Table of Contents

Advertisement

Operating instructions

Screw pump

Only for specialist personnel!

Translation of the original operating instructions

Read the instructions prior to performing any task!

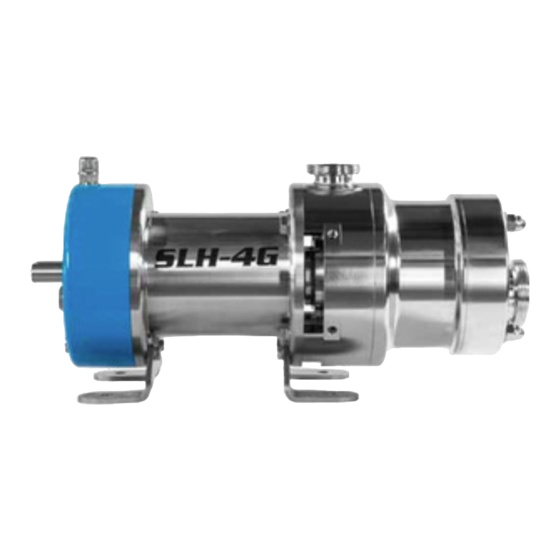

Type

SLH-4G,

SLHS-4G

01/2016 JPB 5

01/2016 RW 5

ITT Bornemann GmbH

Postfach 1162

D-31676 Obernkirchen

Telephone: +49 5724 390-0

Fax: +49 5724 390-290

email: info.bornemann@itt.com

Internet: www.bornemann.com

Advertisement

Table of Contents

Summary of Contents for ITT Bornemann SLHS-4G

- Page 1 Translation of the original operating instructions Read the instructions prior to performing any task! Type SLH-4G, SLHS-4G 01/2016 JPB 5 01/2016 RW 5 ITT Bornemann GmbH Postfach 1162 D-31676 Obernkirchen Telephone: +49 5724 390-0 Fax: +49 5724 390-290 email: info.bornemann@itt.com Internet: www.bornemann.com...

- Page 2 02/2013-Rev0-JPB, 5, en_GB © ITT Bornemann GmbH 2013 01/2016 JPB Rev. 5 Type SLH-4G, SLHS-4G...

-

Page 3: Table Of Contents

Table of contents Table of contents About this manual..................6 1.1 Target groups..................6 1.2 Additionally applicable documentation..........6 1.3 Warning signs and symbols..............7 1.4 Technical terms.................. 8 Safety....................... 10 2.1 Intended use..................10 2.2 Improper use..................10 2.3 Risk assessment................11 2.4 Safety instructions................ - Page 4 Table of contents 5.3.3 Securing the pump unit..............31 5.4 Mounting the pump unit without foundation........32 5.5 Aligning the pump unit..............32 5.5.1 Determining alignment tolerances..........32 5.5.2 Pump alignment tolerances............33 5.5.3 Taking into account peak height changes........35 5.5.4 Checking the coupling alignment...........

- Page 5 Table of contents 6.4.1 Measures in accordance with the conveyed medium....58 6.5 Recommissioning................58 6.6 Operating the stand-by pump............59 6.7 Disposal.................... 59 Maintenance and repairs................ 60 7.1 Wearing parts................... 60 7.2 Monitoring..................60 7.3 Maintaining..................61 7.3.1 Maintenance table................. 63 7.3.2 Lubrication..................

