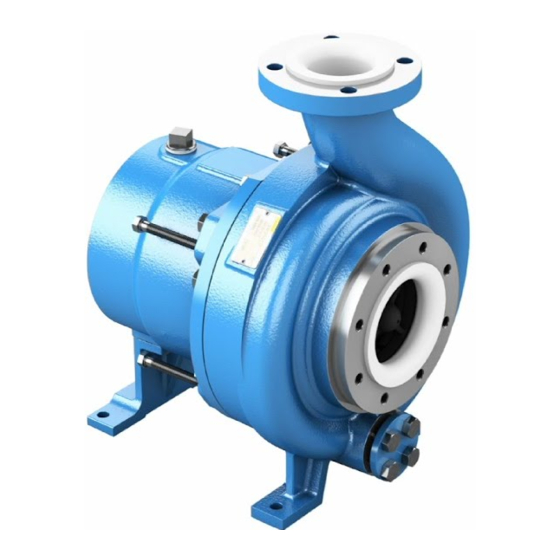

ITT Goulds Pumps 3298 Series Installation, Operation And Maintenance Instructions

Hide thumbs

Also See for Goulds Pumps 3298 Series:

- Installation, operation and maintenance manual (131 pages)

Summary of Contents for ITT Goulds Pumps 3298 Series

- Page 1 Installation, Operation and Maintenance Instructions 3298 Frame Mounted V 3298 SP 3298 3298 Close Coupled Close Coupled 3298 Family...

- Page 2 Pump Safety Tips Safety Apparel: Operation: · Insulated work gloves when handling Do not operate below minimum rated flow, or with suction/discharge valves closed hot bearings or using bearing heater · Heavy work gloves when handling Do not open vent or drain valves, or remove plugs while system is pressurized parts with sharp edges, especially impellers Maintenance Safety:...

- Page 3 IMPORTANT SAFETY REMINDER To: Our Valued Customers Goulds' pumps will provide safe, trouble-free service when properly installed, maintained, and operated. We have an extensive network of experienced sales and service professionals to assist in maximizing your satisfaction with our products. Safe installation, operation, and maintenance of Goulds' equipment are an essential end user responsibility.

-

Page 4: Family Rev

ITT Industries - Goulds shall not be liable for physical injury, damage or delays caused by a failure to observe the instructions for Installation, Operation, and Maintenance contained in this manual. - Page 5 TABLE OF CONTENTS SECTION PAGE SAFETY GENERAL INFORMATION INSTALLATION OPERATION PREVENTIVE MAINTENANCE DISASSEMBLY & REASSEMBLY SPARE AND REPAIR PARTS APPENDICES Hydraulic Coverage Charts Coupling Guard Installation Impeller Trim Procedures Power Monitors Reliability Tips for Operating Lined Magnetically-Driven Sealless Pumps (Quick Reference Guide ®...

- Page 6 3298 Family Rev. 4/07...

- Page 7 CAUTION ITT Industries Goulds Pumps shall not be liable for physical injury, damage or delays caused by a failure to Throttling flow from the suction side may cause observe the instructions in this manual.

- Page 8 NEVER start pump without proper prime (all DO NOT change conditions of service without models), or proper liquid level in self-priming approval of an authorized ITT-Goulds representative. pumps (Model SP3298). EXPLOSION PREVENTION In order to reduce the possibility of accidental explosions in atmospheres containing explosive gases and/or dust, the instructions under the ATEX symbol must be closely followed.

- Page 9 All instructions provided by ITT/Goulds. If there is any question regarding within this manual must be followed at all times. Operat- the intended use of the equipment, please contact an ing, installing or maintaining the pump unit in any way that ITT/Goulds representative before proceeding.

- Page 10 CONDITION MONITORING For assistance in selecting the proper instrumentation and For additional safety precautions, and where noted its use, please contact your ITT/Goulds representative. in this manual, condition monitoring devices should be used. If applicable, devices should comply with ATEX. This includes, but is not limited to:...

- Page 11 GENERAL INFORMATION PUMP DESCRIPTION ......11 NAMEPLATE INFORMATION ..... 12 RECEIVING THE PUMP .

- Page 12 NAMEPLATE INFORMATION Every pump has two Goulds nameplates that provide When ordering spare parts, you will need to identify pump information about the pump. The tags are located on the model, size, serial number, and the item number of required casing and bearing frame.

- Page 13 RECEIVING THE PUMP Inspect the pump as soon as it is received. Make notes of Baseplate mounted units are moved with slings under the damaged or missing items on the receipt and freight bill. pump and driver. (Figs. 5 & 7) File any claims with the transportation company immediately.

- Page 14 Complete vertical pumps are lifted with straps under the pump and motor (Fig. 8). Bare vertical pumps (without a motor) are lifted with straps under the pump and motor adapter (Fig. 9). Fig. 9 Fig. 8 3298 Family Rev. 4/07...

