Table of Contents

Advertisement

Quick Links

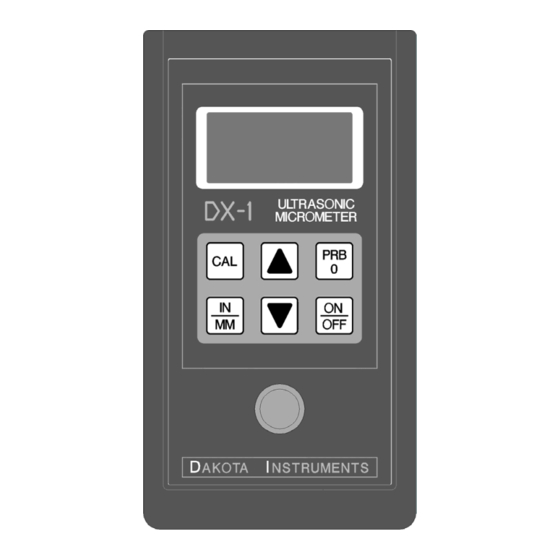

The Dakota Ultrasonics model DX-1 is a precision Ultrasonic

Micrometer. Based on the same operating principles as SONAR, the DX-1

is capable of measuring the thickness of various materials with accuracy as

high as ± 0.001 inches, or ± 0.01 millimeters. The principle advantage of

ultrasonic measurement over traditional methods is that ultrasonic

measurements can be performed with access to only one side of the

material being measured.

This manual is presented in three sections. The first section covers

operation of the DX-1, and explains the keypad controls and display. The

second section provides guidelines in selecting a transducer for a specific

application. The last section provides application notes and a table of

sound velocity values for various materials.

Dakota Ultrasonics maintains a customer support resource in order to

assist users with questions or difficulties not covered in this manual.

Customer support may be reached at any of the following:

• Dakota Ultrasonics, 155-A DuBois Street

Santa Cruz, California 95060 USA

• Telephone: (831) 427-4402

• Facsimile: (831) 427-4403

• http://www.dakotainst.com

INTRODUCTION

DX-1 Ultrasonic Micrometer

1

Advertisement

Table of Contents

Summary of Contents for DAKOTA ULTRASONICS DX-1

- Page 1 This manual is presented in three sections. The first section covers operation of the DX-1, and explains the keypad controls and display. The second section provides guidelines in selecting a transducer for a specific application. The last section provides application notes and a table of sound velocity values for various materials.

- Page 2 Dakota Ultrasonics blank page...

-

Page 3: Operation

The Keypad This key is used to turn the DX-1 on and off. When the gauge is turned ON, it will first perform a brief display test by illuminating all of the segments in the display. After one second, the gauge will display the internal software version number. - Page 4 Dakota Ultrasonics The PRB-0 key is used to "zero" the DX-1 in much the same way that a mechanical micrometer is zeroed. If the gauge is not zeroed correctly, all of the measurements that the gauge makes may be in error by some fixed value.

- Page 5 Refer to page 17 for an explanation of the SCAN measurement mode. The DOWN arrow key has two functions. When the DX-1 is in the CAL mode, this key is used to decrease numeric values on the display. An auto-repeat function is built in, so that when the key is held down, numeric values will decrement at an increasing rate.

- Page 6 When the gauge is making a measurement, six or seven of the bars should be on. If fewer than five bars are on, the DX-1 is having difficulty achieving a stable measurement, and the thickness value displayed will most likely be...

- Page 7 1999.9 millimeters to be displayed. When the IN symbol is on, in conjunction with the /µ µ µ µ s symbol, the DX-1 is displaying a sound-velocity value in inches-per-microsecond.

- Page 8 DX-1. The transducer must be used correctly in order for the DX-1 to produce accurate, reliable measurements. Below is a short description of the transducer, followed by instructions for its use.

-

Page 9: Making Measurements

The Stability Indicator should have six or seven bars darkened, and a number should appear in the display. If the DX-1 has been properly "zeroed" (see page 12) and set to the correct sound velocity (see page 13), the number in the display will indicate the... - Page 10 While the transducer is in contact with the material being measured, the DX-1 will perform four measurements every second, updating its display as it does so. When the transducer is removed from the surface, the display will hold the last measurement made.

