ITT GOULDS PUMPS 3298 Series Installation, Operation And Maintenance Manual

Hide thumbs

Also See for GOULDS PUMPS 3298 Series:

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for ITT GOULDS PUMPS 3298 Series

- Page 1 Installation, Operation, and Maintenance Manual 3298 Family...

-

Page 3: Table Of Contents

Table of Contents Table of Contents 1 Introduction and Safety ............................ 4 1.1 Introduction..............................4 1.1.1 Requesting other information ......................4 1.2 Safety ................................ 4 1.2.1 Safety terminology and symbols ..................... 5 1.2.2 Environmental safety........................6 1.2.3 User safety ............................6 1.2.4 Ex-approved products ........................ - Page 4 Table of Contents 5 Commissioning, Startup, Operation, and Shutdown ................... 42 5.1 Preparation for startup..........................42 5.2 Remove the coupling guard ........................43 5.3 Check the rotation ........................... 45 5.4 Check the rotation - Close Coupled ......................45 5.5 Couple the pump and driver ........................45 5.5.1 Install the coupling guard ......................

- Page 5 8.11 Interchangeability drawings ......................... 117 8.12 Hydraulic coverage charts........................124 9 Other Relevant Documentation or Manuals....................127 9.1 For additional documentation ........................ 127 10 Local ITT Contacts ............................128 10.1 Regional offices........................... 128 3298 Family Installation, Operation, and Maintenance Manual...

-

Page 6: Introduction And Safety

For instructions, situations, or events that are not consid- ered in this manual or in the sales documents, please contact the nearest ITT representative. Always specify the exact product type and identification code when requesting technical information or spare parts. -

Page 7: Safety Terminology And Symbols

Risk of injury and/or property damage. Operating a pump in an inappropriate application can cause over pressurization, overheating, and/or unstable operation. Do not change the service application without the approval of an authorized ITT representative. 1.2.1 Safety terminology and symbols... -

Page 8: Environmental Safety

WARNING: If the product has been contaminated in any way, such as from toxic chemicals or nuclear radi- ation, do NOT send the product to ITT until it has been properly decontaminated and advise ITT of these conditions before returning. - Page 9 1.2 Safety • Always keep the work area clean. • Pay attention to the risks presented by gas and vapors in the work area. • Avoid all electrical dangers. Pay attention to the risks of electric shock or arc flash hazards. •...

-

Page 10: Ex-Approved Products

Personnel requirements These are the personnel requirements for Ex-approved products in potentially explosive atmospheres: • All work on the product must be carried out by certified electricians and ITT-authorized mechanics. Special rules apply to installations in explosive atmospheres. • All users must know about the risks of electric current and the chemical and physical characteristics of the gas, the vapor, or both present in hazardous areas. -

Page 11: Monitoring Equipment

Compliance is fulfilled only when you operate the unit within its intended use. Do not change the condi- tions of the service without the approval of an ITT representative. When you install or maintain explosion proof products, always comply with the directive and applicable standards (for example, IEC/EN 60079–... - Page 12 1.3 Product warranty Warranty claim ITT products are high-quality products with expected reliable operation and long life. However, should the need arise for a warranty claim, then contact your ITT representative. 3298 Family Installation, Operation, and Maintenance Manual...

-

Page 13: Transportation And Storage

2 Transportation and Storage 2 Transportation and Storage 2.1 Inspect the delivery 2.1.1 Inspect the package Inspect the package for damaged or missing items upon delivery. Note any damaged or missing items on the receipt and freight bill. File a claim with the shipping company if anything is out of order. If the product has been picked up at a distributor, make a claim directly to the distributor. - Page 14 2.2 Transportation guidelines • Safe lifting points are specifically identified in this manual. It is critical to lift the equipment only at these points. Integral lifting eyes or eye bolts on pump and motor components are intended for use in lifting the individual components only. •...

- Page 15 2.2 Transportation guidelines Figure 3: Proper lifting method for a vertical pump with a driver Figure 4: Proper lifting method for a vertical pump with no driver Figure 5: Example of a proper lifting method 3298 Family Installation, Operation, and Maintenance Manual...

-

Page 16: Storage Guidelines

You can purchase long-term storage treatment with the initial unit order or you can purchase it and apply it after the units are already in the field. Contact your local ITT sales representative. 3298 Family Installation, Operation, and Maintenance Manual... -

Page 17: Product Description

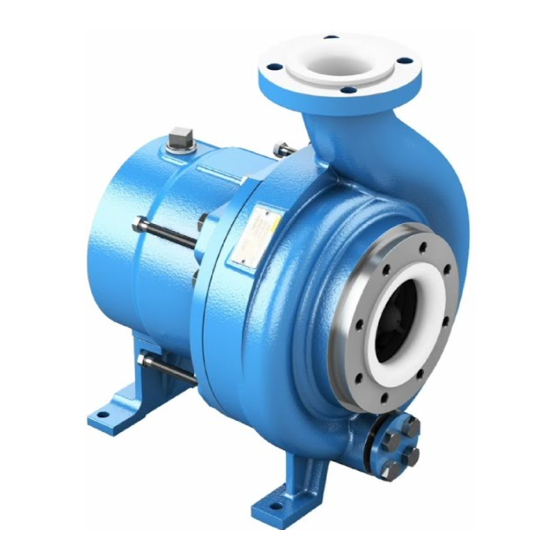

3 Product Description 3 Product Description 3.1 General description Model 3298 Model 3298 is a sealless, close-coupled or frame-mounted, centrifugal pump with an enclosed impeller that is driven by a synchronous magnetic coupling. All sizes of the 3298 meet the dimensional standards of ANSI B73.1 except for 1x1.5-5 and the 1.5x2-6. -

Page 18: Nameplate Information

3.2 Nameplate information Bearings The standard material for radial bearings and thrust bearings is carbon. Pure Sintered Alpha Grade Sili- con Carbide or DryGuard® Pure Sintered Alpha Grade Silicon Carbide are optional. Standard close-coupled mounting The drive magnet assembly is keyed, setscrewed, and mounted directly to the motor shaft. This arrange- ment eliminates the need to perform pump-to-motor alignment. - Page 19 3.2 Nameplate information Nameplate on the pump casing using English units Figure 6: Nameplate on the pump casing using English units Table 2: Explanation of nameplate on the pump casing Nameplate field Explanation IMPLR. DIA. Impeller diameter, in inches MAX. DIA. Maximum impeller diameter, in inches Rated pump flow, in gallons per minute FT HD...