-

Page 15: Table Of Contents

INSTALLATION BASEPLATE INSPECTION......15 SITE/FOUNDATION ......15 LEVEL BASEPLATE . -

Page 16: Level Baseplate

All equipment being installed must be properly grounded to prevent unexpected static electric discharge. This includes ensuring that the PFA lined pumps are pumping fluids that are conductive. If not, a static electric discharge may occur when the pump is drained and disassembled for maintenance purposes. -

Page 17: Feature Fabricated Steel/Api Style

Place the two levels on the pump pads, one lengthwise FEATURE FABRICATED STEEL/ on a single pump pad, and another across the middle of API STYLE both pump pads. (Fig. 16) (BASEPLATES PROVIDED WITH VERTICAL LEVELING ADJUSTORS) Coat the jack screws with an anti-seizing compound to allow for easy removal after the grout has been cured. -

Page 18: Baseplate Leveling Worksheet

BASEPLATE LEVELING WORKSHEET LEVEL MEASUREMENTS 3298 Family Rev. 4/07... -

Page 19: Alignment And Alignment Procedure

ALIGNMENT AND ALIGNMENT PROCEDURE Final Alignment (Hot Alignment) WARNING · After First Run - To obtain correct alignment when both Before beginning any alignment procedure, make sure driver power is locked out. Failure to lock out driver pump and driver are at operating temperature. power can result in serious personal injury. -

Page 20: Set Up

SET UP Mount two dial indicators on one of the coupling halves (X) so they contact the other coupling half (Y) (Fig. 17). Check setting of indicators by rotating coupling half X to ensure indicators stay in contact with coupling half Y but do not bottom out. -

Page 21: Parallel Alignment

Positive Reading - Coupling half Y is to the PARALLEL ALIGNMENT right of coupling half X. Correct by sliding driver A unit is in parallel alignment when indicator P (parallel evenly in the appropriate direction. indicator) does not vary by more than .002 in. (.05 mm) as measured at four points 90°... -

Page 22: Alignment Troubleshooting

ALIGNMENT TROUBLESHOOTING Table 3 Alignment Troubleshooting PROBLEM PROBABLE CAUSE REMEDY Cannot obtain horizontal (Side-to-Side) Loosen pump hold down bolts and slide pump and driver Driver feet bolt bound. alignment, angular or parallel. until horizontal alignment is achieved. Determine if center of baseplate should be raised or Cannot obtain vertical (Top to Bottom) Baseplate not leveled properly, lowered and correct by evenly adding or removing shims... -

Page 23: Piping

PIPING Guidelines for piping are given in the Centrifugal Pump section of the “Hydraulic Institute Standards” and should be reviewed prior to pump installation. WARNING Never draw piping into place by forcing at the flanged connections of the pump. This will impose dangerous strains on the unit and cause misalignment between pump and driver. - Page 24 CORRECT CORRECT PIPING Fig. 26 Fig. 28 Suction Lift Conditions Suction pipe must be free from air pockets Suction piping must slope upwards to pump. Fig. 27 All joints must be air tight. A means of priming the pump must be provided, such as a foot valve, except for the self priming pump.

-

Page 25: Discharge Piping

DISCHARGE PIPING Isolation and check valves should be installed in INCORRECT PIPING discharge line. Locate the check valve between isolation valve and pump, this will permit inspection of the check valve. The isolation valve is required for priming, regulation of flow, and for inspection and maintenance of pump. - Page 26 3298 Family Rev. 4/07...

-

Page 27: Preparation For Start-Up

OPERATION PREPARATION FOR START-UP ....27 Checking Rotation - Frame Mounted ....27 Couple Pump and Driver . -

Page 28: Checking Rotation - Close Coupled

CHECKING ROTATION - CLOSE COUPLED CAUTION Serious damage may result if pump is run in the wrong rotation. Unlock driver power. Make sure everyone is clear. Jog driver just long enough to determine direction of rotation. Rotation of motor fan must correspond to arrow on close coupled frame. -

Page 29: Operation

OPERATION GENERAL CONSIDERATIONS CAUTION Always vary capacity with valve in discharge line. NEVER throttle flow from suction side. Driver may overload if the pumpage specific gravity (density) is greater than originally assumed, or the Driver may overload or magnets de-couple if pumpage rated flow rate is exceeded. -

Page 30: Operating Under Freezing Conditions

OPERATING UNDER FREEZING CONDITIONS Exposure to freezing conditions, while pump is idle, could cause liquid to freeze and damage the pump. Liquid inside pump should be drained. Liquid inside cooling coils, if supplied, should also be drained. 3298 Minimum Continuous Recommended Flow Table 5 - Minimum Flow 60 Hertz 50 Hertz... -

Page 31: Shutdown

SHUTDOWN Slowly close discharge valve. WARNING Shut down and lock out driver to prevent accidental When handling hazardous and/or toxic fluids, skin, eye rotation. and respiratory protection are required. If pump is being drained, precautions must be taken to prevent injury or environmental contamination. - Page 32 3298 Family Rev. 4/07...

- Page 33 PREVENTIVE MAINTENANCE GENERAL COMMENTS ......33 MAINTENANCE SCHEDULE ..... . 33 MAINTENANCE OF BEARINGS —...

- Page 34 ATEX certified and the listed temperature exceeds the applicable value shown in Table 1 under Safety, then that temperature is not valid. When this situation occurs, please consult with your ITT/Goulds representative. OIL LUBRICATED BEARINGS WARNING Pumps are shipped without oil. Oil lubricated bearings must be lubricated at the job site.

