CORNING Lambda EliteMax Instruction Manual

Semi-automated benchtop pipettor

Hide thumbs

Also See for Lambda EliteMax:

- Quick start manual (5 pages) ,

- Service manual (34 pages) ,

- Frequently asked questions (2 pages)

Subscribe to Our Youtube Channel

Summary of Contents for CORNING Lambda EliteMax

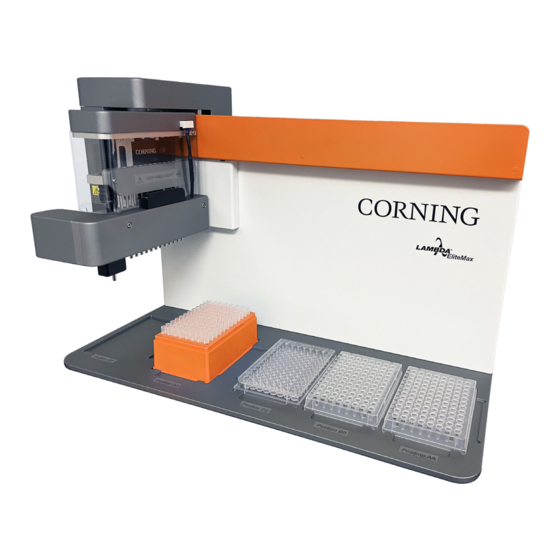

- Page 1 Corning Lambda EliteMax ® ™ Semi-automated Benchtop Pipettor Instruction Manual Catalog Number: 6070...

-

Page 2: Table Of Contents

Table of Contents 1.0 Introduction ......... . 1 3.0 Settings: General Configurations . -

Page 3: Introduction

Corning Lambda EliteMax Benchtop Pipettor are likely to be damaged, the rated safety level to be reduced, and the rated operation conditions to be affected. Corning shall not be in any way responsible for the consequences resulting from the operator not observing the following requirements. -

Page 4: Instrument Identification

If the Corning Lambda EliteMax Benchtop Pipettor is to sit idle for extended periods of time, it is recommended to disconnect the power line from the mains, and cover the device with a piece of soft cloth or plastic to prevent against dust. -

Page 5: Deck Positions And Orientation Convention

If the damage appears significant, call your local Corning representative before connecting the unit to the mains. Instruction Manual... -

Page 6: Package Contents

Corning® Lambda™ EliteMax Semi-automated Benchtop Pipettor 6071 Touch screen controller with software and license 6073 External power supply 6104 Portrait adapter stainless steel plate – Power cords (US, EU, UK, CHN) – Instruction manual – Calibration certificate CORNING LAMBDA ELITEMAX SEMI-AUTOMATED BENCHTOP PIPETTOR... -

Page 7: Specifications

Precision shown as percentage of coefficient of variation. Multi-channel specifications represent the performance of all channels of a pipet. All values shown as reference. Corning EliteMax tips used. See NOTE above. Technical Data Dimensions (W x D x H) Main Unit 20.5 x 11.3 x 14.2 in. -

Page 8: Initial Installation

2.1 Touch Screen User Interface 2.1.1 Main Menu After powering up the Corning Lambda EliteMax Benchtop Pipettor, you will be presented with the main screen or Home Screen. Simply touch the desired button to access the submenu. Plate Filling: Create, run, save, or edit a Plate Filling protocol. -

Page 9: Numeric And Alphanumeric Keypad

2.1.2 Numeric and Alphanumeric Keypad To change settings, touch the text box, dropdown menu, or other control that you wish to interact with. A numeric or alphanumeric keypad will automatically appear next to the selected field or control as shown. If you are unable to edit or change values, the screen is most likely locked or disabled so that you don’t accidentally change any important values or settings. -

Page 10: Protocol Toolbar Description

CAUTION: Verify that the tip rack and other necessary plates/reservoirs are in the correct positions before pressing Run. Running the protocol without the appropriate placement can result in the instrument crashing and possible damage to the instrument or plate sample. CORNING LAMBDA ELITEMAX SEMI-AUTOMATED BENCHTOP PIPETTOR... -

Page 11: Log In User Information

2.1.4 Log In User Information This feature allows different users to share the instrument while avoiding unintentional modification or deletion of user protocols. If this feature is enabled, the user needs to enter their credentials to operate the instrument. After pressing the Log In button, the following screen appears where the user can enter their credentials and log in. User Name and assword fields are case-sensitive. -

Page 12: Creating And Running User Protocols

See Linked File Information (Table 2) for more details. Utilize this dropdown menu to select the rack of tips to be used with this protocol. CORNING LAMBDA ELITEMAX SEMI-AUTOMATED BENCHTOP PIPETTOR... - Page 13 Table 1. General Settings Tab Menu: Plate Filling (continued) Menu Item Description When this box is checked, the instrument will pick up a new row of tips every time a different row or column is accessed on the microplate. Use to select how the disposable tips are going to be consumed. When Specific Row is selected, tips are picked up always from the same ...

