Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for YSI 5000

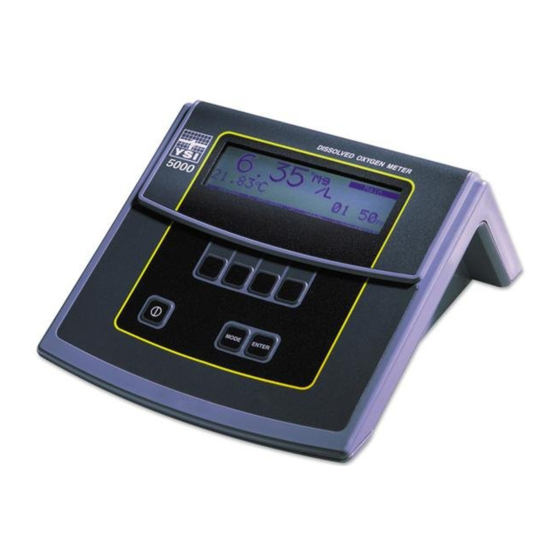

- Page 1 YSI MODEL 5000 YSI MODEL 5100 Dissolved Oxygen Temperature SERVICE MANUAL...

-

Page 3: Table Of Contents

6.3 Reset Ps ........................... 16 Section 7 Troubleshooting Chart ....................17 Section 8 Test Procedure......................19 Section 9 Maintenance........................ 21 9.1 5000 and 5100 Instruments ................... 21 Batteries........................... 21 9.2 5910 and 5905 Dissolved Oxygen Probes ..............22 Electrode Cleaning ......................22 Section 10 Software Upgrade Procedure.................. -

Page 5: Section 1 General Description

Internal memory for storing up to 100 sets of data, and an RS232 port allow you to upload data from the Model 5000 directly to your computer. Or you can use your Model 5000 with YSI BOD Analyst software. -

Page 6: Section 2 Specifications

The Model 5000 and 5100 are designed exclusively for indoor use and are NOT waterproof. POWER The Model 5000 & 5100 are powered by an AC adapter or 4 C-size alkaline batteries. A new set of alkaline batteries will power the selected instrument for approximately 30 hours (not including stirring). -

Page 7: Section 3 Software Flow Chart

SECTION 3 SOFTWARE FLOW CHART The following section shows the software flow chart for the 5000/5100. The two operating modes, Main and Application, are shown at the top with the soft-key functions that are accessed in each mode below them. Functions in shaded boxes are only available on the model 5100. -

Page 8: Section 4 Setup

The [SIZE] soft-key cycles among the two possible display arrangements for Main mode. One selection shows as many parameters as possible, the other shows Dissolved Oxygen in large type with temperature and time in small type. YSI Incorporated Model 5000/5100 Service Manual... - Page 9 The [LAST DIG.] soft-key allows the user to suppress the last digit of the DO reading. Display 24.38°C 11:33 SIZE UNITS CONTRAST LAST DIG. Press the [MODE] key to return to the Setup menu. If you wish to return to Main mode, press [MODE] two more times. YSI Incorporated Model 5000/5100 Service Manual...

-

Page 10: Report Setup

Press the [NEXT] soft-key to change between the minimum and maximum parameter. When the desired number is obtained, pressing [ENTER] will accept the number and exit the RANGE sub-menu. To return to Main mode, press [MODE] three more times. YSI Incorporated Model 5000/5100 Service Manual... -

Page 11: Autostable Setup

[MODE] key instead of [ENTER]. Operation returns to the setup menu. If you wish to disable the autostable feature, set the DO% variation to 0.0. To return to Main mode, press [MODE] two more times. YSI Incorporated Model 5000/5100 Service Manual... -

Page 12: System Setup

TIME / DATE VERSION RS232 The [VERSION] soft-key displays the software version of the instrument on the message line of the display just above the soft-key descriptions. The [RS232] soft-key displays the RS232 setup. YSI Incorporated Model 5000/5100 Service Manual... - Page 13 Press [ENTER] to confirm. The RS232 sub-menu can be left without making any changes by pressing the [MODE] key instead of [ENTER]. Operation returns to the system setup menu. Press [MODE] to return to the previous menu, Setup. To return to Main mode, press [MODE] two more times. YSI Incorporated Model 5000/5100 Service Manual...

-

Page 14: Section 5 Calibration

Prepare the DO probe. Before performing an AUTO CAL, you must check the barometric pressure reading and calibrate the barometer, if necessary, as shown under Calibration, Barometer. The Model 5000 does not contain a barometer, therefore, the current barometric pressure must be entered before an AUTO Cal is performed. -

Page 15: Do Cal (Manual)

7. Model 5100: Verify that the barometer reading is correct. Calibrate the barometer, if necessary, as shown under Calibration, Barometer. Model 5000: Enter the current barometric pressure as shown under Calibration, Barometer. 8. Verify that the salinity is set to the correct value (0.0 ppt for air calibration). See Calibration, Salinity. - Page 16 8.15 Calibration mmHg 24.38°C 11:33 D. O. CALIBRATION SAVED Message DOWN DIGIT NEXT Press [MODE] to return to the Main mode. The instrument is now calibrated and ready to measure dissolved oxygen and temperature. YSI Incorporated Model 5000/5100 Service Manual...