- Page 35 TROUBLESHOOTING Table 7 Troubleshooting Pump Problem / Malfunction Probable Cause Remedy Reprime pump, check that pump and suction 3298-V 3298 line are full of liquid. Pump not primed. Add initial charge to casing. SP 3298 Suction lift greater than maximum allowable - raise sump level.

- Page 36 TROUBLESHOOTING, con't Table 7 Troubleshooting Pump Problem / Malfunction Probable Cause Remedy Head lower than rating. Pumps too much Intall throttle valve. liquid. Liquid heavier than expected. Check specific gravity and viscosity. Motor requires Head higher than rating, capacity at rating. Check impeller diameter.

- Page 37 Table 7A Failure Symptoms Due to Dry Run Operation Poor lubrication or dry run operation of 3298 liquid lubricated bearing surfaces results in a significant increase of heat generation. The lack of cooling flow through the pump also causes significant temperature increase of the bearings. This temperature increase causes damage to the surrounding parts as described and shown in Fig.

- Page 38 3298 Family Rev. 4/07...

- Page 39 DISASSEMBLY& REASSEMBLY REQUIRED TOOLS ......39 PREPARATION FOR DISASSEMBLY ....47 DISASSEMBLY 3298 XS Group .

- Page 40 OPTIONAL TOOLS Optional Tool Kit - #R298TK04 for XS Group 1 x 1½-5 Bearing Spider Installation Driver - Tool Number B03309A Qty. 1 Fig. 34 1½ x2-6 Bearing Spider Installation Driver - Tool Number B04370A Qty. 1 Fig. 35 3298 Family Rev. 4/07...

- Page 41 Radial Bearing Installation Tool - Tool Number B03310A Qty. 1 Fig. 36 Bearing Press Support Tool - Tool Number A06872A Fig. 37 Shaft Wrench - Tool Number A01676A Fig. 38 3298 Family Rev. 4/07...

- Page 42 OPTIONAL TOOL KIT - #R298TK01 for 3298 S Group Sizes 1 x 1 -6, 1 x 1 -8, 2 x 3-6 for SP 3298 S Group Sizes 1 x 1 -6, 2 x 3-6 for V 3298 S Group Sizes 1 x 2-6, 1 x 2 - 8, 2 x 3-6 Bearing Spider Installation Driver - Tool Number B02496A Qty.

- Page 43 OPTIONAL TOOL KIT - #R298TK02 for 3298 M Group Pump Sizes 2 x 3-8, 3 x 4-7, 1 x 2-10 for V 3298 M Group Sizes 1 x 2-10 Bearing Spider Installation Driver - Tool Number B03147A, Qty 1 Fig. 41 Bearing Spider Installation Driver - Tool Number B03148A Qty.

- Page 44 Radial Bearing Installation Tool - Tool Number B03149A Qty. 1 Fig. 43 Magnet Assembly/ Disassembly Guide Rods - Tool Number B03189A Qty. 2 Fig. 44 3298 Family Rev. 4/07...

- Page 45 OPTIONAL TOOL KIT - #R298TK03 for L Group Pump Sizes 3 x 4-10, 4 x 6-10 Bearing Spider Installation Driver - Tool Number B03191A Qty. 1 Fig. 45 Radial Bearing Installation Tool - Tool Number B03175A Qty. 1 Fig. 46 3298 Family Rev.

- Page 46 Radial Bearing Installation Tool - Tool Number B03149A Qty. 1 Fig. 47 Magnetic Assembly/Disassembly Guide Rods - Tool Number B03189A Qty. 2 Fig. 48 3298 Family Rev. 4/07...

- Page 47 PREPARATION FOR DISASSEMBLY WARNING A build up of gases within the pump, sealing system and or process piping system may result in Ensure pump is isolated from system and pressure is an explosive environment within the pump or relieved before any plugs are removed or piping process piping system.

- Page 48 DISASSEMBLY 3298 XS GROUP DISASSEMBLY Grasp suction flange of casing and pull casing liquid WARNING end free from magnet assembly (Fig. 49). Each component must be individually decontami- Remove casing bolts (356A) (Fig. 49). nated using procedures in accordance with all federal, state, local, and company environmental Wrap a piece of emery cloth around the containment regulations.

- Page 49 Remove impeller assembly (101) (Fig. 51). 12. When replacement of the close coupled drive magnet assembly (740B) is required, remove and discard the Remove shaft (122A) if replacement is necessary nylok set screws (222L). Use a puller and the 2 - (Fig.

- Page 50 3298 S GROUP DISASSEMBLY Wrap a piece of emery cloth around the containment WARNING shell (750) and secure with a large hose clamp (Fig. 54). Each component must be individually decontami- Screw C-face motor support / bearing frame bolts nated using procedures in accordance with all (370B) into the tapped holes of the clamp ring federal, state, local, and company environmental (141C) and tighten evenly to remove containment...

- Page 51 14. Place shaft wrench on drive shaft (122B) and remove WARNING the hex nut (355A) (Fig. 57). The magnets contained in this unit are extremely powerful. Keep magnetic drive components and magnetic tools apart from each other by a minimum of three (3) feet [one (1) meter].

- Page 52 18. Remove bearing end cover bolts (370C) (Fig. 60). 25. Remove lip seal (333D) as shown (Fig. 62). 19. Install two end cover bolts (370C) in jacking screw holes, tighten evenly to remove bearing end cover (109A). 20. Slide bearing end cover (109A) back. Labyrinth oil seal (332A) will slide back with the end cover.

