Dixie Narco P Series Technical Manual

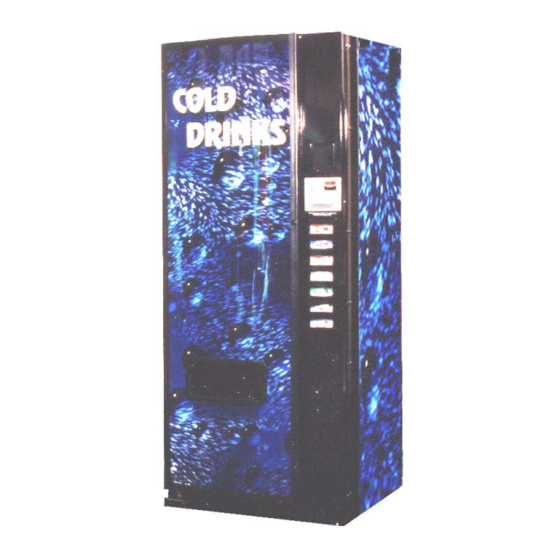

Coca-cola lean marketing vender

Hide thumbs

Also See for P Series:

- Manual (81 pages) ,

- Technical manual (76 pages) ,

- Technical manual (76 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Dixie Narco P Series

- Page 1 Coca-Cola Lean Marketing Vender P Series LMV Models DN552P & DN756P Beginning Production Run 6925CB Dixie-Narco, Inc. P.O. Drawer 719 Manufactured by Williston, SC 29853-0719 803-266-5001 fax: 803-266-5049 Visit us on the web: www.dixienarco.com Part #803,903,780.11...

-

Page 2: Table Of Contents

Table of Contents GENERAL INFORMATION Application................................. 4 Vender Safety Precautions..........................4 Product Identification............................4 Physical Characteristics ..........................4 INSTALLATION & SETUP Unpacking the Vender............................. 5 Electric Power Requirements......................... 5 Ground the Vender............................5 Placing the Vender on Location........................5 Level the Vender .............................. 6 Space the Vender............................. - Page 3 Table of Contents WIRING DIAGRAMS AND SCHEMATICS Figure 1 – LMV Wiring Diagram ......................49-50 Figure 2 – Compressor Wiring Diagram .....................51 PARTS LIST MAIN DOOR EXTERIOR ........................52-53 MAIN DOOR INTERIOR .........................54-55 COIN INSERT............................56-57 SELECT PANEL.............................58 T8 LIGHTING..............................59 ELECTRONIC COMPONENTS ........................60 INNER DOOR ............................61-62 HARNESSING ...............................63 POWER DISTRIBUTION BOX.......................64-65...

-

Page 4: General Information

GENERAL INFORMATION P SERIES The second alpha-character identifies the year: APPLICATION B = 2003 This information applies to P Series venders C = 2004 manufactured the third quarter 2003 which have D = 2005 significant differences in programming and parts content from previous venders. -

Page 5: Unpacking The Vender

INSTALLATION & SETUP P SERIES The Dixie-Narco P Series vender is designed ELECTRIC POWER NEEDED utilizing the latest technology. Refer to the cabinet serial number plate to determine the proper voltage and frequency the machine UNPACKING THE VENDERS requires (domestically this requirement is 120 Volts, Remove the stretch wrap and top cover from the 60 Hertz). -

Page 6: Level The Vender

GENERAL INFORMATION P SERIES INSTALLATION & SETUP GUIDE Narco Technical Service Department or your Dixie- Narco Representative for assistance. COIN CHANGERS & OTHER ACCESSORIES LEVEL THE VENDER The vender must have an MDB coin changer When the vender is level, the door can be opened to installed and can have an MDB bill acceptor any position and it will not move by itself. -

Page 7: Loading Product

GENERAL INFORMATION P SERIES INSTALLATION & SETUP GUIDE Loading Product SERVICE NOTE The P Series Vender is designed to vend a wide range of packages. Battery Backup (SBC) The Single Board Controller is equipped with a battery backup which is used to retain information programmed in All P Series Venders are shipped ready to vend the system (pricing, time, date, etc.) in case of power... - Page 8 PROGRAMMING P SERIES COCA-COLA EVS REVISION 3.0 P SERIES PROGRAMMING METHOD August 2003 The controller has two modes of operation: SALES and SERVICE. SALES MODE: In sales mode, on power up display will show software installed in vender, then change to POS message or decimal point.

