Summary of Contents for Sleipner SRHV240

- Page 1 Installation Guide For Hydraulic Retractable Thruster Models SRHV240, SRHV320 DOCUMENT ID: SLEIPNER MOTOR AS 2933 REVISION: P.O. Box 519 DATE: N-1612 Fredrikstad 2022 Norway LANGUAGE: www.sleipnergroup.com...

-

Page 2: Table Of Contents

SE20/110S - SE20 Tunnel thruster, 12V SE25/110S - SE25 Tunnel thruster, 12V SE30/125S2 - SE30 Tunnel thruster, 12V SE40/125S2 - SE40 Tunnel thruster, 12V Sleipner Motor AS P.O. Box 519, Arne Svendsensgt. 6-8 N-1612 Fredrikstad, Norway MC_0020 SH 240 & SH 320... -

Page 3: Responsibility Of The Installer

Sleipner products. If you are interfacing the S-Link™ bus by agreement with Sleipner through a designated Sleipner supplied interface, you are still required to install at least one original Sleipner control panel to enable efficient troubleshooting if necessary. -

Page 4: Product Measurements

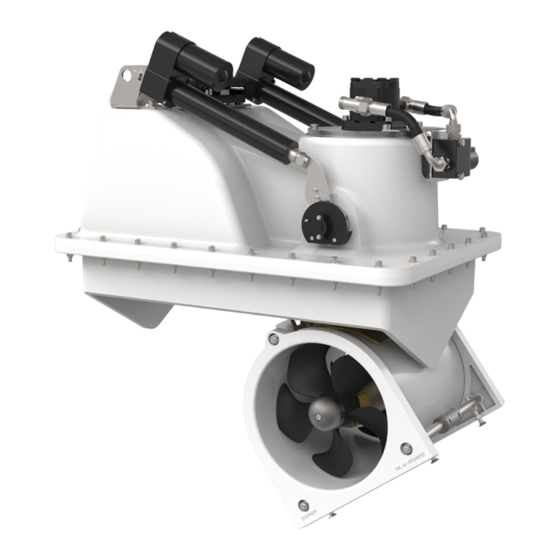

Product Measurements MC_0168 SRH 240 Measurement Measurement description code inch Height 15.4 Length 27.1 Additional Length Width 18.9 Internal Diameter 9.80 Water Depth 9.80 Retract Depth 14.2 Retract Width 13.7 Mould Width 16.3 Mould Height MG_0422 SH 240 & SH 320 2933 2022... - Page 5 Product Measurements MC_0364 SRH 320 Measurement Measurement description code inch Height 17.9 Length 33.2 Width 22.83 Internal Diameter 11.8 Water Depth 11.8 Retract Depth 17.5 Retract Width 16.3 Mould Width 18.9 Mould Height MG_0421 SH 240 & SH 320 2933 2022...

-

Page 6: Product Specifications

Product Specifi cations MC_0169 Light Duty Heavy Duty Power Output Weight Maximum Product Lubrication Thrust is kg Thrust is kg kW / Hp kg / lbs Operation Time SH240 Sealed - Oil bath from tank EP-90 240 kg / 529 lbs 220 kg / 440 lbs 14.9 kW / 20 hp 13.5 kg / 29.76 lbs Continuous... - Page 7 Requirements / Hydraulic hose connections to motor Technical Requirements / Hydraulic Hose Connections to Motor MC_0172 Performance table DRAIN 60 % 80 % 100 % 60 % PORT or max thrust PORT A Thruster Motor Thruster Motor model type model type L/min -Bar 18,8 21,7...

- Page 8 Positioning of the Retract thruster The thruster must be installed as far forward as possible. Allow for 100mm around the thruster for moulding the retract frame and the depth of the retracted propeller is a minimum of: (185mm for retract systems 80 to 100) (250mm for retract systems 130 to 210) (300mm for retract systems 250 to 300) under the waterline.

- Page 9 Hull construction typical in many vessels is a composite layering method called a sandwich. To ensure the retract thruster is installed securely to these hull types, additional hull structure reinforcement is required to strengthen the area around the Sleipner retract housing mould.

- Page 10 Marking and Trimming of SRF Flange MC_0068 ! Please refer to the graphic for special considerations relating to your model ! Identify the location of the thruster considering space required for installation, operation and future maintenance. 2. Mark the keel centre line on the inside of the hull. Flip the SRF flange upside down and use the internal surface to mark the hull for cutting the thruster hatch.

- Page 11 Installation Pre-check MC_0068 ! Please refer to the graphic for special considerations relating to your model ! Temporarily set up the complete installation to ensure no conflicts during the fi nal operation of the thruster. Use polyester or resin in the 4 corners of the lower retract mould and set it over the hatch. Attach the upper retract mould to the lower retract mould with 4 corner screws to hold them securely in place.

