Unigas HP60 Manual Of Installation - Use - Maintenance

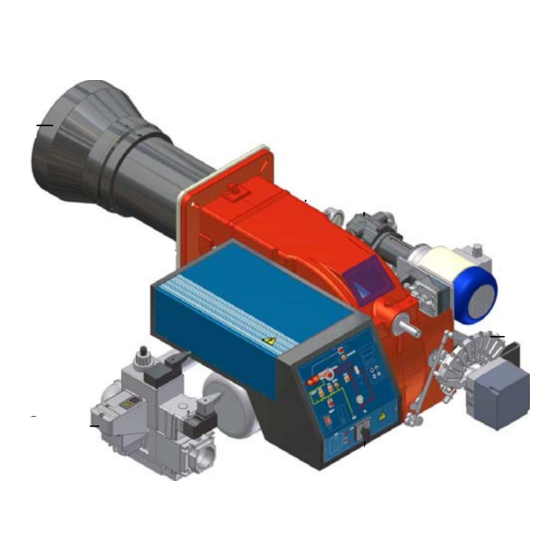

Gas / light oil dual fuel burners double stage

Hide thumbs

Also See for HP60:

- Manual of installation - use - maintenance (96 pages) ,

- Manual (36 pages) ,

- Manual of installation - use - maintenance (60 pages)

Summary of Contents for Unigas HP60

- Page 1 HP60 - HP65 - HP72 Gas / light oil dual fuel burners Double stage MANUAL OF INSTALLATION - USE - MAINTENANCE BURNERS - BRUCIATORI - BRULERS - BRENNER - QUEMADORES - ГОРЕЛКИ M039339CA Rel. 0.5 02/2023...

-

Page 2: General Introduction

DANGERS, WARNINGS AND NOTES OF CAUTION THIS MANUAL IS SUPPLIED AS AN INTEGRAL AND ESSENTIAL PART OF THE PRODUCT AND MUST BE DELIVERED TO THE USER. INFORMATION INCLUDED IN THIS SECTION ARE DEDICATED BOTH TO THE USER AND TO PERSONNEL FOLLOWING PRODUCT INSTALLATION AND MAINTENANCE. -

Page 3: Directives And Standards

3b) FIRING WITH GAS, LIGHT OIL OR OTHER FUELS DIRECTIVES AND STANDARDS GENERAL Gas burners European directives The burner shall be installed by qualified personnel and in compliance -Regulation 2016/426/UE (appliances burning gaseous fuels) with regulations and provisions in force; wrong installation can cause -2014/35/UE (Low Tension Directive) injuries to people and animals, or damage to property, for which the -2014/30/UE (Electromagnetic compatibility Directive) -

Page 4: Symbols Used

Burner data plate Type For the following information, please refer to Model Gas - Light oil burners Year European Directives the data plate: S.Number -Regulation 2016/426/UE (appliances burning gaseous fuels) burner type and burner model: must be Output Oil Flow -2014/35/UE (Low Tension Directive) reported in any communication with the Fuel... - Page 5 PART I: SPECIFICATIONS PART I: SPECIFICATIONS BURNERS FEATURES This series represents monobloc gas burners made in die-cast aluminium housing, that can burn either gas or light oil, thanks to the adjustable combustion head which allows a good performance with both fuels. They can be provided in progressive or fully-modulating version.

-

Page 6: Burner Model Identification

Burners are identified by burner type and model. Burner model identification is described as follows. Type HP60 Model AB. S. BURNER TYPE HP60, HP65, HP72 MG - Natural gas - Light oil FUEL BG - Biogas - Light oil LG - LPG - Light oil OPERATION (Available versions) -

Page 7: Technical Specifications

PART I: SPECIFICATIONS Technical Specifications HP60 HP60 HP60 HP60 BURNER TYPE MG...0.32 MG...0.40 MG...0.50 MG...0.65 170 - 880 Output min. - max. kW Nat. gas - Light oil Fuel see next paragraph Gas category - Natural gas min. - max. (Stm... - Page 8 PART I: SPECIFICATIONS HP72 HP72 HP72 HP72 BURNER TYPE MG..0.40 MG..0.50 MG...0.65 MG...0.80 330 - 1200 Output min. - max. kW Nat. gas - Light oil Fuel see next paragraph Gas category - Natural gas 35 - 127 min.- max. (Stm Gas rate- Natural gas min.