-

Page 17: Barometer

(±10°C), the barometer calibration should be accurate for about 30 days. The Model 5000 does not contain a barometer, therefore, the current barometric pressure must be entered before an AUTO Cal is performed. The reading currently displayed is the value that was entered and stored during the previous calibration. -

Page 18: Zero Calibration

All oxygen probes have a small background current, even in the absence of oxygen. The Model 5000/5100’s default zero value is based on the average probe’s background current. This default value may cause errors when measuring low concentrations of oxygen. -

Page 19: Section 6 Diagnostics

SECTION 6 DIAGNOSTICS 5000 and 5100s have a diagnostic mode that can be used for troubleshooting. In Diagnosis mode you can view specific sensor information, such as DO probe current, DO background current and pressure sensor offset. This data is useful when trying to isolate problems or prevent error messages from occurring. -

Page 20: Sensor

Press the [RESET Ps] soft-key to display the following: Reset Press ENTER to RESET Parameters HISTORY SENSOR HELP RESET Ps Press [ENTER] to confirm. If you do NOT wish to reset the parameters, press [MODE] to return to the Diagnosis menu. YSI Incorporated Model 5000/5100 Service Manual... -

Page 21: Section 7 Troubleshooting Chart

E3: Check DO Low current Insufficient electrolyte or Install new membrane and fouled membrane Membrane See probe maintenance Contaminated electrodes instructions Membrane too thick Try another membrane High resistance in probe Repair or replace connection YSI Incorporated Model 5000/5100 Service Manual... - Page 22 Replace membrane and KCl E5: Check Membrane Probe electrodes needs See probe maintenance servicing instructions Connector improperly Check probe connection installed Intermittent connection in Replace defective assy cable or plug Probe malfunction Replace defective assy YSI Incorporated Model 5000/5100 Service Manual...

-

Page 23: Section 8 Test Procedure

SECTION 8 TEST PROCEDURE This produce is for use with the YSI 16423 Oxygen Test Box. If no test box is available, testing can be performed by inputting the resistance values in column 2 of the charts below. • A display test and system check are automatically run upon instrument start up. - Page 24 Set test box to position F-1. Connect a millivolt meter to the test box red and black binding posts ( Same as, J5 Pins 2 & 3). The reading should be 800 mv ±5%. YSI Incorporated Model 5000/5100 Service Manual...

-

Page 25: Section 9 Maintenance

SECTION 9 MAINTENANCE 5000 AND 5100 INSTRUMENTS Model 5000 series instruments are designed to provide years of trouble free service. The only routine maintenance will be replacement of the batteries. BATTERIES Low batteries are indicated in the display by “LOW BATT” as shown here. -

Page 26: 5910 And 5905 Dissolved Oxygen Probes

Soak the probe in a 14% ammonium hydroxide solution for 2 to 3 minutes or overnight in a 3% ammonium hydroxide solution. Rinse with deionized water, recharge with electrolyte, and install a new membrane. YSI Incorporated Model 5000/5100 Service Manual... -

Page 27: Section 10 Software Upgrade Procedure

RS232 serial cable (not a null modem cable). The 5000/5100 has a female DB-9 connector. A 9 to 25 pin adapter will also be needed if the computer has a 25 pin serial port. The instructions are as follows: 1. - Page 28 11. After the 5000/5100 comes on, you must reset the parameters to the factory default values. Press the [CALIBRATE] soft-key on the 5000/5100 keypad. Then, press the [DIAGNOSIS] soft-key on the 5000/5100 keypad. Then, the [RESET Ps] soft-key on the 5000/5100 keypad Then, press [ENTER], on the 5000/5100 keypad, to confirm.

-

Page 29: Section 11 Disassembly/Assembly Procedures

Hook the three snaps at the rear of the case into place and rotate the lower case into place on the upper case. Make sure all four snaps are fully engaged. Press firmly down on the three rear snaps to make sure they are completely engaged. YSI Incorporated Model 5000/5100 Service Manual... -

Page 30: Section 12 Circuit Description

8 bits. FLASH MEMORY Models 5000/5100 have internal FLASH memory, IC16. When the VPPSHDN (P4.3) control line is left floating or driven high all program operations, including boot and normal blocks, to the chip are disabled. Pulling the VPPSHDN control line low will enable program operations to all sections of the chip except the boot block. - Page 31 P0.0 high. See below for interface and timing details. RS232 PORT The port is driven by U18 (LTC1384) which implements TXD,RXD,DSR and DTR. The logic signals are isolated by opto couplers U14 and U15. The five volt supply is also isolated by YSI Incorporated Model 5000/5100 Service Manual...