- Page 9 PROGRAMMING P SERIES The following are error codes that may be displayed and detailed information accessed: NONE, VEND, CTRL, SEL, STS, CHAR, BUAL, CRDR, S-D, and RFRG. Press select button 2 or 3 to scroll through any error codes that are present.

- Page 10 PROGRAMMING P SERIES "LA", indicating a low coin acceptance rate (less than 80%). "DIS", indicating an acceptor is unplugged. "ROUT", indicating a coin was mis-routed. Press select button 1 will return to "CHAR" if all changer errors have not been cleared.

- Page 11 PROGRAMMING P SERIES "TUFL" TUBE FILL ROUTINE This function allows you to count the coins loaded in the top (separator) of the coin mech that will be routed to an inventory tube. Press select button 4 to enter mode and the total number of the coin type being entered will be displayed and counted in the vender controller as they are installed.

-

Page 12: Programming

PROGRAMMING P SERIES used) are lit with the horizontal elements and "Use Correct Change Only" indicators are lit with the vertical elements. Press select button 1 to return to "DSP". Press select button 2 to scroll to "RELY". "RELY" RELAY TEST This function allows you to test the relay electronic control of the compressor (CNP#), the evaporator fan(s) (FAN#), and the sign front light (LIT#). - Page 13 PROGRAMMING P SERIES * "PRIC" - PRICE SETTING ROUTINE This function allows the user to set pricing. When Configuration Switch 1 is programmed to "C1 1", multi- pricing is on and a price for each selection needs to be set.

- Page 14 PROGRAMMING P SERIES * "CON" MACHINE CONFIGURATION This function allows the user to access and change the programming of the following machine configuration settings. If you press select button 4 and the display shows "LOC", this means configuration setting changes will not be allowed.

- Page 15 PROGRAMMING P SERIES C7 - Configuration Switch 7 - Save Credit This code is used to determine how long a credit will be saved. C7 0 will save the credit for five minutes. C7 1 will save the credit indefinitely.

- Page 16 PROGRAMMING P SERIES Note: If the value set is 00.00, the correct change indicator will never come on. If the controller determines that it cannot return the exact amount of the correct change value or any value less than it then the indicator will be turned on.

- Page 17 PROGRAMMING P SERIES Press select button 4 with the display showing the setting you wish to use and display will return to "ENB#". Press select button 2 to scroll to "YEAR". "YEAR" - Year Setting (2000 to 2099) Press select button 4 and the current year setting will show on display.

- Page 18 PROGRAMMING P SERIES This function is used to disable Lighting Conservation Control "ENB0" (lights will be on at all times) or enable Lighting Conservation Control "ENB1" (lights can be set to turn off). Press select button 4 and the # will begin to flash.

- Page 19 PROGRAMMING P SERIES Press select button 4 and the current “ENB#” setting (#) will start flashing. Press select button 2 or 3 to scroll between “ENB0” and “ENB1”. Press select button 4 with the display showing the setting you wish to use and the display will return to a solid “ENB#”.

- Page 20 PROGRAMMING P SERIES “SETP” - Set Point Control Routine (Default Temperature 35 F / 1.5 This function is used to set the average product temperature for initial pull down and reload recovery. Press select button 4 and “tt.tx” will show on the display where x is F (Fahrenheit) or C (Celsius) and tt.t is the degrees.

- Page 21 PROGRAMMING P SERIES Display will return to "xxx#'. Press select button 2 to scroll to the next day to set or press select button 1 to return to "DAY". Press select button 2 to scroll to "HOUR". "HOUR" - Start Hour and Minute Setting This function is used to set the hours and minutes to start selection blocking.