- Page 14 To save the protocol, select More Options/Save User Program from the toolbar. To execute the protocol, press Run on the toolbar. CORNING LAMBDA ELITEMAX SEMI-AUTOMATED BENCHTOP PIPETTOR...

-

Page 15: Serial Dilution

At any time while the instrument is running, you can press the Stop button located at the bottom left of the Runtime Screen. This will pause the instrument and give you the option to abort or to continue the protocol. After pressing the Run button, the instrument checks for protocol errors or inconsistency such as the filling of a row that will cause the well to overflow. - Page 16 You can also type in the name of the file. Specify a time delay value in seconds between completion of the current protocol and the start of the next linked protocol. CORNING LAMBDA ELITEMAX SEMI-AUTOMATED BENCHTOP PIPETTOR...

- Page 17 Table 3. General Settings Tab Menu: Serial Dilution Protocol (continued) Menu Item Description When this box is checked, the instrument will perform a full Home axis routine. When this box is checked, the instrument will pause between protocols until the operator instructs the instrument to continue. This setting will override any value in the Link File Delay field.

- Page 18 While executing the protocol, the Runtime screen will be displayed. This screen shows the status of each operation performed by the instrument in real time. The wells in the plate image, located on the right side of the screen, will turn green as they are filled. CORNING LAMBDA ELITEMAX SEMI-AUTOMATED BENCHTOP PIPETTOR...

-

Page 19: Plate-To-Plate Transfers

2.2.3 Plate-to-Plate Transfers By pressing the Plate-to-Plate Transfer button in the main menu, the following screen will appear: NOTE: The Plate-to-Plate Transfer protocol contains two tabs: General Settings and Plate-to-Plate Protocol. See Table 5 for more details. If you are unable to edit or change values, the screen is most likely locked or disabled so that you don’t accidentally change any important values or settings. - Page 20 The instrument uses this information to determine the liquid meniscus height to properly position the tips for optimal liquid transfers. Use to specify the volume [µL] that you want to transfer from the Source Plate to the Destination Plate. CORNING LAMBDA ELITEMAX SEMI-AUTOMATED BENCHTOP PIPETTOR...

- Page 21 Table 6. Plate-to-Plate Protocol Tab Menu (continued) Menu Item Description The volume of air [µL] to be displaced after all transfer volume has been dispensed into the wells. This feature helps to dispense all excess liquid that remains in the tip after each dispense.

- Page 22 To enable the screen, just click or touch on the More Options drop down menu and select Edit User Program (Protocol Toolbar). Now you should be able to edit or change any desired values. Every time you open or save a protocol, the screen is automatically disabled for safety reasons. CORNING LAMBDA ELITEMAX SEMI-AUTOMATED BENCHTOP PIPETTOR...

- Page 23 Table 7. General Settings Tab Menu: Single-channel Head Protocol Menu Item Description Name of the current protocol. When this box is checked, it allows the user to specify the following protocol to be executed after the current one is completed. See Linked File Information below for more details.

- Page 24 If you cannot see the cell because the alphanumeric keypad is on top of it, touch and hold on the top gray bar of the keypad to move it around. CORNING LAMBDA ELITEMAX SEMI-AUTOMATED BENCHTOP PIPETTOR...

- Page 25 The following image shows the convention utilized to define the coordinates, row and column of each well in the plates, regardless of the plate orientation. The same principle applies to tip racks or any other accessory. NOTE: It is very important that the plates, tip racks, or any other accessory is properly defined or created to avoid possible collisions.

- Page 26 When this button is pressed, the following message screen appears. It is recommended that you first select the table’s row in which you would like to perform the task. CORNING LAMBDA ELITEMAX SEMI-AUTOMATED BENCHTOP PIPETTOR...

- Page 27 Table 9. Single-channel Head Protocol – Table Controls (continued) Menu Item Description This button allows you to delete the selected row from the table. It is recommended that you first select the table’s row in which you would like to perform the task. This button allows you to copy the selected row from the table.

-

Page 28: Linking Simple Protocols

2.2.5 Linking Simple Protocols The Corning® Lambda™ EliteMax Benchtop Pipettor allows you to specify a protocol to be run after the current one finalizes. In this way, you can create more complex and advanced protocols by linking the simple ones together. -

Page 29: Collision Detection

2.2.6 Collision Detection Misplacing tip racks, plates, and accessories on the deck can make the instrument more prone to crashes while in motion. When a possible collision occurs or an overload condition is detected, the instrument stops immediately, and all servo motors are de-energized for safety reasons. -

Page 30: Settings: General Configurations

The Settings screen is divided in two areas. The area on the left is used to access different setting menus. The area on the right is used to manually move the liquid head mechanism and instrument’s axis. Use the following tabs to access different configuration menus. CAUTION: Exercise caution when entering values as a collision can occur. CORNING LAMBDA ELITEMAX SEMI-AUTOMATED BENCHTOP PIPETTOR... - Page 31 Use the sub-menus on the right to manually move each axis. Table 10. Manual Axis Motion Menu Item Description When pressing a Single Arrow icon, the selected axis will move one step at a time. To jog the axis at a low speed and in short increments, press and hold the single arrow icon. As soon as you release the control, the instrument will stop.