- Page 20 3.2 Nameplate information Nameplate field Explanation STD. NO. ANSI standard designation MAT L. CONST Material of which the pump is constructed SER. NO. Serial number of the pump @ 20°C Kilograms per cubic centimeter at 20°C MAX. DSGN KG/CM Nameplate on the bearing frame Figure 8: Nameplate on the bearing frame Table 4: Explanation of the nameplate on the bearing frame Nameplate field...

- Page 21 Use of equipment unsuitable for the environment can pose risks of ignition and/or explosion. Ensure the pump driver and all other auxiliary components meet the required area classifica- tion at the site. If they are not compatible, do not operate the equipment and contact an ITT representative before proceeding.

-

Page 22: Installation

• Supervision by an authorized ITT representative is recommended to ensure proper instal- lation. Improper installation may result in equipment damage or decreased performance. Evaluate the installation in order to determine that the Net Positive Suction Head Available (NPSH... -

Page 23: Foundation Requirements

4.1 Pre-installation 4.1.2 Foundation requirements Precautions WARNING: Risk of serious injury or death in Ex-classified environments. If the pump is a Model NM3171, NM3196, 3198, 3298, V3298, SP3298, 4150, 4550, or 3107, ignition due to static electric discharge is possible from plastic parts that are not properly grounded. If the pumped fluid is non-conductive, drain and flush the pump with a conductive fluid under conditions that will not allow for a spark to be released to the atmosphere. -

Page 24: Baseplate-Mounting Procedures

4.2 Baseplate-mounting procedures J-type bolts Item Description Baseplate Shims or wedges Foundation Bolt Figure 11: J-type bolts 4.2 Baseplate-mounting procedures 4.2.1 Prepare the baseplate for mounting Remove all the attached equipment from the baseplate. Clean the underside of the baseplate completely. If applicable, coat the underside of the baseplate with an epoxy primer. -

Page 25: Install The Baseplate Using Jackscrews

4.2 Baseplate-mounting procedures Shims or wedges Figure 12: Top view Shims or wedges Figure 13: Side view Lower the baseplate carefully onto the foundation bolts. Put the machinist's levels across the mounting pads of the driver and the mounting pads of the pump. - Page 26 4.2 Baseplate-mounting procedures Cut the plates from the bar stock and chamfer the edges of the plates in order to reduce stress concentrations. Put the plates between the jackscrews and the foundation surface. Use the four jackscrews in the corners in order to raise the baseplate above the foundation. Make sure that the distance between the baseplate and the foundation surface is between 19 mm | 0.75 in.

- Page 27 4.2 Baseplate-mounting procedures Item Description Machinist's levels Driver's mounting pads Foundation bolts Jackscrews Grout hole Pump's mounting pads Figure 15: Level driver mounting pads Turn the center jackscrews down so that they rest on their plates on the foundation surface. Level the pump mounting pads: NOTICE: Remove all dirt from the mounting pads in order to ensure that the correct leveling is achieved.

- Page 28 4.2 Baseplate-mounting procedures Check that the driver's mounting pads are level and adjust the jackscrews and the foundation bolts if necessary. The correct level measurement is a maximum of 0.167 mm/m | 0.002 in./ft . The maximum variation from one side of the baseplate to the other is 0.38 mm | 0.015 in. 3298 Family Installation, Operation, and Maintenance Manual...

-

Page 29: Baseplate-Leveling Worksheet

4.2 Baseplate-mounting procedures 4.2.4 Baseplate-leveling worksheet Level measurements 1)____________________ 2)____________________ 3)____________________ 4)____________________ 5)____________________ 6)____________________ 7)____________________ 8)____________________ 9)____________________ 10)___________________ 11)___________________ 12)___________________ 13)___________________ 14)___________________ 15)___________________ 16)___________________ 17)___________________ 18)___________________ 3298 Family Installation, Operation, and Maintenance Manual... -

Page 30: Pump-To-Driver Alignment

4.3 Pump-to-driver alignment 4.3 Pump-to-driver alignment Precautions WARNING: • Failure to disconnect and lock out driver power may result in serious physical injury or death. Always disconnect and lock out power to the driver before performing any installa- tion or maintenance tasks. •... -

Page 31: Permitted Indicator Values For Alignment Checks

The correct tolerances must be used. Failure to do so can result in misalignment. Contact ITT for further information. When dial indicators are used to check the final alignment, the pump and drive unit are correctly aligned when these conditions are true: •... -

Page 32: Pump-To-Driver Alignment Instructions

4.3 Pump-to-driver alignment Figure 17: Dial indicator attachment Rotate the pump coupling half (X) in order to check that the indicators are in contact with the driver coupling half (Y) but do not bottom out. Adjust the indicators if necessary. 4.3.5 Pump-to-driver alignment instructions 4.3.5.1 Perform angular alignment for a vertical correction Set the angular alignment indicator to zero at the top-center position (12 o’clock) of the driver cou-... - Page 33 4.3 Pump-to-driver alignment 4.3.5.2 Perform angular alignment for a horizontal correction Set the angular alignment indicator (A) to zero on left side of the driver coupling half (Y), 90° from the top-center position (9 o’clock). Rotate the indicator through the top-center position to the right side, 180° from the start position (3 o’clock).

- Page 34 The specified permitted reading values are valid only at operating temperature. For cold set- tings, other values are permitted. The correct tolerances must be used. Failure to do so can result in misalignment. Contact ITT for further information. Maximum permitted value for parallel alignment: •...

