ATI Technologies Protector SR-61 Assembly, Installation And Operation Manual

Robotic collision sensor

Hide thumbs

Also See for Protector SR-61:

- Manual (30 pages) ,

- Replacement manual (11 pages) ,

- Manual (35 pages)

Table of Contents

Advertisement

Quick Links

™

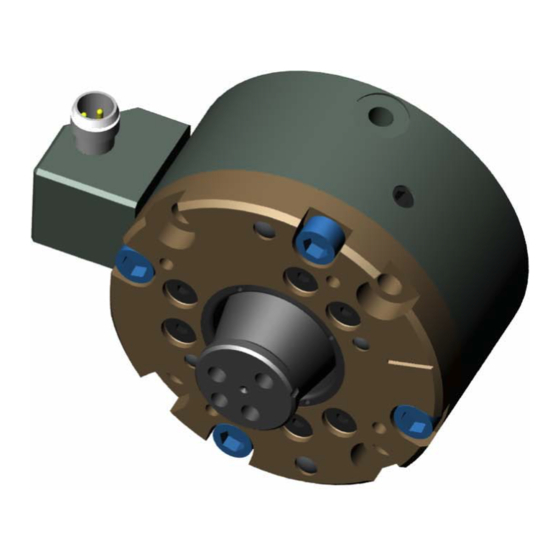

Protector

Robotic Collision Sensor

SR-61

U.S. Patent Nos. 6069415 and 6690208

Installation and Operation Manual

Document #9610-60-1006-10

June 2010

Engineered Products for Robotic Productivity

•

•

•

•

•

•

Pinnacle Park

1031 Goodworth Drive

Apex, NC 27539

Tel: 919.772.0115

Fax: 919.772.8259

www.ati-ia.com

Email: info@ati-ia.com

Advertisement

Table of Contents

Summary of Contents for ATI Technologies Protector SR-61

- Page 1 ™ Protector Robotic Collision Sensor SR-61 U.S. Patent Nos. 6069415 and 6690208 Installation and Operation Manual Document #9610-60-1006-10 June 2010 Engineered Products for Robotic Productivity • • • • • • Pinnacle Park 1031 Goodworth Drive Apex, NC 27539 Tel: 919.772.0115 Fax: 919.772.8259 www.ati-ia.com Email: info@ati-ia.com...

- Page 2 Protector Installation & Operation Manual Document #9610-60-1006-10 CAUTION: This manual describes the function, application and safety considerations of this product. This manual must be read and understood before any attempt is made to install or operate the product, otherwise damage to the product or unsafe conditions may occur.

-

Page 3: Table Of Contents

Protector Installation & Operation Manual Document #9610-60-1006-10 Table of Contents Page Product Overview..........................5 1.1 Introduction ........................... 5 1.2 Safety Considerations........................5 Description ............................6 Installation ............................. 7 3.1 Operating Requirements....................... 7 3.2 Mechanical............................ 7 3.2.1 Fastener Torque Specifications..................8 3.3 Electrical ............................ - Page 4 Protector Installation & Operation Manual Document #9610-60-1006-10 Glossary of Terms Term Definition Body Cylindrical aluminum housing and air pressure chamber. An interface plate to the user’s robot is usually attached here. A hardened steel ring mounted inside the cover on which the hardened steel ball segments mounted to the stem are nested.

-

Page 5: Product Overview

Protector Installation & Operation Manual Document #9610-60-1006-10 1. Product Overview 1.1 Introduction The Protector™ is a pneumatically-pressurized device offering protection to industrial robots and tooling in the event of accidental impacts and unanticipated loads. The Protector™ works by “breaking away” from its working geometry in the event of excessive torsional, moment, or compressive axial forces, or any combination of these. -

Page 6: Description

Protector Installation & Operation Manual Document #9610-60-1006-10 2. Description The Protector™ consists of a piston housing (body) closed with a cover plate assembly. A stem assembly protrudes through the cover plate assembly. The cover plate assembly incorporates a cam to accurately and repeatably position the stem assembly. -

Page 7: Installation

Protector Installation & Operation Manual Document #9610-60-1006-10 3. Installation 3.1 Operating Requirements The Protector™ requires clean, dry, non-lubricated air delivered from a user-supplied, self-relieving regulator. The Protector™ is certified for accurate, repeatable operation when supplied with air at 20–90 psi (1.4–6.2 bar ) of pressure operated in an environment with an ambient temperature range of 40–120°F (5–50°C). -

Page 8: Fastener Torque Specifications

Protector Installation & Operation Manual Document #9610-60-1006-10 3.2.1 Fastener Torque Specifications M3-0.5 Cap Screw 19 in-lbs M4-0.7 Cap Screw 41 in-lbs M5-0.8 Cap Screw 85 in-lbs. Table 3.1—Recommended torques for ATI supplied fasteners CAUTION: Before connecting or uncoupling the air supply to the Protector™ insure that the air supply is turned off and that all trapped air has been vented. -

Page 9: Switch Adjustment

Protector Installation & Operation Manual Document #9610-60-1006-10 CAUTION: The user is responsible for connecting the collision sensor to their controls and providing an “electrical load” in series with the collision sensing switch. The switch is rated for instrument level signals of 100mA (max.) at 10–30 Once the Protector™... -

