Summary of Contents for Mea SMARTPACK 35

- Page 1 SMARTPACK 35 (SP35P SP35D) Owners & Operators Manual 35CFM Compact Petrol or Diesel Driven Air Compressor Revision: 1 Revised: 03/12/2018 7214-D0001-01...

- Page 2 THIS PAGE IS LEFT BLANK INTENTIONALLY. Document No 7214-D0001-01 Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946 P: +61 7 3273 6803 sales@mobileenergyaustralia.com.au www.mobileenergyaustralia.com.au...

- Page 3 MEA Product Warranty Registration Form THIS FORM MUST BE COMPLETED AND RETURNED WITHIN 30 DAYS OF INSTALLATION WARRANTY WILL BE VOID Document No 7214-D0001-01 Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946 P: +61 7 3273 6803 sales@mobileenergyaustralia.com.au...

- Page 4 CUT HERE MEA Product Warranty Registration Form This form must be completed and returned to MEA at the time of Installation. Warranty will be void if this form is not received by MEA within 30 days of installation. MEA Dealer Information...

-

Page 5: Table Of Contents

10. WARRANTY ......................35 MOBILE ENERGY AUSTRALIA - CONTACTS............37 Both the MEA Product Warranty Registration form (located at the FRONT of this Manual) and the Kohler Engine Warranty Registration form (located at the back of this manual) are to be returned to MEA. -

Page 6: Product Safety

Death and permanent disability are possibilities that can occur. The following are suggested as minimum requirements to be followed when operating the MEA Smartpack system. It is important that each work site shall perform a risk analysis and produce a procedure to eliminate or control the hazardous conditions to minimise the risk to personnel and equipment. -

Page 7: Introduction

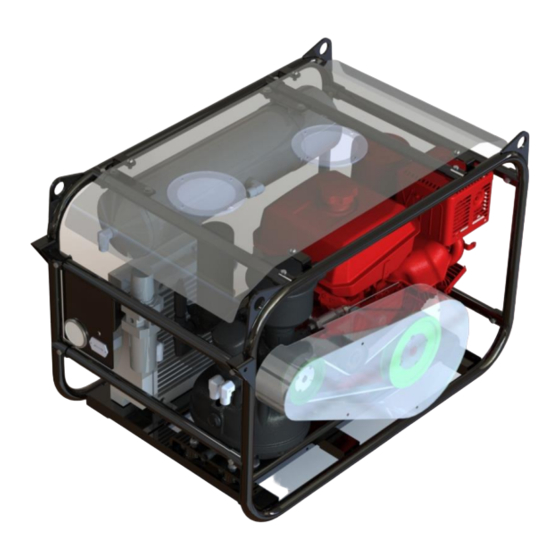

2. INTRODUCTION MEA SmartPack 35 (SP35) – Petrol or Diesel utilizes a single cylinder engine to deliver power via a drive belt to a self-contained twin screw compressor packaged in the smallest frame possible to ensure that the unit can be used on the back of a work utility vehicle as well as in a garage, a workshop, or a property. -

Page 8: Specifications

Relief valve in compressor sump Temperature safety sensor in the compressor Lubrication: All replacement compressor oils must be approved by MEA prior to use. Warranty will be nullified if oil has not been approved. MEA certified and approved semi synthetic compressor oil Part Number 10019-K0005 Quantity of Compressor Oil Required ~ 3.5 Litres... -

Page 9: Operating Procedure

4. OPERATING PROCEDURE CHECKS REQUIRED PRIOR TO STARTING EACH DAY Check the oil level in the engine. Check the oil level in the compressor. Check all hoses are secured and not damaged. Replace all damaged hoses before starting. Check all electrical cables are secure. Secure all cables that are not tied down. Check the air inlet and air filter on the engine are clean. - Page 10 OPERATING PROCEDURE - Continued STARTING / STOPPING UNIT STARTING THE PETROL ENGINE 1. Check the air outlet valve is closed. 2. If the engine is cold, move the choke lever to closed (under the air filter). 3. Ensure that the fuel tap is on (under the air filter). 4.

-

Page 11: Installation

5. INSTALLATION The compressor is a rotary screw type driven by either a petrol or diesel engine. Compression occurs when inlet air (at normal atmospheric pressure) enters a chamber where it is trapped between the rotating rotor lobes. A lubricated pitch line provides sealing. As the lobes mesh, they reduce the volume of the air (compression). - Page 12 (250 mm) clearance between exhaust and any other components mounted on the vehicle. If this is not possible, and was not discussed prior to purchase, please contact MEA to purchase an exhaust deflector. If the unit is installed in an area considered to be enclosed, it is strongly recommended that the unit is tested to certain criteria to ensure proper working.