- Page 9 PART I: SPECIFICATIONS HP60 HP60 HP60 HP60 HP60 HP60 HP60 HP60 BURNER TYPE LG...0.32 LG...0.40 LG...0.50 LG...0.65 BG...0.32 BG...0.40 BG...0.50 BG...0.65 170 - 880 170 - 880 Output min. - max. kW Biogas - Light oil LPG - Light oil...

- Page 10 PART I: SPECIFICATIONS HP72 HP72 HP72 HP72 HP72 HP72 HP72 HP72 BURNER TYPE LG...0.40 LG...0.50 LG...0.65 LG...0.80 BG...0.40 BG...0.50 BG...0.65 BG...0.80 330 - 1200 330 - 1200 Output min. - max. kW Biogas - Light oil LPG - Light oil Fuel see next paragraph Gas category - LPG...

- Page 11 PART I: SPECIFICATIONS Gas categories and countries of application GAS CATEGORY COUNTRY AT, ES, GR, SE, FI, IE, HU, IS, NO, CZ, DK, GB, IT, PT, CY, EE, LV, SI, MT, SK, BG, LT, RO, TR, CH LU, PL 2E( R ) B 2ELL Fuel Type...

- Page 12 Fit a counterflange between burner and boiler. As an alternative, make a smaller hole H, but greather than Y and fit the blast tube from the internal side of boiler. B*: SPECIAL blast tube lengths must be agreed with Cib Unigas...

- Page 13 HP60, HP65, HP72 (max output > 1200kW) Fig. 3 - 3I2MG25 Hydraulic diagram OIL TRAIN Filter Flexible hose Pump and pressure governor Electrical motor Solenoid valve Solenoid valve oil inlet Pressure gauge Pressure governor Solenoid valve oil outlet Pressure switch One-way valve 16.1...

- Page 14 PART I: SPECIFICATIONS How to read the burner “Performance curve” To check if the burner is suitable for the boiler to which it must be instal- Campo di lavoro bruciatori lled, the following parameters are needed: Tipo P60 Mod. M-xx.x.IT.A.0.50 - M-.xx.x.IT.A.0.65 furnace input, in kW or kcal/h (kW = kcal/h / 860);...

-

Page 15: Performance Curves

PART I: SPECIFICATIONS Performance Curves HP60 HP65 HP72 ...0.xx HP72 ..1.xx To get the input in kcal/h, multiply value in kW by 860. Data are referred to standard conditions: atmospheric pressure at 1013mbar, ambient temperature at 15°C NOTE: The performance curve is a diagram that represents the burner performance in the type approval phase or in the laboratory tests, but does not represent the regulation range of the machine. - Page 16 Power kW Potenza / Output (kW) Pressure in the Network / gas flow rate curves (natural gas) HP60 HP65 HP72 ...0.xx HP72 ...1.xx Caution: the gas rate value is quoted on the x-axis, the related network pressure is quoted on the y-axis (pressure value in the combustion chamber is not included).

- Page 17 PART I: SPECIFICATIONS Combustion head gas pressure curves depending on the flow rate The curves referred to the gas pressure in the combustion head, depending on the gas flow rate, are referred to the burner properly adjusted (percentage of residual O in the flues as shown in the “Recommended combustion values”...

- Page 18 PART I: SPECIFICATIONS Pressure - rate in combustion head curves (natural gas) Curves are referred to pressure = 0 mbar in the combustion chamber! HP60 HP65 HP72...