- Page 53 3298 M GROUP DISASSEMBLY Tighten jacking screws (418) until gap between WARNING clamp ring (141C) and C-face motor support bearing Each component must be individually decontami- frame is 3.5 inches. Then grasp suction flange of nated using procedures in accordance with all casing and pull casing liquid end free from magnet federal, state, local, and company environmental assembly (Fig.

- Page 54 Remove impeller assembly (101) (Fig. 65). 12. Inspect rear impeller wear ring (203) and remove if replacement is necessary. Remove shaft (122A) if replacement is necessary (Fig. 65). 13. Remove reverse thrust bearing (197C) from containment shell (750) if replacement is necessary. 10.

- Page 55 17. Tighten jacking screws evenly and in sequence until 27. Press bearings (112) off shaft and inspect. the magnet assembly (740B) can be removed. 28. Remove lip seal (333D) as shown (Fig. 73). 18. Remove magnet assembly (740B) and set aside away from attracting metals (Fig.

- Page 56 3298 L GROUP DISASSEMBLY Screw C-face motor support / bearing frame bolts WARNING (370B) into the tapped holes of the clamp ring Each component must be individually decontami- (141C) and tighten evenly to remove containment nated using procedures in accordance with all shell.

- Page 57 11. Press out radial bearings (197B) from impeller assembly (101) utilizing the bearing tool if replacement is necessary (Fig. 77). Fig. 79 16. Place shaft wrench on drive shaft (122B) and remove the hex nut (355A) (Fig. 79). Jacking Screws Fig.

- Page 58 20. Remove " rub ring cap screw (372Y) from bottom 27. Remove drive shaft (122B) with ball bearings (112) of bearing frame (228) (Fig. 82). and wave washer (529) (Fig. 84). Fig. 82 Fig. 84 Fig. 84 21. Remove rub ring (144A) from bearing frame 28.

- Page 59 SP 3298 DISASSEMBLY Remove the backplate bolts (372V) (Fig. 87). WARNING Thread casing bolts (372V) into tapped holes in Each component must be individually decontami- backplate (444) and tighten evenly to remove the nated using procedures in accordance with all backplate / clamp ring assembly from the casing federal, state, local, and company environmental (100).

- Page 60 12. Remove volute insert (100U) from casing (100) (Fig. 89). WARNING The magnets contained in this unit are extremely powerful. Keep magnetic drive components and magnetic tools apart from each other by a minimum of three (3) feet [one (1) meter]. Serious injury to fingers and hands will result.

- Page 61 18. Place three " x 2" cap screws in jacking screw holes in magnet assembly (740B) (Fig. 92). 19. Tighten jacking screws evenly and in sequence until the magnet assembly (740B) can be removed. Jacking Screws Fig. 94 Fig. 92 20.

- Page 62 V 3298 DISASSEMBLY Remove casing bolts (356A) (Fig. 97) WARNING Wrap a piece of emery cloth around the containment Each component must be individually decontami- shell (750) and secure with a large hose clamp (Fig. 98). nated using procedures in accordance with all federal, state, local, and company environmental Screw C-face motor support / bearing frame bolts regulations.

- Page 63 Remove impeller assembly (101) (Fig. 99). Remove shaft (122A) if replacement is necessary (Fig. 99). 10. Inspect bearing spider (101A) and pull out from casing (100) using spider removal tool if replacement is necessary (Fig. 99). Fig. 100 This completes disassembly of the V 3298 close coupled version.

- Page 64 INSPECTIONS Model 3298 parts must be inspected to the following criteria before reassembly to ensure pump will run properly. Any part not meeting required criteria should be replaced. CASING (100) Casing (100) should be inspected for excessive wear, abrasive damage, cut or a loose liner. VOLUTE INSERT (SP 3298 Only) Volute insert (100U) should be inspected for excessive wear, abrasive damage or cut surfaces.

- Page 65 RADIAL BEARING (197B) CONTAINMENT SHELL (750) Inspect bearings for cracks or chips. Must be free from scratches or cracks. Inspect dimensions per Table 10: Grooves in excess of .010 in. (.25 mm) for the outside diameter and .030 in (.75mm) for the inside Table 10 diameter require containment shell replacement.

- Page 66 3298 REASSEMBLY 3298 XS GROUP REASSEMBLY Refer to Table 11 for torque values while reassembling CAUTION pump. Use caution when using a hydraulic press as you Table 11 cannot feel when the bearing hits the bottom of the bore. *Bolt Torque Table Ft-Lbs (Nm) NOTE: On occasion, the action of pressing the radial bearings into the impeller may cause some ETFE to...

- Page 67 Slide impeller assembly (101) onto shaft (Fig. 107). Fig. 107 Press spider (101A) into casing (100) with spider tool (Fig. 108). Fig. 109 Install clamp ring (141C) to casing (100) with 6 hex cap screws (356A) (Fig. 109). Fig. 108 Check rotary assembly total travel.

- Page 68 11. For use with 143TC/145TC motor frames. Install 17. Remove the shim. Rotate the magnet assembly 90° four expansion plugs (408Z) into C-face motor to access the other set screw. Tighten. support (228) by tapping on the plug with a 5/8" rod (Fig.