-

Page 32: Rack Positions Menu

Tip Top Position: The Position in which the tip is touching the liquid meniscus at the well’s working volume. Tip Bottom Position: Approx. 0.1 to 0.3 mm above the bottom of the plate well or reservoir. CORNING LAMBDA ELITEMAX SEMI-AUTOMATED BENCHTOP PIPETTOR... - Page 33 Table 11. Rack Positions Tab Menu (continued) Menu Item Description This section is used to define the rack. Row Spacing: The distance between wells. This value can be obtained by counting the steps between well centers. Well Volume: The working volume [µL] of the well. ...

- Page 34 NOTE: This is highly important, especially when dispensing into dry plates. Proper tip height also helps with plate’s manufacturing deviations. Proper height positioning of the pipet tips in the plate or reservoir is crucial to improve instrument performance and precision. CORNING LAMBDA ELITEMAX SEMI-AUTOMATED BENCHTOP PIPETTOR...

-

Page 35: Procedure To Align New Plates Or To Check Current Plate Positions

3.2.1 Procedure to Align New Plates or to Check Current Plate Positions 1. Press the Home All button to initialize the instrument. 2. From the dropdown menu in the Actual Rack field, select the rack you want to edit or a similar one that can be used as a reference rack to create a newer one. -

Page 36: Tips Calibration

Since the algorithm utilizes calibration points, it’s possible to target a specific volume range or to fine tune reagents of various viscosities. The following chart is a graphical representation of the liquid transfer algorithm. Figure 1. Graphical representation of the liquid transfer algorithm. CORNING LAMBDA ELITEMAX SEMI-AUTOMATED BENCHTOP PIPETTOR... - Page 37 Table 12. Tips Calibration Tab Menu Menu Item Description Tip’s volume capacity [µL]. This will usually be 200 [µL] for 96-well plates (12-channel head). 1 µL Steps Lower Limit Calibration Point. Simple Calibration Method: Fill a row with 10 [µL] using the Plate Filling protocol. Use ...

-

Page 38: Motor Settings

3.5 System Information Tab Press the Refresh button to populate the system information box. This screen is used to detect instrument configuration, software version, and to perform troubleshooting. CORNING LAMBDA ELITEMAX SEMI-AUTOMATED BENCHTOP PIPETTOR... -

Page 39: User Management

Table 13. System Information Tab Menu The instrument can be controlled externally by a PC or embedded system. Special software and driver is necessary. Do not enable remote control when using the instrument as a stand-alone device. CAUTION: This command menu should only be used when performing service or troubleshooting. -

Page 40: Miscellaneous Settings

User Profile privileges. Select the user on the table, and then press the button to delete it. Confirm from the message box. 3.7 Miscellaneous Settings After pressing the Misc tab, the following screen is presented. CORNING LAMBDA ELITEMAX SEMI-AUTOMATED BENCHTOP PIPETTOR... - Page 41 Table 15. Miscellaneous Tab Menu Menu Item Description Set date and time. Press the Adjust button, then adjust the date and time accordingly. When you are done, press the Set button so the changes take effect. Set the touch screen backlight saver timer. Check this box to select your preferred alphanumeric keypad: To prevent loss of data caused by user error or unit failure, it is recommended that you perform an instrument back up on a regular basis or before making any changes to the...

-

Page 42: Software Update

USB flash drive with the instrument as long as it has been formatted to the “FAT32” format. For questions on formatting your drive, contact your IT administrator or your local Corning representative. 4. Insert the USB flash drive with the supplied instrument’s software file (for example “MDZ 042319.frw”) into the port labeled USB... -

Page 43: Spare Parts And Accessories

Claims for transit damage should be filed with the transportation carrier. In the event this product fails within the specified period of time because of a defect in material or workmanship, contact Corning Customer Service at: USA/Canada 1.800.492.1110, outside the U.S. +1.978.442.2200, visit www.corning.com/lifesciences, or contact your local support office. - Page 44 Not for use in humans. These products are not intended to mitigate the presence of microorganisms on surfaces or in the environment, where such organisms can be deleterious to humans or the environment. Corning Life Sciences makes no claims regarding the performance of these products for clinical or diagnostic applications.

Need help?

Do you have a question about the Lambda EliteMax and is the answer not in the manual?

Questions and answers