- Page 19 PART II: INSTALLATION PART II: INSTALLATION MOUNTING AND CONNECTING THE BURNER Transport and storage ATTENTION! The equipment must be installed in compliance with the regulations in force, following the manufac- turer’s instructions, by qualified personnel. All handling operations must be carried out with appropriate resources and qualified personnel ATTENTION: Use intact and correctly dimensioned hoisting equipment, conforms to the local regulations and health and safety regulations.

- Page 20 PART II: INSTALLATION Keys Burner Fixing nut Washer Sealing gasket Stud bolt Blast tube The burner is designed to work positioned according to the picture below. For different installations, please contact the Technical Department. SIDE UP SIDE DOWN Note: the figure is indicative only. Matching the burner to the boiler The burners described in this manual have been tested with combustion chambers that comply with EN676 regulation and whose dimensions are described in the diagram .

-

Page 21: Assembling The Gas Train

PART II: INSTALLATION GAS TRAIN CONNECTIONS Referring to the P&ID of the burner, execute the connection. WARNING: BEFORE EXECUTING THE CONNECTIONS TO THE GAS PIPE NETWORK, BE SURE THAT THE MANUAL CUTOFF VALVES ARE CLOSED. Assembling the gas train gas supply network ”direction”... -

Page 22: Mounting Positions

PART II: INSTALLATION MULTIBLOC DUNGS MB-DLE 405..412 Mounting 1. Mount flange onto tube lines: use appropriate sealing agent (see Fig. 8); 2. insert MB-DLE: note position of O rings (see Fig. 8); 3. tighten screws A, B, C and D (Fig. 6 - Fig. 7), accordind to the mounting positions (Fig. 9); 4. - Page 23 PART II: INSTALLATION Siemens VGD20.. and VGD40.. gas valves - with SKP2.. (pressure governor) Mounting When mounting the VGD.. double gas valve, two flanges are required (as for VGD20.. model, the flanges are threaded); to prevent cuttings from falling inside the valve, first fit the flanges to the piping and then clean the associated parts; install the valve;...

- Page 24 PART II: INSTALLATION Gas Filter (if provided) The gas filters remove the dust particles that are present in the gas, and prevent the elements at risk (e.g.: burner valves, counters and regulators) from becoming rapidly blocked. The filter is normally installed upstream from all the control and on-off devices. ATTENTION: it is reccomended to install the filter with gas flow parallel to the floor in order to prevent dust fall on the safety valve during maintenance operation.

- Page 25 PART II: INSTALLATION OIL TRAIN CONNECTIONS Hydraulic diagrams for light oil supplying circuits Fig. 15 - Gravity circuit Fig. 16 - Ring circuit Fig. 17 - Suction circuit Manual valve Light oil filter Light oil feeding pump One way valve Flexible hoses Relief valve NOTE: in plants where gravity or ring feed systems are provided, install an automatic interception device.

- Page 26 PART II: INSTALLATION Installation diagram of light oil pipes PLEASE READ CAREFULLY THE “WARNINGS” CHAPTER AT THE BEGINNING OF THIS MANUAL. From tank To tank Fig. 18 - Double-pipe system The burner is supplied with filter and flexible hoses, all the parts upstream the filter and downstream the return flexible hose, must be installed by the customer.

- Page 27 PART II: INSTALLATION About the use of fuel pumps Do not use fuel with additives to avoid the possible formation over time of compounds which may deposit between the gear teeth, thus obstructing them. After filling the tank, wait before starting the burner. This will give any suspended impurities time to deposit on the bottom of the tank, thus avoiding the possibility that they might be sucked into the pump.

- Page 28 PART II: INSTALLATION Connecting the oil flexible hoses to the pump To connect the flexible oil hoses to the pump, proceed as follows, according to the pump provided: remove the closing nuts A and R on the inlet and return connections of the pump; screw the rotating nut of the two flexible hoses on the pump being careful to avoid exchanging the lines: see the arrows marked on the pump.