-

Page 6: About This Manual

ITT Bornemann GmbH pumps; be qualified, trained or instructed; be aware of all relevant regulations and standards; have specialist electrical engineering knowledge. -

Page 7: Warning Signs And Symbols

About this manual 1.3 Warning signs and symbols Warning information Warning information given in this manual is designated by the use of symbols. The warning information is initiated by signal words which indicate the extent of the risk. Warning information Danger level Consequences in the event of non- compliance... -

Page 8: Technical Terms

About this manual Warning signs Type of danger Warning – danger zone. Tips and recommendations This symbol highlights useful tips and recommendations as well as information for ensuring efficient and trouble-free operation. Additional designation The following designations are used in the manual to highlight instructions, results, lists, references and other elements: Labelling Explanation... - Page 9 About this manual Term Meaning Quench medium Medium used for quenching mechanical seals or shaft seals. Sterilisation In Place. Sealing Sealing system in which the pressure of the barrier fluid is higher than the pressure of the pumped medium. The seal is lubricated by the barrier fluid. The pumped medium absorbs barrier fluid.

-

Page 10: Safety

Any other use must be agreed with the ITT Bornemann GmbH. Observe the operational limits of the pump in relation to temperature, pres- sure, viscosity, pump capacity and speed ( pump data sheet). -

Page 11: Risk Assessment

Safety The pumping of acids and other corrosive liquids without approval of ITT Bornemann GmbH, The pumping of pure gases, The operation of pipelines without approval of ITT Bornemann GmbH, Operation without the required safety redundancies, Throttling of the outlet side,... -

Page 12: Safety Instructions

Safety The pump may pose a risk to the environment due to: Unprofessional handling, Operating substances (pumped media, lubricants, motor oil, etc.), Gas emissions, Noise emissions, Risk of fire. Damage to the pump may arise due to: Unprofessional handling, Overloading, Overheating, Oil level in the synchronisation transmission being too high/low, Failure to adhere to operating and maintenance specifications,... -

Page 13: Obligations Of The Operator

Only use original spare parts and accessories which have been approved by ITT Bornemann GmbH. Regular maintenance in accordance with the maintenance schedule. Do not change the connection and setting values! Contact ITT Bornemann GmbH if necessary. Personnel executing work on the system must not be under the influence of medication, alcohol or drugs. -

Page 14: Obligations Of The Personnel

Safety 2.4.3 Obligations of the personnel Obligations of the personnel Observe local safety regulations. Read and observe the documentation, especially the respective "Safety" chapters. Follow all safety regulations,signs and labels. Observe the information on the pump and keep this in a legible condition, e.g. arrows indicating the direction of rotation, labels for liquid connections. -

Page 15: Potentially Explosive Area

Safety 2.5.1 Potentially explosive area DANGER! Mortal danger due to explosion! Observe the additional ATEX instructions! 2.5.2 Hazardous pumped medium Please note: When handling hazardous pumped medium (e.g. hot, flammable, explosive, toxic, harmful to health) observe the safety regulations applicable to the han- dling of hazardous substances safety datasheets). -

Page 16: Structure And Function

Structure and function Structure and function 3.1 Labelling 3.1.1 Type plate The serial number is additionally stamped on the pump casing. Fig. 1: Type plate (example) Description Description Viscosity Type Pump capacity Speed Order number Max. inlet pressure Serial number Year of manufacture Differential pressure Output demand... -

Page 17: Type Designation

Structure and function 3.1.2 Type designation Fig. 2: Type designation (example) Description Series Size Conveyor screw incline [mm] 3.2 Structure The structure of the pump is shown here as an example only. The dimensional drawing is the decisive source concerning the arrange- ment of the inlet and outlet nozzles and the dimensions of the pump dimensional drawing). - Page 18 Structure and function Fig. 3: Structure of the pump without base plate (example) Description Description Inlet nozzle Bearing casing Pump casing Gearing casing Outlet nozzle Drive shaft 01/2016 JPB Rev. 5 Type SLH-4G, SLHS-4G...