- Page 22 PROGRAMMING P SERIES *"BLC2" - BLOCK SEL ECTION BANK 2 ROUTINE (CON 2 must be enabled - C2 1) This function is a second set used to set selection(s) which will be blocked during certain periods of the day. Press select button 4 will enter "ENB#" with # being the current enable setting.

- Page 23 PROGRAMMING P SERIES “HOUR” - Start Hour and Minute Settings Set this feature using instructions for “BLC1" "STRT" "HOUR". “STOP” - Stop Discount Pricing This function is used to set the day(s) and times to stop discount prices. Press select button 4 and “DAY” will show on the display.

- Page 24 PROGRAMMING P SERIES enable (don’t allow Vending). Press select button 4 and “#” will start flashing. Press select button 2 or 3 to scroll between "UNDO" and "UND1". Press select button 4 with the display showing the setting you wish to use to save that setting.

- Page 25 PROGRAMMING P SERIES "SDEP" - SET COLUMN DEPTH ROUTINE (CON 2 must be enabled – “C2 1” – This must be set before setting package type to “CUSTOM”) This function is used to set the product depth for the selected column.

- Page 26 PROGRAMMING P SERIES This function is used to set the hours and minutes to stop satellite vending and can be set in the same manner as Start Hour and Minute Setting. Press select button 1 to return to "STOP". Press select button 2 to scroll to "SEL".

- Page 27 PROGRAMMING P SERIES COMMON PACKAGE SETTING INSTRUCTIONS RESUME HERE “SAVE” will be displayed. Press select button 1 to keep the current package type and “XX #” will be displayed. Press select button 4 to save the package type selected and “PRM# “ will be displayed, where # is the column to prime.

-

Page 28: Quick Reference Prompts

PROGRAMMING P SERIES P SERIES SBC QUICK REFERENCE MENU PROMPTS Main Menu Sub-Menu Sub-Sub-Menu Main Menu Sub-Menu Sub-Sub-Menu EROR – Error VEND – Vend Mech Error CJ# - Column Jam # TEST con't. DSP – Dislay CS – Chute Sensor failure... -

Page 29: Set Vender Type

PROGRAMMING P SERIES Setting The Vender Type NORMAL MODE: Note: If ”COLS” “” appears on the display on power up with the door open, you will need to program the vender model number in the controller. To program with “COLS” on the display press select button 4. The display will show “6” for six columns. -

Page 30: Default Space To Sales Setting

PROGRAMMING P SERIES Factory Default Setting Selection # Column # Selection # Column # Page 30 of 83... -

Page 31: Power

INSTALLATION & SETUP P SERIES The most important facets of proper vender care and 3. Any corrosion inside of the vender should be maintenance are the electrical power supplied to it, removed with a fine steel wool and the area leveling, and cleanliness of the machine and its should be painted with aluminum paint. -

Page 32: Eprom Replacement

PROGRAMMING P SERIES EPROM REPLACEMENT Software changes / upgrades are accomplished by changing the EPROM on the Control Board. Single Board Controller (SBC) Software Update Procedure This document describes how to update software on the Single Board Controller (SBC). Note: All existing software revisions, except software version 804,919,770.01, will automatically update the software revision... - Page 33 PROGRAMMING P SERIES the newly installed EPROM) shows on the display, the SBC software has been successfully updated. Note: To remove the EPROM after programming is complete, remove power to the vender, ground yourself on the vender cabinet before removing the EPROM, remove the EPROM, while still grounded install a label on the microprocessor showing the revision of software that is installed in the SBC, power the vender back on and test for proper operation.