-

Page 29: Electrical Connections

PART II: INSTALLATION ELECTRICAL CONNECTIONS WARNING! Respect the basic safety rules. make sure of the connection to the earthing system. do not reverse the phase and neutral connections. fit a differential thermal magnet switch adequate for connection to the mains. WARNING! before executing the electrical connections, pay attention to turn the plant’s switch to OFF and be sure that the burner’s main switch is in 0 position (OFF) too. - Page 30 PART III: OPERATION PART III: OPERATION WARNING: before starting the burner up, be sure that the manual cutoff valves are open and check that the pressure upstream the gas train complies the value quoted on paragraph “Technical specifications”. Be sure that the mains switch is closed.

-

Page 31: Fuel Selection

PART III: OPERATION Keys Main switch (0=Off, 1=GAS, 2=OIL) Lock-out LED Hi-flame operation LED Lo-flame operation LED “Ignition transformer operation” LED “Fan motor overload tripped” LED Gas valves EV2 operation signalling lamp Gas valves EV1 operation signalling lamp Gas pressure switch signal lamp Gas proving system lockout signalling lamp EVG1 solenoid valve operation LED EVG2 solenoid valve operation LED... - Page 32 PART III: OPERATION AIR FLOW AND FUEL ADJUSTMENT WARNING! During commissioning operations, do not let the burner operate with insufficient air flow (danger of formation of carbon monoxide); if this should happen, make the fuel decrease slowly until the normal combustion values are achieved.

- Page 33 PART III: OPERATION ADJUSTMENT PROCEDURE FOR LIGHT OIL OPERATION The oil flow rate can be adjusted choosing a nozzle that suits the boiler/utilisation output and setting the delivery and return pressure values according to the ones quoted on the following charts. NOZZLE HIGH FLAME LOW FLAME...

- Page 34 PART III: OPERATION NOZZLE SUPPLY PRESSURE = 20 bar Example (Bergonzo): if a 220kg/h flow rate BERGONZO nozzle is provided, set the return pressure at 11bar, supply at 20bar on the delivery to get a 220kg/h flow rate. If the return pressure needed is 5bar, instead, act on the V adjusting screw on the pressure gover- nor.

- Page 35 PART III: OPERATION Fig. 20 Example (Bergonzo): if a 140kg/h flow rate BERGONZO 45° nozzle is provided, set the return pressure at 13bar, supply at 20bar on the delivery to get a 110kg/h flow rate. If the return pressure needed is 5bar, instead, act on the adjusting screw on the pressure gover- nor.

- Page 36 PART III: OPERATION FLUIDICS KW3...45° NOZZLE SUPPLY PRESSURE = 20 bar. VISCOSITY AT NOZZLE = 5 cSt The nominal size of the nozzle is indicated at the ends of the curve Pressure on return (bar) Pressure on return (bar) Pressure on return (bar)

- Page 37 PART III: OPERATION FLUIDICS KW3...45° NOZZLE SUPPLY PRESSURE = 20 bar. VISCOSITY AT NOZZLE = 5 cSt The nominal size of the nozzle is indicated at the ends of the curve Pressure on return (bar) Pressure on return (bar) Pressure on return (bar)

- Page 38 PART III: OPERATION FLUIDICS KW3...60° NOZZLE SUPPLY PRESSURE = 20 bar. VISCOSITY AT NOZZLE = 5 cSt The nominal size of the nozzle is indicated at the ends of the curve Pressure on return (bar)

- Page 39 PART III: OPERATION FLUIDICS KW3...60° NOZZLE SUPPLY PRESSURE = 20 bar. VISCOSITY AT NOZZLE = 5 cSt The nominal size of the nozzle is indicated at the ends of the curve Pressure on return (bar) The nominal size of the nozzle is indicated at the ends of the curve Pressure on return (bar)

- Page 40 PART III: OPERATION FLUIDICS KW3...60° NOZZLE SUPPLY PRESSURE = 20 bar. VISCOSITY AT NOZZLE = 5 cSt The nominal size of the nozzle is indicated at the ends of the curve Pressure on return (bar) The nominal size of the nozzle is indicated at the ends of the curve Pressure on return (bar) The nominal size of the nozzle is indicated at the ends of the...

