ATI Technologies Protector SR-61 Manual

Robotic collision sensor

Hide thumbs

Also See for Protector SR-61:

- Manual (30 pages) ,

- Replacement manual (11 pages) ,

- Assembly, installation and operation manual (24 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for ATI Technologies Protector SR-61

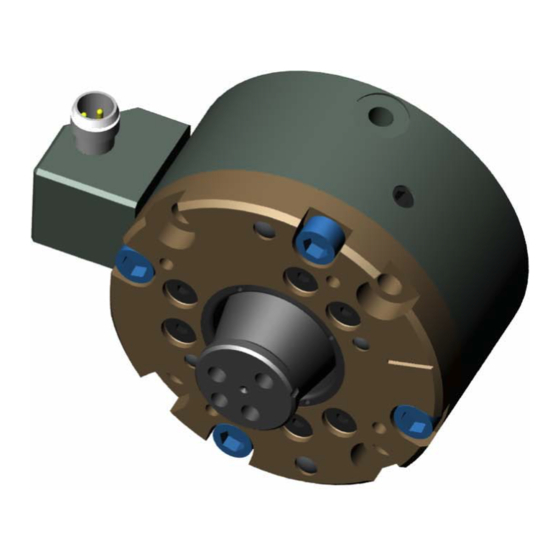

- Page 1 Protector™ Robotic Collision Sensor SR-61 Manual U.S. Patent Nos. 6069415 and 6690208 Document #: 9610-60-1006-13 Engineered Products for Robotic Productivity Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com...

- Page 2 Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 CAUTION: This manual describes the function, application and safety considerations of this product. This manual must be read and understood before any attempt is made to install or operate the product. Failure to read and understand the information in this manual may result in damage to equipment or injury to personnel.

-

Page 3: Table Of Contents

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 Table of Contents Safety ............................6 1.1 Explanation of Notifications ......................6 General Safety Guidelines ......................6 Safety Precautions ........................7 Product Overview ........................8 Product Description ........................8 Installation ..........................9 Mechanical Installation ......................... 9 3.1.1 Fastener Torque Specifications .................. - Page 4 Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 7. Specifications ......................... 31 Serviceable Parts ........................31 SR-61 with C5 Boot ........................31 Drawings ..........................32 SR-61 Collision Sensor with Original Style Switch ..............32 SR-61 Collision Sensor with Current Style Switch ..............33 10.

- Page 5 Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 Glossary of Terms Term Definition Body Cylindrical aluminum housing and air pressure chamber. An interface plate to the user’s robot is usually attached here. A hardened steel ring mounted inside the cover on which the hardened steel ball segments mounted to the stem are nested.

-

Page 6: Safety

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 1. Safety The safety section describes general safety guidelines to be followed with this product, explanation of the notifications found in this manual, and safety precautions that apply to the product. More specific notifications are imbedded within the sections of the manual were they apply. -

Page 7: Safety Precautions

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 1.3 Safety Precautions WARNING: Do not perform maintenance or repair on the Collision Sensor with air pressure applied, current supplied to the sensor, or the robot not in a safe condition. Injury or equipment damage can occur if this is not observed. Always ensure that air pressure has been vented from the unit, that electrical current is not supplied to the Protector’s signal circuit, and that the robot is in a safe, locked-out condition consistent with local and national safety standards before performing maintance or repair on the... -

Page 8: Product Overview

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 2. Product Overview The Protector is a pneumatically-pressurized device offering protection to industrial robots and tooling in the event of accidental impacts and unanticipated loads. The Protector works by “breaking away” from its working geometry in the event of excessive torsional, moment, or compressive axial forces, or any combination of these. -

Page 9: Installation

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 3. Installation The Protector is commonly mounted with its body toward the robot and its stem toward the user tooling, however, this is strictly up to the user. 3.1 Mechanical Installation The Protector can be mounted directly to the robot or to the user tooling using the dowel pin holes and the clearance / tapped holes in the Protector body. -

Page 10: Electrical Connection

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 3.2 Electrical Connection The Protector is connected to the user’s control wiring as a normally-open PNP or NPN proximity switch. The following sketch details the connections between the internal switch and the pins in the Connector Block Assembly. -