- Page 35 4.3 Pump-to-driver alignment Slide the driver carefully in the appropriate direction. NOTICE: Make sure to slide the driver evenly. Failure to do so can negatively affect horizontal angular correction. Figure 21: Top view of an incorrect horizontal alignment Repeat the previous steps until the permitted reading value is achieved. Maximum permitted value for parallel alignment: •...

-

Page 36: Grout The Baseplate

4.4 Grout the baseplate Maximum permitted value for parallel alignment: • 0.05 mm | 0.002 in. total indicated runout at operating temperature When the procedure is complete, both the angular and parallel alignment must meet the permitted toler- ances. 4.4 Grout the baseplate Required equipment: •... -

Page 37: Piping Checklists

4.5 Piping checklists Item Description Baseplate Grout Foundation Bolt Figure 23: Fill remainder of baseplate with grout Tighten the foundation bolts. Recheck the alignment. 4.5 Piping checklists 4.5.1 Fastening WARNING: Risk of serious personal injury or property damage. Fasteners such as bolts and nuts are criti- cal to the safe and reliable operation of the product. - Page 38 4.5 Piping checklists CAUTION: Do not move the pump to the pipe. This could make final alignment impossible. CAUTION: Never draw piping into place at the flanged connections of the pump. This can impose danger- ous strains on the unit and cause misalignment between the pump and driver. Pipe strain ad- versely affects the operation of the pump, which results in physical injury and damage to the equipment.

-

Page 39: Suction-Piping Checklist

4.5 Piping checklists Alignment criteria for pump flanges Type Criteria Axial The flange gasket thickness ±0.8 mm | 0.03 in. Parallel Align the flange to be within 0.025 mm/mm to 0.8 mm/mm | 0.001 in./in. to 0.03 in./in. of the flange di- ameter. - Page 40 4.5 Piping checklists Check Explanation/comment Checked Check that the distance between the inlet This minimizes the risk of cavitation in the suction in- flange of the pump and the closest elbow let of the pump due to turbulence. is at least two pipe diameters. See the Example sections for illustrations.

- Page 41 4.5 Piping checklists Liquid source above the pump Check Explanation/comment Checked Check that an isolation valve is installed in This permits you to close the line during pump inspec- the suction piping at a distance of at least tion and maintenance. two times the pipe diameter from the suc- Do not use the isolation valve to throttle the pump.

-

Page 42: Discharge Piping Checklist

4.5 Piping checklists Example: Suction piping equipment Correct Incorrect Suction pipe sloping upwards from liquid source Air pocket, because the eccentric reducer is not used and because the suction piping does not Long-radius elbow slope gradually upward from the liquid source Strainer Foot valve Eccentric reducer with a level top... -

Page 43: Final Piping Checklist

4.5 Piping checklists Check Explanation/comment Checked If quick-closing valves are installed in the This protects the pump from surges and water hammer. system, check that cushioning devices are used. Example: Discharge piping equipment Correct Incorrect Check valve (incorrect position) Bypass line The isolation valve should not be positioned be- Shut-off valve tween the check valve and the pump. -

Page 44: Commissioning, Startup, Operation, And Shutdown

5 Commissioning, Startup, Operation, and Shutdown 5 Commissioning, Startup, Operation, and Shutdown 5.1 Preparation for startup WARNING: • Risk of serious physical injury or death. Exceeding any of the pump operating limits (e.g. - pressure, temperature, power, etc.) could result in equipment failure, such as explosion, seizure, or breach of containment. -

Page 45: Remove The Coupling Guard

5.2 Remove the coupling guard Precautions CAUTION: When a cartridge mechanical seal is used, ensure that the set screws in the seal locking ring are tightened and that the centering clips have been removed prior to startup. This prevents seal or shaft sleeve damage by ensuring that the seal is properly installed and centered on the sleeve. - Page 46 5.2 Remove the coupling guard Slightly spread the bottom apart. Lift upwards. Item Description Annular groove Driver half of the coupling guard Driver Remove the remaining nut, bolt, and washers from the pump half of the coupling guard. It is not necessary to remove the end plate from the pump side of the bearing housing. You can access the bearing-housing tap bolts without removing this end plate if maintenance of internal pump parts is necessary.

-

Page 47: Check The Rotation

5.3 Check the rotation 5.3 Check the rotation WARNING: • Starting the pump in reverse rotation can result in the contact of metal parts, heat genera- tion, and breach of containment. Ensure correct driver settings prior to starting any pump. •... -

Page 48: Install The Coupling Guard

5.5 Couple the pump and driver WARNING: Failure to disconnect and lock out driver power may result in serious physical injury or death. Always disconnect and lock out power to the driver before performing any installation or main- tenance tasks. •... - Page 49 5.5 Couple the pump and driver Item Description End plate, drive end End plate, pump end Guard half, 2 required 3/8-16 nut, 3 required 3/8 in. washer 3/8-16 x 2 in. hex head bolt, 3 re- quired Figure 24: Required parts De-energize the motor, place the motor in a locked-out position, and place a caution tag at the start- er that indicates the disconnect.

- Page 50 5.5 Couple the pump and driver XLT-X Description Driver Pump end plate Bearing housing Jam nut Put the pump-half of the coupling guard in place: Slightly spread the bottom apart. Place the coupling guard half over the pump-side end plate. Item Description Annular groove Pump-side end plate...

- Page 51 5.5 Couple the pump and driver Item Description Annular groove End plate (pump end) Guard half Figure 26: Annular groove in coupling guard Use a bolt, a nut, and two washers to secure the coupling guard half to the end plate. Tighten se- curely.

- Page 52 5.5 Couple the pump and driver Item Description Annular groove Driver half of the coupling guard Driver Place the driver-side end plate over the motor shaft. Driver 234B Figure 28: Placement of driver half of coupling guard Place the driver-side end plate in the annular groove of the driver-half of the coupling guard. Use a bolt, a nut, and two washers to secure the coupling guard half to the end plate.

