Summary of Contents for Pepperl+Fuchs SIL LVL-M4

- Page 1 Functional Safety Vibration Limit Switch LVL-M4 with Electronic Insert FEL68 Manual ISO9001...

- Page 2 Phone: +49 621 776 - 0 E-mail: info@de.pepperl-fuchs.com North American Headquarters Pepperl+Fuchs Inc. 1600 Enterprise Parkway Twinsburg, Ohio 44087 Phone: +1 330 425-3555 E-mail: sales@us.pepperl-fuchs.com Asia Headquarters Pepperl+Fuchs Pte. Ltd. P+F Building 18 Ayer Rajah Crescent Singapore 139942 Phone: +65 6779-9091 E-mail: sales@sg.pepperl-fuchs.com https://www.pepperl-fuchs.com...

-

Page 3: Table Of Contents

Functional Safety LVL-M4 with Electronic Insert FEL68 Contents Introduction ............5 Content of this Document . - Page 4 Functional Safety LVL-M4 with Electronic Insert FEL68 Contents Proof Test ............18 Basic Test Sequence .

-

Page 5: Introduction

Additionally, the following parts may belong to the documentation, if applicable: • EU-type examination certificate • EU declaration of conformity • Attestation of conformity • Certificates • Control drawings • FMEDA report • Assessment report • Additional documents For more information about Pepperl+Fuchs products with functional safety, see www.pepperl-fuchs.com/sil. -

Page 6: Safety Information

Functional Safety LVL-M4 with Electronic Insert FEL68 Introduction Safety Information Target Group, Personnel Responsibility for planning, assembly, commissioning, operation, maintenance, and dismounting lies with the plant operator. Only appropriately trained and qualified personnel may carry out mounting, installation, commissioning, operation, maintenance, and dismounting of the product. The personnel must have read and understood the instruction manual and the further documentation. - Page 7 Functional Safety LVL-M4 with Electronic Insert FEL68 Introduction Informative Symbols Note This symbol brings important information to your attention. Action This symbol indicates a paragraph with instructions. You are prompted to perform an action or a sequence of actions. ▶ Reference to another section or to further documentation Permitted Procedures, processes or actions that are permitted.

-

Page 8: Supplementary Documentation

Functional Safety LVL-M4 with Electronic Insert FEL68 Supplementary Documentation Supplementary Documentation Note For further information is available on the product detail page of the devices on the Internet at www.pepperl-fuchs.com. Enter the order designation in the search field Select the appropriate product →... -

Page 9: Requirements And Assumptions

Functional Safety LVL-M4 with Electronic Insert FEL68 Requirements and Assumptions Requirements and Assumptions Permitted Device Types The details pertaining to functional safety in this manual relate to the device options listed below and are valid as of the specified firmware and hardware versions. Unless otherwise specified, all subsequent versions can also be used for safety functions. -

Page 10: Identification Marking

Functional Safety LVL-M4 with Electronic Insert FEL68 Requirements and Assumptions Additional Options (12) Additional approval SIL Functional Safety Identification Marking SIL-certified devices are marked with the SIL logo on the nameplate. Safety Function The device's safety functions are: • Maximum level monitoring (overfill prevention, MAX detection) •... - Page 11 Functional Safety LVL-M4 with Electronic Insert FEL68 Requirements and Assumptions ρ [g/cm³] 1.000 0.100 0.010 0.001 ±0 +120 +180 +240 +300 [°C] +140 +248 +356 +464 +527 [°F] Figure 3.1 Density of gas phase above the medium Switch position for density 0.7 g/cm³ Switch position for density 0.5 g/cm³...

- Page 12 Functional Safety LVL-M4 with Electronic Insert FEL68 Requirements and Assumptions 3.4.3 Solid Particles - Heterogeneous Mixtures (only for MIN Detection) The medium may not contain solid particles with a diameter greater than 5 mm (0.2 inch). Solid particles lodged between the tines of the tuning fork can have the effect that the demand mode of the safety function is not detected and the device will not switch as intended.

-

Page 13: Useful Lifetime Of Electric Components

Functional Safety LVL-M4 with Electronic Insert FEL68 Requirements and Assumptions 3.4.9 EMC Compatibility The device is certified in accordance with IEC 61326-3-1 and is thus suitable for general industrial, safety-related applications. If the specified electromagnetic ambient conditions are exceeded, the switch status might not be reliably detected. An unshielded cable can be used between the devices in these environmental conditions. -

Page 14: Characteristic Safety Values

Functional Safety LVL-M4 with Electronic Insert FEL68 Characteristic Safety Values Characteristic Safety Values Device with Electronic Insert FEL68 Parameters Characteristic values Assessment type and Full assessment documentation Device type Mode of operation Low demand mode oder high demand mode Safety function Overfill prevention, MAX detection or dry running protection, MIN detection Valid hardware version 01.00.ww (ww: any double number) -

Page 15: Commissioning

Functional Safety LVL-M4 with Electronic Insert FEL68 Commissioning Commissioning Requirements for Personnel The personnel for installation, commissioning, diagnostics and maintenance must fulfill the following requirements: • Trained, qualified specialists must have a relevant qualification for this specific function and task. •... - Page 16 Functional Safety LVL-M4 with Electronic Insert FEL68 Commissioning 5.5.1 MIN/MAX Detection Mode >0,7 – >0,5 >0,7 >0,5 – Figure 5.1 Selection of MIN/MAX detection mode Additional safety equipment 5.5.2 Density Mode – >0,7 >0,5 U= 0 V Figure 5.2 Selection of density mode Default setting (density >0.7 g/cm³), always use this setting where possible.