-

Page 19: Shaft Seals

Structure and function Fig. 4: Structure of the pump with base plate (example) Description Description Inlet nozzle Coupling Pump casing Motor Outlet nozzle Base plate Bearing casing 3.3 Shaft seals Only one of the following shaft seals can be used. 3.3.1 Slide ring seal Mechanical seals have function-related leakage. -

Page 20: Auxiliary Operating Systems

Structure and function Single-action slide rings seal without shaft seal ( pump data sheet, manu- facturer's documentation). Single-action slide rings seal with shaft seal and pressureless storage reser- voir ( pump data sheet, manufacturer's documentation). Dual-action slide rings seal and sealing system ( pump data sheet, manu- facturer's documentation). -

Page 21: Transport And Storage

4.1.1 Unpacking and checking the condition of contents Unpack the pump/unit on receipt and check for externally visible signs of transport damage. Immediately report transport damage to the haulage company and ITT Bornemann GmbH. Dispose of packaging materials in accordance with locally applicable regu- lations. - Page 22 Transport and storage Fig. 5: Fastening the lifting tackle to the pump Fig. 6: Fastening the lifting tackle to the pump unit The lifting eyelets and anchoring points for transport are labelled on the pump. Select the lifting equipment in accordance with the total weight to be trans- ported ( dimensional drawings).

-

Page 23: Preservation

Transport and storage 4.2 Preservation All visible shaft sections, blank parts and non-corrosion-resistant metal components are preserved for shipping, unless otherwise ordered. NOTICE! Property damage due to improper preservation! – Only use preservative compatible with pumping media. – Preserve the pump properly, both internally and externally. –... -

Page 24: Storage

In the case of drive-side oil lubrication of the bearings, fill the hollow spaces of the bearings with oil. Following storage periods exceeding 3 years: ITT Bornemann GmbH should be contacted in order to put the pump back into oper- ation. - Page 25 Transport and storage WARNING! Damage to health resulting from cleaning agents! – Use personal protective equipment for all work involving the use of cleaning agents. – Do not inhale cleaning agent vapour. NOTICE! Property damage resulting from excessive water pressure or sprayed water! –...

-

Page 26: Installation And Connection

Installation options: – With steel foundation frames ( dimensioned drawing, pump system operating instructions) – With a concrete foundation (please consult with ITT Bornemann GmbH) DANGER! Mortal danger due to explosion! Observe the additional ATEX instructions! WARNING! Risk of injury due to unprofessional work! –... -

Page 27: Fitting The Coupling

Installation and connection NOTICE! Material damage due to incorrect insulation! – Install thermal insulation such that any leakage can be reliably detected. NOTICE! Property damage due to overheating! – Fit thermal insulation only to the pump housing. Install the heat insulation properly (only in area A), do not insulate gear casing and bearing casing. -

Page 28: Installing The Motor On Base Plate

Installation and connection 5.1.4 Installing the motor on base plate Only required when the pump unit is completed at the site of instal- lation. If the pump is supplied without base plate, design the base plate so that torsion and non-permitted vibrations can be safely prevented during operation. -

Page 29: Preparing The Foundation And Base

Installation and connection 5.2.3 Preparing the foundation and base For installation on a concrete foundation, please consult with ITT Bornemann GmbH. Ensure that the foundation and base fulfils the following requirements: Level: Permissible deviation dimensioned drawings, pump oper- ating instructions,... -

Page 30: Placing The Pump Unit On The Foundation

Installation and connection 5.3.1 Placing the pump unit on the foundation Special tool: Spirit level Materials: Foundation bolts Steel fixtures Casting mortar, non-shrinking Fig. 7: Installation on a foundation (schematic diagram) Lift pump unit ( pump system operating instructions and Ä... -

Page 31: Securing The Pump Unit

Installation and connection Fig. 8: Aligning the base plate (tolerances) Designation Foundation Base plate Tolerance Do not exceed the following tolerances for the (steel) installation points of the base plate on the foundation: Base plate shorter than or equal to 3 m: –... -

Page 32: Mounting The Pump Unit Without Foundation

Installation and connection 5.4 Mounting the pump unit without foundation Special tool: Spanner Spirit level Fig. 9: Mounting without foundation (schematic diagram) Ä Chapter 4.1.2 ‘Lifting’ on page 21). Lift the pump unit ( Install four levelling feet (3) as shown. Place the pump unit on the base. -