-

Page 53: Bearing Lubrication

Risk of explosive hazard and premature failure from sparks and heat generation. Ensure bearings are properly lubricated prior to startup. These bearing lubrication sections list different pumped-fluid temperatures. If your pump is ATEX certi- fied and your pumped-fluid temperature exceeds the permitted temperature values, then consult your ITT representative. Pump type... -

Page 54: Acceptable Oil For Lubricating Bearings

5.7 Pump priming 5.6.2 Acceptable oil for lubricating bearings Acceptable lubricants Table 7: Acceptable lubricants Brand Lubricant type Chevron GST Oil 68 Exxon NUTHO H68 Mobil DTE Heavy Medium Phillips 66 Turbine Oil VG68 MM motor oil SAE 20-20W HDS motor oil SAE 20-20W Shell Turbo T 68 Gulf... -

Page 55: Prime The Pump With The Suction Supply Above The Pump

5.7 Pump priming 5.7.1 Prime the pump with the suction supply above the pump Slowly open the suction isolation valve. Open the air vents on the suction and discharge piping until the pumped fluid flows out. Close the air vents. Item Description Discharge isolation valve Check valve... - Page 56 5.7 Pump priming Item Description Discharge isolation valve Shutoff valve From outside supply Foot valve Check valve Figure 32: Pump priming with suction supply below pump with foot valve and an outside supply 3298 Family Installation, Operation, and Maintenance Manual...

-

Page 57: Other Methods Of Priming The Pump

5.8 Start the pump Item Description By-pass line Shutoff valve Foot valve Check valve Discharge isolation valve Figure 33: Pump priming with suction supply below pump with foot valve using bypass around check valve 5.7.3 Other methods of priming the pump You can also use these methods in order to prime the pump: •... -

Page 58: Minimum Continuous Recommended Flow

5.8 Start the pump NOTICE: • Risk of equipment damage due to dry operation. Immediately observe the pressure gauges. If discharge pressure is not quickly attained, stop the driver immediately, reprime, and attempt to restart the pump. • On frame mounted units, ensure that the oil level is correct prior to starting pump. Close coupled pumps do not have oil lubricated bearings. -

Page 59: Pump Operation Precautions

15% of the time). Contact ITT for more information. Contact the factory for pump efficiency at minimum flows. You can operate the pump at substantially lower flows with an adequate NPSH margin. Contact ITT for de- tails. 5.9 Pump operation precautions... -

Page 60: Shut Down The Pump

5.10 Shut down the pump • Risk of explosion and serious physical injury. Do not operate pump with blocked system piping or with suction or discharge valves closed. This can result in rapid heating and vaporization of pumpage. • Risk of equipment damage and serious physical injury. Heat build-up can cause rotating parts to score or seize. - Page 61 5.11 Make the final alignment of the pump and driver • Misalignment can cause decreased performance, equipment damage, and even cata- strophic failure of frame-mounted units leading to serious injury. Proper alignment is the responsibility of the installer and the user of the unit. Check the alignment of all drive components prior to operating the unit.

-

Page 62: Maintenance

6 Maintenance 6 Maintenance 6.1 Maintenance schedule Maintenance inspections A maintenance schedule includes these types of inspections: • Routine maintenance • Routine inspections • Three-month inspections • Annual inspections Shorten the inspection intervals appropriately if the pumped fluid is abrasive or corrosive or if the envi- ronment is classified as potentially explosive. -

Page 63: Bearing Maintenance

For ATEX applications bearing replacement (all) is recommended after 17,500 hours of operation. These bearing lubrication sections list different temperatures of the pumped fluid. If the pump is ATEX-certified and the temperature of the pumped fluid exceeds the permitted temperature values, then consult your ITT representative. 6.3 Required tools WARNING: This pump contains extremely strong magnets. -

Page 64: Disassembly

6.4 Disassembly Group Kit number Optional tools Tool number Description B03189A Magnet assembly/disassembly guide rods R298TK03 B03191A Bearing spider installation driver B03175A Radial bearing installation tool B03149A Radial bearing installation tool B03189A Magnetic assembly/disassembly guide rods 6.4 Disassembly 6.4.1 Disassembly precautions WARNING: •... -

Page 65: Prepare The Pump For Disassembly

6.4 Disassembly NOTICE: Use a bench with a non-magnetic work surface such as wood or brass when you work on the pump. 6.4.2 Prepare the pump for disassembly Lock out power to the driver. WARNING: Failure to disconnect and lock out driver power may result in serious physical injury or death. Always disconnect and lock out power to the driver before performing any installation or main- tenance tasks. - Page 66 6.4 Disassembly 141C 141C Suction Suction Flange Flange 370B 370B Figure 37: L group Figure 36: M group Suction Flange 370B Suction Flange 370B 141C Figure 38: SP group Figure 39: V group For the M and L group pumps, tighten the jacking screws (418) until the gap between the clamp ring (141C) and the C-face motor support and bearing frame is 8.89 cm | 3.50 in.

- Page 67 6.4 Disassembly Hose Clamp 370B Emery Cloth 141C Figure 42: XS, X, S, M, and L groups Disassemble the containment shell: Screw the C-face motor support and bearing frame bolts (370B) into the tapped holes of the clamp ring (141C) and tighten evenly in order to remove the containment shell. Remove the O-ring (412M) from the containment shell (750) and discard it.

-

Page 68: Disassemble The Frame-Mounted Pump

6.4 Disassembly 197B 157A 197B Figure 45: S, M, L, SP, and V groups Figure 44: XS group Inspect and replace these parts as necessary: Pump Step group M and L Inspect the rear impeller wear ring (203) and remove it if replacement is necessary. Remove the retaining ring (361H). - Page 69 6.4 Disassembly 355A Figure 47: S, L, M, and SP groups Place three capscrews in the jacking screw holes in the magnet assembly (740B). Group Capscrew size S and SP 5/16 in. by 2 in. M and L 5/8 in. by 4 in. 740B Jacking Screws...

- Page 70 6.4 Disassembly 740B 178Y Figure 49: Magnet assembly removal For the L and M group pumps, remove the 5/16 in. wear ring capscrew (372Y) and the wear ring from the bottom of the bearing frame (228). 144A 372Y Figure 50: L and M group wear ring removal Remove the bearing end-cover bolts (370C).

