Table of Contents

Advertisement

Quick Links

ABCDE

OM-00743-02

December 3, 1979

Rev. A 03-14-05

INSTALLATION, OPERATION,

AND MAINTENANCE MANUAL

WITH PARTS LIST

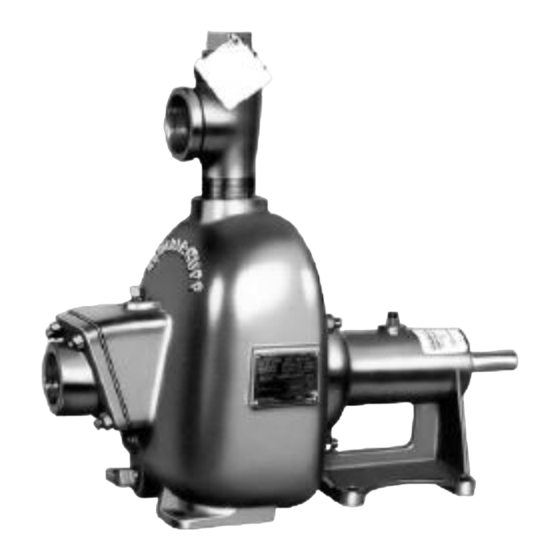

80 SERIES PUMP

MODEL

81 1/2A3-B

THE GORMAN-RUPP COMPANY D MANSFIELD, OHIO

www.gormanrupp.com

D

GORMAN-RUPP OF CANADA LIMITED

ST. THOMAS, ONTARIO, CANADA

Printed in U.S.A.

e

Copyright by the Gorman-Rupp Company

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for GORMAN-RUPP 81 1/2A3-B

- Page 1 Rev. A 03-14-05 INSTALLATION, OPERATION, AND MAINTENANCE MANUAL WITH PARTS LIST 80 SERIES PUMP MODEL 81 1/2A3-B THE GORMAN-RUPP COMPANY D MANSFIELD, OHIO www.gormanrupp.com GORMAN-RUPP OF CANADA LIMITED ST. THOMAS, ONTARIO, CANADA Printed in U.S.A. Copyright by the Gorman-Rupp Company...

-

Page 2: Table Of Contents

TABLE OF CONTENTS INTRODUCTION ..........PAGE I −... - Page 3 TABLE OF CONTENTS (continued) PUMP MAINTENANCE AND REPAIR - SECTION E ....PAGE E − 1 STANDARD PERFORMANCE CURVE ........PAGE E −...

-

Page 4: Introduction

80 SERIES OM−00743 INTRODUCTION Thank You for purchasing a Gorman-Rupp pump. The following are used to alert maintenance per- Read this manual carefully to learn how to safely sonnel to procedures which require special atten- install and operate your pump. Failure to do so... -

Page 5: Safety - Section A

OM−00743 SAFETY - SECTION A This information applies to 80 Series ba- containing specified entrained solids. sic pumps. Gorman-Rupp has no con- Only the Gorman-Rupp Company or an trol over or particular knowledge of the authorized Gorman-Rupp distributor power source which will be used. Refer... - Page 6 OM−00743 80 SERIES of time. If operated against a closed dis- charge valve, pump components will deteriorate, and the liquid could come to a boil, build pressure, and cause the If this pump is used with volatile and/or pump casing to rupture or explode. flammable liquids, overheating may produce dangerous fumes.

-

Page 7: Installation − Section Bpage B

E, Page 1). Most of the information pertains to a standard For further assistance, contact your Gorman-Rupp static lift application where the pump is positioned distributor or the Gorman-Rupp Company. above the free level of liquid to be pumped. -

Page 8: Preinstallation Inspection

If the maximum shelf life has been exceeded, or if anything appears to be abnormal, contact your Pump performance is adversely effected by in- Gorman-Rupp distributor or the factory to deter- creased suction lift, discharge elevation, and fric- mine the repair or updating policy. Do not put the tion losses. -

Page 9: Materials

80 SERIES OM−00743 Materials slopes down to the pump at any point along the suction run, air pockets will be created. Either pipe or hose maybe used for suction and Fittings discharge lines; however, the materials must be compatible with the liquid being pumped. If hose is Suction lines should be the same size as the pump used in suction lines, it must be the rigid-wall, rein- inlet. -

Page 10: Suction Line Positioning

OM−00743 80 SERIES tion inlet because the inflow will carry air down into Suction Line Positioning the sump, and air entering the suction line will re- duce pump efficiency. The depth of submergence of the suction line is critical to efficient pump operation. Figure 2 shows If it is necessary to position inflow close to the suc- recommended minimum submergence vs. -

Page 11: Bypass Lines

NOTE Check Rotation, Section C, before final alignment of the pump. When mounted at the Gorman-Rupp factory, driver and pump are aligned before shipment. Misalign- ment will occur in transit and handling. Pumps must be checked and realigned before operation. -

Page 12: V-Belt Drives

OM−00743 80 SERIES MISALIGNED: MISALIGNED: ALIGNED: SHAFTS SHAFTS SHAFTS PARALLEL AND NOT PARALLEL NOT IN LINE SHEAVES IN LINE Figure 3C. Alignment of V-Belt Driven Pumps Tighten the belts in accordance with the belt manu- Figure 3B. Aligning Non-Spider Type facturer’s instructions. -

Page 13: Operation − Section C

Only the Gorman-Rupp Company or an authorized Gorman-Rupp distributor may modify a pump or approve its use for handling volatile, flammable liquids. If the pump is used for handling volatile,... -