Page 33: Pump Alignment Tolerances

Installation and connection Determine alignment tolerances for coupling. Permissible deviations and dimensions manufacturer's data. Determine alignment tolerances for motor. Permissible deviations and dimensions manufacturer's data. Determine the lowest value from the ascertained alignment tolerances (pump, coupling, motor) and apply this in order to align the coupling. 5.5.2 Pump alignment tolerances Axial offset Fig. - Page 34 Installation and connection Angle offset Fig. 11: Angle offset Size perm 750 min 1000 min 1200 min 1450 min 1750 min 2000 min 2400 min 2800 min SLH-4G 10xx 0.25 mm 0.22 mm 0.20 mm 0.18 mm 0.16 mm 0.15 mm 0.14 mm 0.13 mm SLH-4G 20xx 0.28 mm...

-

Page 35: Taking Into Account Peak Height Changes

Installation and connection Size perm 750 min 1000 min 1200 min 1450 min 1750 min 2000 min 2400 min 2800 min SLH-4G 30xx 0.32 mm 0.27 mm 0.25 mm 0.23 mm 0.21 mm 0.19 mm 0.18 mm 0.16 mm SLH-4G 40xx 0.36 mm 0.31 mm 0.28 mm 0.26 mm... - Page 36 Installation and connection Peak height change Fig. 13: Peak height change Size SLH 80, SLH-4G 10xx SLH-4G 20xx SLH 125 SLH-4G 30xx SLH-4G 40xx SLH 180 01/2016 JPB Rev. 5 Type SLH-4G, SLHS-4G...

-

Page 37: Checking The Coupling Alignment

Installation and connection 5.5.4 Checking the coupling alignment Special tool: Laser alignment device Feeler gauge Straight edge Dial gauge. Materials: Manufacturer's instructions DANGER! Mortal danger due to moving machinery! – Before all installation and maintenance work: Switch off the motor and secure to prevent it being switched on again. Fig. -

Page 38: Aligning The Motor

Installation and connection Fig. 15: Checking the lateral and height offset Check the lateral and height offset using a dial gauge: Carry out measurement as shown. In the event of a lateral or height offset, align the motor Ä Chapter 5.5.5 ‘Aligning the motor’ on page 38). Permissible axial or radial deviation, measured on the front face of the coupling or at the coupling circumference: manufacturer's data. -

Page 39: Fitting The Coupling Guard

If a protective hood is used: Ensure space between protective hood and pump/motor for ventilating the unit. 5.6 Planning pipes Parallel operation of pumps only with express approval of ITT Bornemann GmbH. 5.6.1 Configuring supports and flange connections NOTICE! Property damage due to excessively high forces and torques of the piping on the pump! –... -

Page 40: Determining Pipeline Lengths

5.6.4 Optimising cross sectional and direction changes Avoid sudden changes in cross section and direction in the pipe course. Parallel operation of pumps only with express approval of ITT Bornemann GmbH. If multiple pumps are operated in parallel and gas-charged media is being... -

Page 41: Including Safety And Control Equipment

Installation and connection Discharge flammable and potentially explosive pumped media safely. Ensure that the pressure level in the safe area guarantees pressure relief via the safety device. 5.6.6 Including safety and control equipment Avoiding contamination A filter in the inlet line is also recommended during ongoing opera- tion. - Page 42 Installation and connection In order to monitor the contamination include differential pressure moni- toring: Observe permissible differential pressure of the filter ( Manufactur- er's instructions). Avoiding running in reverse NOTICE! Property damage resulting from pump reversal. – Do not operate the pump without non-return protection. With a safety-related component (non-return protection), make sure that the medium cannot flow back after switching off the pump.