Page 11: Test Switch Functionality

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 3.2.1 Test Switch Functionality Once the Protector has been installed and connected as described in the preceding paragraphs, proper electrical operation of the unit may be confirmed. Supply the Protector with approximately 15 psi (1 bar) and ensure that the unit is electrically connected to the user’s control circuit or to a test box per Figure 3.2. - Page 12 Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 Figure 3.3—Collision Sensor Loading Diagram Formulas: Axial Load (F) = F2 Torque (T) = F3*D3 Moment (M) = NOTICE: F1, F2, & F3 consist of the sum of their respective Static, Dynamic, and Working force components;...

-

Page 13: Obtain Required Pressure Setting

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 3.3.2.2 Obtain Required Pressure Setting The pressure setting required can be approximated from the following formula: P = Pm + Pt + Pf + PmA + PtA Where Pm, Pt, and Pf are the pressure components related to the moment, torque, and force load components expected at the break-away. -

Page 14: Determining Exact Pressure Required

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 3.3.3 Determining Exact Pressure Required Set the pressure approximately 5 psi (0.3 Bar) higher than the pressure calculated in Section 3.3.2—Calculating Estimated Pressure Setting. Run the robot through a fully loaded cycle. Watch for crash signals. -

Page 15: Operation

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 4. Operation With the Protector mounted and connected pneumatically and electrically the unit may be placed into operation. If possible, for safety and convenience, position the Protector and the tooling vertically so that the load is suspended below the Protector. -

Page 16: Maintenance

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 5. Maintenance WARNING: Do not perform maintenance or repair on the Collision Sensor with air pressure applied, current supplied to the sensor, or the robot in an unsafe condition. Injury or equipment damage can occur if this is not observed. Always ensure that air pressure has been vented from the unit, that electrical current is not supplied to the Protector’s signal circuit, and that the robot is in a safe, locked-out condition consistent with local and national safety standards before performing maintance or repair on the Collision Sensor. -

Page 17: Cover Plate And Stem Cleaning And Lubrication

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 5.1.2 Cover Plate and Stem Cleaning and Lubrication Clean the lubricant from the working surfaces of the Cam and the Clearance Ring. Set the Cover Plate assembly aside for later re-use (see Figure 5.2). -

Page 18: Cover Plate And Stem Re-Assembly

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 5.1.3 Cover Plate and Stem Re-assembly Apply a generous coating of CRC Extreme Pressure Moly C.V. Joint Grease (Moly Grease) to the top surface of the Piston (see Figure 5.4). Apply a generous coat of Moly Grease to each of the three (3) ball segments on the Stem Assembly and to the rounded edge of the shoulders between the ball segments. -

Page 19: Troubleshooting

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 6. Troubleshooting The Protector will offer exceptional performance in normal operation. However, the Protector is not a compliance device and frequent collisions should be avoided to maximize performance and life. The Protector is designed to automatically return to its working position once the disturbing force is removed. -

Page 20: Cable Replacement

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 6.1 Cable Replacement If the cable attached to your Protector becomes broken or worn, replacement cables may be purchased as follows: Protector Model Number: 9610-061-Pxx-XX-x-x-x. (x = any value). Table 6.1—Cable choices Cable Number Description No cable purchased with Protector –... -

Page 21: Replacement Of Original Style Switch/Connector Block Assembly

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 6.2.1 Replacement of Original Style Switch/Connector Block Assembly Remove the mounting screw using a 2.5mm hex key (see Figure 6.2). Pull the Connector Block away from the Protector being careful not to strain the wires inside. Loosen the locknut on the proximity switch. -

Page 22: Replacement Of Current Style Switch/Connector Block Assembly

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 mounting surface. 6.2.2 Replacement of Current Style Switch/Connector Block Assembly Remove the mounting screw using a 2.5mm hex key (see Figure 6.4). Pull the Connector Block away from the Protector. Discard the entire assembly. Figure 6.4—Removal of Switch/Connector Block Assembly from the Protector 9160-SENSOR-061-2 M3 Socket Head Cap Screw... -