- Page 12 Required Modifi cations After Pre-check MC_0068 ! Please refer to the graphic for special considerations relating to your model ! To increase the space between the hatch and the hull the entire SRF flange and motor must be raised at the stern end. With the hatch in the open position raise the stern end of the SRF flange and motor until the appropriate clearance is achieved.

- Page 13 SRF Flange Installation MC_0068 ! Please refer to the graphic for special considerations relating to your model ! Surfaces to be moulded/ bonded must be ground to remove coating and material to achieve suffi cient adhesion. Apply Epoxy fi ller or equivalent on bottom edges of SRF flange or on the hull for bonding between connection surfaces. Ensure the fi ller is compatible with hull materials.

- Page 14 Motor House Installation MC_0068 ! Please refer to the graphic for special considerations relating to your model ! Apply MS Polymer or equivalent on SRF flange top surface to seal and avoid water leakage. (NB: Ensure that glue is compatible with SRF and thruster case materials.) Place the upper thruster Housing down on the SRF flange.

- Page 15 Hatch Installation MC_0068 ! Please refer to the graphic for special considerations relating to your model ! Fit custom made pin bolts to the tunnel rings. The ends of the bolts must be sharp to create marks in the hatch. The pin bolts must be in correct height so the hatch will fi t in its inner position.

- Page 16 Motor to House Installation MC_0173 ! Please refer to the graphic for special considerations relating to your model ! Install the motor onto the motor bracket ensuring both the couplings and the drive shafts have locked together. The motor must be installed with the solenoid facing the control box.

- Page 17 Hydraulic connections Drain Port A Port B MG_0186 SH 240 & SH 320 2933 2022...

- Page 18 Oil Tank Installation MC_0023 ! Please refer to the graphic for special considerations relating to your model ! Install the oil tank above the waterline by at least 20% of the distance from the waterline to the centre of the tunnel. This ensures enough overpressure for the oil in the gear leg.

- Page 19 (NB: If two or more control panels are operated at the same time in opposite directions, the electronic control box will stop the thruster until it receives a single signal or thrust in one direction.) • Sleipner on/off equipment it is entirely “plug & play” and require no additional confi guration setup. See the Control panel manual for more information. Retract...

- Page 20 MC_0120 S-Link is a CAN-based control system used for communication between Sleipner products installed on a vessel. The system uses BACKBONE Cables as a common power and communication bus with separate SPUR Cables to each connected unit. Units with low power consumption are powered directly from the S-Link bus therefore one power cable must be connected to the BACKBONE Cable through a T-Connector.

- Page 21 Visual Wiring Diagram Joystick Control panel PJC 221 (1 thruster) PJC 222 (2 thrusters) +12/24v S-link supply Power black supply yellow cable End Terminator 120 ohm End Terminator 120 ohm Hydr. tank unit + Supply 12v / 24v Actuator 2 - (See dim.

- Page 22 Technical Wiring Diagram To S-link control system + 12v / +24v supply Brown black Crossover Valve Actuators black Controller Blue 150000 Thruster Motor Blue Position Sensor Suggested supply cable dimensioning: Max total length. Sum of pos and neg cable. 6 mm2 10 mm2 16 mm2 25 mm2 4.2m 6.7m...

- Page 23 Check drive shaft alignment MC_0069 IMPORTANT Before the thruster motor is operated, check the drive shaft alignment is completely straight when it reaches the end position form the control panel operation: 1) Connect power to thruster and S-link system. 2) Sett DIP-switch on the controller to 0000. 3) Turn on the panel.

-

Page 24: Control Panel Installation

Control Panel Installation MC_0398 For Control Panel installation please refer to the Installation Guide accompanying the control panel to be installed. Installation Guide Control Panel SLEIPNER MOTOR AS DOCUMENT ID: P.O. Box 519 REVISION: N-1612 Fredrikstad DATE: Norway LANGUAGE: www.sleipnergroup.com SH 240 &... -

Page 25: Pre-Delivery Checklist

Pre-delivery Checklist MC_0033 []..The bolts holding the gear house and motor bracket together are tightened correctly. []..The bolts holding the motor to its bracket are tightened correctly. []..All electrical connections are clean, dry and tight, and the correct cable, fuse and main switch size. -

Page 26: Service And Support

11. This warranty gives you specific legal rights, and you may also have other rights which vary from country to country. Patents MC_0024 At Sleipner we continually reinvest to develop and offer the latest technology in marine advancements. To see the many unique designs we have patented visit our website www.sleipnergroup.com/patents SH 240 & SH 320... - Page 27 Notes MC_0037 ..............................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................SH 240 & SH 320 2933 2022...

- Page 28 © Sleipner Group, All rights reserved The information given in the document was right at the time it was published. However, Sleipner Group cannot accept liability for any inaccuracies or omissions it may contain. Continuous product improvement may change the product specifi cations without notice.

Need help?

Do you have a question about the SRHV240 and is the answer not in the manual?

Questions and answers