-

Page 43: Using Hose Lines

Installation and connection Enabling measurement of the operating Provide pressure monitoring in the inlet and outlet lines: modes As near as possible to the pump. In doing so, maintain the limit values pump data sheet) Include temperature measurement on the pump side. Include dry operation protection. -

Page 44: Avoid Contamination Of The Pipes

Installation and connection 5.7.1 Avoid contamination of the pipes NOTICE! Property damage resulting from pump contamination! – Ensure that no contaminants enter the pump. Prior to assembly, clean all pipe sections and valves. Ensure that flange seals do not protrude inwards. Remove blank flanges, plugs, protective film and/or protective paint on the flanges. -

Page 45: Check That Pipe Connection Is Tension Free

Installation and connection Fit the heating line. Ensure that the flange seals do not protrude inwards. 5.7.6 Check that pipe connection is tension free Prerequisite Pipe installed and cooled. Procedure Disconnect the pipe connection flanges from the pump. Check that the pipe can be moved freely in all directions in the vicinity of anticipated expansion: Nominal diameters <... -

Page 46: Checking The Direction Of Rotation

Installation and connection Install the EMERGENCY STOP button. 5.8.3 Checking the direction of rotation Check the direction of rotation with a field direction tester, if avail- able. DANGER! Mortal danger due to moving machinery! – Use personal protective equipment during all work on the pump. –... -

Page 47: Operation

Operation Operation DANGER! Mortal danger due to explosion! Observe the additional ATEX instructions! For pumps as part of a pump system pump system operating instructions. NOTICE! Irreparable damage to the pump system due to throttling on the outlet side! – Severe loading of the pump due to liquid sludge with throttling on the outlet side. -

Page 48: Commissioning After Shutdown

6.1.5 Preparing auxiliary operating systems (if present) WARNING! Risk of injury due to the use of third-party systems! – Use only ITT Bornemann GmbH approved auxiliary systems. Sealing system Ensure that the barrier fluid is compatible with the pumped medium. Determine the appropriate sealing system ( Pump data sheet). -

Page 49: Inertisation (For Atex)

Operation Pressure safety valve WARNING! Risk of injury due to pressure safety valve! – The pressure safety valve is under pressure, do not touch. – The pressure safety valves are configured and may not be changed. – Ensure that the factory setting of the pressure safety valve com- plies with the requirements of the pump. -

Page 50: Filling And Bleeding

Operation Preparation for inertisation Securely close all interfaces to the pumping process: – "Double block and bleed" principle – Blank flange – Spectacle blinds (secure against unintended opening) – Shut valves – Effectively disconnect the drive power for valve drives –... -

Page 51: Switching On

Operation Ä Chapter 6.1.6 ‘Inertisa- Prerequisites for filling Pump correctly installed, connected and inertised ( tion (for ATEX)’ on page 49) All connections leak-tight and tension-free Inlet and outlet side valve (supplied by customer) closed Drainage valves closed. Auxiliary system ready for operation Process for filling Fully open inlet side valve. - Page 52 Operation NOTICE! Property damage due to dry running! Ensure that the pump is correctly filled. NOTICE! Irreparable damage to the pump system due to throttling on the outlet side! – Severe loading of the pump due to liquid sludge with throttling on the outlet side.

-

Page 53: Switching Off

Operation 6.1.9 Switching off WARNING! Risk of injury due to hot pump parts! – Use personal protective equipment during all work on the pump. – Allow the pump to cool prior to work. Switch off motor. Maintain the following functions, if present: Sealing system Cooling water supply until pump operating temperature has dropped below 100 °C. - Page 54 Operation DANGER! Risk of injury due to running pump! – Do not touch the pump when it is running. – Do not work on the pump when it is running. – If possible: Allow the pump to cool prior to work. DANGER! Risk of injury and poisoning due to hazardous pumped media! –...