- Page 41 PART III: OPERATION Double-stage burners with the electrical panel open, prime the oil pump acting directly on the related CP contactor (see next picture): check the pump motor rotation and keep pressing for some seconds until the oil circuit is charged; bleed the air from the M pressure gauge port by loosing the cap without removing it, then release the contactor.

- Page 42 PART III: OPERATION Pressure gauge port Fig. 21 Fig. 22 - Oil manual governor D Adjusting screw cap Pressure adjusting screw M Pressure gauge port VT Needle screw B Return to tank CReturn from nozzle Fig. 23 always checking the combustion values, adjust the low flame air flow rate by means of the actuator ST1 (Berger)/III (Siemens) cam;...

- Page 43 PART III: OPERATION Maximum oil pressure switch The oil pressure switch on the return line, checks that the pressure does not exceed a default value. This value must not be higher than the maximum acceptable pressure on the return line (this value is reported on the specification table). A pressure change on the return line could affect the combustion parameters: for this reason, the pressure switch must be set, say, at 20% over the pressure recorded during the combustion adjustment.

-

Page 44: Adjustments For Gas Operation

PART III: OPERATION ADJUSTMENTS FOR GAS OPERATION Adjustments - brief description Check that the combustion parameters are in the suggested limits. .Check the flow rate measuring it on the counter or, if it was not possible, verifying the combustion head pressure by means of a differential pressure gauge. - Page 45 PART III: OPERATION Fig. 24 Now adjust the pressure switches . 10 In the case that the flue gas temperature is not the one required, go back to the light oil operation and adjust the oil flow rate as to meet the flue gas temperature values reqested.

- Page 46 PART III: OPERATION Adjusting the maximum gas pressure switch (when provided) To calibrate the maximum pressure switch, proceed as follows according to its mounting position: remove the pressure switch plastic cover; if the maximum pressure switch is mounted upstreaam the gas valves: measure the gas pressure in the network, when flame is off; by means of the adjusting ring nut VR, set the value read, increased by the 30%.

- Page 47 PART III: OPERATION (HP72) Center head holes gas flow regulation (LPG burners) To adjust the gas flow, partially close the holes, as follows: loosen the three V screws that fix the adjusting plate D; insert a screwdriver on the adjusting plate notches and let it move CW/CCW as to open/close the holes; once the adjustmet is performed, fasten the V screws.

- Page 48 PART IV: MAINTENANCE PART IV: MAINTENANCE WARNING: ALL OPERATIONS ON THE BURNER MUST BE CARRIED OUT WITH THE MAINS DISCONNECTED AND THE FUEL MANAUL CUTOFF VALVES CLOSED! ATTENTION: READ CAREFULLY THE “WARNINGS” CHAPTER AT THE BEGINNIG OF THIS MANUAL. At least once a year carry out the maintenance operations listed below. In the case of seasonal servicing, it is recommended to carry out the maintenance at the end of each heating season;...

- Page 49 PART IV: MAINTENANCE Gas filter maintenance ATTENTION: Before opening the filter, close the manual cutoff valve downstream the filter and bleed the gas; check that inside the filter there is no pressurised gas. To clean or remove the filter, proceed as follows: remove the cap unscrewing the fixing screws (A);...

- Page 50 PART IV: MAINTENANCE Removing the filter in the MULTIBLOC DUNGS MB-DLE 415 - 420 B01 1” 1/2 - 2” Check the filter at least once a year! Change the filter if the pressure difference between pressure connection 1 and 2 (Fig. 28-Fig. 29) Δp> 10 mbar. Change the filter if the pressure difference between pressure connection 1 and 2 (Fig.

- Page 51 PART IV: MAINTENANCE Replacing the spring in the gas valve group To replace the spring in the gas valve group,proceed as follows: Carefully twist the protection cap 1 and the O-ring 2. remove the “set value” spring 3 from housing 4. Replace spring 3.

