.p.m. (897 l.p.m.)

275 g.p.m. (1041 l.p.m.)

. . .

2.8 gal. (10.6 lit.)

3/8" dia. (9.5 mm)

-60_ to 280_ F (-51_ to 138_ C)

-40_ to 225_ F (-40_ to 107_ C)

40_ to 225_ F (4_ to 107_ C)

see page 8

. . . .

83.0 db(A)

PM30X-X-X-C02

MODEL DESCRIPTION CHART

PM30 X - C S S - X X X - C02

CENTER SECTION MATERIAL

A - Aluminum

S - Stainless Steel

PORT

C - Tri-Clamp

FLUID CAPS & MANIFOLD MATERIAL

S - Stainless Steel

HARDWARE MATERIAL

S - Stainless Steel

SEAT MATERIAL

A - Santoprene

S - 316 Stainless Steel

BALL MATERIAL

A - Santoprene

T - PTFE

DIAPHRAGM MATERIAL

A - Santoprene

T - PTFE / Santoprene

FLUID SECTION SERVICE KIT SELECTION

EXAMPLE: MODEL # PM30S-CSS-SAA-C02

FLUID SECTION SERVICE KIT # 637303-AA

RELEASED:

2-14-05

REVISED:

5-11-10

(REV. 03)

3" DIAPHRAGM PUMP

PM30S-CSS-XXX-C02

PM30X - CSS - X X X - C02

637303 - X X

Ball

Diaphragm

Advertisement

Table of Contents

Summary of Contents for Ingersoll-Rand ARO PM30 C02 Series

- Page 1 OPERATOR’S MANUAL PM30X-X-X-C02 INCLUDING: OPERATION, INSTALLATION & MAINTENANCE RELEASED: 2-14-05 REVISED: 5-11-10 (REV. 03) 3” DIAPHRAGM PUMP 1:1 RATIO (METALLIC) READ THIS MANUAL CAREFULLY BEFORE INSTALLING, OPERATING OR SERVICING THIS EQUIPMENT. It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference. SERVICE KITS 3”...

-

Page 2: Operating And Safety Precautions

OPERATING AND SAFETY PRECAUTIONS READ, UNDERSTAND, AND FOLLOW THIS INFORMATION TO AVOID INJURY AND PROPERTY DAMAGE. Obtain Material Safety Data Sheets on all materials from the HAZARDOUS MATERIALS supplier for proper handling instructions. EXCESSIVE AIR PRESSURE HAZARDOUS PRESSURE STATIC SPARK WARNING EXPLOSION HAZARD. -

Page 3: Maintenance

GENERAL DESCRIPTION MAINTENANCE The ARO diaphragm pump offers high volume delivery even at low air Provide a clean work surface to protect sensitive internal moving pressure and a broad range of material compatibility options available. parts from contamination from dirt and foreign matter during service Refer to the model and option chart. - Page 4 PARTS LIST / PM30X-X-X-C02 FLUID SECTION FLUID SECTION SERVICE KITS (637303-XX) L KITS INCLUDE: BALLS (See Ball Option, refer to -XX in chart below), DIAPHRAGMS (See Diaphragm Option, refer to -XX in chart below), and items; 3, 19, 70, 144, 175, 196, (listed below) plus (174) and 94276 Lubriplate FML-2 grease (page 6). SEAT OPTIONS BALL OPTIONS PM30X-CSS-XXX-C02...

- Page 5 PARTS LIST / PM30X-X-X-C02 FLUID SECTION FOR THE COLOR CODE AIR MOTOR SECTION DIAPHRAGM BALL SEE PAGES 6 & 7 MATERIAL COLOR COLOR Santoprene Santoprene Green (Backup) PTFE White White 26 , G Torque Sequence 175 k 70 k 175 k 70 k 14 , 144 k 144 k...

- Page 6 PARTS LIST / PM30X-X-X-C02 AIR SECTION Indicates parts included in 637421 Air Section Service Kit shown below and items (70), (144), (175), (180) shown on page 4. AIR MOTOR PARTS Item Description Qty Part No. [Mtl] Item Description Qty Part No. [Mtl] (size) (size)

- Page 7 PARTS LIST / PM30X-X-X-C02 AIR SECTION 169 k 168 k 172 k 171 k PILOT VALVE PART GROUP k 174 k 173 244 k 243 k 199 k 132 k 173 k 174 k 141 k 200 k 241 k 128 240 , 176 k .

-

Page 8: Troubleshooting

TROUBLE SHOOTING Product discharged from exhaust outlet. Low output volume, erratic flow, or no flow. Check for diaphragm rupture. Check air supply. Check tightness of diaphragm nut. Check for plugged outlet hose. Check for kinked (restrictive) outlet material hose. Air bubbles in product discharge. Check for kinked (restrictive) or collapsed inlet material hose.

Need help?

Do you have a question about the ARO PM30 C02 Series and is the answer not in the manual?

Questions and answers