-

Page 34: Major Component Description Electrical

MAJOR COMPONENT DESCRIPTION P SERIES ELECTRICAL REFRIGERATION Transformer Provides 24 volt and 12 volt 115 VAC power to the Machine Controller Compressor Embraco, 1/3 HP, 115 VAC, 60 Hz Fuse (F1) 1.6 Amp Slo Blo 1 Phase Control Board Power Unit uses 9.0 oz. -

Page 35: Sbc Control Board

PROGRAMMING P SERIES SBC CONTROL BOARD Motor Secondary DEX Display Select Switches Temp Sensor Energy Management Sold Out LED’s Ready to Vend AC Power Battery Service Switch Page 35 of 83... -

Page 36: All Coins Are Rejected

TROUBLESHOOTING FLOWCHARTS These charts are intended to isolate and correct most problems you might encounter. ALL COINS ARE REJECTED Page 36 of 83... -

Page 37: All Bills Are Rejected

TROUBLESHOOTING P SERIES ALL BILLS ARE REJECTED Page 37 of 83... -

Page 38: Incorrect Change Dispensed

TROUBLESHOOTING P SERIES INCORRECT CHANGE DISPENSED Page 38 of 83... -

Page 39: Selection Will Not Vend

TROUBLESHOOTING P SERIES SELECTION WILL NOT VEND Page 39 of 83... -

Page 40: Ice / Frost On Evaporator

TROUBLESHOOTING P SERIES ICE / FROST ON EVAPORATOR COMPRESSOR RUNS CONTINUOUSLY Page 40 of 83... -

Page 41: Compressor Will Not Start

TROUBLESHOOTING P SERIES COMPRESSOR WILL NOT START Page 41 of 83... -

Page 42: Machine Not Cooling

TROUBLESHOOTING P SERIES MACHINE NOT COOLING Page 42 of 83... -

Page 43: Can't Enter The Menu Or Diagnostics

TROUBLESHOOTING P SERIES CAN’T ENTER THE MENU OR DIAGNOSTICS Note: Prior to checking wires or connections, ensure power has been removed from vender. Page 43 of 83... -

Page 44: Lights Are Not On

TROUBLESHOOTING P SERIES LIGHTS ARE NOT ON Page 44 of 83... -

Page 45: One Or Motors Run When The Main Door Is Closed

TROUBLESHOOTING P SERIES ONE OR MORE MOTORS RUN WHEN MAIN DOOR IS CLOSED (Display Scrolls “PRIM”) Page 45 of 83... -

Page 46: Sold Out

TROUBLESHOOTING P SERIES SOLD OUT Page 46 of 83... -

Page 47: The Display Is Dead

TROUBLESHOOTING P SERIES THE DISPLAY IS DEAD Page 47 of 83... -

Page 48: Can't Read The Display

TROUBLESHOOTING P SERIES CAN’T READ THE DISPLAY Page 48 of 83... - Page 49 WIRING DIAGRAMS AND SCHEMATICS P SERIES LMV 8 Select / 6 Column Page 49 of 83...

- Page 50 WIRING DIAGRAMS AND SCHEMATICS P SERIES LMV 12 Select / 8 Column Page 50 of 83...

- Page 51 WIRING DIAGRAMS AND SCHEMATICS P SERIES Refrigeration Circuit Diagrams Page 51 of 83...

-

Page 52: Main Door Exterior

PARTS LIST P SERIES MAIN DOOR EXTERIOR Page 52 of 83... - Page 53 P SERIES MAIN DOOR EXTERIOR ITEM PART DESCRIPTION DN552P DN756P Main Door Assembly P Series Domestic LMV - 8 642,053,20x.x3 Main Door Assembly P Series Domestic LMV - 12 642,053,30x.x3 Main Door Assembly P Series Export LMV - 12 642,055,10x.x3 Door Weld Assembly 642,053,50x.x3...

-

Page 54: Main Door Interior

PARTS LIST P SERIES MAIN DOOR INTERIOR Page 54 of 83... - Page 55 PARTS LIST P SERIES MAIN DOOR INTERIOR DN552P DN756P ITEM PART DESCRIPTION Door Weld Assembly 642,053,50x.x3 642,053,30x.x3 Protective Plate Main Door 165,150,33x.x3 Same Rain Guard, Black 169,050,34x.x3 164,151,14x.x3 Change Cup Chute 642,050,42x.x3 Same Top Bulkhead 642,050,36x.x3 Same Bottom Bulk Head 642,050,37x.x3...