-

Page 55: Switching Off

Operation 6.2.3 Switching off NOTICE! Property damage due to voltage peaks! – Only switch the unit off using the EMERGENCY STOP button in an emergency! Switch off motor. Maintain the following functions, if available: for double ring seals: Sealing pressure, until pump is pressure-free ( manufacturer's specifications), sealing system, cooling water supply until pump operating temperature has dropped... -

Page 56: Cip Cleaning/Sterilising At Cip Temperature Below 80 °C

Operation 6.3.1 CIP cleaning/sterilising at CIP temperature below 80 °C Prerequisites: For pumps with sealing system: Sealing system in operation. Pump stopped. Switch pipeline system to CIP medium. Start the pump ( Ä Chapter 6.2.2 ‘Switching on’ on page 53). Clean pipeline system and pump. -

Page 57: Mechanically Cleaning/Sterilising

Operation NOTICE! Material damage due to turbine effect! – During cleaning/sterilising due to steaming: Lock pump. Switch pipeline system to CIP medium. Clean pipeline system and pump. Remove all traces of the CIP medium. Remove the blockage. 6.3.4 Mechanically cleaning/sterilising Prerequisites: Pump switched off and depressurised. -

Page 58: Putting Out Of Operation

Operation Unscrew fastening screws. Pull pump casing off carefully. Remove sealing ring on intermediate flange. Clean/sterilise pump casing and internal parts of the pump with suitable cleaning agent. Carefully slide on the pump casing over the spindles, heed the installed position of inlet and outlet nozzles ( dimensioned drawing). -

Page 59: Operating The Stand-By Pump

Operation 6.6 Operating the stand-by pump Parallel operation of pumps only with express approval of ITT Bornemann GmbH. Alternately operate the pump and stand-by pump. Prerequisite: Standby pump filled and bled. Operate the stand-by pump at least once per week. -

Page 60: Maintenance And Repairs

– Observe statutory or other safety and accident prevention regu- lations. Use original parts or parts approved by ITT Bornemann GmbH exclusively. Spare parts lists and repair instructions on request, where not included in the scope of supply. 7.1 Wearing parts Wearing parts have a limited shelf-life because of their functionality and are there- fore not subject to the warranty. -

Page 61: Maintaining

Maintenance and repairs DANGER! Risk of injury due to running pump! – Do not touch the pump when it is running. – Do not work on the pump when it is running. – If possible: Allow the pump to cool prior to work. WARNING! Risk of injury and poisoning due to hazardous pumped media! –... - Page 62 Maintenance and repairs DANGER! Risk of injury due to running pump! – Do not touch the pump when it is running. – Do not work on the pump when it is running. – Prior to all assembly and maintenance work, switch off the motor and safeguard against being switched on again.

-

Page 63: Maintenance Table

Maintenance and repairs 7.3.1 Maintenance table Unless otherwise necessary due to the operating mode, carry out mainte- nance work in accordance with the following table. Maintenance – intervals and measures to be carried out Interval Module (if available) Measure Ä Chapter 5.5.3 ‘Taking Once, after reaching Pump, clutch, motor Specialist per-... -

Page 64: Lubrication

Maintenance and repairs Interval Module (if available) Measure With intermittent opera- Specialist per- Change lubricating oil ( Ä Chapter 7.3.2 Gear casing tion: Every 1000 hours sonnel ‘Lubrication’ on page 64). of operation, at the latest after 6 months Every 6 months Barrier system Specialist per- Change barrier fluid. -

Page 65: Remove Pump And Send To Manufacturer

Maintenance and repairs Filling lubricating oil Fig. 18: Oil level gauge on gear casing or bearings hood Description Maximum oil level Minimum oil level Procedure Switch off pump and safeguard against a restart. Let pump cool (min. 15 min cooling time). Open oil filling screw. -

Page 66: Remove Pump

Maintenance and repairs WARNING! Risk of injury and poisoning due to hazardous or hot pumped media! – Use personal protective equipment during all work on the pump. – Allow the pump to cool prior to work, if possible. – Ensure that the pump is pressure-free. –... -