- Page 69 3298 S GROUP REASSEMBLY Slide key (178S) into impeller (101). To hold key in Slide bearing spacer (157A) into impeller (Fig. 117). place, stake impeller at end of key (Fig. 115). Use a Press second radial bearing (197B) into impeller center punch.

- Page 70 Slide impeller assembly (101) onto shaft (Fig. 119). 12. Install containment shell / impeller assembly into casing (100). Use care that the O-ring (412M) remains in place. WARNING The magnets contained in this unit are extremely powerful. Serious injury to fingers and hands will result if care is not taken.

- Page 71 18. Install two set screws (222L) into magnet assembly This completes the assembly of a closed coupled drive (740B) (Fig. 124). end. Proceed to Step 24. Frame Mounted Assembly 15. Install ball bearings (112) on shaft (122B) at both ends. NOTE: There are several methods used to install bearings.

- Page 72 18. Install shaft (122B) with ball bearings (112) into WARNING bearing frame (228). The threaded end of the shaft goes toward the magnets (Fig. 129). Use non-magnetic socket and wrench to avoid personal injury or damage to parts. 22. Install magnet assembly (740B) onto shaft (122B) (Fig.

- Page 73 3298 M GROUP REASSEMBLY Slide key (178S) into impeller (101). To hold key in Slide bearing spacer (157A) into impeller (Fig. 134). place, stake impeller at end of key (Fig. 132). Use a Press second radial bearing (197B) into impeller center punch.

- Page 74 10. Slide impeller assembly (101) onto shaft (Fig. 136). 13. Install containment shell / impeller assembly into casing (100). Use care that the O-ring (412M) remains in place. WARNING The magnets contained in this unit are extremely powerful. Serious injury to fingers and hands will result if care is not taken.

- Page 75 19. Install two set screws (222L) into magnet assembly 22. Remove the shim. Rotate the magnet assembly 90° (740B) (Fig. 141). to access the other set screw. Tighten. This completes the assembly of a closed coupled drive end. Proceed to Step 27. Frame Mounted Assembly 16.

- Page 76 19. Install shaft (122B) with ball bearings (112) into bearing frame (228). The threaded end of the shaft goes toward the magnets (Fig. 146). Install wave washer (529) (Fig. 147). Fig. 148 Fig. 146 NOTE: Ensure shaft O-ring, grooves, shaft keyways and keyway in frame are free of burrs.

- Page 77 25. Install rub ring (144A) into bearing frame (228). 30. Install guide rods (Qty = 2, B03189A) into clamp Line up through hole in rub ring with tapped hole in ring (141C). These rods will help guide the casing frame (228) by using scribe mark on the rub ring to assembly into C-face support / frame (228) which reference tapped hole in frame.

- Page 78 3298 L GROUP REASSEMBLY Install o-ring (496G) into driven magnet assembly (740A). Lubricate o-ring (496G) with Parker o-ring lube or equivalent. Press driven magnet assembly (740A) onto impeller assembly (101). Install retaining ring (361H) into groove in impeller assembly (101) (Fig.

- Page 79 Slide reverse thrust bearing (197D) on shaft (122A). 12. Check rotary assembly total travel. See Fig. 161 for Press shaft (122A) into containment shell (750). the appropriate measurements needed. For the L pump, total travel is A - B and should be 0.020 - Coat O-ring (412M) with O-ring lubricant.

- Page 80 Close Coupled Assembly 16. For motor frames 284TSC - 286TSC install 4 expansion plugs (408Z) into C-face motor support (228) by tapping on the plug with a 1" rod (Fig. 163). Fig. 165 Fig. 155 Fig. 163 For motor frames 182TC - 256TC and motor frame 324TSC expansion plugs are not used.

- Page 81 Frame Mounted Assembly 16. Install ball bearings (112) on shaft (122B) at both ends. NOTE: There are several methods used to install bearings. The preferred method is to use an induction heater that heats as well as demagnetizes the bearings. 17.

- Page 82 21. Press labyrinth seal (332A) into end cover (109A). Ensure O-rings are in grooves of labyrinth seal. Orient expulsion ports to the 6 o’clock position and press into bearing end cover (109A) until it is shouldered against end cover. No adjustment is necessary.

- Page 83 30. Install guide rods (Qty = 2, B03189A) into clamp ring (141C). These rods will help guide the casing assembly into C-face support/frame (228) which contains drive magnets (740B) (Fig. 175). Fig. 176 33. Untighten jacking screws (418) and slowly draw casing assembly into C-face support/bearing frame assembly.

- Page 84 SP 3298 REASSEMBLY S GROUP REASSEMBLY Slide key (178S) into impeller (101). To hold key in place, stake impeller at end of key (Fig. 177). Use a center punch. Fig. 177 Fig. 178 Lubricate the outside of both radial bearings. Press the first radial bearing (197B) into impeller using the bearing installation tool.

- Page 85 Fig. 181 Coat O-ring (412M) with O-ring lubricant. The lubricant is used to help the O-ring remain in place. Insert O-ring in containment shell (Fig. 180). Place backplate (444) face down on work surface. 10. Place containment shell with reverse thrust bearing in backplate.