Page 23: Switch Adjustment

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 6.3 Switch Adjustment There are two styles of switch/connector block assemblies for the SR-61 Collision Sensor. The Original Style has a larger connector body than the current style. The current style has an adjustemnt set screw in the side of the connector body, refer to Figure 6.6. -

Page 24: Current Style Switch Adjustment

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 11. Push on the press handle until the switch circuit opens and check the distance traveled on the dial indicator. 12. If the distance traveled is greater than desired turn the proximity switch counterclockwise. If the distance traveled is less turn the proximity switch clockwise. - Page 25 Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 Remove the user-installed mounting hardware from the Protector and remove the unit. Take the unit to a test bench equipped with a clean working surface and compressed air. Ensure that the Protector returns to its Reset or Working position with the stem fully extended and the alignment mark on the stem in line with the alignment mark on the cover plate.

-

Page 26: Spring Conversion

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 6.4 Spring Conversion The collision sensor may be equipped with an assist spring which provides a force equivalent to 5 psi (P05), 10 psi (P10) or 15 psi (P15) of applied pressure. An SR-61 may be field converted to add an assist spring or to contain a different range spring. -

Page 27: Seal Replacement

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 6.5 Seal Replacement Disassemble Cover assembly and Stem Assembly per Section 5.1.1—Cover Plate and Stem Disassembly. Remove the two (2) M4 dog point setscrews using an M2.5 hex key (see Figure 5.5). (If unit is equipped with an assist spring, temporarily place the Stem assembly on top of the Piston and push down while removing the setscrews.) Remove the Stem assembly, Piston assembly and assist spring (if present). -

Page 28: Ip65 Boot Replacement

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 6.6 IP65 Boot Replacement Remove four (4) M3 x 6 SFHCS and Shield Retainer (see Figure 6.11). Remove Boot and discard. Use a clean cloth soaked in isopropyl alcohol to remove gasket sealer from the Stem and Cover Plate. Apply Permatex®... -

Page 29: Weld Splatter Shield Replacement

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 6.7 Weld Splatter Shield Replacement Remove four (4) M3 x 6 SFHCS and Shield Retainer (see Figure 6.12). Remove Weld Shield and EPDM Seal and discard. Install new EPDM Seal by stretching the center hole over the Stem. Place the new Weld Shield on top of the Cover Plate and partially covering the EPDM Seal. -

Page 30: Flexible Boot Replacement

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 6.8 Flexible Boot Replacement Remove the two garter springs retaining the flexible boot to the Protector body and the Interface plate. (see Figure 6.13). Remove the flexible boot and discard. Install the new flexible boot by stretching over the Protector body and the Interface plate. Secure the flexible boot using the two garter springs, make sure the garter springs fit tightly in the groove in the Protector body and the interface plate. -

Page 31: Specifications

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 7. Specifications Figure 7.1—Specifications Displacement Angular +/- 11° max. Torsional +/- 20° max. Axial 0.22 in. (5.6mm) max. Load Limit Moment 248 in-lbs. (28 N-m) Axial 195 lb. (867 N) Torsional 216 in-lbs. (24 N-m) Weight 0.70 lb. -

Page 32: Drawings

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 9. Drawings 9.1 SR-61 Collision Sensor with Original Style Switch Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com... -

Page 33: Collision Sensor With Current Style Switch

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 9.2 SR-61 Collision Sensor with Current Style Switch Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com... - Page 34 Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com...

-

Page 35: Terms And Conditions Of Sale

Manual, Collision Sensor, Protector ™ ,SR-61 Document #9610-60-1006-13 10. Terms and Conditions of Sale The following Terms and Conditions are a supplement to and include a portion of ATI’s Standard Terms and Conditions, which are on file at ATI and available upon request. ATI warrants to Purchaser that Protector products purchased hereunder will be free from defects in material and workmanship under normal use for a period of one (1) year from the date of shipment.

Need help?

Do you have a question about the Protector SR-61 and is the answer not in the manual?

Questions and answers