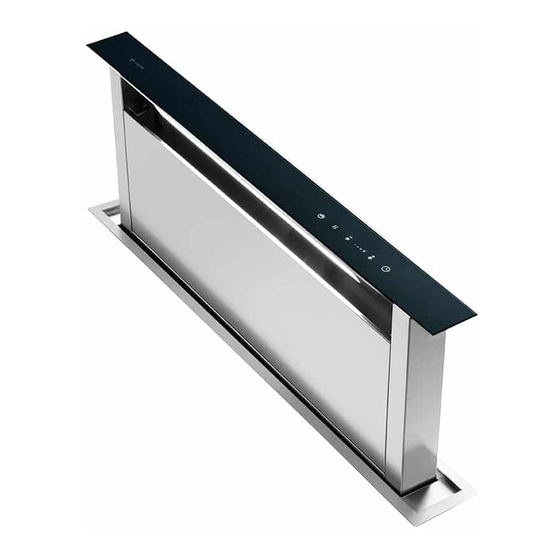

Summary of Contents for Caple DD912BK

- Page 1 D o w n d r a f t H o o d I n s t r u c t i o n M a n u a l DD912BK Contact Caple on 0117 938 7420 for spare parts or www.caple.co.uk...

-

Page 2: Table Of Contents

Safety Instructions Dimensions Installing the Extractor Grease Filter Removal, Installing the Activated Charcoal Filter Electrical Connection Operating the Downdraft Extractor Cleaning the Extractor Troubleshooting Aftersales Service Caple Contact Details Instruction manual DD912BK Please keep this instruction manual for future reference... -

Page 3: Introduction

We thank you for taking note of these suggestions before installing and using the appliance. They have been written for your personal safety and the safety of others. Instruction manual DD912BK Please keep this instruction manual for future reference... -

Page 4: Safety Instructions

- Do not ever change or try to change the characteristics of this appliance. This would be a danger. Repairs must be performed only by a Caple approved engineer. - Always disconnect the hood before carrying out cleaning or maintenance operations. - Page 5 field of action of the extractable unit. Keep your hands clear of moving parts. - There must be a minimum space of 50mm between the edge of a gas hob and the downdraft frame. Instruction manual DD912BK Please keep this instruction manual for future reference...

- Page 6 Caple. The air collected must not be conveyed into a flue used for smoke or fumes from appliances powered by anything other than electricity (central heating systems, etc.).

- Page 7 Registration can also be completed online by visiting www.caple.co.uk. Ensure you keep your warranty card safe, you may need to show it to Caple Service together with proof of purchase. If you fail to show your warranty card you will incur all repair charges.

-

Page 8: Dimensions

In the absence of any instructions supplied with a gas hob, there must be a minimum space of 50mm between the edge of a gas hob and the downdraft frame. Instruction manual DD912BK Please keep this instruction manual for future reference... -

Page 9: Installing The Extractor

100mm for the 1200cm model and 542 x 100mm for the 60cm model. › Put the Downdraft in the opening, inserting it from above as shown in (Fig. 2). Instruction manual DD912BK Please keep this instruction manual for future reference... - Page 10 (Fig. 7). The motor can be installed either on the front or rear side of the downdraft. After installing the motor, connect the air ducts. Instruction manual DD912BK Please keep this instruction manual for future reference...

- Page 11 Before connecting the air exhaust hose, make sure that the non-return valves can move freely. In case of outside air discharge installation, fit a non-return valve to prevent wind and back air from entering. Instruction manual DD912BK Please keep this instruction manual for future reference...

- Page 12 Air can be vented either through a 5mm slot around the whole plinth (Fig 11a) or through a plinth grille (Fig 11b). N OT E : Universal plinth grille (GRILL/SENSE600) can be purchased at www.caple.co.uk Fig 11a Fig 11b 5mm gap...

-

Page 13: Grease Filter Removal, Installing The Activated Charcoal Filter

After having replaced the filters, reinstall the front stainless steel panel, otherwise the downdraft is not functional. N OT E : Replacement filters (CAP43CF) can be purchased at www.caple.co.uk. Instruction manual DD912BK Please keep this instruction manual for future reference... -

Page 14: Electrical Connection

The appliance must be fed through a differential protection device (RCD), with a nominal residual current not exceeding 30mA. If the power cord is damaged, call Caple Service to avoid any risk. WA R N I N G : The downdraft connection to the electrical network must be carried out only by professional and qualified technicians. - Page 15 Check that: › Power is enough. › Feeder lines (mains) are in good condition. › The cable diametre complies with installation regulations. Instruction manual DD912BK Please keep this instruction manual for future reference...

-

Page 16: Operating The Downdraft Extractor

LED switching on.(see timer can be cancelled by pressing the key again. 'Timing' on pg 11 for further information) • This signals that all filters have been satu function selection Instruction manual DD912BK Please keep this instruction manual for future reference... - Page 17 If there is an obstacle while the extractable unit is closing, the Downdraft stops closing and rises again thanks to a security system. WA R N I N G : This operation has to be carried out by a specialised technician. Instruction manual DD912BK Please keep this instruction manual for future reference...

- Page 18 › If the appliance is working at 3rd speed, it is automatically switched to 2nd speed, after › 7 minutes operation. Operation speeds can also be changed during operation. The energy consumption of the appliance in standby mode is lower than 0.5W. Instruction manual DD912BK Please keep this instruction manual for future reference...

-

Page 19: Cleaning The Extractor

• This signals the speed setting, by only the relevant LED switching on.(see 'Timing' on pg 11 for further information) • This signals that all filters have been satu Instruction manual DD912BK Please keep this instruction manual for future reference... - Page 20 The LED light must be replaced by an authorised engineer or similar only. For more Unplug the unit from the power supply before starting the process. information, please contact Caple service - 0117 938 7420 or service@caple.co.uk Unplug the unit from the power supply before starting the process.

-

Page 21: Troubleshooting

» The non-return valves of the suctioning unit are free to rotate. The cooker hood stops in the middle of Check that: operation. » There is not a power outage. » The omnipolar device has not tripped. Instruction manual DD912BK Please keep this instruction manual for future reference... -

Page 22: Aftersales Service

Any maintenance operation on your appliance should be carried out by: › Either your retailer; › Or another Caple approved engineer or similar qualified person. If a problem still persists and further assistance is required, please contact our Caple after sales team on: T - 0117 938 7420 E - service@caple.co.uk... - Page 23 Instruction manual DD912BK Please keep this instruction manual for future reference...

-

Page 24: Caple Contact Details

Caple Service BS11 8DW Fourth Way T: 0117 938 1900 Avonmouth E: service@caple.co.uk Bristol www.caple.co.uk...

Need help?

Do you have a question about the DD912BK and is the answer not in the manual?

Questions and answers