- Page 13 (idle speed). Pressure settings of the unit has been adjusted by the factory to the customer specifications. If the pressure is not at the specified pressure, contact MEA before attempting any adjustments.

-

Page 14: Schedule Maintenance

6. SCHEDULE MAINTENANCE This section is dedicated to the maintenance schedules as outlined by the engine and compressor manufacturer under standard operating conditions. If the conditions are severe steps need to be taken for the affected areas to be maintained at shorter intervals. Daily inspection should happen before each start-up. - Page 15 Change Engine oil 1.1L. In case of low use, every year. In using lower quality oil, Every 500 Hours (in change case of low use every 150 hours. every year) Change engine oil filter. Replace fuel filter. Change Air filter. Change compressor oil filter Replace engine air...

-

Page 16: Spare Parts And Service Kits

7. SPARE PARTS AND SERVICE KITS 7.1 COMPRESSOR Document No 7214-D0001-01 Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946 P: +61 7 3273 6803 sales@mobileenergyaustralia.com.au www.mobileenergyaustralia.com.au... - Page 17 DRIVE BELT DIESEL ENGINE 10004-P0201 DRIVE BELT PLEASE CONTACT MEA SPARE PART SALES FOR ITEMS WHICH ARE NOT COVERED HEREIN. Document No 7214-D0001-01 Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946 P: +61 7 3273 6803 sales@mobileenergyaustralia.com.au...

- Page 18 SMARTPACK 35D SERVICE KITS AND PART NUMBERS 200 Hour - 7219-KB0001 Part Number Description Quantity 10019-K0007 OIL 5 LITRE CONTAINER DIESEL 10021-P0006 DECAL OIL MEA OIL 10008-P0126 FILTER OIL ENGINE KOHLER 10008-P0128 FILTER AIR ENGINE KOHLER 7201-P0075 DECAL NEXT SERVICE DUE 400 Hour - 7219-KB0002...

- Page 19 7.3 SPARE PARTS AND SERVICE KITS Cont. 7214 Smartpack 35P 200 Hour Part Number Description Quantity 10021-P0006 DECAL OIL MEA OIL 10019-K0007 OIL 5 LITRE CONTAINER DIESEL 7201-P0075 DECAL NEXT SERVICE DUE 10008-P0146 FILTER AIR KOHLER CH440 400 Hour Part Number...

-

Page 20: Troubleshooting

5-Check the thermostatic valve. If necessary, 5-The thermostatic valve does not work replace the damaged parts with spare parts kit correctly. Contact MEA for parts required) 6-Clogged oil filter 6-Replace the oil filter During unloading phase, 1-Check the valve. If necessary, replace the 1-The intake valve remains open. - Page 21 1-Check the valve. If necessary, replace the under loading phase. (does not close) damaged parts with spare parts kit. 1-Unknown particles inside. 1-Call MEA technical support. Rotor seizure 2-Insufficient lubrication. 2-Call MEA technical support. 1-Separator filter damaged. 1-Replace the separator filter.

- Page 22 Oil level too high Clogged air filter Overloaded Black smoke Injector not adjusted Extra fuel control level sticking Excessive idle operation Incomplete run-in Incorrect injection timing White smoke Rings worn or sticking Worn cylinder Fuel filter clogged Air leaks in fuel system White Smoke Faulty fuel feeding pump Oil level too high...

-

Page 23: Drawings & Illustrations

9. DRAWINGS & ILLUSTRATIONS GA DRAWING – NEW PACKSMART61 (PETROL ENGINE) Document No 7214-D0001-01 Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946 P: +61 7 3273 6803 sales@mobileenergyaustralia.com.au www.mobileenergyaustralia.com.au... - Page 24 GA DRAWING – OLD PACKSMART61 (PETROL ENGINE) Document No 7214-D0001-01 Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946 P: +61 7 3273 6803 sales@mobileenergyaustralia.com.au www.mobileenergyaustralia.com.au...

- Page 25 GA DRAWING – FRAMELESS (PETROL ENGINE) Document No 7214-D0001-01 Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946 P: +61 7 3273 6803 sales@mobileenergyaustralia.com.au www.mobileenergyaustralia.com.au...

- Page 26 GA DRAWING – OLD FRAMELESS (PETROL ENGINE) Document No 7214-D0001-01 Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946 P: +61 7 3273 6803 sales@mobileenergyaustralia.com.au www.mobileenergyaustralia.com.au...