-

Page 11: Condition And Preparation Of Surfaces

DX-1 Ultrasonic Micrometer Condition and Preparation of Surfaces In any ultrasonic measurement scenario, the shape and roughness of the test surface are of paramount importance. Rough, uneven surfaces may limit the penetration of ultrasound through the material, and result in unstable, and therefore unreliable, measurements. -

Page 12: Probe Zero

Dakota Ultrasonics Probe Zero Setting the Zero Point of the DX-1 is important for the same reason that setting the zero on a mechanical micrometer is important. If the gauge is not "zeroed" correctly, all of the measurements the gauge makes will be in error by some fixed number. - Page 13 This will ensure that the instrument is always correctly zeroed. Calibration In order for the DX-1 to make accurate measurements, it must be set to the correct sound-velocity for the material being measured. Different types of material have different inherent sound-velocities. For example, the velocity of sound through steel is about 0.233 inches-per-microsecond,...

-

Page 14: Calibration To A Known Thickness

8) Press the CAL key again. The IN/µ µ µ µ s (or M/s) symbols should begin flashing. The DX-1 is now displaying the sound velocity value it has calculated based on the thickness value that was entered in step 7. -

Page 15: Calibration To A Known Velocity

(0.233 IN/µs). To achieve the most accurate measurements possible, it is generally advisable to always calibrate the DX-1 to a sample piece of known thickness. Material composition (and thus, its sound-velocity) sometimes varies from lot to lot and from manufacturer to manufacturer. Calibration to a sample of known thickness will ensure that the gauge is set as closely as possible to the sound velocity of the material to be measured. -

Page 16: Two Point Calibration

8) Press the Probe key. The display will flash 1OF2. Repeat steps 3 through 7 on the second calibration point. The DX-1 will now display the sound velocity value it has calculated based on the thickness values that were entered in step 7. -

Page 17: Scan Mode

While the DX-1 excels at making single point measurements, it is sometimes desirable to examine a larger region, searching for the thinnest point. The DX-1 includes a feature, called Scan Mode, which allows it to do just that. In normal operation, the DX-1 performs and displays four measurements every second, which is quite adequate for single measurements. -

Page 18: Transducer Selection

Generally speaking, the best transducer for a job is one that sends sufficient ultrasonic energy into the material being measured such that a strong, stable echo is received by the DX-1. Several factors affect the strength of ultrasound as it travels. These are outlined below: •... - Page 19 DX-1 Ultrasonic Micrometer strength of the waves, and thus, the DX-1's ability to detect the returning echo. Higher frequency ultrasound is absorbed and scattered more than ultrasound of a lower frequency. While it may seem that using a lower frequency transducer might be better in every instance, low frequencies are less directional than high frequencies.

- Page 20 Dakota Ultrasonics Selection of the proper transducer is often a matter of tradeoffs between various characteristics. It may be necessary to experiment with a variety of transducers in order to find one that works well for a given job. Dakota Ultrasonics can provide assistance in choosing a transducer, and offers a broad selection of transducers for evaluation in specialized applications.

- Page 21 DX-1 Ultrasonic Micrometer APPENDIX A Product Specifications Physical Weight: 7 ounces Size: 3.25W x 6.0H x 1.35D inches (82.5W x 152.4H x 34.3D mm). Operating Temperature: -20 to 120 °F (-20 to 50 °C) Case: impact resistant ABS plastic Keypad Sealed membrane, resistant to water and petroleum products.

- Page 22 Dakota Ultrasonics blank page...

- Page 23 DX-1 Ultrasonic Micrometer APPENDIX B Application Notes • • • • Measuring pipe and tubing When measuring a piece of pipe to determine the thickness of the pipe wall, orientation of the transducers is important. If the diameter of the pipe...

- Page 24 (refer to page 11) on a sample piece of known thickness, which is at or near the temperature of the material to be measured. This will allow the DX-1 to correctly calculate the velocity of sound through the hot material.

- Page 25 DX-1 Ultrasonic Micrometer An additional important consideration when measuring laminates, is that any included air gaps or pockets will cause an early reflection of the ultrasound beam. This effect will be noticed as a sudden decrease in thickness in an otherwise regular surface. While this may impede accurate measurement of total material thickness, it does provide the user with positive indication of air gaps in the laminate.

- Page 26 Dakota Ultrasonics blank page...

- Page 27 DX-1 Ultrasonic Micrometer APPENDIX C Sound Velocities of some Common Materials M a te r ia l s o u n d v e lo c ity in /u s m /s A lu m in u m 0 .2 5 0...

- Page 28 Dakota Ultrasonics blank page...

-

Page 29: Warranty Information

Dakota Ultrasonics warrants transducers and accessories against such defects for a period of 90 days from receipt by the end user. If Dakota Ultrasonics receives notice of such defects during the warranty period, Dakota Ultrasonics will either, at its option, repair or replace products that prove to be defective. - Page 30 Dakota Ultrasonics blank page...