Advertisement

Quick Links

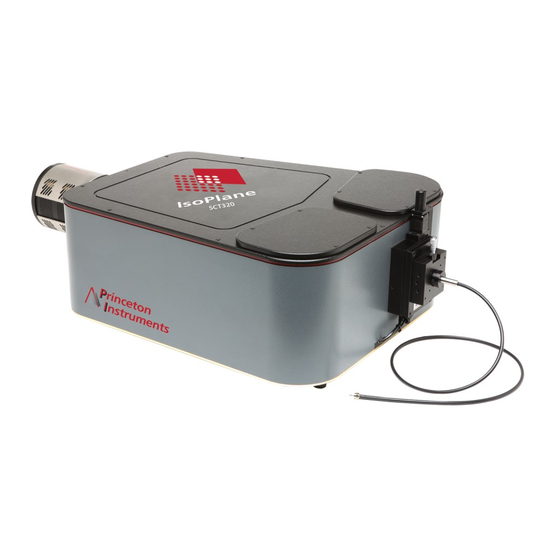

Adding or Interchanging Turrets and Gratings in the IsoPlane SCT-320

If it becomes necessary to add or interchange turrets and gratings in the SCT-320 IsoPlane, the following procedure is

recommended. This procedure should be done only by personnel familiar with handling delicate optical components

and familiar with the alignment of optical instruments. The following equipment is required:

PC running Windows

Monochromator Control Software and Manual

Alignment Posts

Helium Neon Laser

CCD camera controlled by WinSpec or Lightfield

Low Pressure Mercury Lamp (IntelliCal Light Source recommended)

NOTES:

MAKE SURE THAT MONO CONTROL SOFTWARE IS RUNNING BEFORE STARTING LIGHTFIELD

OR WINSPEC. THIS IS IMPORTANT BECAUSE MONO CONTROL SOFTWARE MUST HAVE

CONTROL OF THE SCT-320 FOR THIS ALIGNMENT PROCEDURE.

THE CCD SHOULD ALREADY BE MOUNTED, ALIGNED AND FOCUSED TO THE SCT-320 USING

THE ORIGINAL GRATING TURRET PROVIDED, BEFORE PERFORMING THIS INSTALLATION

PROCEDURE. FOR THIS PROCEDURE THE CCD IS CONTROLLED BY LIGHTFIELD OR WINSPEC.

PRIOR TO INSTALLING A NEW TURRET OR GRATING, SET THE SHUTTER CONTROL WITHIN

LIGHTFIELD OR WINSPEC TO DISABLED OPEN. THIS IS NECESSARY TO ALLOW LASER LIGHT

TO ENTER THE SCT-320 CHAMBER FOR OPTICAL ALIGNMENT.

Setting the IsoPlane SCT-320 to Recognize the New Grating

Refer to the Monochromator Control Software Manual Section II for directions on how to install the

Monochromator Control Software.

Refer to the Monochromator Control Software Manual Section III for directions on how to operate the

monochromator using the Monochromator Control Software

1) From the Monochromator Control Software Main Window, select the Install Gratings Button.

2) If you are replacing a grating on the turret, you must first remove the existing grating by selecting the grating to

be removed in the gratings list, and then selecting the Uninstall Button.

3) To install a grating, select the grating position, then enter the Groove Density (g/mm) and Blaze in the appropriate

boxes and select install.

4) The software will respond that you need to calibrate the grating, respond OK.

5) This concludes the initial software installation or the grating.

Instructions for

1

Advertisement

Summary of Contents for Teledyne IsoPlane SCT-320

- Page 1 Instructions for Adding or Interchanging Turrets and Gratings in the IsoPlane SCT-320 If it becomes necessary to add or interchange turrets and gratings in the SCT-320 IsoPlane, the following procedure is recommended. This procedure should be done only by personnel familiar with handling delicate optical components and familiar with the alignment of optical instruments.

- Page 2 Turret Installation and Alignment 1) Install turret refer to section 2.7 of the Isoplane SCT-320 manual 2) Reinitialize the instrument and verify that when the magnets go by the magnet switch it recognizes by slowing down the index motor driver. (2 magnets represent turret #2, 3 magnets turret#3) 3) The SCT-320 incorporates a detent system to precisely index gratings into operating position.

- Page 3 b) Select Goto Configure Motors c) Select Main Board 3 –OnAxis d) Change values on Pos6 for turret#1 Pos7 for turret#2 Pos8 for turret#3...

- Page 4 ENTER A VALUE in the appropriated box, press the SET button immediately right of the value and then press the RESET MONO button after each adjustment. Repeat the test as outlined in Step 4 to determine the detent position. Note that this procedure might required multiple iterations before the detent is properly adjusted.

- Page 5 Figure 2: Alignment Post, Position 2, near collimating mirror 7) Align the helium neon laser so that the beam passes through the center of the entrance slits, and the pinholes of both alignment posts (Pos 1 and 2). This insures that the laser is properly aligned to the SCT-320. CAUTION: DO NOT MOVE THE SCT-320 OR LASER IN RELATION TO EACH OTHER FROM THIS POINT, OR THE ALIGNMENT WILL NOT BE CORRECT.

- Page 6 Rotation Adjustment Screw (Zero Order only) Tangent Adjustment Screw (High Wavelengths Only) Tilt Adjustment Screw (Zero Order only) Figure 4: Location of Grating Adjustment Screws 11) Turn the grating TILT adjusting screw until the laser beam is approximately centered in height on the pinhole of Alignment Post 3 CAUTION: DO NOT APPLY EXCESS FORCE TO ANY OF THE ADJUSTING SCREWS.

- Page 7 NOTE: WAVELENGTH POSITION ACCURACY AT HIGH WAVELENGTHS (632.8NM) IS ACHIEVED WHEN CALIBRATING THE SYSTEM USING THE GADJUST FUNCTION IN MONO CONTROL SOFTWARE. THIS WILL REQUIRE USE OF A CCD DETECTOR. Calibrating the SCT-320 using Software This procedure requires the use of a CCD detector, Lighfield or WinSpec software, and a mercury lamp installed on the entrance slit of the SCT-320.

- Page 8 26) Set the Jog pull down menu to Scan Rate and Scan Speed to 10nm/min. 27) With the CCD running in continuous or focus mode, use the Up/Down Jog Buttons to position 547.074nm at the center of the CCD. 28) Note the wavelength displayed in Wavelength box located to the left of the Goto button. 29) Return to the MAIN MENU by selecting the RETURN button.

- Page 9 Wavelength Gadjust Menu. 31) Select 546.074nm from the Mercury Lines pull down menu. 32) Enter the wavelength determined in Step 28 above. 33) Press the Calculate Gadjust button. This returns the Calculated Gadjust number shown in the Gadjust box at the left side of the screen.

Need help?

Do you have a question about the IsoPlane SCT-320 and is the answer not in the manual?

Questions and answers