Page 14: Starting

OM−00743 80 SERIES STARTING OPERATION Lines With a Bypass Consult the operations manual furnished with the power source. Close the discharge throttling valve (if so equipped) so that the pump will not have to prime If the pump has been approved for use with petro- against the weight of the liquid in the discharge line. -

Page 15: Strainer Check

OM−00743 80 SERIES boil, build pressure, and cause the pump to rup- lift, and should then stabilize. If the vacuum reading ture or explode. If overheating occurs, stop the falls off rapidly after stabilization, an air leak exists. pump and allow it to completely cool before servic- Before checking for the source of the leak, check the point of installation of the vacuum gauge. - Page 16 OM−00743 80 SERIES curately by placing a contact-type thermometer rect level (see LUBRICATION in Section E). Bear- against the housing. Record this temperature for ing overheating can also be caused by shaft future reference. misalignment and/or excessive vibration. A sudden increase in bearing temperatures is a When pumps are first started, the bearings may warning that the bearings are at the point of failing seem to run at temperatures above normal.

-

Page 17: Troubleshooting − Section D

80 SERIES OM−00743 TROUBLESHOOTING − SECTION D Review all SAFETY information in Section A. Before attempting to open or service the pump: 1. Familiarize yourself with this man- ual. 2. Lock out or disconnect the power source to ensure that the pump will remain inoperative. - Page 18 OM−00743 80 SERIES TROUBLE POSSIBLE CAUSE PROBABLE REMEDY Impeller or other wearing parts worn Replace worn or damaged parts. PUMP STOPS OR FAILS TO DELIVER or damaged. Check that impeller is properly RATED FLOW OR centered and rotates freely. PRESSURE (cont.) Impeller clogged.

-

Page 19: Preventive Maintenance

Gorman-Rupp pump. For specific questions con- For new applications, a first inspection of wearing cerning your application, contact your Gorman- parts at 250 hours will give insight into the wear rate Rupp distributor or the Gorman-Rupp Company. - Page 20 OPERATING PERFORMANCE. STANDARD PERFORMANCE FOR PUMP MODEL 81 1/2A3−B Based on 70_ F (21_ C) clear water at sea level Contact the Gorman-Rupp Company to verify per- formance or part numbers. with minimum suction lift. Since pump installations are seldom identical, your performance may be dif- ference due to such factors as viscosity, specific gravity, elevation, temperature, and impeller trim.

- Page 21 80 SERIES OM−00743 SECTION DRAWING PARTS PAGE Figure 1. Pump Model 81 1/2A3−B PAGE E − 2 MAINTENANCE & REPAIR...

- Page 22 PARTS LIST Pump Model 81 1/2A3-B (From S/N 275382 up) If your pump serial number is followed by an N", your pump is NOT a standard production model. Contact the Gorman-Rupp Company to verify part numbers. ITEM PART MAT’L PART NAME...

- Page 23 80 SERIES OM−00743 PUMP AND SEAL DISASSEMBLY 4. Check the temperature before opening any covers, plates, or AND REASSEMBLY plugs. 5. Close the suction and discharge Review all SAFETY information in Section A. valves. 6. Vent the pump slowly and cau- Follow the instructions on all tags, label and de- tiously.

- Page 24 OM−00743 80 SERIES Pump Casing and Wear Plate Removal spring will be released as the impeller is un- screwed. To service the wear plate (20), remove the nuts (18) securing the pump casing to the seal plate (6) and Inspect the impeller and replace it if cracked or pedestal (16).

- Page 25 80 SERIES OM−00743 Remove the slinger ring (7) from the shaft. Remove the pedestal mounting hardware from the base. Tie and tag any shims used under the mounting feet for leveling. Bearings must be kept free of all dirt and Use snap ring pliers to remove the bearing retain- foreign material.

- Page 26 OM−00743 80 SERIES NOTE If a hot oil bath is used to heat the bearings, both the oil and the container must be absolutely clean. If the oil has been previously used, it must be thor- When installing the shaft and bearings into oughly filtered.

- Page 27 80 SERIES OM−00743 non-oil based solvent and a clean, lint-free tissue. If a replacement seal is being used, remove it from Wipe lightly in a concentric pattern to avoid the container and inspect the precision finished scratching the faces. faces to ensure that they are free of any foreign matter.

- Page 28 OM−00743 80 SERIES Slide the shaft sleeve onto the impeller shaft until ket set until the correct clearance is achieved. Se- the seal faces contact. Continue to push the sleeve cure the pump casing to the seal plate and pedes- through the seal until the sleeve seats squarely tal with the nuts (18).

- Page 29 80 SERIES OM−00743 ever comes first. Do not over-lubricate. Over-lu- Under normal conditions, change the grease after brication will cause the bearings to over-heat, re- each 5000 hours of operation, or at 12 month inter- sulting in premature bearing failure. vals, whichever comes first.

- Page 30 For U.S. and International Warranty Information, Please Visit www.grpumps.com/warranty or call: U.S.: 419−755−1280 International: +1−419−755−1352 For Canadian Warranty Information, Please Visit www.grcanada.com/warranty or call: 519−631−2870 THE GORMAN-RUPP COMPANY D MANSFIELD, OHIO GORMAN-RUPP OF CANADA LIMITED ST. THOMAS, ONTARIO, CANADA...

Need help?

Do you have a question about the 81 1/2A3-B and is the answer not in the manual?

Questions and answers