-

Page 56: Coin Insert

PARTS LIST P SERIES COIN INSERT 5C - Push Button 801,807,25x.x1 1 - Transaction/Coin Insert Panel Assy. 642,050,60x.x3 Domestic 642,050,70x.x3 Export 2 - T handle Assy. 801,518,20x.x1 2A – T Handle 801,518,14x.x1 5 - Coin Return Assy. 6 - Coin Chute Assy. - Page 57 PARTS LIST P SERIES COIN INSERT ITEM DESCRIPTION DN552P DN756P Assembly Transaction & Coin Insert Panel 642,050,60x.x3 Same (includes T Handle Assembly) Domestic Assembly Transaction & Coin Insert Panel 642,050,70x.x3 Same (includes T Handle Assembly) Export T Handle Assembly Flush Mount 801,518,20x.x1...

-

Page 58: Select Panel

PARTS LIST P SERIES SELECT PANEL DN552P DN756P ITEM PART DESCRIPTION 642,051,70x.x3 Select Panel Assembly, 8 Select 642,051,60x.x3 Select Panel Assembly, 12 Select 642,051,40x.x3 Assembly Stud Select Panel/Port - 8 642,051,50x.x3 Assembly Stud Select Panel/Port - 12 804,100,74x.x1 Same Select Switch, SBC 801,810,62x.x1... -

Page 59: T8 Lighting

PARTS LIST P SERIES T8 LIGHTING DN552P DN756P ITEM PART DESCRIPTION Ballast T8 Advance 3 Lamp Domestic 115V 804,400,61x.x1 Same Ballast T8 Sylvania 2 Lamp Export 220V 804,400,75x.x1 Same Lighting Harness 3 Lamp Domestic 804,921,07x.x1 804,921,02x.x1 Lighting Harness 2 Lamp Export 804,923,33x.x1... -

Page 60: Electronic Components

PARTS LIST P SERIES ELECTRONIC COMPONENTS DN552P DN756P ITEM PART DESCRIPTION 640,010,00x.x3 Same Control Board Assembly SBC 804,914,11x.x1 Same Display Board 14 Segment 804,923,31x.x1 Same Transformer - Domestic 804,923,32x.x1 Same Transformer - Export 804,868,03x.x1 Same Fuse 1.6 Amp (F1) SBC 804,910,93x.x1... -

Page 61: Inner Door

PARTS LIST P SERIES INNER DOOR Page 61 of 83... - Page 62 PARTS LIST P SERIES INNER DOOR ITEM PART DESCRIPTION DN552P DN756P Inner Door Assembly 640,050,80x.x3 639,050,40x.x3 Inner Door Gasket 801,819,05x.x1 801,819,04x.x1 Sub Assembly Inner Door 640,050,90x.x3 639,050,50x.x3 Label, STS/Package Set Up 803,871,38x.x1 Same Gate, Front Product Positioner 801,819,15x.x1 Same Discharge Frame Retainer 801,809,15x.x1...

-

Page 63: Harnessing

Motor Harness (6 Motor Stack) 000595 Motor Harness (8 Motor Stack) 804,922,14x.x1 804,922,14x.x1 Board Power Harness (includes transformer) J1 000110 Same Harness, P Series 44” Door 804,920,83x.x1 Same Harness, MDB 25” 804,921,09x.x1 Same Harness, Select Door LMV8 804,921,08x.x1 Harness, Select Door LMV12 804,907,83x.x1... - Page 64 PARTS LIST P SERIES POWER DISTRIBUTION Page 64 of 83...

