Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Aerotech AOM360D Series

-

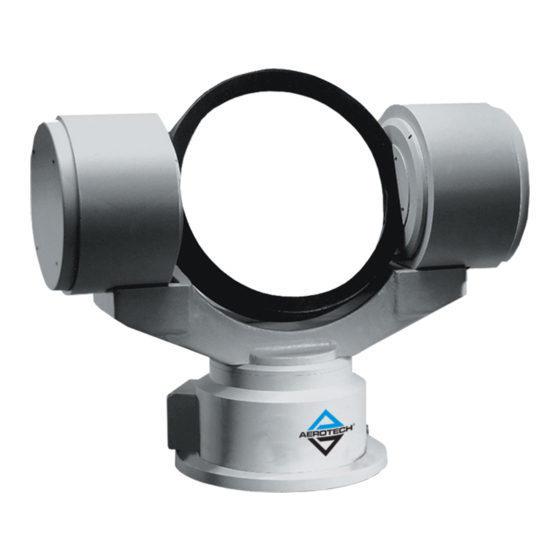

Page 1: Aom360D Series Direct-Drive Gimbals

AOM360D Series Direct-Drive Gimbals HARDWARE MANUAL Revision 2.00... - Page 2 Global Technical Support Portal for information and support about your Aerotech, Inc. products. The website supplies software, product manuals, Help files, training schedules, and PC-to-PC remote technical support. If necessary, you can complete Product Return (RMA) forms and get information about repairs and spare or replacement parts.

-

Page 3: Table Of Contents

Hardware Manual AOM360D Table of Contents AOM360D Series Direct-Drive Gimbals Table of Contents List of Figures List of Tables EU Declaration of Incorporation UKCA Declaration of Incorporation Safety Procedures and Warnings Installation and Operation Electrical Warnings Motor-Related Warnings Pinch Points Handling and Storage Chapter 1: Overview 1.1. -

Page 4: List Of Figures

Figure 2-2: AOM360D-300 Dimensions Figure 2-3: AOM360D-400 Dimensions Figure 2-4: AOM360D-500 Dimensions Figure 2-5: View of AOM360DShowing Mounting Holes Figure 3-1: Motor and Feedback Wiring (AZ/EL) Figure 3-2: Feedback Interconnection Drawing Figure 3-3: Machine Direction Figure 3-4: Hall Phasing Diagram www.aerotech.com... -

Page 5: List Of Tables

Thermistor Specifications Table 3-7: Inductosyn Specifications Table 3-8: Limit Switch Specifications Table 3-9: S-180-44 [EL] and S-180-69 [AZ] Rotary Motor Specifications (-200 and -300 options) Table 3-10: S-240-63 [EL] and S-240-83 [AZ] Rotary Motor Specifications (-400 and -500 options) 37 www.aerotech.com... -

Page 6: Eu Declaration Of Incorporation

AOM360D Hardware Manual EU Declaration of Incorporation Manufacturer Aerotech, Inc. 101 Zeta Drive Pittsburgh, PA 15238-2811 herewith declares that the product: AOM360D gimbal is intended to be incorporated into machinery to constitute machinery covered by the Directive 2006/42/EC as amended;... -

Page 7: Ukca Declaration Of Incorporation

Hardware Manual AOM360D UKCA Declaration of Incorporation Manufacturer Aerotech, Inc. 101 Zeta Drive Pittsburgh, PA 15238-2811 herewith declares that the product: AOM360D gimbal To which this declaration relates, meets the essential health and safety requirements and is in conformity with the relevant UK Legislation listed below:... -

Page 8: Safety Procedures And Warnings

To find the newest information about this product, refer to www.aerotech.com. If you do not understand the information in this manual, contact Aerotech Global Technical Support. IMPORTANT: This product has been designed for light industrial manufacturing or laboratory environments. -

Page 9: Installation And Operation

WARNING: Trip Hazard! Route, house, and secure all cables, duct work, air, or water lines. Failure to do so could introduce trip hazards around the system that could result in physical injury or could damage the equipment. www.aerotech.com... -

Page 10: Electrical Warnings

It is the responsibility of the End User/System Integrator to make sure that stages are properly connected and grounded per Engineering Standards and applicable safety requirements. It is the responsibility of the End User/System Integrator to configure the system drive or controller within the Aerotech motor/stage electrical and mechanical specifications. www.aerotech.com... -

Page 11: Motor-Related Warnings

Hardware Manual AOM360D Motor-Related Warnings Aerotech motors are capable of producing high forces and velocities. Obey all warnings and all applicable codes and standards when you use or operate a stage or system that incorporates Aerotech motors. DANGER: Mechanical Hazard! Personnel must be made aware of the mechanical hazards during set up or when you do service to the stage. -

Page 12: Pinch Points

(during normal operation, for example). when the system is moved manually (during the installation process or when you do maintenance, for example). Motors are capable of very high speeds and acceleration rates. Figure 1: Typical Pinch Point Locations www.aerotech.com... -