- Page 86 14. Press spider (101A) into volute insert (100U) with spider tool (Fig. 183). 15. Press volute insert with spider into the casing (100) (Fig. 183). CAUTION Ensure volute insert is oriented such that the cut- water (tongue) is up. If installed incorrectly, pump will not prime and could cause pump failure.

- Page 87 22. Install two set screws (222L) into magnet assembly This completes the assembly of a closed (740B) (Fig. 187). coupled drive end. Proceed to Step 28. Frame Mounted Assembly 19. Install ball bearings (112) on shaft (122B) at both ends. NOTE: There are several methods used to install bearings.

- Page 88 22. Install shaft (122B) with ball bearings (112) into NOTE: Ensure shaft O-ring, grooves, shaft keyways bearing frame (228). The threaded end of the shaft and keyway in frame are free of burrs. goes toward the magnets (Fig. 192). 25. Install key (178Y) on shaft (122B) (Fig. 194). WARNING Use non-magnetic socket and wrench to avoid personal injury or damage to parts.

- Page 89 V 3298 GROUP REASSEMBLY Slide key (178S) into impeller (101). To hold key in Slide bearing spacer (157A) into impeller place, stake impeller at end of key (Fig. 195). Use a (Fig. 197). center punch. Press second radial bearing (197B) into impeller (Fig.

- Page 90 Slide impeller assembly (101) onto shaft (Fig. 199). 11. Install containment shell / impeller assembly into casing (100). Use care that the O-ring (412M) remains in place. WARNING The magnets contained in this unit are extremely powerful. Serious injury to fingers and hands will result if care is not taken.

- Page 91 17. Install two set screws (222L) into magnet assembly (740B) (Fig. 204). Fig. 207 19. Rotate the magnet assembly (740B) to line up the key (178Y) with the access hole on the C-face motor Fig. 204 support (228). Tighten the first set screw (222L) through the access hole.

- Page 92 Sectional 3298 XS Group Close Coupled Sizes 1 x 1 -5 and 1½ x 2-6 NEMA Motors Motors 3298 XS 1 x 1 -5 and 1½ x 2-6 — Close Coupled 3298 Family Rev. 4/07...

- Page 93 3298 XS Group Close Coupled Sizes 1 x 1 -5 and 1½ x 2-6 Close Coupled Item # Part Name Material ® Casing Ducitle Iron / Tefzel ® Impeller, Assembly Carbon Filled Tefzel ® Standard - Carbon Filled Tefzel / Silicon Carbide 101A Bearing Spider Optional - DryGuard Silicon Carbide...

- Page 94 Sectional 3298 S Group Frame Mounted Sizes 1 x 1 -6, 1 x 1 -8, 1½ x 3-7, 2 x 3-6 3298 S Group Frame Mounted Version 3298 Family Rev. 4/07...

- Page 95 3298 S Group Frame Mounted Sizes 1 x 1 -6, 1 x 1 -8, 1½ x 3-7, 2 x 3-6 Frame Mounted Item # Part Number Material ® Casing Ductile Iron / Tefzel ® Impeller, Assembly Carbon filled Tefzel ® Standard - Carbon filled Tefzel / Silicon Carbide ®...

- Page 96 Sectional 3298 S Group Close Coupled Sizes 1 x 1 -6, 1 x 1 -8, 1½ x 3-7, 2 x 3-6 NEMA Motors Motors 3298 S Group Close Coupled Version 3298 Family Rev. 4/07...

- Page 97 3298 S Group Close Coupled Sizes 1 x 1 -6, 1 x 1 -8, 1½ x 3-7, 2 x 3-6 3298 S Group Close Coupled Item Number Part Name Material ® Casing Ductile Iron / Tefzel ® Impeller, Assembly Carbon Filled Tefzel ®...

- Page 98 Sectional 3298 M Group Frame Mounted Sizes 3 x 4-7, 1½ x 3-8, 2 x 3-8, 1 x 2-10 3298 M Group Frame Mounted Version 3298 Family Rev. 4/07...

- Page 99 3298 M Group Frame Mounted Sizes 3 x 4-7, 1½ x 3-8, 2 x 3-8, 1 x 2-10 Frame Mounted Item Number Part Name Material ® Casing Ductile Iron / Tefzel ® Impeller, Assembly Carbon filled Tefzel ® Standard - Carbon filled Tefzel / Silicon Carbide ®...

- Page 100 Sectional 3298 M Group Close Coupled Sizes 3 x 4-7, 1½ x 3-8, 2 x 3-8, 1 x 2-10 3298 M Group Close Coupled Version 3298 Family Rev. 4/07...

- Page 101 3298 M Group Close Coupled Sizes 3 x 4-7, 1½ x 3-8, 2 x 3-8, 1 x 2-10 Close Coupled Item Number Part Name Material ® Casing Ductile Iron / Tefzel ® Impeller, Assembly Carbon filled Tefzel ® Standard - Carbon filled Tefzel / Silicon Carbide ®...

- Page 102 3298 L Group Frame Mounted Sizes 1½ x 3-10, 2 x 3-10, 3 x 4-10G, 3 x 4-10H, 4 x 6-10 3298 L Group Frame Mounted Version 3298 Family Rev. 4/07...

