Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Carlisle Ransburg DR-1

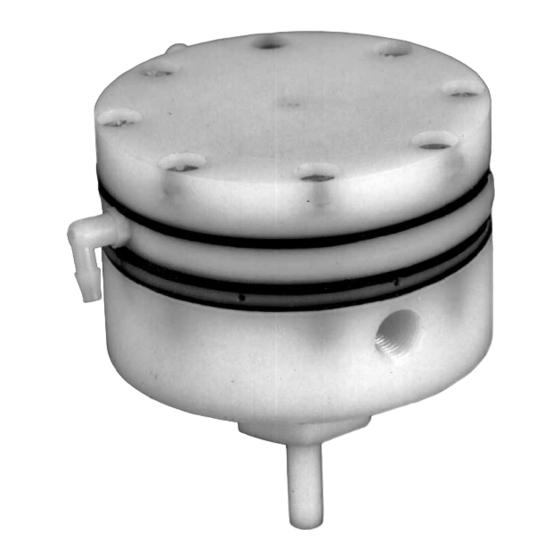

- Page 1 SERVICE MANUAL DR-1 Plastic Fluid Regulator Model: 75902 IMPORTANT: Before using this equipment, carefully read SAFETY PRECAUTIONS and all instructions in this manual. Keep this Service Manual for future reference. LN-9228-00-R5 (03/2019) 1 / 21 www.carlisleft.com...

- Page 2 MANUAL CHANGES NOTE: This manual has been changed from revision LN-9228-00.4 to revision LN-9228-00-R5. Reasons for this change are noted under “Manual Change Summary” inside the back cover of this manual. LN-9228-00-R5 (03/2019) 2 / 21 www.carlisleft.com...

-

Page 3: Table Of Contents

CONTENTS CONTENTS CONTENTS SAFETY: SAFETY: Safety Precautions ..............................4 Safety Precautions ..............................4 Hazards / Safeguards ..............................5 Hazards / Safeguards ..............................5 INTRODUCTION: INTRODUCTION: 9-10 9-10 Features ..................................9 Features ..................................9 Specifications ................................9 Specifications ................................9 Graphs ..................................10 Graphs .................................. -

Page 4: Safety

This information relates to USER SAFETY and safety literature for your equipment, contact your local and PREVENTING EQUIPMENT PROBLEMS. To help you Carlisle Fluid Technologies representative or Carlisle Fluid recognize this information, we use the following symbols. Technologies technical support. -

Page 5: Hazards / Safeguards

SAFETY Return To Contents AREA SAFEGUARDS HAZARD Tells where hazards Tells how to avoid the hazard. Tells what the hazard is. may occur. Fire Hazard Spray Area Fire extinguishing equipment must be present in the Improper or inadequate spray area and tested periodically. operation and maintenance procedures will cause a fire Spray areas must be kept clean to prevent the... - Page 6 SAFETY Return To Contents AREA SAFEGUARDS HAZARD Tells where hazards Tells how to avoid the hazard. Tells what the hazard is. may occur. Explosion Hazard Spray Area Improper or inadequate Electrostatic arcing must be prevented. Safe sparking operation and maintenance distance must be maintained between the parts being procedures will cause a coated and the applicator.

- Page 7 SAFETY Return To Contents AREA SAFEGUARDS HAZARD Tells where hazards Tells how to avoid the hazard. Tells what the hazard is. may occur. Spray Area / Electrical Discharge High Voltage There is a high voltage device Parts being sprayed and operators in the spray Equipment that can induce an electrical area must be properly grounded.

- Page 8 SAFETY Return To Contents AREA SAFEGUARDS HAZARD Tells where hazards Tells how to avoid the hazard. Tells what the hazard is. may occur. Electrical Discharge Electrical Unless specifically approved for use in hazardous Equipment locations, the power supply, control cabinet, and all High voltage equipment is utilized in the process.

-

Page 9: Introduction

INTRODUCTION Return To Contents INTRODUCTION FEATURES • Two independently controlled flow pressure ranges. • High flow range port for higher fluid deliveries. • Low flow range for more precise control over lower fluid deliveries. • Interchangeable low flow ratios (1:1, 1:2, 1:3, 1:4, 1:6, 1:8, 1:10) for precise control. • Plastic and coated wetted parts for decreased color change time. • Factory Mutual listed in conjunction with the Aerobell 33 SPECIFICATIONS Environmental/Physical Height With Fittings: Model B: 3-inches Diameter: 3-3/4-inches w/fittings Mechanical... -