Page 13: Handling And Storage

Use a cart, dolly, or similar device to move the stage to a new location. Gently set the stage on a smooth, flat, and clean surface. Use compressed nitrogen or clean, dry, oil- free air to remove any dust or debris that has collected during shipping. www.aerotech.com... -

Page 14: Storage

Before you operate the stage, let it stabilize at room temperature for at least 12 hours. This will ensure that all of the alignments, preloads, and tolerances are the same as they were when they were tested at Aerotech. Each stage has a label listing the system part number and serial number. These numbers contain information necessary for maintenance or system hardware and software updates. -

Page 15: Chapter 1: Overview

Hardware Manual AOM360D Chapter 1: Overview Table 1-1: Model Numbers and Ordering Options AOM360D Optical Mount Cell Size (Required) -200 200 mm diameter cell -300 300 mm diameter cell -400 400 mm diameter cell -500 500 mm diameter cell www.aerotech.com... -

Page 16: Environmental Specifications

Indoor use only 1.2. Accuracy and Temperature Effects Aerotech products are designed for and built in a 20°C (68°F) environment. Temperature changes could cause a decrease in performance or permanent damage to the gimbal. At a minimum, the environmental temperature must be controlled to within 0.25ºC per 24 hours to ensure the gimbal specifications are repeatable over an extended period of time. -

Page 17: Basic Specifications

Paint: Textured Epoxy (Polane-T), Pebble Grey Color (1) Special cell adapters and slip ring assemblies available by special order. (2) Requires Aerotech controls and axis calibration. (3) Maximum speed based on stage capability. Maximum application velocity may be limited by system data rate and system resolution. -

Page 18: Vacuum Operation

6. To reduce outgassing during the initial pump-down to vacuum pressure, Aerotech recommends that you bake out vacuum systems when you first install them into the vacuum chamber. Bake the vacuum components at 60 °C for 24 to 48 hours to desorb water vapor from surfaces and... -

Page 19: Export Restrictions

This product is export controlled by United States Commerce Department export regulations. If you are from a non-US country and wish to make a purchase, contact Aerotech to determine if an export license is required. People in countries embargoed by the United States cannot purchase and import one of these products. - Page 20 AOM360D Hardware Manual This page intentionally left blank. www.aerotech.com...

-

Page 21: Chapter 2: Installation

Chapter 2: Installation The gimbal installation must be in accordance with the instructions provided by this manual and any accompanying documentation. Failure to follow these instructions could result in injury or damage to the equipment. 2.1. Dimensions Figure 2-1: AOM360D-200 Dimensions www.aerotech.com... -

Page 22: Figure 2-2: Aom360D-300 Dimensions

AOM360D Hardware Manual Figure 2-2: AOM360D-300 Dimensions www.aerotech.com... -

Page 23: Figure 2-3: Aom360D-400 Dimensions

Hardware Manual AOM360D Figure 2-3: AOM360D-400 Dimensions www.aerotech.com... -

Page 24: Figure 2-4: Aom360D-500 Dimensions

AOM360D Hardware Manual Figure 2-4: AOM360D-500 Dimensions www.aerotech.com... -

Page 25: Securing The Base To The Mounting Surface

Stage Mounting Surface Flatness Requirement Stage Flatness Requirement All Frame Sizes 2.5 µm AOM360D series stages have a fixed mounting pattern (refer to Figure 2-5). Refer to Section 2.1. specific model mounting locations and dimensions. Tightening torque values for the mounting hardware are dependent on the properties of the surface to which the stage is being mounted. -

Page 26: Figure 2-5: View Of Aom360Dshowing Mounting Holes

AOM360D Hardware Manual Figure 2-5: View of AOM360DShowing Mounting Holes www.aerotech.com... -

Page 27: Attaching The Payload To The Stage

If you start the AOM360D without a payload, the servo gains provided by Aerotech with the shipment may not be appropriate and servo instability can occur. Refer to the controller help file for tuning assistance. - Page 28 AOM360D Hardware Manual This page intentionally left blank. www.aerotech.com...

-

Page 29: Chapter 3: Electrical Installation

Aerotech motion control systems are adjusted at the factory for optimum performance. When the AOM360D is part of a complete Aerotech motion control system, setup should only require that you connect the gimbal to the appropriate drive chassis with the cables provided. Labels on the system components should indicate the appropriate connections. -

Page 30: Motor And Feedback Connectors

Stages equipped with standard motors and encoders come from the factory completely wired and assembled. IMPORTANT: Refer to the other documentation accompanying your Aerotech equipment. Call your Aerotech representative if there are any questions on system configuration. IMPORTANT: If you are using standard Aerotech motors and cables, motor and encoder connection adjustments are not required. -

Page 31: Table 3-1: 26-Pin Motor Connector Pinouts [Az And El]

Signal Shield Motor Shield (1) with Brake option. (2) with Limit option. (3) with Home Limit option. Table 3-2: Mating Connector Part Numbers for the 26-Pin Motor Connector Mating Connector Aerotech P/N Third Party P/N Connector ECK00622 ITT Cannon, KPT06J16-26S www.aerotech.com... -