-

Page 65: Power Distribution Box

PARTS LIST P SERIES POWER DISTRIBUTION DN552P DN756P ITEM PART DESCRIPTION Power Distribution Box Assembly Domestic (prior to 7644) 639,030,400.03 Power Distribution Box Assembly Domestic (7644 & 639,030,90x.x3 Same higher) 639,030,60x.x3 Same Power Distribution Box Assembly Export (7644 & higher) 804,101,18x.x1... -

Page 66: Cabinet And Vend Mechanism (Section 1)

PARTS LIST P SERIES CABINET AND VEND MECHANISM (Section 1) DN552P DN756P ITEM PART DESCRIPTION 631,051,07x.x3 169,000,13x.x3 Cover, Hinge Pocket 642,050,35x.x3 Same Weld assembly Top Hinge (Main Door) 642,053,40x.x4 Same Kit, Door Hinge 169,000,15x.x3 Same Hinge, Spacer 805,300,42x.x1 Same Bearing, Hinge – Pin less 900,201,23x.x1... -

Page 67: Cabinet And Vend Mechanism (Section 2)

PARTS LIST P SERIES CABINET AND VEND MECHANISM (Section 2) DESCRIPTION DN552P DN756P Assembly Rear Spacer Narrow 639,075,00x.x3 Same Vend Motor - Narrow Column 804,501,23x.x1 Same Vend Motor - Wide Column 639,071,80x.x3 Same Vend Motor Cover 640,070,06x.x3 639,070,55x.x3 Assembly Rear Spacer Wide 639,071,70x.x3... -

Page 68: Cabinet

PARTS LIST P SERIES CABINET ITEM DESCRIPTION DN552P DN756P Plate, Protective Left Side (Specify Color) 594,020,14x.x3 Same Plate, Protective Right Side Cabinet (Specify Color) 165,000,04x.x3 Same Caterpillar Grommeting 801,809,93x.x1 Same Mullion 801,819,57x.x1 801,819,58x.x1 Mullion Cap 801,818,92x.x1 801,818,93x.x1 Screw, Phil Pan 8-18x1/2 900,301,50x.x1... -

Page 69: Vend Rotor

PARTS LIST P SERIES VEND MECHANISM - ROTOR DN552P DN756P ITEM DESCRIPTION Load Bar - steel 801,306,59x.x1 Same Vend Rotor - Narrow Column 801,201,79x.x1 Same Nyliner, .750 801,819,52x.x1 Same Nyliner, .312 801,819,53x.x1 Same Bushing, .312 (Load Bar) 801,819,54x.x1 Same Push Arm 801,819,55x.x1... -

Page 70: Vend Mechanism Oscillator

PARTS LIST P SERIES VEND MECHANISM OSCILLATOR DN552P DN756P ITEM DESCRIPTION Nyliner, .750 801,819,52x.x1 Same Screw, 8-32 x 1 Phil Pan 800,303,86x.x1 Same Front Gate Extension, Wide 639,070,13x.x3 Same Vend Motor Assy., Wide (Electronic) 639,071,80x.x3 Same Vend Oscillator - Wide Column 801,201,73x.x1... -

Page 71: Rear Spacers

PARTS LIST P SERIES REAR SPACERS DN552P DN756P ITEM PART DESCRIPTION 639,075,00x.x3 Same Assembly Rear Spacer, Narrow 801,819,56x.x1 Same Bracket Rear Spacer, Narrow 639,070,27x.x3 Same Spacer Rear Narrow 801,819,59x.x1 Same Guide Channel 801,819,61x.x1 Same Latch, Rear Spacer 805,202,57x.x1 Same Assembly Guide Arm 639,071,70x.x3... -

Page 72: Chute Assembly

PARTS LIST P SERIES CHUTE ASSEMBLY ITEM PART DESCRIPTION DN552P DN756P Chute Assembly 640,071,10x.x3 639,071,20x.x3 Chute 640,070,41x.x3 639,070,35x.x3 Liner, Chute 640,070,42x.x3 639,070,36x.x3 Sensor Plate Assembly 640,070,33x.x3 639,070,38x.x3 Sensor Support Plate 640,070,32x.x3 639,070,37x.x3 Bracket, Chute (prior to 7644) 000658 Housing Cover, Vend Sensor 639,070,41x.x3... -

Page 73: Evaporator Fan Housing

PARTS LIST P SERIES EVAPORATOR FAN ASSEMBLY Page 73 of 83... - Page 74 PARTS LIST P SERIES EVAPORATOR FAN ASSEMBLY ITEM DESCRIPTION DN552P DN756P Harness, Evaporator 3 Fan 804,921,73x.x1 Same Evaporator Fan Motor Assy. 115V/60Hz 640,040,30x.x3 Same Evaporator Fan Motor Assy. 220V 639,040,60x.x3 Bracket, Evaporator Fan Motor 640,040,06x.x3 Same Bracket, Evaporator Fan Panel Left Hand 640,040,08x.x3...