-

Page 17: Operation

Functional Safety LVL-M4 with Electronic Insert FEL68 Operation Operation Danger! Danger to life from missing safety function If the safety loop is put out of service, the safety function is no longer guaranteed. • Do not deactivate the device. • Do not bypass the safety function. -

Page 18: Proof Test

Functional Safety LVL-M4 with Electronic Insert FEL68 Proof Test Proof Test Warning! The safety function can be impaired. The functional integrity of the device in the SIL mode must be verified during commissioning, when changes are made to safety-related parameters, as well as at appropriate time intervals. The operator must determine the time intervals. -

Page 19: Basic Test Sequence

Functional Safety LVL-M4 with Electronic Insert FEL68 Proof Test Basic Test Sequence Figure 7.1 Basic test sequence Status OK Output signal for status OK? Establish demand mode Output signal for demand mode? Re-install the sensor that was removed (optional) Establish status OK Output signal for status OK? Note The output signal can be evaluated based on the response of the following components... -

Page 20: Test Sequence A, Min Detection

Functional Safety LVL-M4 with Electronic Insert FEL68 Proof Test Test Sequence A, MIN Detection • Approach the level or • Remove and immerse in a medium of similar density and viscosity Proof Test Procedure, Step 1 Raise the level or immerse the tuning fork of the sensor that has been removed into the medium until the tuning fork is fully covered. -

Page 21: Test Sequence A, Max Detection

Functional Safety LVL-M4 with Electronic Insert FEL68 Proof Test Test Sequence A, MAX Detection • Approach the level or • Remove and immerse in a medium of similar density and viscosity Proof Test Procedure, Step 1 Lower the level or take the tuning fork of the sensor that has been removed out of the medium until the tuning fork is completely free. -

Page 22: Test Sequence B, Simulation With Test Button Or Test Magnet

Functional Safety LVL-M4 with Electronic Insert FEL68 Proof Test Test Sequence B, Simulation with Test Button or Test Magnet on the Device No change of level in the vessel is necessary for this sequence. Note the following for the test sequences: Test sequence B (simulation) is not permitted for a commissioning test. -

Page 23: Verification Criterion

Functional Safety LVL-M4 with Electronic Insert FEL68 Proof Test Verification Criterion If one of the test criteria from the test sequences described above is not fulfilled, the device may no longer be used as part of a safety instrumented system. •... -

Page 24: Repair And Fault Handling

Repair means restoring functional integrity by replacing defective components. Components may be repaired/replaced by the customer's technical staff if genuine spare parts from Pepperl+Fuchs are used (they can be ordered by the end user) and the appropriate installation instructions are followed. -

Page 25: Decommissioning

WEEE as unsorted municipal waste. Do not dispose of products bearing this marking as unsorted municipal waste. Instead, return them to Pepperl+Fuchs for disposal under the applicable conditions. -

Page 26: Appendix

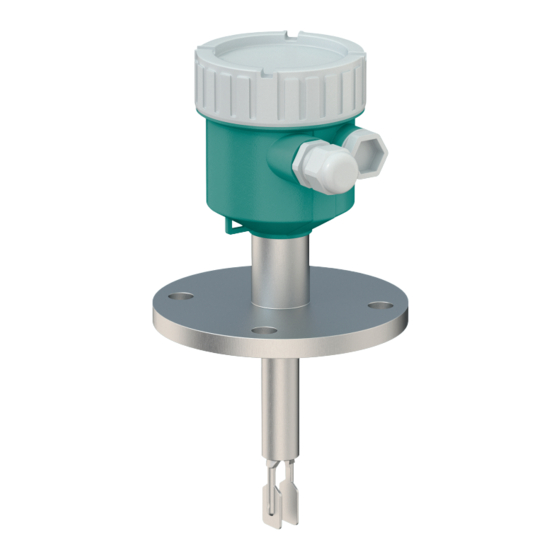

Functional Safety LVL-M4 with Electronic Insert FEL68 Appendix Appendix Structure of the Measuring System 9.1.1 System Components The measuring system's devices are shown in the following diagram (example). Figure 9.1 System components Measuring device/sensor 9.1.2 Description of Application as a Safety Instrumented System The sensor's tuning fork vibrates at its intrinsic frequency. - Page 27 Functional Safety LVL-M4 with Electronic Insert FEL68 Appendix 9.1.3 Measurement Function Choice of operating modes: • MIN detection The measuring system is used to protect against a level that is too low (e. g. pump dry running protection, protection against emptying or protection against insufficient filling).

- Page 28 Pepperl+Fuchs Quality Download our latest policy here: www.pepperl-fuchs.com/quality FY01000O/98/EN/02.20 www.pepperl-fuchs.com © Pepperl+Fuchs · Subject to modifications Printed in Germany / DOCT-8304...

Need help?

Do you have a question about the SIL LVL-M4 and is the answer not in the manual?

Questions and answers