Page 10: Graphs

INTRODUCTION Return To Contents DR-1 FLOW VS SIGNAL PRESSURE DR-1 Flow vs. Signal Pressure Viscosity=40 sec. Zahn #2 15ft 1/4 I.D. tubing HIGH FLOW .093 orfice 1:10 SIGNAL PRESSURE (PSI) DR-1 Flow vs. Signal Pressure 1400 Viscosity=25 sec. Zahn #2 1200 15ft 1/4 I.D. -

Page 11: Operation

OPERATION Return To Contents OPERATION The DR-1 Plastic Regulator is designed to provide remote The low flow (i.e. 1:2, 1:4, etc.) port provides a lower, more control fluid regulation for automatic coating applications. precise flow response curve. Fluid output, as a result, is less likely to be affected by pilot signal errors. An increase The regulator features two independently controllable flow in the ratio (i.e. from 1:2 to 1:4) provides a lower slope in the pressure ranges from the fluid output port. The high flow flow/air signal pressure curve, but, more precise response range port accomm-odates higher fluid deliveries and min-... -

Page 12: Maintenance

MAINTENANCE Return To Contents MAINTENANCE TOOLS REQUIRED 1. Remove Item 4 (8-screws) holding the regulator as- sembly together with the screwdriver. • 3/4-inch Open End Wrench 2. Remove Item 1 (cap), Item 9 (diaphragm), spacer ring • Adjustable Wrench assembly and the lower housing assembly. •... -

Page 13: Regulator Exploded View

MAINTENANCE Return To Contents Figure 1: Regulator Exploded View LN-9228-00-R5 (03/2019) 13 / 21 www.carlisleft.com... -

Page 14: Assembly Procedures

MAINTENANCE Return To Contents ASSEMBLY PROCEDURES Place Item 11 (regulating needle) into lower housing with the ball end against Item 11 (regulating seat). (Refer to Figure 1) Place Item 10 (o-ring) on Item 13 (retaining plug). Place Item 10 (o-ring) in the slot on Item 6 (lower Place Item 12 (spring) into lower housing over Item 11 diaphragm retainer). -

Page 15: Aerobell 33R (Robot Mount)

MAINTENANCE Return To Contents AEROBELL 33R (ROBOT MOUNT) 3. Set air regulator to zero. Gradually increase fluid pressure to 80 psi, visually checking for leakage. Clean or replace Item 11 (needle and seat) if leakage at outlet port. NOTE † If water or solvent is used for testing, it is normal for minor leakage to occur at the fluid output port, due to the low viscosities of these fluids. -

Page 16: Troubleshooting Guide

MAINTENANCE Return To Contents TROUBLESHOOTING GUIDE General Problem Possible Cause Solution Flush clean Plugged inlet No Flow Remove and clean or replace Item 11 (needle and seat) stuck Check air pilot No pilot air Remove and clean or replace Item 11 (needle and seat) dirty Will Not Shut Off Check air supply Pilot air not shut off... -

Page 17: Parts Identification

PARTS IDENTIFICATION Return To Contents PARTS IDENTIFICATION Figure 3: Regulator Cross-Sectional View LN-9228-00-R5 (03/2019) 17 / 21 www.carlisleft.com... - Page 18 PARTS IDENTIFICATION Return To Contents DR-1 PLASTIC FLUID REGULATOR - PARTS LIST (Figures 1 & 3) Item # Part # Description Select Options Below DR-1 Regulator Assembly*** 75902-01 Ratio 1:1 75902-02 Ratio 1:2 75902-03 Ratio 1:3 75902-04 Ratio 1:4 75902-06 Ratio 1:6 75902-08 Ratio 1:8...

- Page 19 PARTS IDENTIFICATION Return To Contents DR-1 PLASTIC FLUID REGULATOR - PARTS LIST (Figures 1 & 3) (Cont.) Item # Part # Description Select Options Below Upper Diaphragm Retainer, For (Cont.): 12** 74161-00 Spring 75920 Retaining Plug, Aerobell 33R (Robot Mount) 74157-04 Diaphragm, Center 74183-20C...

-

Page 20: Manual Change Summary

MANUAL CHANGES Return To Contents MANUAL CHANGE SUMMARY LN-9228-00-R5 - Replaces LN-9228-00.4 with the folowing changes: Change Description Page(s) Update to newest manual format LN-9228-00-R5 (03/2019) 20 / 21 www.carlisleft.com... - Page 21 This product is covered by Carlisle Fluid Technologies materials and workmanship limited warranty. The use of any parts or accessories, from a source other than Carlisle Fluid Technologies, will void all warranties. For specific warranty information please contact Carlisle Fluid Technologies.

Need help?

Do you have a question about the Ransburg DR-1 and is the answer not in the manual?

Questions and answers