- Page 32 (channel 4) and low (channel 3) outputs, the ultimate result being the difference in the two conversions adjusted to gain 1 (% of AVCC from BARO+ to BARO-). The user is expected to provide a calibration point close to typical operating temperatures. YSI Incorporated Model 5000/5100 Service Manual...

- Page 33 The input to the analog to digital converter is selected by the multiplexor U23. The gain applied before conversion is adjusted by selection of the feedback tap on the resistor string R53, 54, R64- 68, and R79. Dual slope integration conversions are performed with U27 under timing control of U5. YSI Incorporated Model 5000/5100 Service Manual...

-

Page 34: Section 13 Schematic Diagrams

SECTION 13 SCHEMATIC DIAGRAMS Main CPU Representative drawing. Actual circuit may vary. YSI Incorporated Model 5000/5100 Service Manual... - Page 35 Display and Memory Representative drawing. Actual circuit may vary. YSI Incorporated Model 5000/5100 Service Manual...

- Page 36 Keypad and Real Time Clock Representative drawing. Actual circuit may vary. YSI Incorporated Model 5000/5100 Service Manual...

- Page 37 RS 232 and Expansion Connector Representative drawing. Actual circuit may vary. YSI Incorporated Model 5000/5100 Service Manual...

- Page 38 Power Supply Representative drawing. Actual circuit may vary. YSI Incorporated Model 5000/5100 Service Manual...

- Page 39 Analog Front End Representative drawing. Actual circuit may vary. YSI Incorporated Model 5000/5100 Service Manual...

- Page 40 A to D and Multipluxer Representative drawing. Actual circuit may vary. YSI Incorporated Model 5000/5100 Service Manual...

-

Page 41: Section 14 Pc Board Layout

TP33 TP35 TP106 TP61 TP76 TP112 TP123 TP62 TP72 TP60 TP81 TP122 TP83 TP101 TP73 TP80 TP121 TP82 TP126 TP74 TP105 TP93 TP220 TP37 TP69 TP104 TP70 TP111 TP66 TP128 TP13 TP19 TP118 TP129 YSI Incorporated Model 5000/5100 Service Manual... - Page 42 Representative drawing. Actual layout may vary. YSI, 5100 ASSY ITEM 051020 DWG D51020-1 5000 ASSY ITEM 050100 DWG D51020-2 YSI Incorporated Model 5000/5100 Service Manual...

-

Page 43: Section 15 Pc Board Components

ICSM, PA28F400B 4MEG FLASH ICSM, 74HC32 OR GATE ISCM, 74HC04 HEX INVERTER R42, 43, 70 RES, SMD TNF 2.0K 0.1% 1/8W ICSM, 74HC374 OCTAL D-LATCH RES, SMD TKF 4.99K 1% 1/8w ICSM, DS2404S RT CLOCK YSI Incorporated Model 5000/5100 Service Manual... -

Page 44: Section 16 Accessories And Replacement Parts

Cable Assy, RS232 5000, 5100 051042 Service Manual 5000, 5100 YSI Model 5011 Probe adapter (converts from probe 5000, 5100 MS connector to meter DIN) * INSTRUMENTS 96L DATE CODE OR EARLIER CONTACT YSI TECHNICAL SUPPORT YSI Incorporated Model 5000/5100 Service Manual... -

Page 45: Section 17 Warranty And Repair

SECTION 17 WARRANTY AND REPAIR YSI Model 5000 and 5100 are warranted for two years from date of purchase by the end user against defects in materials and workmanship. YSI Model 5000 and 5100 probes and cables are warranted for one year from date of purchase by the end user against defects in material and workmanship. - Page 46 AUTHORIZED U.S. SERVICE CENTERS NORTH AND EAST REGION YSI Incorporated • Repair Center • 1725 Brannum Lane • Yellow Springs, Ohio • 45387 • Phone: (800) 765-4974 • (937) 767-7241• E-Mail: info@ysi.com SOUTH REGION C.C. Lynch & Associates • 212 E. 2nd Street • Suite 203 • Pass Christian, Mississippi • 39571 •...

- Page 47 Disposition costs will be the responsibility of the sender. When service is required, either at the user's facility or at YSI, the following steps must be taken to insure the safety of our service personnel.

- Page 48 Model No. of Device ______ Lot Number _________ Contaminant (if known) _____________________ Cleaning Agent(s) used _____________________ Radioactive Decontamination Certified? (Answer only if there has been radioactive exposure) ___ Yes ___ No Cleaning Certified By _________________________ Name Date YSI Incorporated Model 5000/5100 Service Manual...

- Page 49 YSI Incorporated Model 5000/5100 Service Manual...

- Page 50 1700/1725 Brannum Lane Yellow Springs, Ohio 45387 USA (800) 765-4974 (937) 767-7241 FAX: (937) 767-9320 Website: http://www.ysi.com E-mail: info@ysi.com Item # 051042 Drawing # A51042C July 1998...

Need help?

Do you have a question about the 5000 and is the answer not in the manual?

Questions and answers