Summary of Contents for DAKOTA ULTRASONICS MMX-6 DL

- Page 1 OPERATION MANUAL DAKOTA ULTRASONICS MMX-6 DL MULTI-MODE ULTRASONIC THICKNESS GAUGE P/N P-143-0002 Rev 1.10 / 11, January 2008 GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 2 Dakota Ultrasonics. Every precaution has been taken in the preparation of this publication. Dakota Ultrasonics assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of information contained herein.

-

Page 3: Table Of Contents

MMX-6 DL Ultrasonic Thickness Gauge CONTENTS NTRODUCTION PERATION EYPAD ISPLAY RANSDUCER AKING EASUREMENTS ONDITION AND REPARATION OF URFACES ROBE ALIBRATION NITS ACKLIGHT LARM , RS232 P & D ULTI EEPER OGGER RANSDUCER ELECTION A: P PPENDIX RODUCT PECIFICATIONS B: A... - Page 4 Dakota Ultrasonics DISCLAIMER – Very Important! Inherent in ultrasonic thickness measurement is the possibility that the instrument will use the second rather than the first echo from the back surface of the material being measured while in standard pulse-echo mode.

-

Page 5: Introduction

The Dakota Ultrasonics model MMX-6 DL is a precision Ultrasonic Micrometer. Based on the same operating principles as SONAR, the MMX-6 DL is capable of measuring the thickness of various materials with accuracy as high as ± 0.001 inches, or ± 0.01 millimeters. The principle... -

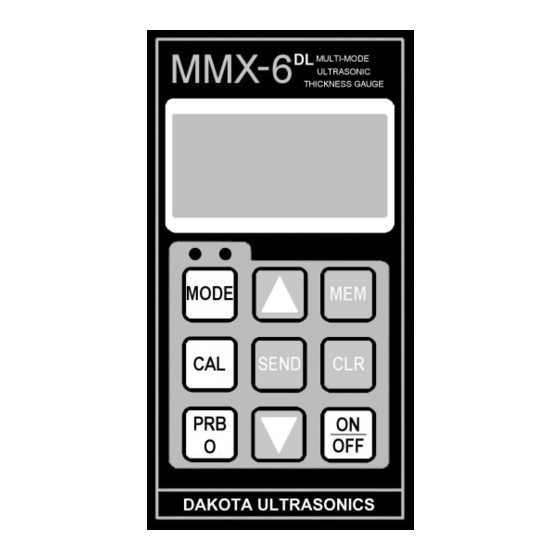

Page 6: Operation

The Keypad This key is used to turn the MMX-6 DL on and off. When the tool is turned ON, it will first perform a brief display test by illuminating all of the segments in the display. After one second, the tool will display the internal software version number and the current file location and status. - Page 7 Dakota Ultrasonics The PRB-0 key is used to "zero" the MMX-6 DL in much the same way that a mechanical micrometer is zeroed. If the tool is not zeroed correctly, all of the measurements that the tool makes may be in error by some fixed value.

- Page 8 MMX-6 DL Ultrasonic Thickness Gauge The UP arrow key has three functions. When the MMX-6 DL is in calibration mode, this key is used to increase numeric values on the display. An auto-repeat function is built in, so that when the key is held down, numeric values will increment at an increasing rate.

- Page 9 DL. This key is used in conjunction with the UP/DOWN arrows, SEND, AND CLR keys (hi-lighted in green). The combination of these keys control the data logging features of the MMX-6 DL. Refer to the section on data logging page 28.

-

Page 10: The Display

If fewer than five bars are on, the MMX-6 DL is having difficulty achieving a stable measurement, and the thickness value displayed will most likely be erroneous. - Page 11 Dakota Ultrasonics When the IN symbol is on, the MMX-6 DL is displaying a thickness value in inches. The maximum thickness that can be displayed is 19.999 inches. When the MM symbol is on, the MMX-6 DL is displaying a thickness value in millimeters.

- Page 12 MMX-6 DL Ultrasonic Thickness Gauge When the + symbol is on and blinking, this indicates that the MMX-6 DL is currently operating in echo-echo ( Thru-paint/coating ) mode. GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

-

Page 13: The Transducer

Dakota Ultrasonics The Transducer The transducer is the "business end" of the MMX-6 DL. It transmits and receives ultrasonic sound waves that the MMX-6 DL uses to calculate the thickness of the material being measured. The transducer connects to the MMX-6 DL via the attached cable, and two coaxial connectors. -

Page 14: Making Measurements

If the MMX-6 DL has been properly "zeroed" (see page 14) and set to the correct sound velocity (see page 15), the number in the display will indicate the actual thickness of the material directly beneath the transducer. - Page 15 While the transducer is in contact with the material that is being measured, the MMX-6 DL will perform four measurements every second, updating its display as it does so. When the transducer is removed from the surface, the display will hold the last measurement made.