-

Page 71: Preassembly Inspections

6.5 Preassembly inspections Install two bearing end-cover bolts (370C) in the jacking screw holes and tighten them evenly in or- der to remove the bearing end cover (109A). Slide the bearing end cover (109A) backwards. The labyrinth oil seal (332A) slides back with the end cover. Remove the labyrinth seal (332A) and the bearing end cover (109A). - Page 72 6.5 Preassembly inspections Impeller • Inspect the leading and trailing edges of the vanes for erosion damage. • Inspect the impeller for cracks and grooves in excess of 0.75 mm | 0.03 in. • Check the impeller for blocked passages. Back wear ring Inspect the back wear ring according to the clearances in the Back wear ring clearances table.

- Page 73 6.5 Preassembly inspections Figure 55: 0.020 in. (0.051 cm) minimum groove height Stationary shaft Make sure the stationary shaft is free from cracks and scoring. Containment shell • The containment shell must be free from scratches or cracks. • Replace the containment shell when grooves are in excess of 0.25 mm | 0.01 in. for the outside diameter and 0.75 mm | 0.030 in.

-

Page 74: Reassembly

6.6 Reassembly • Make sure that the gasket surface is clean. • Replace the lip seal. • Inspect the shaft for cracks and scoring. Inspection locations 6.6 Reassembly 6.6.1 Reassembly precautions WARNING: Explosion risk. Rubbing could lead to excess heat generation and sparks. Rotate the shaft by hand to make sure it rotates smoothly and that there is no rubbing. -

Page 75: Reassemble The Rotary Assembly

6.6 Reassembly • There are several methods you can use to install bearings. The recommended method is to use an induction heater that heats and demagnetizes the bearings. • You may need to lightly press the shaft with bearings into the bearing frame. It is impor- tant that you press the bearings in by putting a sleeve on the inner race of the outboard ball bearing. - Page 76 6.6 Reassembly Use the bearing installation tool to press the radial bearing (197B) into the impeller. Support the impeller with the bearing press support tool. Line up the keyway in the bearing with the key in the impeller. 197B Figure 58: XS group For all groups except XS, slide the bearing spacer (157A) into the impeller and then press the sec- ond radial bearing (197B) into the impeller.

- Page 77 6.6 Reassembly 157A 197D 197D 157A 197B 197B Figure 62: 3298, and V3298 M Figure 61: 3298, SP3298, and and L groups V3298 For all groups except XS, slide the reverse thrust bearing onto the shaft. Press the shaft (122A) into the containment shell (750). Coat the O-ring (412M) with an O-ring lubricant and insert it in the containment shell (750).

- Page 78 6.6 Reassembly 141C 197C 122A 412M 356A Figure 65: SP3298 Slide the impeller assembly (101) onto the shaft. Figure 66: 3298 XS, S, M, and Figure 67: SP group L groups, and V3298 12. Press the spider (260) into the volute insert (100U) with the spider tool. Then press the volute insert with the spider into the casing (100).

- Page 79 6.6 Reassembly Figure 69: V3298 Figure 70: SP3298 13. Check the total travel of the rotary assembly: Pump group Travel between A and B in millimeters | inches 3298 XS 0.66 - 2.11 mm | 0.026 - 0.083 in. 3298 S, V3298 S, and SP3298 0.33 - 2.5 mm | 0.013 - 0.100 in. 3298 M and L, and V3298 M 0.51 - 2.67 mm | 0.020 - 0.105 in.

- Page 80 6.6 Reassembly Figure 74: V3298 Figure 73: SP3298 14. For the 3298 and V3298, install these items into the casing: Install the containment shell and impeller assembly into the casing (100). Use care that the O- ring (412M) remains in place. Install the clamp ring (141C) into the casing (100) with the hex capscrews (356A).

-

Page 81: Reassemble The Close-Coupled Pump

6.6 Reassembly 6.6.3 Reassemble the close-coupled pump Install four expansion plugs (408Z) into the C-face motor support (228) by tapping on the plug with a 5/8 in. rod. Expansion plugs are not used for the 182TC - 256TC and 324TSC motor frames. 408Z Figure 78: Close coupled frame Set the C-face motor support (228) on the motor and install four screws (371). -

Page 82: Reassemble The Frame-Mounted Pump

6.6 Reassembly 0.0 in. ±0.010 0.0 in. ±0.010 740B 740B Figure 81: XS and S group installa- Figure 82: M and L group installation tion dimensions dimensions Rotate the magnet assembly (740B) to line up the key (178Y) with the access hole on the C-face motor support (228). - Page 83 6.6 Reassembly Figure 84: Bearing frame secured to bench Install the shaft (122B) with ball bearings (112) into the bearing frame (228). Point the threaded end of the shaft towards the magnets. 122B Figure 85: S group bearing installation For the M and L group, install the wave washer. 122B Figure 86: M and L group bearing installation Install the bearing-end cover gasket (360A) and bearing end cover (109A) with hex capscrews...

- Page 84 6.6 Reassembly 360A 109A 332A 370C Figure 87: Bearing frame assembly Press the labyrinth seal (332A) into the end cover (109A): Make sure that the O-rings are in grooves of labyrinth seal. Orient the expulsion ports to the 6 o’clock position and press the seal into the bearing end cov- er (109A) until it is shouldered against the end cover.

-

Page 85: Complete The Reassembly (Close-Coupled And Frame-Mounted Pumps)

6.6 Reassembly 178Y 144A 740B 355A 372Y Scribe Mark Figure 89: M and L group drive magnet assembly 6.6.5 Complete the reassembly (close-coupled and frame-mounted pumps) For all groups except XS, install the gasket (360W) into the clamp ring (141C). Bolt the C-face support and frame (228) to the work bench. -

Page 86: Assembly References

6.6 Reassembly 360W Casing assembly Guide rods Figure 91: Casing assembly with guide rods Slide the casing assembly into the C-face support and bearing frame assembly: If your Then... pump group is... XS or S Hold the casing firmly by the suction flange and suction side of the discharge flange. Keep hands away from the clamp ring in order to avoid pinched fingers. - Page 87 6.6 Reassembly 6.6.6.1 Bolt torque values Location Dry threads torque in Nm | ft-lbs Hex nut – 355A 40 | 30 Clamp ring screws – 356A 40 | 30 Support / frame screws – 370B 40 | 30 Cover-to-frame – 370C 40 | 30 Drain screws –...