- Page 103 3298 L Group Frame Mounted Sizes 1½ x 3-10, 2 x 3-10, 3 x 4-10G, 3 x 4-10H, 4 x 6-10 Frame Mounted Item Number Part Name Material ® Casing Ductile Iron / Tefzel ® Impeller, Assembly Carbon Fiber Reinforced Tefzel ®...

- Page 104 3298 L Group Close Coupled Sizes 1½ x 3-10, 2 x 3-10, 3 x 4-10G, 3 x 4-10H, 4 x 6-10 3298 L Group Close Coupled Version 3298 Family Rev. 4/07...

- Page 105 3298 L Group Close Coupled Sizes 1½ x 3-10, 2 x 3-10, 3 x 4-10G, 3 x 4-10H, 4 x 6-10 Close Coupled Item Number Part Name Material ® Casing Ductile Iron / Tefzel ® Impeller, Assembly Carbon Fiber Tefzel ®...

- Page 106 SP 3298 S Group Frame Mounted Sizes 1 x 1 -6, 2 x 3-6 SP 3298 S Group Frame Mounted Version 3298 Family Rev. 4/07...

- Page 107 SP 3298 S Group Frame Mounted Sizes 1 x 1 -6, 2 x 3-6 Frame Mounted Item Number Part Name Material ® Casing Ductile Iron / TEFZEL ® 100U Volute Insert Carbon Filled TEFZEL ® Impeller, Assembly TEFZEL ® 101A* Bearing Spider TEFZEL / Silicon Carbide...

- Page 108 SP 3298 S Group Close Coupled Sizes 1 x 1 -6, 2 x 3-6 NEMA Motors Motors SP 3298 S Group Close Coupled Version 3298 Family Rev. 4/07...

- Page 109 SP 3298 S Group Close Coupled Sizes 1 x 1 -6, 2 x 3-6 Close Coupled Item Number Part Name Material ® Casing Ductile Iron / TEFZEL ® 100U Volute Insert Carbon Filled TEFZEL ® Impeller, Assembly TEFZEL ® 101A* Bearing Spider TEFZEL - Silicon Carbide...

- Page 110 Sectional V 3298 Sizes 1 x 2-6, 2 x 3-6, 1 x 2-8 M: 1 x 2-10 NEMA Motors Motors V 3298 3298 Family Rev. 4/07...

- Page 111 V 3298 Group Close Coupled Sizes S: 1 x 2-6, 2 x 3-6, 1 x 2-8 M: 1 x 2-10 Close Coupled Item Number Part Name Material ® Casing Ductile Iron / TEFZEL ® Impeller, Assembly TEFZEL ® 101A Bearing Spider TEFZEL - Silicon Carbide 122A...

- Page 112 3298 Family Rev. 4/07...

- Page 113 SPARE AND REPAIR PARTS RECOMMENDED SPARES ......113 HOW TO ORDER PARTS ......115 INTERCHANGEABILITY .

- Page 114 Table 12 3298 Repair Kits Bearing Kits Repair Kit Carbon / Power Dry- Silicon Dry- Silicon Size Carbon Carbide Guard™ Carbide Guard™ XS Group 1X1.5-5 R298BKCXS26 R298BKSXS15 R298BKSFXS15 R298K155V R298RKSFX15 1.5X2-6 R298BKCXS6 R298BKSXS6 R298BKSFXS6 R298RK526V R298RKS526 S Group R298PKS 1X1.5-6 R298BKCS15 R298BKSS15 R298BKSF15...

- Page 115 3298 Family Rev. 4/07...

- Page 116 INTERCHANGEABILITY 3298 XS GROUP 3298 Family Rev. 4/07...

- Page 117 INTERCHANGEABILITY 3298 S GROUP 3298 Family Rev. 4/07...

- Page 118 INTERCHANGEABILITY 3298 M GROUP INTERCHANGEABILITY 3298 M GROUP (SIZE 1½ x 3-8 ONLY) 3298 Family Rev. 4/07...

- Page 119 INTERCHANGEABILITY 3298 L GROUP 3298 Family Rev. 4/07...

- Page 120 INTERCHANGEABILITY SP 3298 S GROUP 3298 Family Rev. 4/07...

- Page 121 INTERCHANGEABILITY V 3298 S GROUP 3298 Family Rev. 4/07...

- Page 122 INTERCHANGEABILITY V 3298 M GROUP 3298 Family Rev. 4/07...

- Page 123 All pumps must be decontaminated prior to return. Refer writing. The correct Material Safety Data Sheet (MSDS) to Preparation for Disassembly and Decontamination must accompany the parts along with decontamination Procedure. "sign off." This information is stated within the ITT 3298 Family Rev. 4/07...

- Page 124 3298 Family Rev. 4/07...

- Page 125 APPENDIX I 3298 HYDRAULIC COVERAGE CHARTS 3298 Family Rev. 4/07...

- Page 126 3298 HYDRAULIC COVERAGE CHARTS 3298 Family Rev. 4/07...

- Page 127 SP 3298 HYDRAULIC COVERAGE CHARTS 3298 Family Rev. 4/07...

- Page 128 SP 3298 HYDRAULIC COVERAGE CHARTS 3298 Family Rev. 4/07...

- Page 129 V 3298 HYDRAULIC COVERAGE CHARTS 3298 Family Rev. 4/07...