- Page 52 ATTENTION: avoid the ignition and detection electrodes to contact metallic parts (blast tube, head, etc.), other- wise the boiler’s operation would be compromised. Check the electrodes position after any intervention on the combustion head. Adjust the electrodes position, according to the quotes shown othe next picture. HP60 LG.. 10÷ HP65 LG.. 3÷4 3÷4...

- Page 53 ATTENTION: avoid the ignition and detection electrodes to contact metallic parts (blast tube, head, etc.), other- wise the boiler’s operation would be compromised. Check the electrodes position after any intervention on the combustion head. Adjust the electrodes position, according to the quotes shown othe next picture. HP60 MG.. - HP65 MG.. 3÷4 3÷4 HP72 MG..

-

Page 54: Seasonal Stop

PART IV: MAINTENANCE Checking the detection current To check the detection signal follow the scheme in the picture below. If the signal is less than the value indicated, check the position of the detection electrode or detector, the electrical contacts and, if necessary, replace the electrode or the detector. Control box Minimum detection signal Siemens LME21-22... -

Page 55: Wiring Diagrams

PART IV: MAINTENANCE WIRING DIAGRAMS Refer to the attached wiring diagrams. WARNING 1 - Electrical supply 230V / 400V 50Hz 3N a.c. 2 - Do not reverse phase with neutral 3 - Ensure burner is properly earthed... - Page 58 PART IV: MAINTENANCE TROUBLESHOOTNG GUIDE - Light oil operation * No electric power supply * Wait for electric power supply is back * Main switch open * Close the switch * Thermostats open * Check set points and thermostat connections * Bad thermostat set point or broken thermostat * Set or replace the thermostat * No gas pressure...

- Page 59 PART IV: MAINTENANCE TROUBLESHOOTNG GUIDE - Gas operation * No electric power supply * Wait until power supply is back * Main switch open * Close the switch * Thermostats open * Check set points and thermostat connections * Bad thermostat set point or broken thermostat * Set or replace the thermostat * No gas pressure * Restore gas pressure...

-

Page 60: Start-Up Program

APPENDIX SIEMENS LME11/21/22 CONTROL BOX The series of equipment LME.. is used for the starup and supervisione of START-UP PROGRAM 1- or 2- stage gas burners. The series LME.. is interchangeable with the series LGB.. and LMG.., all diagrams and accessories are interchangea- As far as the startup program, see its time diagram: ble. - Page 61 LME11 control sequence LME21 control sequence B´ B´ SB / R SB / R W / GP W / GP (LR) BV2 7101d05/0206 Control sequence Waiting time LME22 control sequence Purge time B´ TSA Ignition safety time SB / R Preignition time W / GP Postignition time...

- Page 62 LME11 connection diagram Connection diagram Error message (alarm) Fuel valve PC control EK2 Remote lockout reset button RESET Flame signal Gas pressure switch Air pressure switch Load controller K2/1 K2/2 Fan motor Control thermostat/pressurestat R / W Safety limit thermostat Limit thermostat /pressure switch Ignition transformer 7101 24 /0606...

- Page 63 CONTROL PROGRAM IN THE EVENT OF FAULT CONTROL BOX LOCKED If a fault occurs, all outputs will immediately be deactivated (in less In the event of lockout, the LME.. remains locked and the red signal lamp than 1s). (LED) will light up.The burner control can immediately be reset. This state After an interruption of power, a restart will be made with the full pro- is also mantained in the case fo mains failure.

- Page 64 C.I.B. UNIGAS S.p.A. Via L.Galvani, 9 - 35011 Campodarsego (PD) - ITALY Tel. +39 049 9200944 - Fax +39 049 9200945/9201269 web site: www.cibunigas.it - e-mail: cibunigas@cibunigas.it Note: specifications and data subject to change. Errors and omissions excepted.

Need help?

Do you have a question about the HP60 and is the answer not in the manual?

Questions and answers