- Page 75 PARTS LIST P SERIES REFRIGERATION SYSTEM Page 75 of 83...

-

Page 76: Refrigeration

PARTS LIST P SERIES REFRIGERATION SYSTEM (SECTION ONE) DN552P DN756P ITEM DESCRIPTION Model 3001C-E Kit 115V/60Hz 609,047,10x.x4 Same Model 3021-E Refrigeration Unit 220V 639,040,50x.x3 Same Base Plate 639,040,02x.x3 Same Condenser, 1.33 FPI 802,600,69x.x1 Same Assembly, Heat Exchanger 640,040,00x.x3 Same Fan Blade, Condenser (FV900CW30S) 801,306,65x.x1... -

Page 77: Miscellaneous Labels

803,876,03x.x1 Same Label, Lower Refill Wide Column 803,876,04x.x1 Same Kit, ID Number Labels 615,000,10x.x4 609,000,70x.x4 Wiring Diagram P Series LMV 8 Select 803,871,49x.x1 Wiring Diagram P Series LMV 12 Select 803,873,26x.x1 Technical Manual 803,903,78x.x1 Same Installation Set Up Guide 803,903,93x.x1 Same Part numbers &... -

Page 78: Signs And Decals

PARTS LIST P SERIES DOMESTIC SIGNS & SIDE DECALS (Contact Parts Department for any not listed) ITEM DESCRIPTION DN552P DN756P Side Decals – Universal Ribbon ‘03 803,869,76x.x1 Same Side Decals – Liquid 04 803,873,33x.x1 Same Sign – Universal Ribbon ‘03 805,033,17x.x1... -

Page 79: Screws & Nuts

PARTS LIST P SERIES SCREWS & NUTS Page 79 of 83... - Page 80 PARTS LIST P SERIES SCREWS & NUTS ITEM PART NUMBER PART NAME AND DESCRIPTION 900,301,70x.x1 Screw, Phil Pan Swage Form #6 - 32 x 3/8" 900,301,64x.x1 Screw, Phil Pan Swage Form w/washer #8 - 32 x 1/2" 900,301,83x.x1 Screw, Phil Pan Swage Form #10 - 32 x 5/16"...

-

Page 81: Washers, Bolts, & Misc. Hardware

PARTS LIST P SERIES WASHERS, BOLTS, & MISC. HARDWARE Page 81 of 83... - Page 82 PARTS LIST P SERIES WASHERS, BOLTS, & MISC. HARDWARE ITEM PART NUMBER PART NAME AND DESCRIPTION 900,700,60x.x1 Washer, Delrin .047 Thick 3/8"IDx5/8"OD 901,303,77x.x1 Washer, Door Hinge 901,503,06x.x1 Washer, Flat #2949 (T-Handle) 901,503,08x.x1 Washer, Hex #29-34 (T-Handle) 900,700,36x.x1 Lockwasher, Split 3/8"...

- Page 83 PARTS LIST P SERIES WASHERS, BOLTS, & MISC. HARDWARE ITEM PART NUMBER PART NAME AND DESCRIPTION 901,901,89x.x1 Clamp, Cable 1" Heyco 3390 900,901,79x.x1 Clamp, Nylon 5/16" Black Heyco 3355 or Dennison 10159 900,901,80x.x1 Clamp, Nylon 1/2" Heyco 3328 901,901,06x.x1 Hand Tie, x.x"...

Need help?

Do you have a question about the P Series and is the answer not in the manual?

Questions and answers