- Page 130 V 3298 HYDRAULIC COVERAGE CHARTS 3298 Family Rev. 4/07...

- Page 131 APPENDIX II COUPLING GUARD INSTALLATION - Frame Mounted Only XLT-X Align the end plate (pump end) to the pump The coupling guard used in an ATEX classified bearing housing so that the large slots on the end environment must be constructed from a non- plate clear the bearing housing tap bolts and the small sparking material.

- Page 132 2. Spread bottom of coupling guard half (pump end) slightly and place over pump end plate as shown in Fig. II-4. The annular groove in the guard half is located around the end plate (Fig. II-5). Fig. II-7 4. Spread bottom of coupling guard half (driver end) slightly and place over coupling guard half (pump end) so that annular groove in coupling guard half (driver end) faces the motor as shown in Fig.

- Page 133 5. Place end plate (driver end) over motor shaft as shown in Fig. II-9. Locate the end plate in the annular groove at the rear of the coupling guard half (driver end) and secure with a bolt, nut, and two washers through the round hole at the rear of the guard half.

- Page 134 3298 Family Rev. 4/07...

- Page 135 APPENDIX III IMPELLER AND SP 3298 TRIM PROCEDURE IMPELLER TRIM PROCEDURE DO NOT chuck the impeller assembly. DO NOT take cuts larger than .050". DO NOT over tighten arbor screw (this could crack the carbon bearings). Use Arbor tool A06785A01 (XS Group size 1 x 1 -5).

- Page 136 IMPELLER TRIM PROCEDURE Group S & M Fig. III-2 Group L Fig. III-3 3298 Family Rev. 4/07...

- Page 137 RECOMMENDED CUTTING TOOL Fig. III-4 SP3298 VOLUTE INSERT TRIM PROCEDURE DO NOT take cuts larger than .050” Use Arbor Tool C06820A (SP3298 1X1.5-6) 2.. Use Arbor Tool C06821A (SP3298 2X3-6) Make sure arbor is running true within .002” tir. Fig. III-5 3298 Family Rev.

- Page 138 SP3298 VOLUTE INSERT CUTWATER TRIM PROCEDURE Machine cutwater diameter to full depth "R" as shown in Table III-1. Table III-1 Impeller Diameter "R" +/0 0/010" a. Use arbor C06820A for SP3298 1x1.5-6 5.00 2.563 b. Use arbor C06821A for SP3298 2x3-6 5.12 2.625 5.25...

- Page 139 14. When using dual trip power monitors, select high and Fig. IV-1 low trip points designed to protect your specific system within the recommended pump operating region defined by ITT Goulds Pumps. This method 3. Understand your systems requirements and will create boundaries for a safe pump operating limitations.

- Page 140 · Broken or Damaged Shaft maximize protection of your pump. · Broken or Damaged Coupling 17. For variable speed operation, consult ITT Goulds · Pumps or the power monitor manufacturer for Jammed Impeller appropriate auxiliary devices designed for operating ·...

- Page 141 NPSHa as well as vapor pressure is mandatory to superior reliability, please request the Lined Mag-Drive prevent cavitation or vaporization in localized low Reliability Guide from your ITT Goulds Pumps’ pressure regions within the pump. representative. ·...

- Page 142 3298 Family Rev. 4/07...

- Page 143 300° F (150° C) may be permissible. Contact Combo. Do not pry against the Polyshield mounting your ITT Industries - Goulds Pumps representative for block when moving the motor during shaft alignment. assistance in determining acceptability of a specific 5.

- Page 144 ® outdoor location, cover the Polyshield completely with a tarpaulin or dark plastic sheeting to prevent UV degradation of the surface. NOTE: UV degradation (bleaching) of the polymer concrete is the normal result of exposure to sunlight. This phenomenon is purely a visible change in the color of the material, which in no way compromises the performance or corrosion resistance characteristics of the Polyshield®.

- Page 145 After satisfactory slinging has been achieved, the ® Polyshield ANSI Combo may be hoisted onto its foundation. Take care not to bump the unit against fixed objects or induce any unnecessary shock loads. Lower the unit slowly over the foundation using care to center the unit over the rebar cage.

- Page 146 ® 6. Check and verify the dimensions again before the POLYSHIELD ANSI COMBO grouting procedure begins. SEALING KIT EPOXY NOVOLAC (EN) INSTRUCTIONS 7. A low slump standard concrete mix is suitable for ® filling the Polyshield ANSI Combo in new construction.

- Page 147 ® POLYSHIELD ANSI COMBO SHELF LIFE AND STORAGE SEALING KIT VINYL ESTER (VE) Store resin and hardener in their unopened containers in a INSTRUCTIONS dry cool place away from open flames, heat or sources of ignition. Shelf life is limited to 60 days if stored in a cool, dry location.

- Page 148 Please take our customer satisfaction survey online at: http://www.gouldspumps.com/feedbacksurvey.html We appreciate you taking the time to provide your feedback. Thank you for buying Goulds pumps, parts, and controls. Visit our website at www.gouldspumps.com Form No. I3298 4/07 © 2007 Goulds Pumps, Incorporated a subsidiary of ITT Corporation...

Need help?

Do you have a question about the Goulds Pumps 3298 Series and is the answer not in the manual?

Questions and answers