Page 67: Return Pump To The Manufacturer

Pump cooled. Pump cleaned. All flanges and bore holes plugged. Only return pump or individual components to ITT Bornemann GmbH Ä Chapter 9.2 ‘Declaration of no objection’ on page 74). Depending on the desired repair, observe the required measures for return in accordance with the following table. -

Page 68: Order Spare Parts

Maintenance and repairs DANGER! Risk of injury due to running pump! – Do not touch the pump when it is running. – Do not work on the pump when it is running. – Prior to all assembly and maintenance work, switch off the motor and safeguard against being switched on again. -

Page 69: Lubricant

Maintenance and repairs 7.7 Lubricant The lubricant to be used is noted on a material label on the pump. NOTICE! Property damage resulting from the use of incompatible lubri- cants! – Only use one type of lubricant. 7.7.1 Gear oil, temperature of the medium to be pumped 10 – 300 °C The following gearbox oils are suitable for use in the foodstuffs and pharmaceuticals sectors. -

Page 70: Preservative Agents

Maintenance and repairs 7.9 Preservative agents Manufacturer Preservative agents oily waxy Finke Pharmawhite W – 00 7.10 Cleaning fluid The specified cleaning agents are only suitable for external cleaning. Cleaning agents for the interior are available on request. Area of application Cleaning fluid Other Cleaning solvent, wax remover, diesel,... -

Page 71: Fault Finding

Faults that are not specified in the following table or which are not traceable to one of the specified causes should be discussed with ITT Bornemann GmbH. The list of possible faults are given with a number in the following table. This number can be used to look up the cause and measure for rectification in the faults table. - Page 72 - - - X X - X Bearings/gears faulty. Consult with ITT Bornemann GmbH. If necessary, send the pump to ITT Bornemann GmbH. - - - X X - X Pump excessively tight. Check the connections and pipeline nozzles and fastenings on the pump.

-

Page 73: Appendix

Additional technical data pump data sheet. 9.1.1 Ambient conditions Consult the pump data sheet or contact ITT Bornemann GmbH. Temperature max. 40 °C, min. -10 °C (or pump data sheet). Installation above sea level max. 1000 m. 9.1.2 Noise level Measurements carried out as per DIN 45635, Part 1. -

Page 74: Declaration Of No Objection

Appendix 9.2 Declaration of no objection Please copy and send with the pump. Declaration of no objection Statutory regulations oblige all commercial companies to protect their employees, the public and the environment from the hazardous effects of dangerous substances. For this reason, repair and inspection of the products and their parts may only be undertaken once the following declaration has been correctly and fully filled out and signed by an authorised, qualified engineer. -

Page 75: Declaration In Accordance With The Ec Machinery Directive

The original declaration is supplied with the respective pump. Declaration of conformity EG declaration of conformity in accordance with Machinery Directive 2006/42/EC appendix II A We hereby declare, ITT Bornemann GmbH Postbox 1162, 31676 Obernkirchen Tel. +49 (0) 5724-390-0, Fax +49 (0) 5724-390-290, that the following machine:... -

Page 76: Declaration Of Incorporation In Accordance With The Ec Machinery Directive

The original declaration is supplied with the respective pump. Declaration of incorporation EG declaration of incorporation in accordance with Machinery Directive 2006/42/EC appendix II B We hereby declare, ITT Bornemann GmbH Postbox 1162, 31676 Obernkirchen Tel. +49 (0) 5724-390-0, Fax +49 (0) 5724-390-290, that the following incomplete machine:... - Page 77 Appendix Head of Engineering Head of Sales 01/2016 JPB Rev. 5 Type SLH-4G, SLHS-4G...

- Page 78 www.bornemann.com...

Need help?

Do you have a question about the Bornemann SLHS-4G and is the answer not in the manual?

Questions and answers