-

Page 16: Condition And Preparation Of Surfaces

MMX-6 DL Ultrasonic Thickness Gauge Condition and Preparation of Surfaces In any ultrasonic measurement scenario, the shape and roughness of the test surface are of paramount importance. Rough, uneven surfaces may limit the penetration of ultrasound through the material, and result in unstable, and therefore unreliable, measurements. -

Page 17: Probe Zero

Check that the wearface of the transducer is clean and free of any debris. 3) The metal probe-disc is on the top end of the MMX-6 DL. Apply a single droplet of ultrasonic couplant to the face of this disc. -

Page 18: Calibration

Calibration In order for the MMX-6 DL to make accurate measurements, it must be set to the correct sound-velocity for the material being measured. Different types of material have different inherent sound-velocities. For example, the velocity of sound through steel is about 0.233 inches-per-microsecond,... - Page 19 The two point calibration allows for greater accuracy over small ranges by calculating the probe zero and velocity. The MMX-6 DL provides three simple methods for setting the sound-velocity, described in the following pages. GlobalTestSupply www.

- Page 20 1) 1) Make sure the MMX-6 DL is on and switched to P-E (pulse- echo) mode. Press the Dual-Multi key to toggle modes.

- Page 21 7. 9) Press the CAL key once more to exit the calibration mode. The MMX-6 DL is now ready to perform measurements. GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 22 A table of common materials and their sound-velocities can be found in Appendix C. 1) Make sure the MMX-6 DL is on and switched to P-E (pulse-echo) mode. Press the Dual-Multi key to toggle modes.

- Page 23 Dakota Ultrasonics varies from lot to lot and from manufacturer to manufacturer. Calibration to a sample of known thickness will ensure that the tool is set as closely as possible to the sound velocity of the material to be measured.

- Page 24 1) Make sure the MMX-6 DL is on and switched to P-E (pulse-echo) mode. Press the Dual-Multi key to toggle modes. Note: The calibration function has been disabled in E-E (echo-echo) mode.

- Page 25 Dakota Ultrasonics 8) Press the Probe key. The display will flash 1OF2. Repeat steps 3 through 7 on the second calibration point. The MMX-6 DL will now display the sound velocity value it has calculated based on the thickness values that were entered in step 7. The MMX-6 DL is now ready to perform measurements within this range.

- Page 26 MMX-6 DL Ultrasonic Thickness Gauge The Back light The back light of the MMX-6 DL can be set to three different positions on/off/auto. The following steps outline the procedure for changing the settings of the back light: Using The Back Light 1) Press ON/OFF key to power up the MMX-6 DL.

- Page 27 5) Press the MODE key once again to return to measurement mode. Alarm Mode The Alarm Mode feature of the MMX-6 DL allows the user to set an audible and visual parameter when taking measurements. If the measurement falls below a nominal value, set by the user, a red light will be illuminated on the front panel of the gauge and the beeper sounded.

- Page 28 5) Press the MODE key once again to return to measurement mode. Alarm Mode 1) Press ON/OFF key to power up the MMX-6 DL. 2) Press the MODE key to activate features and settings. 3) Press the UP / Down arrow keys to scroll to the ALAr symbol.

- Page 29 Dual-Multi Mode 1) Press ON/OFF key to power up the MMX-6 DL. 2) Press MODE key to activate features and settings. 3) Press the UP or DOWN arrow keys to scroll to GAtE.

- Page 30 Connecting To a Computer 1) Connect the accessory cable (part# N-306-0010) to the 2 pin jack located on the bottom of the MMX-6 DL, and the 9 pin connector to a serial port on the computer. 2) Start the communications software that will be used to collect the measurements (i.e.

- Page 31 Lotus123™) for further reporting requirements. Using The Data Logger The MMX-6 DL is equipped with an on board data logging feature. This will prove to be a valuable reporting tool for inspection purposes. It will increase efficiency by reducing the time it takes to manually record the measurements during the inspection process.