- Page 88 6.6 Reassembly Small radius 0.005 to 0.002 45° rake angle Figure 92: Recommended cutting tool Tool features: • 200 to 300 RPM • 300 to 500 ft./min • High-speed steel tool • Light hand feed Trimming guidelines • Make sure that the arbor runs within 0.002 TIR. •...

- Page 89 6.6 Reassembly Trimming examples Impeller Steel washer with rubber bond Paper gasket Arbor Figure 93: XS group Steel washer with rubber bond Socket head capscrew Impeller Paper gasket Arbor Figure 94: S and M groups 3298 Family Installation, Operation, and Maintenance Manual...

- Page 90 6.6 Reassembly Steel washer with rubber bond Socket head capscrew Impeller Paper gasket Arbor Figure 95: L group 6.6.6.3 SP3298 volute insert trimming guidelines Trimming guidelines Do not make cuts larger than 0.127 cm | 0.050 in. Use arbor tool C06820A for SP3298 size 1x1.5-6 and C06821A for SP3298 size 2x3-6. Make sure that the arbor runs within 0.005 cm | 0.002 in.

- Page 91 6.6 Reassembly Use arbor tool C06820A for SP3298 size 1x1.5-6 and tool C06821A for SP3298 size 2x3-6. Table 9: Cutwater radius Impeller diameter in centimeters | inches "R" +/- 0.25 mm | 0.010 inches 12.70 | 5.00 6.510 | 2.563 13.00 | 5.12 6.668 | 2.625 13.34 | 5.25...

-

Page 92: Spare Parts

6.7 Spare parts 6.7 Spare parts Liquid end Part Part number Material Quantity Containment shell O-ring 412M Standard – viton Optional – EDPM Optional – PTFE-encapsulated viton Gasket – clamp ring 360W Aramid fiber / EDPM binder Bearing spider Tefzel / silicon carbide Impeller bearing 178S Tefzel... - Page 93 6.7 Spare parts Size Repair cartridge Power end kit Carbon Silicon carbide DryGuard® 2 x 3-8 C298M2800CV000 C298M2800SV000 C298M2800FV000 R298PKML 3 x 4-7 C298M3700CV000 C298M3700SV000 C298M3700FV000 R298PKML 1.5 x 3-10 C298L1510CV000 C298L1510SV000 C298L1510FV000 R298PKML 2 x 3-10 C298L2100CV000 C298L2100SV000 C298L2100FV000 R298PKML 3 x 4-10H C298L3100CV000...

-

Page 94: Troubleshooting

7 Troubleshooting 7 Troubleshooting 7.1 Operation troubleshooting Symptom Cause Remedy The pump is not delivering The pump is not primed. For the 3298 and V3298, reprime the pump and liquid. check that the pump and suction line are full of liquid. - Page 95 7.1 Operation troubleshooting Symptom Cause Remedy There is a partially-clogged impeller Disassemble the impeller and remove the block- causing the imbalance. age. There is a broken or bent impeller or Replace as required. shaft. The base is not rigid enough. Tighten the pump and motor hold-down bolts or adjust the stilts.

-

Page 96: Alignment Troubleshooting

7.2 Alignment troubleshooting Check to see if the plastic that surrounds the outboard thrust bearing is melted. Check to see if the plastic that surrounds the carbon or silicon carbide impeller radial bearings is melted. Check to see if the plastic that surrounds the inboard thrust bearings is melted. If the impeller seizes on the shaft due to excessive heat, the shaft can spin in the shaft spider, which wears the inside diameter of the shaft spider. -

Page 97: Parts Listings And Cross-Sectionals

8 Parts Listings and Cross-Sectionals 8 Parts Listings and Cross-Sectionals 8.1 3298 XS group close-coupled pump in sizes 1 x 1-1/2 - 5 and 1-1/2 x 2-6 With NEMA motor 3298 Family Installation, Operation, and Maintenance Manual... - Page 98 8.1 3298 XS group close-coupled pump in sizes 1 x 1-1/2 - 5 and 1-1/2 x 2-6 With IEC motor 427P 222L 492A 408A 370F Parts list Item Part name Material Casing Ductile iron / Tefzel Impeller assembly Carbon-filled Tefzel Bearing spider Standard: carbon-filled Tefzel / silicon carbide Optional: DryGuard®...

-

Page 99: 3298 S Group Frame-Mounted Pump In Sizes 1 X 1-1/2 - 6, 1 X 1-1/2 - 8, 1-1/2 X 3-7, And 2 X 3-6

8.2 3298 S group frame-mounted pump in sizes 1 x 1-1/2 - 6, 1 x 1-1/2 - 8, 1-1/2 x 3-7, and 2 x 3-6 Item Part name Material Frame foot Ductile iron 351G Gasket – casing drain Gylon 356A Hex capscrew – clamp ring to casing 304 SS Cover –... - Page 100 8.2 3298 S group frame-mounted pump in sizes 1 x 1-1/2 - 6, 1 x 1-1/2 - 8, 1-1/2 x 3-7, and 2 x 3-6 Item Part name Material Optional: carbon-filled Tefzel / DryGuard® silicon carbide 109A End cover Ductile iron Ball bearings Steel 122A Stationary shaft...

-

Page 101: 3298 S Group Close-Coupled Pump In Sizes 1 X 1-1/2 - 6, 1 X 1-1/2 - 8, 1-1/2 X 3-7, And 2 X 3-6

8.3 3298 S group close-coupled pump in sizes 1 x 1-1/2 - 6, 1 x 1-1/2 - 8, 1-1/2 x 3-7, and 2 x 3-6 8.3 3298 S group close-coupled pump in sizes 1 x 1-1/2 - 6, 1 x 1-1/2 - 8, 1-1/2 x 3-7, and 2 x 3-6 With NEMA motor With IEC motor... - Page 102 8.3 3298 S group close-coupled pump in sizes 1 x 1-1/2 - 6, 1 x 1-1/2 - 8, 1-1/2 x 3-7, and 2 x 3-6 S group close-coupled parts list Item Part name Material Casing Ductile iron / Tefzel Impeller assembly Carbon-filled Tefzel Bearing spider Standard: carbon-filled Tefzel / silicon carbide...