Page 32: Table 3-3: 19-Pin Feedback Connector Pinouts [Az And El]

-12 V supply input Reserved Signal-2/Signal-4 Shield Signal 4 Sine Shield SIN- (Encoder Sine-) REF- Ref Shield Table 3-4: Mating Connector Part Numbers for the 19-Pin Feedback Connector Mating Connector Aerotech P/N Third Party P/N Connector ECK00619 ITT Cannon, KPT06J14-19S www.aerotech.com... -

Page 33: Motor And Feedback Wiring

Hardware Manual AOM360D 3.2. Motor and Feedback Wiring Shielded cables are required for the motor and feedback connections. Figure 3-1: Motor and Feedback Wiring (AZ/EL) www.aerotech.com... -

Page 34: Figure 3-2: Feedback Interconnection Drawing

AOM360D Hardware Manual Figure 3-2: Feedback Interconnection Drawing www.aerotech.com... -

Page 35: Hall, Thermistor, Inductosyn, And Limits Specifications

Requires external pull-up to +5 V (10 kΩ recommended) Note: If the AOM360D is driven beyond the electrical limit, it will encounter a mechanical stop. Impacting the mechanical stop could cause damage to the stage even at low speeds. www.aerotech.com... -

Page 36: Table 3-9: S-180-44 [El] And S-180-69 [Az] Rotary Motor Specifications (-200 And -300 Options)

7. Maximum winding temperature is 100 °C (thermistor trips at 100 °C). 8. Ambient operating temperature range 0 °C - 25 °C; consult Aerotech for performance in elevated ambient temperatures. 9. All Aerotech amplifiers are rated A ; use torque constant in N·m/A when sizing. -

Page 37: Table 3-10: S-240-63 [El] And S-240-83 [Az] Rotary Motor Specifications (-400 And -500 Options)

7. Maximum winding temperature is 100 °C (thermistor trips at 100 °C). 8. Ambient operating temperature range 0 °C - 25 °C; consult Aerotech for performance in elevated ambient temperatures. 9. All Aerotech amplifiers are rated A ; use torque constant in N·m/A when sizing. -

Page 38: Limits, Marker, And Machine Direction

Hardware Manual 3.4. Limits, Marker, and Machine Direction Aerotech stages are configured to have positive and negative "machine" directions. The machine direction defines the phasing of the feedback and motor signals and is dictated by the stage wiring (refer to Section 3.2.). -

Page 39: Motor And Feedback Phasing

CW rotation must produce a positive change in machine counts for proper servo-loop phasing. This is the same as a positive change in position, assuming the motion controller has a positive scale factor, and is not configured to reverse the machine direction. Figure 3-4: Hall Phasing Diagram www.aerotech.com... - Page 40 AOM360D Hardware Manual This page intentionally left blank. www.aerotech.com...

-

Page 41: Chapter 4: Maintenance

Visually inspect the stage and cables. Re-tighten loose connectors. Replace or repair damaged cables. Clean the AOM360D and any components and cables as needed. Repair any damage before operating the AOM360D. Inspect and perform an operational check on all safeguards and protective devices. www.aerotech.com... -

Page 42: Cleaning And Lubrication

4. We recommend that you do not disassemble the stage beyond the instructions given in this manual. Proper assembly and calibration can only be done at the factory. Contact Aerotech for more information. -

Page 43: Appendix A: Warranty And Field Service

All Other Repairs - After Aerotech's evaluation, the buyer shall be notified of the repair cost. At such time the buyer must issue a valid purchase order to cover the cost of the repair and freight, or authorize the product(s) to be shipped back as is, at the buyer's expense. - Page 44 Aerotech's approval. On-site Warranty Repair If an Aerotech product cannot be made functional by telephone assistance or by sending and having the customer install replacement parts, and cannot be returned to the Aerotech service center for...

-

Page 45: Appendix B: Revision History

Hardware Manual AOM360D Appendix B: Revision History Revision General Information 2.00 General product and manual update 1.00 New manual www.aerotech.com... - Page 46 AOM360D Hardware Manual This page intentionally left blank. www.aerotech.com...

-

Page 47: Index

Electrical Specifications S-240 S-180 Protection Rating S-240 protective ground connection Electrical Warnings EN 60204-1 2010 EN ISO 12100 2010 S-180 EU 2015/863 Electrical Specifications Export Restrictions Performance Specifications S-240 Electrical Specifications gimbal Performance Specifications distortion serial number 13-14 grease shims www.aerotech.com... -

Page 48: Warnings

AOM360D Hardware Manual solvents Specifications Hall-Effect Sensors Inductosyn Specifications Limit Switch Thermistor Specifications stabilizing stage stage stabilizing Storage Table of Contents Temperature Effects Thermistor Specifications vacuum guidelines vacuum lubricant (Braycote 602EF) Vacuum Operation Vibration Warnings Warranty and Field Service www.aerotech.com...

Need help?

Do you have a question about the AOM360D Series and is the answer not in the manual?

Questions and answers