- Page 32 MMX-6 DL Ultrasonic Thickness Gauge 3) Press the SEND key to enter file setup. Using the Data Logger (con't) • The current file will be diplayed ( F-01, F-03, etc. ) 4) Press the UP / DOWN arrow keys to scroll to the file ( 1-10 ) that will be used to record the measurements.

- Page 33 Dakota Ultrasonics 9) Repeat step 8 as required. Clearing a Storage Location The user may require a storage location, that is currently full, be over written. This procedure is outlined in the following steps: Note: § Assuming the steps in Using The Data Logger have been completed, and step 8 is being repeated.

- Page 34 L001. The procedure is outlined in the following steps: 1) Press the ON/OFF key to power up the MMX-6 DL. 2) Press the MEM key to activate the data logging functions and settings.

- Page 35 Dakota Ultrasonics Clearing all Files 1) Press the ON/OFF key to power up the MMX-6 DL. 2) Immediately press the CLR key. CLr? Will be displayed. 3) Press the CLR key once again to clear all files. Sending All Files to a Computer At the end of the inspection process, or end of the day, the user may require the readings be transferred to a computer.

- Page 36 1) Refer to the section on Connecting to a Computer, page 27, before proceeding. 2) Press the ON/OFF key to power up the MMX-6 DL. 3) Press the MEM key to activate the data logging functions and settings.

-

Page 37: Transducer Selection

Generally speaking, the best transducer for a job is one that sends sufficient ultrasonic energy into the material being measured such that a strong, stable echo is received by the MMX-6 DL. Several factors affect the strength of ultrasound as it travels. These are outlined below: •... - Page 38 MMX-6 DL Ultrasonic Thickness Gauge reduce the strength of the waves, and thus, the MMX-6 DL's ability to detect the returning echo. Higher frequency ultrasound is absorbed and scattered more than ultrasound of a lower frequency. While it may seem that using a lower frequency transducer might be better in every instance, low frequencies are less directional than high frequencies.

- Page 39 • Through Paint & Coatings The MMX-6 DL has the ability to measure through and eliminate the thickness of paint or coatings on the surface of metals. While this is a very convenient feature, it must be used with the proper transducers in order to produce favorable results.

-

Page 40: Appendix A: Product Specifications

Dakota Ultrasonics APPENDIX A Product Specifications Physical Weight: 10 ounces Size: 2.5W x 4.75H x 1.25D inches (63.5W x 120.6H x 31.75D mm). Operating Temperature: -20 to 120 °F (-20 to 50 °C) Case: Extruded aluminum body / nickel plated aluminum end caps. -

Page 41: Appendix B: Application Notes

MMX-6 DL Ultrasonic Thickness Gauge APPENDIX B Application Notes • Measuring pipe and tubing When measuring a piece of pipe to determine the thickness of the pipe wall, orientation of the transducers is important. If the diameter of the pipe... - Page 42 (refer to page 15) on a sample piece of known thickness, which is at or near the temperature of the material to be measured. This will allow the MMX-6 DL to correctly calculate the velocity of sound through the hot material.

- Page 43 MMX-6 DL Ultrasonic Thickness Gauge An additional important consideration when measuring laminates, is that any included air gaps or pockets will cause an early reflection of the ultrasound beam. This effect will be noticed as a sudden decrease in thickness in an otherwise regular surface. While this may impede accurate measurement of total material thickness, it does provide the user with positive indication of air gaps in the laminate.

- Page 44 MMX-6 DL Ultrasonic Thickness Gauge APPENDIX C Sound Velocities of some Common Materials M a t e r i a l s o u n d v e l o c i t y i n / u s m / s A l u m i n u m 0 .

-

Page 45: Warranty Information

Dakota Ultrasonics warrants transducers and accessories against such defects for a period of 90 days from receipt by the end user. If Dakota Ultrasonics receives notice of such defects during the warranty period, Dakota Ultrasonics will either, at its option, repair or replace products that prove to be defective. - Page 46 MATERIAL SAFETY DATA SHEET N/A = not applicable or not available (To comply with 29 CFR 1910.1200) SECTION 1 – PRODUCT IDENTIFICATION NFPA Hazardous Materials Identification System (est) Product Name: SOUNDSAFE® Health……………………0 Generic Name: Ultrasonic Couplant Manufacturer: Sonotech, Inc. Flammability…………….0 Reactivity………………..0 SECTION 2 –...

Need help?

Do you have a question about the MMX-6 DL and is the answer not in the manual?

Questions and answers