- Page 27 GA DRAWING -NEW PACKSMART61 (DIESEL) Document No 7214-D0001-01 Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946 P: +61 7 3273 6803 sales@mobileenergyaustralia.com.au www.mobileenergyaustralia.com.au...

- Page 28 GA DRAWING -OLD PACKSMART61 (DIESEL) Document No 7214-D0001-01 Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946 P: +61 7 3273 6803 sales@mobileenergyaustralia.com.au www.mobileenergyaustralia.com.au...

- Page 29 GA DRAWING – FRAMELESS (DIESEL ENGINE) Document No 7214-D0001-01 Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946 P: +61 7 3273 6803 sales@mobileenergyaustralia.com.au www.mobileenergyaustralia.com.au...

- Page 30 GA DRAWING – OLD FRAMELESS MODEL (DIESEL ENGINE) Document No 7214-D0001-01 Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946 P: +61 7 3273 6803 sales@mobileenergyaustralia.com.au www.mobileenergyaustralia.com.au...

- Page 31 V61 Compressor Arrangement Document No 7214-D0001-01 Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946 P: +61 7 3273 6803 sales@mobileenergyaustralia.com.au www.mobileenergyaustralia.com.au...

- Page 32 V61 PACKSMART HYDRAULIC DIAGRAM 1-oil return from separator 2-Intake valve 4-Screw air-end 5-Oil cooler 6-Thermostatic valve 7-Safety valve 8-Air/oil separator tank 9-Minimum pressure valve 10-Switch load/no load (only for electric version) 11-Pressure switch controller (only for electric version) 12-Air cooler 13-Separator filter 14-VMC recovery oil viewer 15-Air/oil pipe from air end to separator tank...

- Page 33 ENGINE COMPONENTS OVERVIEW – PETROL Document No 7214-D0001-01 Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946 P: +61 7 3273 6803 sales@mobileenergyaustralia.com.au www.mobileenergyaustralia.com.au...

- Page 34 *FURTHER INFORMATION CAN BE FOUND IN THE ENGINE MANUAL Document No 7214-D0001-01 Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946 P: +61 7 3273 6803 sales@mobileenergyaustralia.com.au www.mobileenergyaustralia.com.au...

- Page 35 ENGINE COMPONENTS OVERVIEW - DIESEL FURTHER INFORMATION CAN BE FOUND IN THE ENGINE MANUAL Document No 7214-D0001-01 Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946 P: +61 7 3273 6803 sales@mobileenergyaustralia.com.au www.mobileenergyaustralia.com.au...

- Page 36 KOHLER ENGINE ELECTRICAL SYSTEM (DIESEL) Document No 7214-D0001-01 Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946 P: +61 7 3273 6803 sales@mobileenergyaustralia.com.au www.mobileenergyaustralia.com.au...

- Page 37 KOHLER ENGINE FUEL SYSTEM (DIESEL) Document No 7214-D0001-01 Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946 P: +61 7 3273 6803 sales@mobileenergyaustralia.com.au www.mobileenergyaustralia.com.au...

- Page 38 Wiring Diagram Document No 7214-D0001-01 Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946 P: +61 7 3273 6803 sales@mobileenergyaustralia.com.au www.mobileenergyaustralia.com.au...

-

Page 39: Warranty

Components supplied under warranty shall be warranted for the remainder of the original warranty period. MEA factory rebuilt components shall be warranted for a period of 6 months from date of shipment. MEA OBLIGATIONS The obligation of MEA is limited to repairing or replacing parts, during normal business hours, at an authorized service facility, any component, that in the judgment of MEA are defective. - Page 40 WARRANTY (continued) BUYER OBLIGATIONS Buyer shall notify MEA of the alleged defect within 10 days of initial discovery and return the allegedly defective component(s) within 35 days of initial discovery. The Buyer must prepay all costs associated with the warranty.

-

Page 41: Mobile Energy Australia - Contacts

MOBILE ENERGY AUSTRALIA - CONTACTS Sales Email: sales@mobileenergyaustralia.com.au Office: 07 3273 6803 Spare Parts Office: 07 3273 6803 Email: sales@mobileenergyaustralia.com.au Service Office: 07 3273 6803 Email: workshop@mobileenergyaustralia.com.au Document No 7214-D0001-01 Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946 P: +61 7 3273 6803 sales@mobileenergyaustralia.com.au...

Need help?

Do you have a question about the SMARTPACK 35 and is the answer not in the manual?

Questions and answers