Page 10: Cable Replacement

Protector Installation & Operation Manual Document #9610-60-1006-10 Figure 3.3—Checking Switch Height Adjustment 14. Tighten the locknut on the proximity sensor. 15. Slide the connector block over the proximity sensor carefully routing the wires into the slotted area under the proximity sensor. Line up the dowel pin with the hole in the body and the screw hole with the threaded hole in the body. -

Page 11: Pneumatic

Protector Installation & Operation Manual Document #9610-60-1006-10 3.4 Pneumatic Compressed air is to be supplied to the port marked “P” in the range of 20 psi to 90 psi. This port accepts #10-32 or M4 pneumatic fittings. The pressure setting required for a particular application can be estimated using the procedure outlined in section 3.4.1. -

Page 12: Obtain Required Pressure Setting

Protector Installation & Operation Manual Document #9610-60-1006-10 Formulas: Axial Load (F) = F2 Torque (T) = F3*D3 Moment (M) = √ (F1*D1) + (F2*D2) Notes: F1, F2, & F3 consist of the sum of their respective Static, Dynamic, and Working force components;... -

Page 13: Determining Exact Pressure Required

Protector Installation & Operation Manual Document #9610-60-1006-10 P = [(50 lb-in x 0.376) – 3.3) + (30 lb-in x 0.444) – 6.3] + [(50 lb-in x 0.376 x 2G’s) – 3.3] = 15.5 psi + 7 psi + 34.3 psi = 56.8 psi A nominal air pressure setting of 57 psi is required. -

Page 14: Maintenance

Protector Installation & Operation Manual Document #9610-60-1006-10 5. Maintenance CAUTION: Do not adjust or remove either of the two (2) set screws installed in the wall of the Body. Doing so may result in damage to the unit or failure of the switch to operate. -

Page 15: Replacement

Protector Installation & Operation Manual Document #9610-60-1006-10 5.2.2 Replacement 1. Provide 5 to 15 psi of air to the unit at the port marked “P” (unless the unit is equipped with preload springs). CAUTION: If the piston is not up against the dog point screws while screwing in the proximity switch, applying air to the unit could damage the proximity switch. - Page 16 Protector Installation & Operation Manual Document #9610-60-1006-10 2. Remove the Cover Plate assembly by carefully pulling it straight up and off of the Body. This may be difficult due to the close fit of the dowel pins used to align the parts.

-

Page 17: Re-Assembly

Protector Installation & Operation Manual Document #9610-60-1006-10 Figure 5.5—Cleaning and Re-lubricating the Stem Figure 5.6—Cleaning and Re-lubricating Top Surface of Piston 5.3.2 Re-assembly 1. Apply a generous coating of CRC Extreme Pressure Moly C.V. Joint Grease (Moly Grease) to the top surface of the Piston (see Figure 5.6). 2. -

Page 18: Spring Conversion

Protector Installation & Operation Manual Document #9610-60-1006-10 Figure 5.7—Cover Plate and Stem Alignment 5.4 Spring Conversion The collision sensor may be equipped with an assist spring which provides a force equivalent to 5 psi (P05), 10 psi (P10) or 15 psi (P15) of applied pressure. An SR-61 may be field converted to add an assist spring or to contain a different range spring. -

Page 19: Seal Replacement

Protector Installation & Operation Manual Document #9610-60-1006-10 Figure 5.8—Piston Orientation 5.5 Seal Replacement 5.5.1 Disassembly 1. Disassemble Cover assembly and Stem Assembly per section 5.3.1. 2. Disassemble Piston per section 5.4.1. 3. Remove and discard o-ring from groove on outside of Piston. 4. -

Page 20: Ip65 Boot Replacement

Protector Installation & Operation Manual Document #9610-60-1006-10 5.6 IP65 Boot Replacement 5.6.1 Disassembly 1. Remove four (4) M3 x 6 SFHCS and Shield Retainer (see figure 5.10). 2. Remove Boot and discard. 3. Use a clean cloth soaked in isopropyl alcohol to remove gasket sealer from the Stem and Cover Plate. -

Page 21: Troubleshooting

Protector Installation & Operation Manual Document #9610-60-1006-10 2. Place the new Weld Shield on top of the Cover Plate and partially covering the EPDM Seal. Line up the screw holes and clearance slots. 3. Place the Shield Retainer on top of the Weld Shield. Line up the screw holes and clearance slots. - Page 22 Protector Installation & Operation Manual Document #9610-60-1006-10 be necessary. See section 3.3.1 for adjustment procedure. If the switch is closed under this condition examine the system for control wiring and logic problems. Check for mechanical obstructions. The Protector™ will not be free to rotate back to its working position if obstructions prevent its free motion.

-

Page 23: Specifications And Drawings

Protector Installation & Operation Manual Document #9610-60-1006-10 7. 7. Specifications and Drawings 7.1 SR-61 Specifications Displacement Load Limit Operating Connector Type Sensitivity Spring Assist Weight Switch Rating Option Angular Torsional Axial Moment Axial Torsional Pressure Temp. 3-pole “Nano” .02 in. 5, 10,15 psi 0.22 in. -

Page 24: Terms And Conditions Of Sale

Protector Installation & Operation Manual Document #9610-60-1006-10 8. Terms and Conditions of Sale The following Terms and Conditions are a supplement to and include a portion of ATI’s Standard Terms and Conditions, which are on file at ATI and available upon request. ATI warrants to Purchaser that Protector™...

Need help?

Do you have a question about the Protector SR-61 and is the answer not in the manual?

Questions and answers