-

Page 103: 3298 M Group Frame-Mounted Pump In Sizes 3 X 4 - 7, 1-1/2 X 3 - 8, 2 X 3 - 8, 1 X 2 - 10

8.4 3298 M group frame-mounted pump in sizes 3 x 4 - 7, 1-1/2 x 3 - 8, 2 x 3 - 8, 1 x 2 - 10 Item Part name Material 503 Ring – adapter Cast iron 742B Ring – centering Carbon steel Used with motor frame 132 and 160 only. - Page 104 8.4 3298 M group frame-mounted pump in sizes 3 x 4 - 7, 1-1/2 x 3 - 8, 2 x 3 - 8, 1 x 2 - 10 Item Part name Material 144A Rub ring Cast iron 157A Bearing spacer – radial PTFE Key –...

-

Page 105: 3298 M Group Close-Coupled Pump In Sizes 3 X 4 - 7, 1-1/2 X 3 - 8, 2 X 3 - 8, 1 X 2 - 10

8.5 3298 M group close-coupled pump in sizes 3 x 4 - 7, 1-1/2 x 3 - 8, 2 x 3 - 8, 1 x 2 - 10 8.5 3298 M group close-coupled pump in sizes 3 x 4 - 7, 1-1/2 x 3 - 8, 2 x 3 - 8, 1 x 2 - 10 M group close-coupled drawing M group close-coupled parts list... -

Page 106: 3298 L Group Frame-Mounted Pump In Sizes 1-1/2 X 3 - 10, 2 X 3 - 10, 3 X 4 - 10G, 3 X 4 - 10H, And 4 X 6 - 10

8.6 3298 L group frame-mounted pump in sizes 1-1/2 x 3 - 10, 2 x 3 - 10, 3 x 4 - 10G, 3 x 4 - 10H, and 4 x 6 - 10 Item Part name Material Frame – close coupled Cast iron Gasket –... - Page 107 8.6 3298 L group frame-mounted pump in sizes 1-1/2 x 3 - 10, 2 x 3 - 10, 3 x 4 - 10G, 3 x 4 - 10H, and 4 x 6 - 10 Figure 97: Two-piece impeller L group frame-mounted parts list Item Part name Material...

- Page 108 8.6 3298 L group frame-mounted pump in sizes 1-1/2 x 3 - 10, 2 x 3 - 10, 3 x 4 - 10G, 3 x 4 - 10H, and 4 x 6 - 10 Item Part name Material 361H Retaining ring PTFE-encapsulated silicone 370B Hex capscrew –...

-

Page 109: 3298 L Group Close-Coupled Pump In Sizes 1-1/2 X 3 - 10, 2 X 3 - 10, 3 X 4 - 10G, 3 X 4 - 10H, And 4 X

8.7 3298 L group close-coupled pump in sizes 1-1/2 x 3 - 10, 2 x 3 - 10, 3 x 4 - 10G, 3 x 4 - 10H, and 4 x 6 - 10 8.7 3298 L group close-coupled pump in sizes 1-1/2 x 3 - 10, 2 x 3 - 10, 3 x 4 - 10G, 3 x 4 - 10H, and 4 x 6 - 10 L group close-coupled drawing Figure 98: Two-piece impeller... - Page 110 8.7 3298 L group close-coupled pump in sizes 1-1/2 x 3 - 10, 2 x 3 - 10, 3 x 4 - 10G, 3 x 4 - 10H, and 4 x 6 - 10 Item Part name Material Bearing – radial Standard: carbon graphite 197B Optional: silicon carbide...

-

Page 111: Sp3298 S Group Frame-Mounted Pump In Sizes 1 X 1-1/2 - 6 And 2 X 3 - 6

8.8 SP3298 S group frame-mounted pump in sizes 1 x 1-1/2 - 6 and 2 x 3 - 6 8.8 SP3298 S group frame-mounted pump in sizes 1 x 1-1/2 - 6 and 2 x 3 - 6 SP3298 S group frame-mounted drawing SP3298 S group frame-mounted parts list Item Part name... - Page 112 8.8 SP3298 S group frame-mounted pump in sizes 1 x 1-1/2 - 6 and 2 x 3 - 6 Item Part name Material Frame – bearing Cast iron Sight window steel / glass Labyrinth seal Carbon-filled PTFE 332A Lip seal Buna rubber 333D Flanged hex nut...

-

Page 113: Sp3298 S Group Close-Coupled Pump In Sizes 1 X 1-1/2 - 6 And 2 X 3 - 6

8.9 SP3298 S group close-coupled pump in sizes 1 x 1-1/2 - 6 and 2 x 3 - 6 8.9 SP3298 S group close-coupled pump in sizes 1 x 1-1/2 - 6 and 2 x 3 - 6 SP3298 S group close-coupled drawing, with NEMA motor SP3298 S group close-coupled drawing, with IEC motor 742B 492A 222L... - Page 114 8.9 SP3298 S group close-coupled pump in sizes 1 x 1-1/2 - 6 and 2 x 3 - 6 SP3298 S group close-coupled drawing Item Part name Material Casing Ductile iron / Tefzel 100U Volute insert Carbon-filled Tefzel Impeller assembly Tefzel Bearing spider Tefzel / silicon carbide...

- Page 115 8.9 SP3298 S group close-coupled pump in sizes 1 x 1-1/2 - 6 and 2 x 3 - 6 Item Part name Material Recommended spare parts Item Part name Material 228 Frame – close coupled (IEC) Ductile iron 222L Setscrew 304 SS 371 Hex capscrew –...

-

Page 116: V3298 Close-Coupled S Group Pump In Sizes 1-1/2 X 2 - 6, 2 X 3 - 6, 1-1/2 X 2 - 8 And M Group Size

8.10 V3298 close-coupled S group pump in sizes 1-1/2 x 2 - 6, 2 x 3 - 6, 1-1/2 x 2 - 8 and M group size 1-1/2 x 2 - 10 8.10 V3298 close-coupled S group pump in sizes 1-1/2 x 2 - 6, 2 x 3 - 6, 1-1/2 x 2 - 8 and M group size 1-1/2 x 2 - 10 V3298 S and M group drawing, with NEMA motor 3298 Family Installation, Operation, and Maintenance Manual... - Page 117 8.10 V3298 close-coupled S group pump in sizes 1-1/2 x 2 - 6, 2 x 3 - 6, 1-1/2 x 2 - 8 and M group size 1-1/2 x 2 - 10 Figure 99: Drain detail V3298 S and M group drawing, with IEC motor 742B 388T 492A...

- Page 118 8.10 V3298 close-coupled S group pump in sizes 1-1/2 x 2 - 6, 2 x 3 - 6, 1-1/2 x 2 - 8 and M group size 1-1/2 x 2 - 10 Item Part name Material 197D Bearing – impeller thrust Standard: carbon-filled PTFE Optional: silicon carbide Optional: DryGuard®...

-

Page 119: Interchangeability Drawings

8.11 Interchangeability drawings 8.11 Interchangeability drawings 3298 XS group interchangeability Motor frame Drive Clamp Containment Shaft Impeller Bearing Casing Size Frame magnet ring shell assembly spider assembly NEMA C-face 213-215TC 1.5x2-6 142-145TC 182-184TC 1x1.5-5 IEC B3/B5 19F165 24F165 3298 Family Installation, Operation, and Maintenance Manual... - Page 120 8.11 Interchangeability drawings 3298 S group interchangeability Motor Adapter Frame Drive Drive Clamp Containment Shaft Impeller Bearing Casing Size shaft frame magnet ring shell assembly spider assembly NEMA 140-256 80-160 NEMA long NEMA C-face coupled 1x1.5-6 NEMA Close 1x1.5-8 coupled IEC B3/B5 19F165 1.5x3-7...

- Page 121 8.11 Interchangeability drawings 3298 M group interchangeability Motor Frame Drive Drive Clamp Containment Shaft Impeller Bearing Casing Size shaft frame magnet ring shell assembly spider assembly 1x2-10 NEMA 180-320 Frame Mounted 180TC 2x3-8 NEMA C-face 180TC 210TC 210TC 3x4-7 250TC 250TC 280TSC 280TSC...

- Page 122 8.11 Interchangeability drawings 3298 M group interchangeability – size 1½ x 3-8 only Motor Frame Drive Drive Clamp Containment Shaft Impeller Bearing Casing Size shaft frame magnet ring shell assembly spider assembly NEMA 180-320 Frame mounted 180TC 1.5x3-8 NEMA C-face 180TC 210TC 210TC...

- Page 123 8.11 Interchangeability drawings 3298 L group interchangeability Carrier Motor Frame Drive Drive Clamp Containment Shaft Impeller Bearing Casing Size shaft frame magnet ring shell assembly spider assembly 1.5x3-10 NEMA 180-320 Frame 2x3-10 mounted 210TC NEMA C-face 210TC 3x4-10G 250TC 250TC 3x4-10H 280TSC 280TSC...

- Page 124 8.11 Interchangeability drawings SP3298 S group interchangeability Motor Adapter Frame Drive Drive Clamp Containment Backplate Shaft Impeller Bearing Volute Casing Size shaft assembly spider insert frame magnet ring shell assembly NEMA 140-256 80-160 NEMA NEMA C-face Long coupled 1x1.5-6 NEMA Close coupled 2x3-6...

- Page 125 8.11 Interchangeability drawings V3298 S group interchangeability Motor Adapter Frame Drive Clamp Containment Shaft Impeller Bearing Casing frame magnet ring shell assembly spider assembly NEMA C-face NEMA Close coupled IEC B3/B5 19F165 24F165 28F215 28F215 Close coupled 38F265 42F300 3298 Family Installation, Operation, and Maintenance Manual...

-

Page 126: Hydraulic Coverage Charts

8.12 Hydraulic coverage charts V3298 M group interchangeability Motor Frame Drive Clamp Containment Shaft Impeller Bearing Casing Size frame magnet ring shell assembly spider assembly 180TC NEMA C-face 180TC 210TC 210TC 250TC 1-1/2x2-10 250TC/280TSC 250TC/280TSC 280TSC 320TSC Close coupled 320TSC 8.12 Hydraulic coverage charts 3298 charts 3298 Family Installation, Operation, and Maintenance Manual... - Page 127 8.12 Hydraulic coverage charts SP3298 charts 3298 Family Installation, Operation, and Maintenance Manual...

- Page 128 8.12 Hydraulic coverage charts V3298 charts 3298 Family Installation, Operation, and Maintenance Manual...

-

Page 129: Other Relevant Documentation Or Manuals

9 Other Relevant Documentation or Manuals 9 Other Relevant Documentation or Manuals 9.1 For additional documentation For any other relevant documentation or manuals, contact your ITT representative. 3298 Family Installation, Operation, and Maintenance Manual... -

Page 130: Local Itt Contacts

Los Angeles Vertical Products Operation +1 562-949-2113 +1 562-695-8523 3951 Capitol Avenue City of Industry, CA 90601-1734 Asia Pacific ITT Fluid Technology Asia Pte +65 627-63693 +65 627-63685 1 Jalan Kilang Timor #04-06 Singapore 159303 Europe ITT - Goulds Pumps... - Page 131 Visit our website for the latest version of this document and more information: www.gouldspumps.com ITT Goulds Pumps, Inc. 240 Fall Street Seneca Falls, NY 13148 Form IOM.3298.en-US.2020-04 ©2020 ITT Inc. The original instruction is in English. All non-English instructions are translations of the original instruction.

Need help?

Do you have a question about the GOULDS PUMPS 3298 Series and is the answer not in the manual?

Questions and answers